2. Security Tag

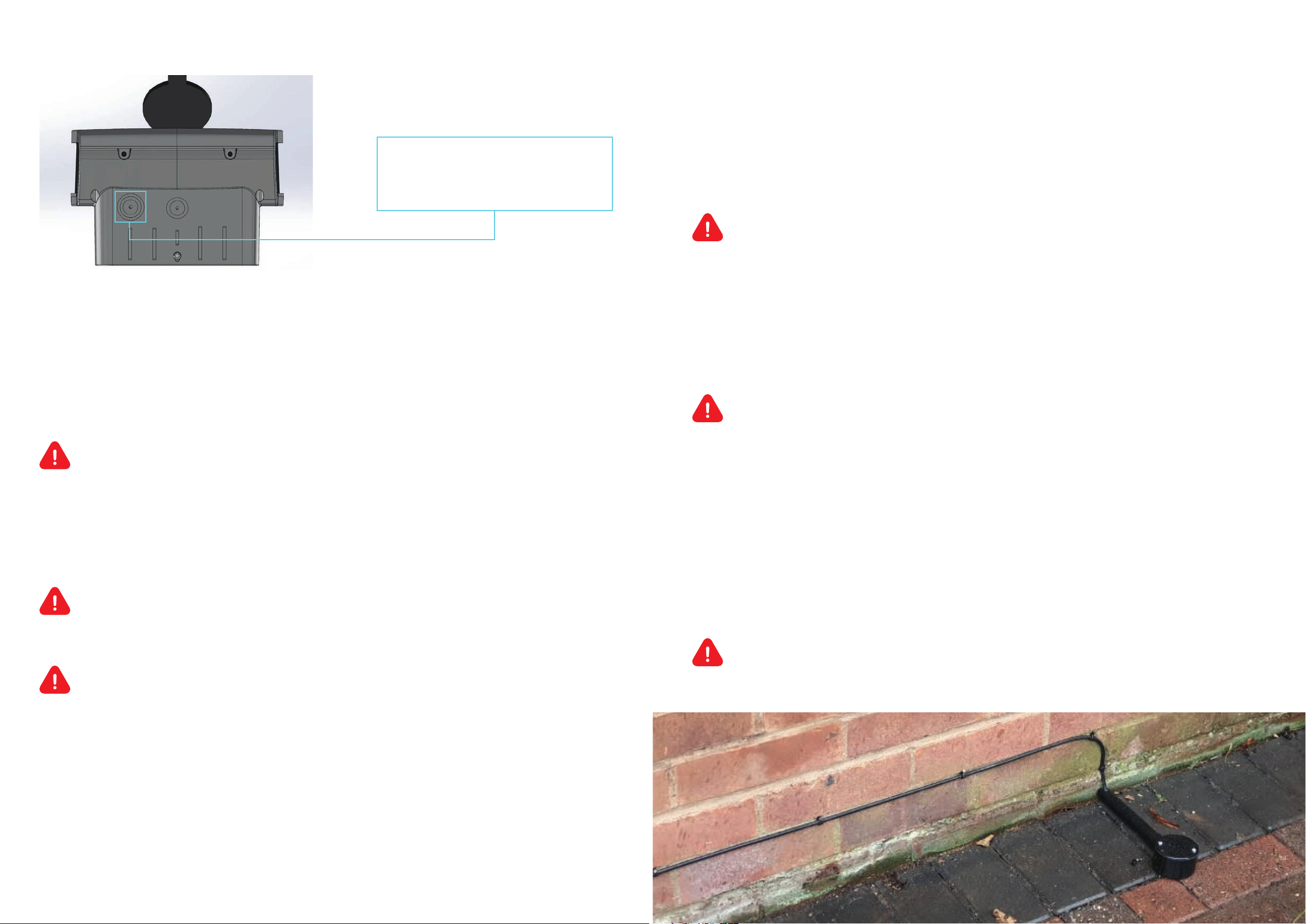

A security tag is provided with Indra chargers. The tag

should be fitted to the charger once installation has been

completed and before the facia is fitted – see image.

The number on the security tag should be recorded during the installation

in the Installer portal or via Indra support.

Requirement: The fitting and recording of the security tag is a legal

requirement so the installed charger is compliant with the Electric Vehicles

(Smart Charge Points) Regulations 2021.

3. Statement of Compliance

The Statement of Compliance is provided in the charger's welcome pack.

This must be completed by the seller, signed, and given to the customer

at the end of the installation.

Requirement: The completion and issue of the Statement of Compliance Is a

requirement of the Electric Vehicles (Smart Charge Points) Regulations 2021.

What changes Indra’s has made to be compliant with the regulations?

Indra has made a number of changes to Indra chargers for compliance with the

June Electric Vehicles (Smart Charge Points) Regulations 2021. These include

updating the charger’s firmware to version 10.x. When used with the Indra,

ev.energy, or Kaluza App, firmware version 10 meets the additional

regulatory requirements, including metering, a randomised delay solution,

and off peak scheduling. In addition, the installation process and back office management software has

been updated to comply with the regulations, for example enabling the security tag to be recorded, and

a record of sales to be securely stored.

Servicing an Indra Charger

When an Indra charger is serviced, it is necessary to first validate the security seal on the unit.

This should be done by scanning the QR code on the charger. This will take you to a portal where the

security tag status and information can be recorded. Once the service is concluded, a new security tag

can be recorded. A step-by-step process is provided in the portal.

The fitting and recording of the security tag is a requirement to ensure that the installed charger is

compliant with the Electric Vehicles (Smart Charge Points) Regulations 2021

Requirement: The security tag must be recorded in order to comply with the Electric Vehicles

(Smart Charge Points) Regulations from June 2022.

Parts

You can order a Smart Charger Regulations Spare Kit including Statement of Compliance, Charger

Regulation Installation document, Charger Tamper Seal, and CT Clamp Security Seal, from Indra to

update any chargers you have in stock. Charger Tamper Seals and CT Clamp Security Seals can also be

ordered for servicing Indra chargers.

QR Code for the Indra

Installation Manual:

QR code for the

Statement of Compliance

Document number: SMAPRWRWH002

INDRA INSTALLER SMART CHARGE REGULATION DOCUMENT

Part Numbers

SMASAFX00003 Smart Charger Regulations Spares Kit

CONPRLBSV001 Charger Tamper Seal

SMAPRCCRD001 CT Clamp Security Seal Cable Tie