Indu-Sol PROFINET-INspektor NT User manual

Indu-Sol GmbH

Blumenstraße 3

D-042626 Schmölln

Phone: +49 (0)34491 / 580-0

Fax: +49 (0)34491 / 5818-99

Email: info@indu-sol.com

Web: https://www.indu-sol.com

Our technical support team is available at +49 (0)34491 / 58 18 14, weekdays between 7:30 –16:30 (CET). You

can also email us at: support@indu-sol.com

Is your plant standing still? You can reach our emergency service around the clock at:

+49 (0)34491 / 58 18 0.

Indu-Sol GmbH

Blumenstraße 3

D-042626 Schmölln

Phone: +49 (0)34491 / 580-0

Fax: +49 (0)34491 / 5818-99

Email: info@indu-sol.com

Web: https://www.indu-sol.com

Our technical support team is available at +49 (0)34491 / 58 18 14, weekdays between 7:30 –16:30 (CET). You

can also email us at: support@indu-sol.com

Is your plant standing still? You can reach our emergency service around the clock at:

+49 (0)34491 / 58 18 0.

Revision overview

PROFINET-INspektor®NT - User Manual 3

Revision overview

Date

Revision

Change(s)

10/09/2015

0

First version

04/07/2016

1

Firmware Update 1.4

22/12/2016

2

Firmware Update 1.5

10/05/2019

3

Firmware Update 2.0

15/05/2020

4

Firmware Update 2.1

27/10/2021

5

Firmware Update 2.2

10/08/2022

6

Firmware Update 2.3

© Copyright 2022 Indu-Sol GmbH

We reserve the right to amend this document without notice. We continuously work on further developing

our products. We reserve the right to make changes to the scope of supply in terms of form, features and

technology. No claims can be derived from the specifications, illustrations or descriptions in this

documentation. Any kind of reproduction, subsequent editing or translation of this document, as well as

excerpts from it, requires the written consent of Indu-Sol GmbH. All rights under copyright law are expressly

reserved for Indu-Sol GmbH.

W A R N I N G

Commissioning and operation of this device must only be performed by qualified personnel. Qualified

personnel within the meaning of the safety notices in this manual are persons authorised to commission,

ground, and mark devices, systems, and circuits in accordance with safety engineering standards.

Improper use or configuration of the PROFINET-INspektor®in the network may cause severe physical

injury as well as property and material damage, also due to uncontrolled machine movements.

Contents

PROFINET-INspektor®NT - User Manual 4

Contents

Revision overview 3

Contents 4

1General information 8

1.1 Purpose of use 8

1.2 Use of Open Source Licenses 8

1.3 Scope of supply 9

1.4 General safety instructions 9

Operating personnel 9

Power supply 9

Utilization of PROFINET-INspektor®NT 9

Intended use 9

Batteries 10

2Installation 11

2.1 Device interfaces 11

2.2 Installation instructions 12

2.3 Voltage supply 13

2.4 Measurement location 13

2.5 Connection to the PROFINET network 13

Fixed installation within the master system 13

Connection via feedback-free measurement point 14

2.6 Web interface 14

2.7 Signal inputs and outputs 15

2.8 Display screen 16

3Web interface and selection functions 17

3.1 Homepage 18

Alarm overview 19

Timeline 20

Network overview 21

Node overview 22

Network statistics 24

Office network 24

3.2 Alarms 25

3.3 Switch statistics 26

3.4 Analysis 27

Netload chart 27

Contents

PROFINET-INspektor®NT - User Manual 5

Reports 27

Topologies 28

Jitter overview 28

Node statistic 29

Frame statistic 29

Tools 30

3.5 Configuration 31

System 31

General 32

Security 32

Services 34

Time and language settings 34

Network 35

Digital Input 37

GSDML Administration 38

Factory reset 39

Import/Export 39

Information 40

Monitoring 41

Node names and monitoring 41

Network state 42

Device status 42

Triggers & alarms 45

Automated report 53

Network scan and Topology determination 54

Firmware update 57

4Explanation of terms 58

4.1 PROFINET quality parameters 58

Bus node failures 58

Bus node restart 58

Releases 58

Alarm (high priority / low priority) 58

Update rate 58

Contents

PROFINET-INspektor®NT - User Manual 6

Controller Transmit clock 59

Jitter 59

Telegram gaps 59

Consecutive telegram gaps 59

Telegram overtakes 59

Load ratio 59

Error telegrams 59

Netload 59

Data throughput 60

4.2 Trigger types 60

Threshold-dependent trigger parameters 60

Status change 60

History 60

Global netload 60

Frame flood 61

New device detection 61

Double addressing 61

S7 Communication 61

Loop Detection 61

Interval 61

SNMP Trap 61

Topology 62

4.3 Other 62

IPv4 62

IPv6 62

Broadcast telegrams 63

Multicast telegrams 63

Unicast telegrams 63

ARP 63

DCP 63

MRP 63

LLDP 63

PTCP 63

PN-RT 64

PN-RTA 64

5Support and contact 65

General information

PROFINET-INspektor®NT - User Manual 8

1 General information

Please read this document thoroughly from start to finish before you begin installing the device and putting

it into operation.

1.1 Purpose of use

The PROFINET-INspektor®NT permanently monitors all data traffic in a PROFINET (PN) master system.

You will receive a maintenance requirement notification when critical changes that could lead to unplanned

system downtimes are detected.

Based on the report analysis (purely passive behaviour), the following quality parameters are monitored:

•Update rate

•Error telegrams (sent/received)

•Alarms (low and high-priority)

•Telegram gaps

•Telegram overtakes

•Bus node failure

•Bus node restart

•Jitter

•Netload (sent/received)

One PN-INspektor®NT is required per PROFINET master system. This PN-INspektor is looped into the

connection between the IO controller (PLC) and the first device (switch) for analysis, or integrated within

the network through a feedback-free measurement point (e.g. PNMA II; art. no. 114090100).

No additional IP addresses or adjustments to the PLC program are required for using the PN-INspektor®

NT. It works in an entirely manufacturer-independent way; i.e. the analysis works completely independently

of the type of control system and IO devices.

For long-term analysis, the PN-INspektor®NT can remain in the bus system without any time restrictions.

The relevant telegram traffic is continuously analysed and evaluated in order to detect deviations from

normal conditions and trigger alarms.

1.2 Use of Open Source Licenses

Indu-Sol offers to provide source code of software licensed under the GPL or LGPL or other open source

licenses requiring source code distribution. The individual licenses used in Indu-Sol products can be

found in the product front ends.

General information

PROFINET-INspektor®NT - User Manual 9

1.3 Scope of supply

The scope of supply comprises the following individual parts:

•PROFINET-INspektor®NT

•3-pole plug-in terminal block (power supply)

•6-pole plug-in terminal block (alarm contacts)

•User Quick Start Guide

•CD with software for the report analysis and device manual

Please check the contents are complete before putting into operation.

1.4 General safety instructions

Operating personnel

This device may only be put into operation and operated by qualified personnel. Qualified personnel, as

referred to in the safety-related information of this manual, are persons who are authorised to put into

operation, to earth and to label devices, systems and electrical circuits in accordance with the standards of

safety engineering.

Power supply

The devices are designed for the operation with SELV-voltages (Safety Extra Low Voltage) via LPS (Limited

Power Source). Only SELV/LPS conformal extra-low voltages according to IEC 60950-1 / EN60950-1 /

VDE0805-1 as well as power packs for voltage supplies according to NEC Class 2 (National Electrical

Code) may be used.

The shield of the RJ45-socket is connected to the device housing for dissipating interferring currents. Note

possible short circuits when using shielded cables.

Utilization of PROFINET-INspektor®NT

Do not open the housing of the device. The warranty expires when the housing is opened. The device should

be sent back to the supplier in case of any defects. There are no components in the devices, which could be

maintained by the user.

Intended use

The devices are designed for use in the industrial sector in the protection class IP20. These must therefore

not be connected directly to the public low-voltage network. The installation must be carried out in an

industrial control cabinet. The industrial control cabinet may be located at a maximum height of 3000

meters.

General information

PROFINET-INspektor®NT - User Manual 10

Batteries

Caution: Risk of Explosion if Battery is replaced by an Incorrect Type. Dispose of Used Batteries

According to the Instructions

Installation

PROFINET-INspektor®NT - User Manual 11

2 Installation

2.1 Device interfaces

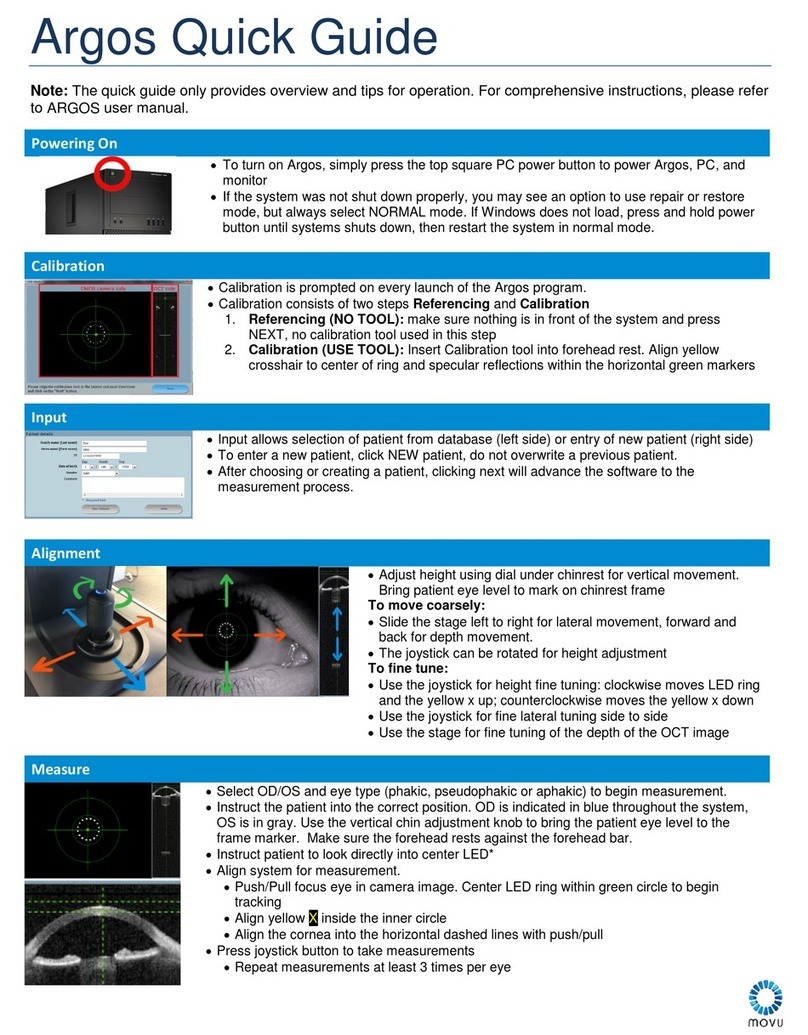

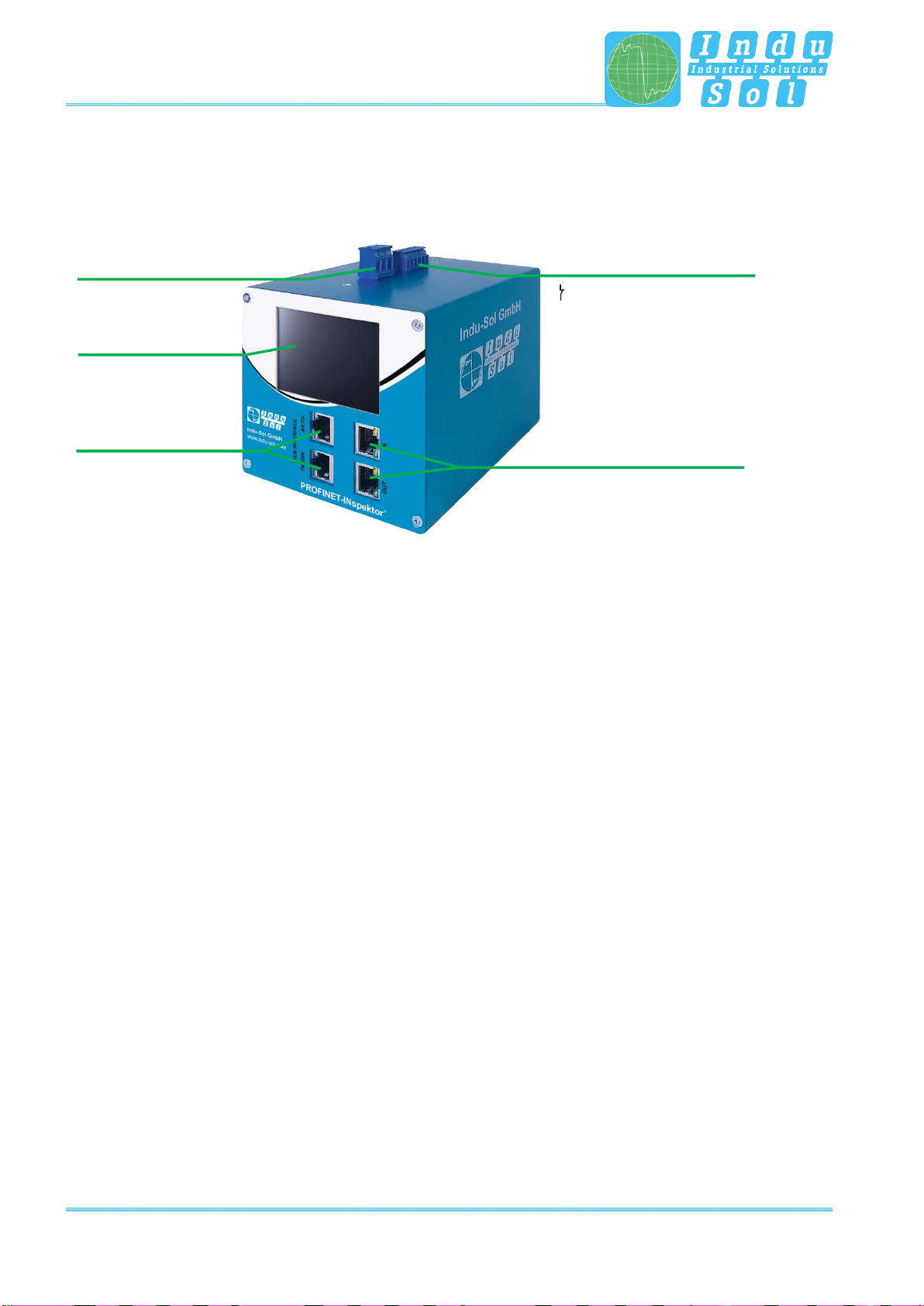

Figure 1: Device ports

X5 Fault output /

digital inputs

Potential-free switch contact

Alarm acknowledgement (switch contact)

1

2

Alarm deactivation (configurable)

3

reference ground for 1–3

GND

Alarm acknowledgement (Web + switch contact)

System display

RJ45 PROFINET ports

X4 Power supply

24 V DC + PE

RJ45 network port

PROFINET

X1/P1 IN

X1/P2 OUT

Web interface

X2 ACTIVE

X3 PASSIVE

Installation

PROFINET-INspektor®NT - User Manual 12

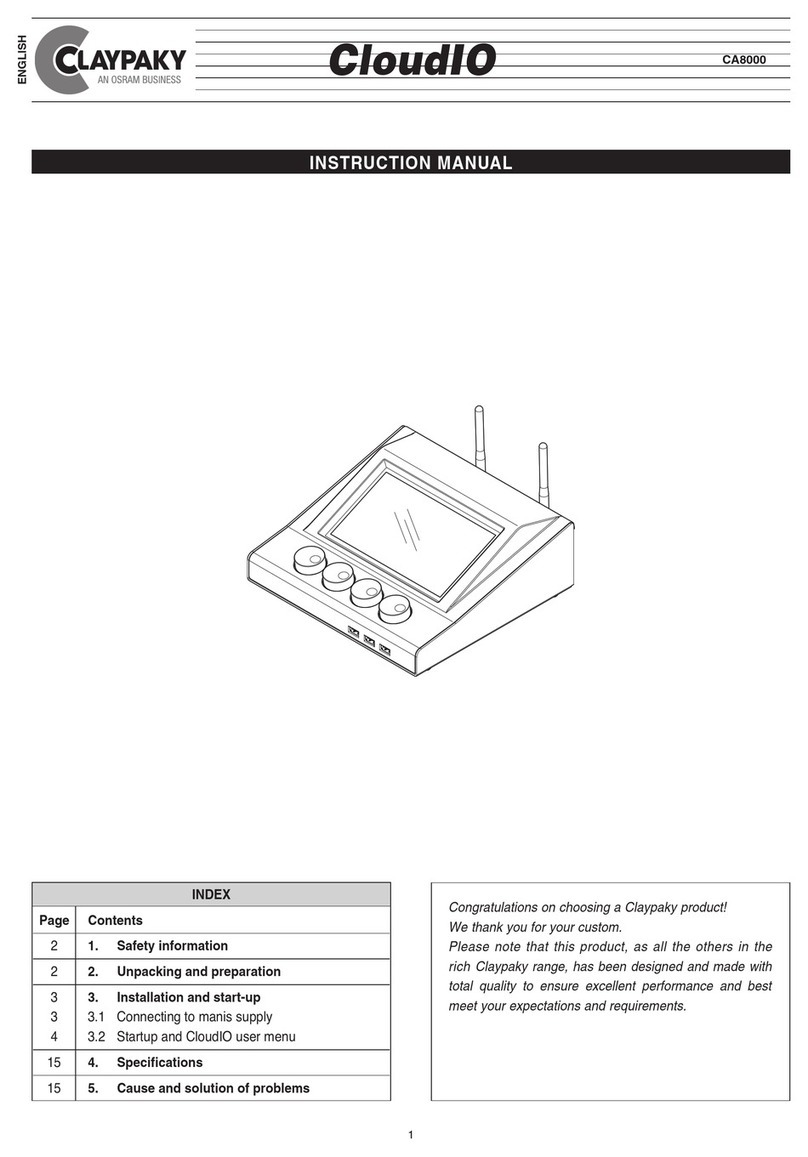

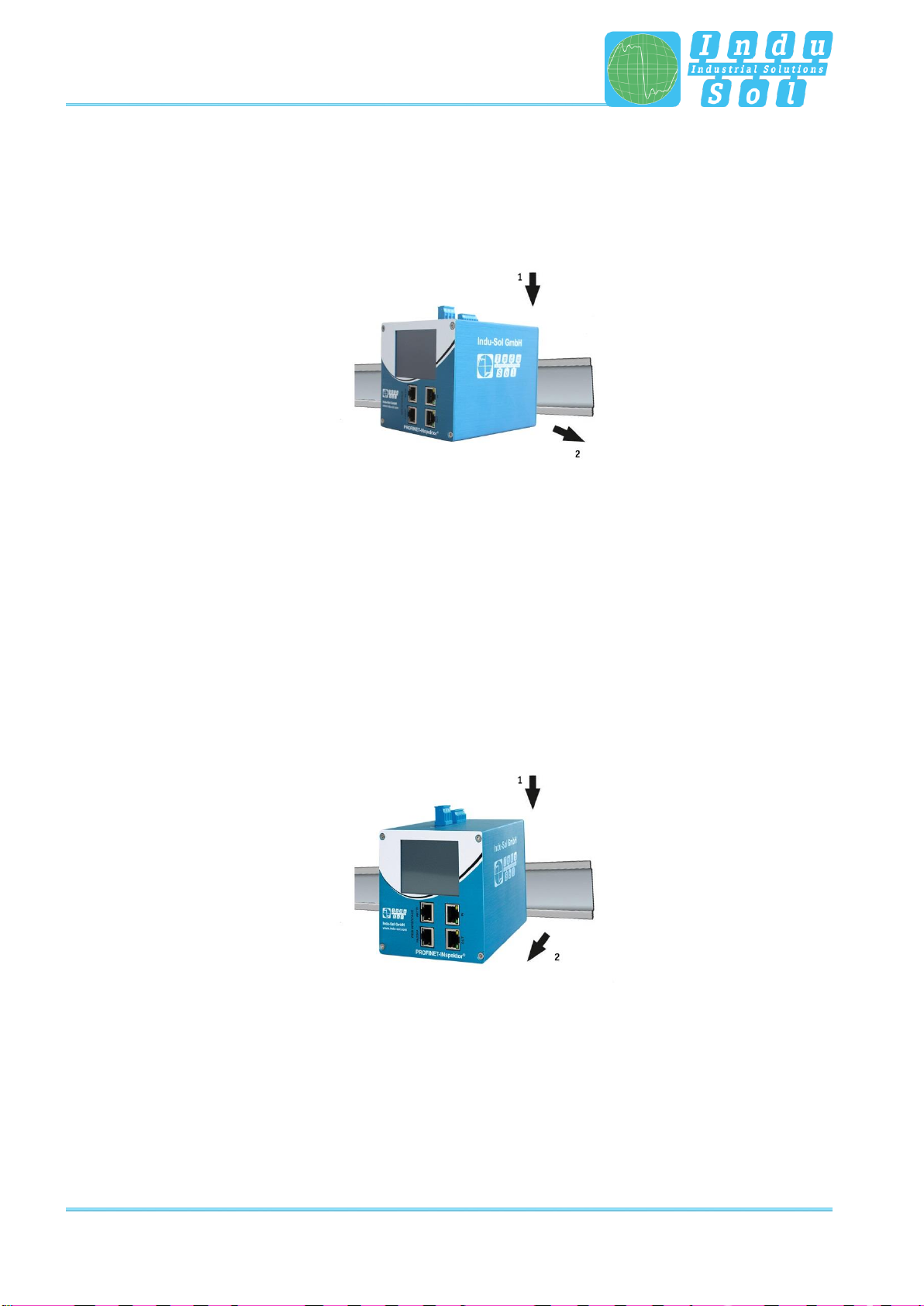

2.2 Installation instructions

PROFINET-INspektor®NT is installed horizontally inside the cabinet on a 35 mm top-hat rail in accordance

with DIN EN 60715.

Figure 2: Device installation on top-hat rail

Caution: The following distances must be maintained from other modules for correct installation:

•From left and right: 20 mm

•From top and bottom: 50 mm

Removal for alternate use of the PN-INspektor®NT in different master systems is illustrated in Figure 3.

Figure 3: Removal

Installation

PROFINET-INspektor®NT - User Manual 13

2.3 Voltage supply

Operation requires 24 V of external direct current, which is to be connected to the device via the 3-pole

plug-in terminal block (X4) supplied in the package. The PE contact should be connected to the local PE

system.

X4

Caution: When connecting, make sure that the polarity is correct.

2.4 Measurement location

Wherever possible, the PN-INspektor®NT should always be installed in the network connection between

the PLC and the first I/O device or switch, since the majority of communication typically takes place via this

connection.

2.5 Connection to the PROFINET network

You can connect to the PROFINET network in different ways. The various options are described below.

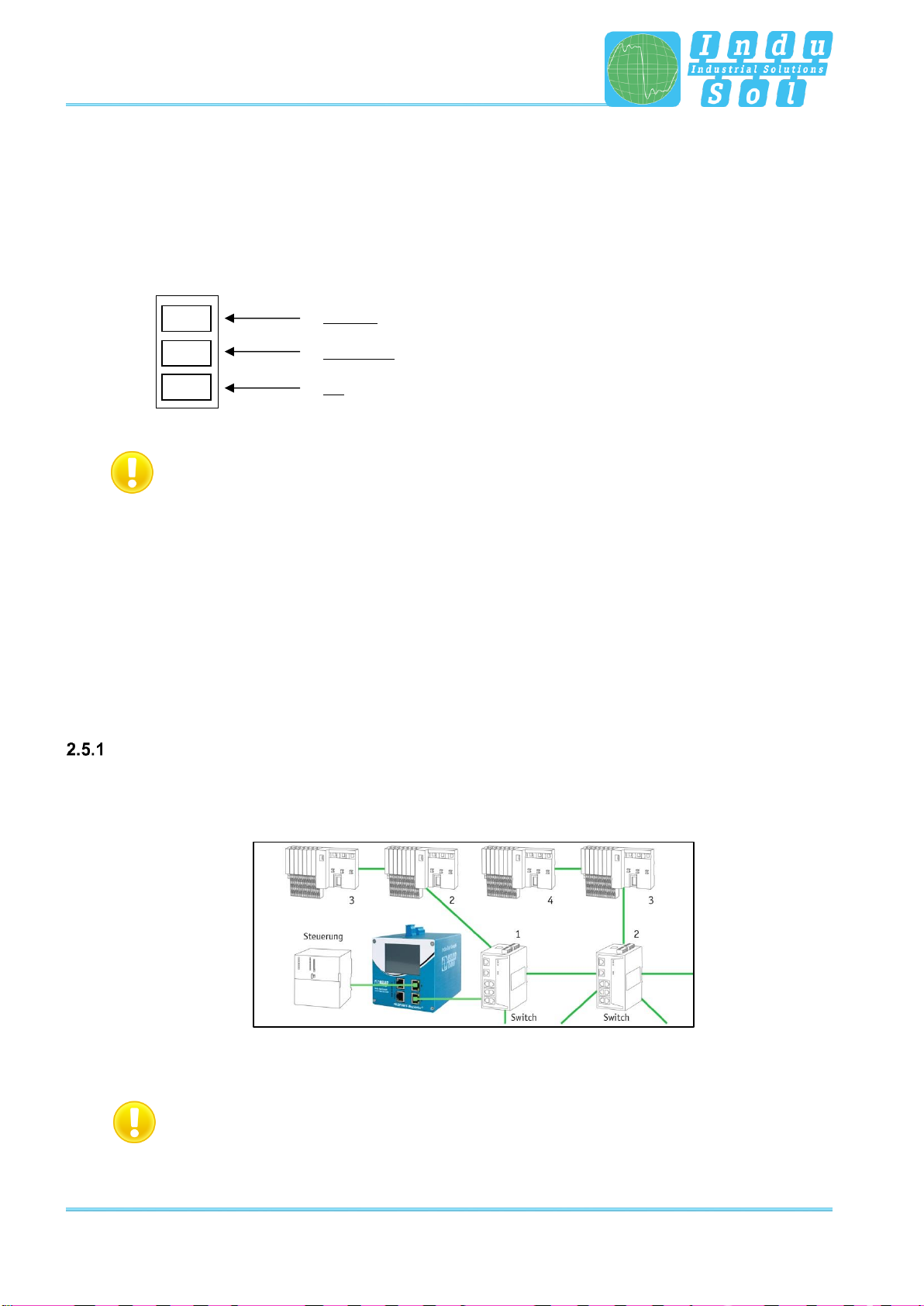

Fixed installation within the master system

The PN-INspektor®NT is firmly integrated into the network for continuous, permanent network analysis. To

do this the device is integrated into the system via the IN and OUT sockets.

Figure 4: PROFINET-INspektor® NT fixed installation

Caution: Installing the device with this connection option causes a PROFINET network fault and

should be performed during system standstill.

DC 24V

0V ground

PE

OUT

OUT

24V

0V

PE

Installation

PROFINET-INspektor®NT - User Manual 14

Connection via feedback-free measurement point

In conjunction with a feedback-free measurement point (e.g. PNMA II; art. no. 114090100), PN-INspektor®

NT can be connected to the PROFINET-system at any time without compromising ongoing system

operation. This can also be performed on a temporary basis if required. To do this, the PN-INspektor®NT

is hooked up to the M1 and M2 monitor sockets of the measurement point by means of two patch cables.

Figure 5: PN-INspektor®NT connection via PNMA II

2.6 Web interface

The LAN connections X2 and X3 of the web interface constitute the link to the PN-INspektor® NT. This

involves 10Base-T/1000Base-T RJ45 interfaces. A standard Ethernet cable is used as a connection cable

to a PC/ laptop (not included in the scope of supply).

A Web-server function is integrated for access to the device and can be opened with an appropriate

standard browser (e.g. Microsoft Internet Explorer from version 11 or Mozilla Firefox from version 45;

JavaScript must be activated). You can reach the device’s user interface by entering the IP address of the

PN-INspektor® NT in the browser’s command line.

Caution: To display the website correctly, the following ports must be enabled in firewalls,

gateways and routers: TCP/80 (http) and TCP/443 (https).

The PROFINET-INspektor® NT is supplied with the following factory-set network configuration:

PASSIVE –X2

ACTIVE –X3

IP address:

192.168.212.212

192.168.213.212

Subnet mask:

255.255.255.0

255.255.255.0

Installation

PROFINET-INspektor®NT - User Manual 15

Both the evaluation of internally recorded data and the parametrisation of the device are possible through

the PASSIVE and ACTIVE connection sockets. These are two independent network access. Additional to

the web access the active web interface can send requests to the PROFINET Network. For this it is

necessary to start a "Device scan" in the Device overview. This is used to retrieve and store information

such as the name, IP address and network topology for the respective device.

The active port must be configured to a free IP address from the PROFINET system to be scanned (see

section 3.5.1.5 Network) and integrated into the network (e.g. via a free switch port).

2.7 Signal inputs and outputs

The 6-pole connector terminal block (X5) at the top of the device is assigned as follows:

X5

Output:

- Potential-free switch contact (relay)

- Opener

Power supply Potential-free switch contact

max. 30V DC; max. 1A

3 inputs:

- Max. 24V DC ±20%

- Inactive < 3V

- Active > 10V

- Maximum current 0.15 mA

- Galvanically isolated

GND:

- Input earth potential

3

1

2

GND

OUT

OUT

Installation

PROFINET-INspektor®NT - User Manual 16

Input 1: Alarm acknowledgement (Web interface + switch contact)

Input 2: Alarm acknowledgement (switch contact)

Input 3: Alarm deactivation

Additional functions can be configured via the Web interface (see point 3.5.1.7 Digital Input)

2.8 Display screen

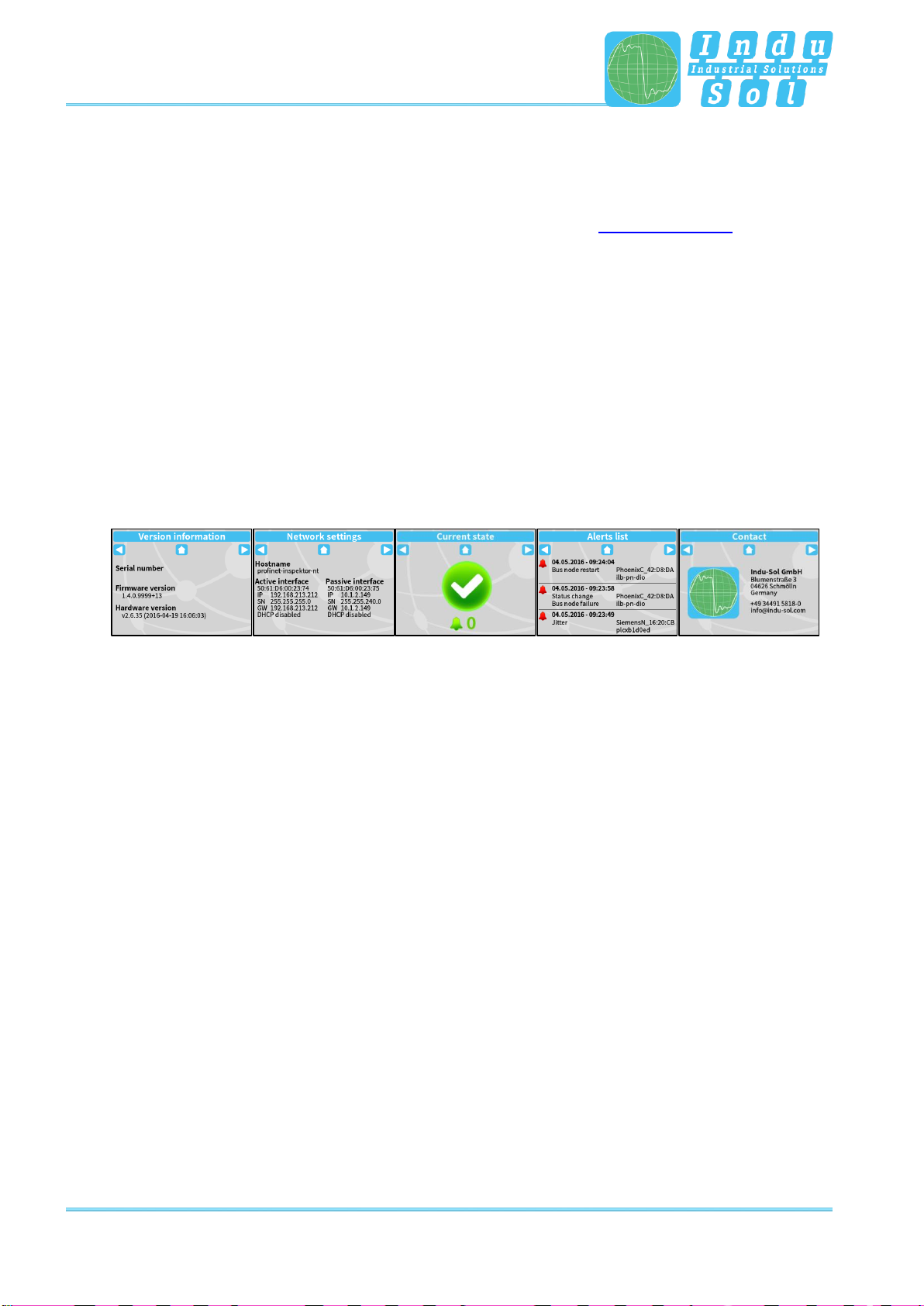

After connecting the power supply, the display conveys the system start-up of the PN-INspektor®NT.

After successful system start-up, the current state of the PROFINET network is always displayed on the

Home screen. You can scroll between the menu items with the arrow keys on both sides. The Home key

takes you directly to the Home screen.

The pending alarms are acknowledged by longer pressing (> 5 s) on the status symbol.

Figure 6: Touch-Screen menu

Web interface and selection functions

PROFINET-INspektor®NT - User Manual 17

3 Web interface and selection functions

To access the Web interface, and thus the recorded data of the PN-INspektor®NT, use an Internet browser

and enter the IP address (PASSIVE: 192.168.212.212; ACTIVE: 192.168.213.212) of the device to open

the web interface.

The following icons were used in the Web interface for a simple overview of the individual statuses of the

network and devices:

No faults: PROFINET communication is working without any problems.

Warning: A communication fault or a diagnostic message has appeared

in the network, or originated from a device, and this fault or message has

not yet led to system failure. The sources of these events should be

localised and resolved.

Fault: A critical fault has appeared in the network, or originated from a

device, and this fault leads to system failure. It is urgently necessary to

resolve the fault.

The bus communication in the network has failed or cannot be detected

by the PN-INspektor®NT (serious fault in the network) or the device is no

longer communicating or is not in the network.

Web interface and selection functions

PROFINET-INspektor®NT - User Manual 18

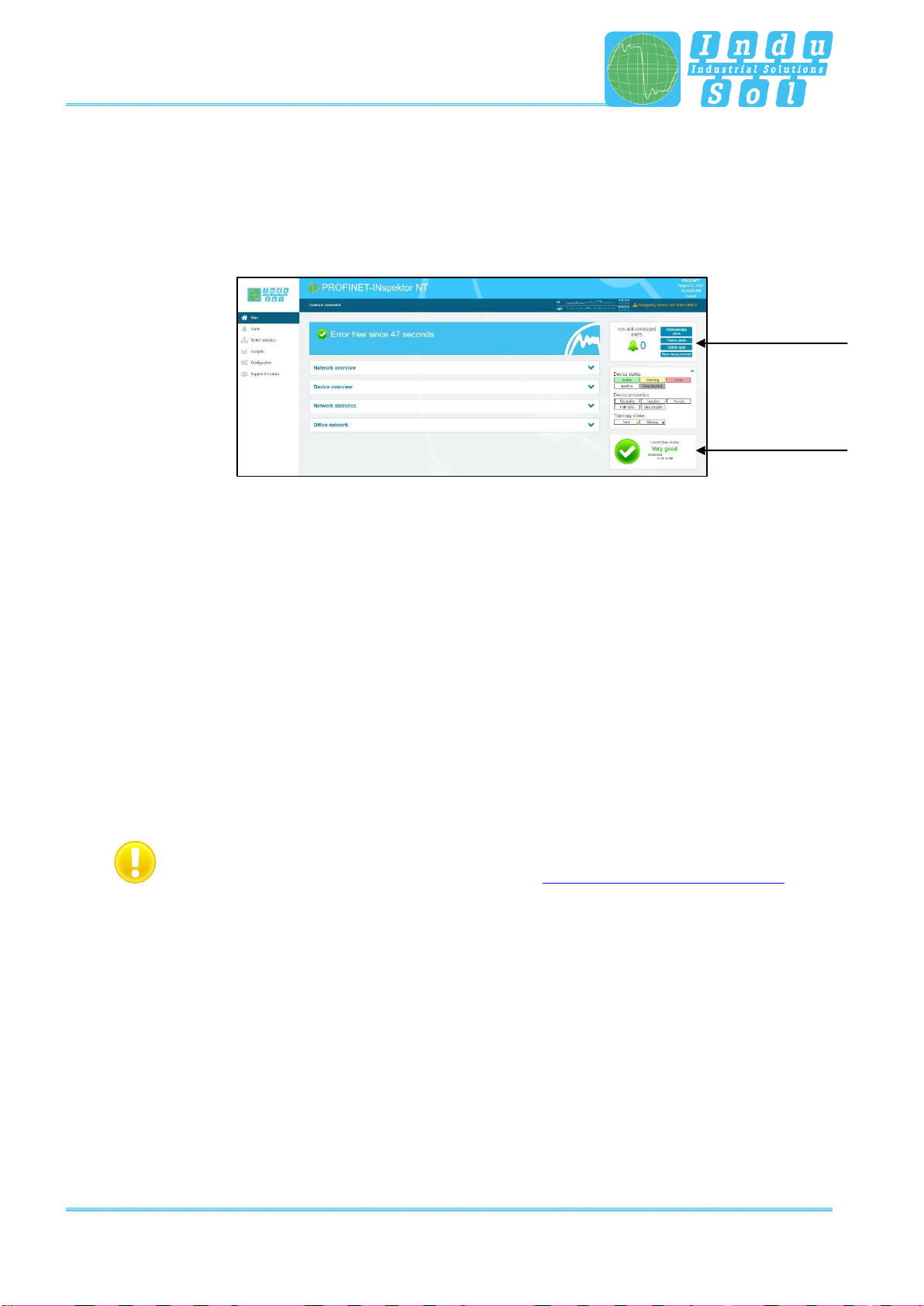

3.1 Homepage

The homepage provides a complete overview of the status of the connected PROFINET system since the

start since the start of the current measurement.

If there are no entries here, the system is working stably and there are no urgent actions required.

Figure 7: Complete overview

There are additional helpful functions for obtaining more detailed information on the state of the network.

These can be accessed via drop-down menus or the Alarm Overview.

Specifying the time period, with a corresponding display of device information, is possible in the sub-menus

of the homepage. The relevant period of evaluation can be selected by switching the time window between

“current”, “last minute” and “history”. The “current” setting always displays the node condition (live list) at

that particular moment, and the “last minute” option shows the device information over the course of the

previous minute. With the “history” pre-selection, all data is displayed since the beginning of the recording

or the last time the “Delete data” or “New measurement” function was commanded. You can use these

different time references to determine whether PROFINET faults are occurring occasionally or permanently.

To adapt the user language of the web interface, it is possible to select the language by means of a mouse

over function on the "Language" item.

Language switching only affects the user interface. The settings for the display and the log text are

made by changing the system language (see section 3.5.1.4 Time and language settings).

Alarm overview

Timeline

Web interface and selection functions

PROFINET-INspektor®NT - User Manual 19

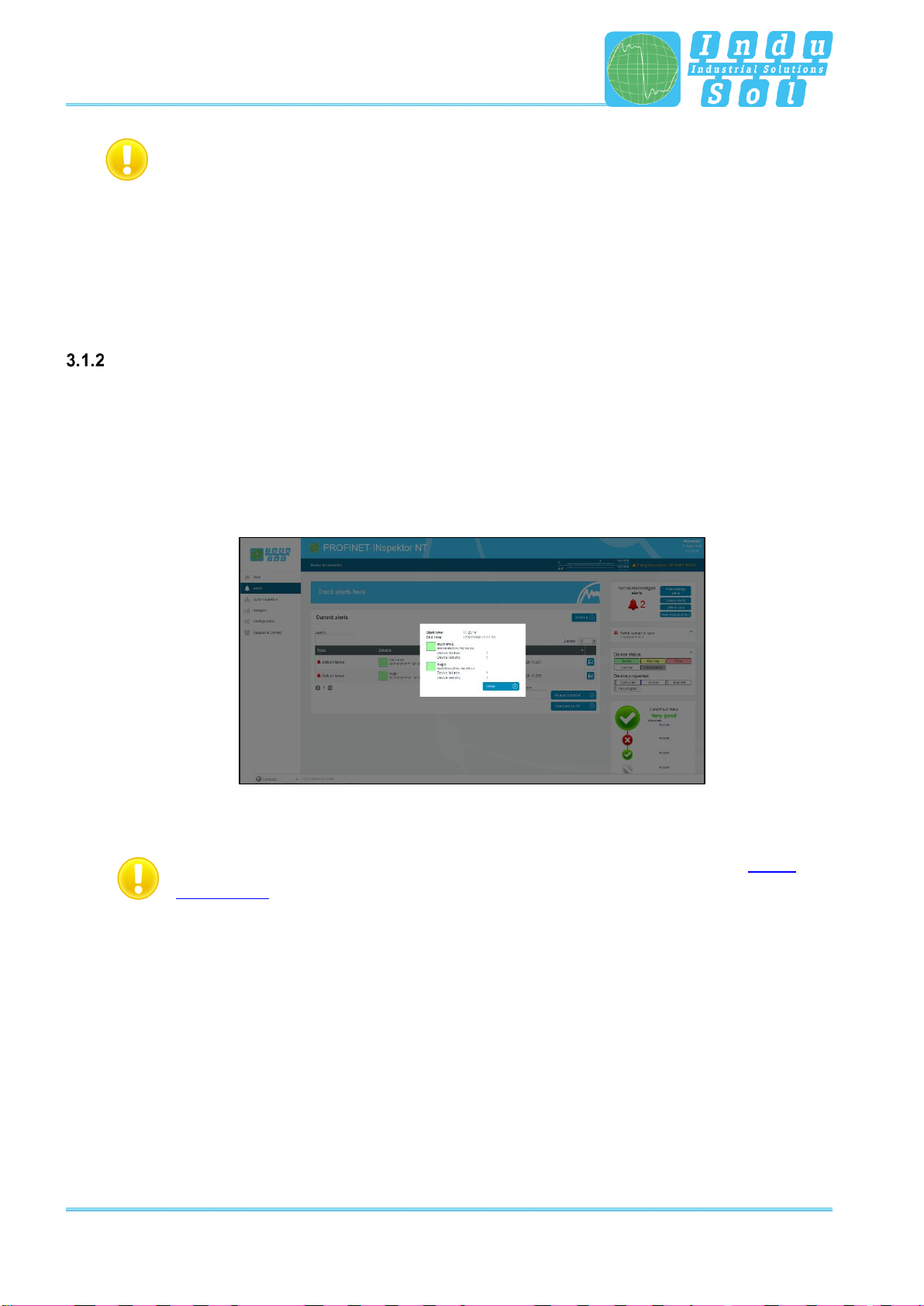

If errors occur during the overrun period, the relevant error trigger is triggered. This leads to entries in the alarm

overview, the timeline and the alarm list.

Figure 8: General overview in case of error

If the switching contact is activated at this time (see section 3.5.2.3 Triggers & alarms, factory setting: On), the

alarm signalling contact is switched on at the same time (contact opens) and the entry "Switching contact is

open" with the corresponding time stamp is displayed in the hint field.

In addition, changes made to the basic settings in the "Device status" menu (see section 3.5.2.2. Device status)

are indicated by the message "Status Settings have been changed" and in the "Triggers & Alarms" menu (see

section 3.5.2.3 Triggers & Alerts) by the display "Alarm Settings have been changed".

Alarm overview

In the alarm overview the number of unacknowledged alarms are indicated to you. The entries in the alarm

list are opened automatically with a mouse click on the alarm bell.

You can also perform the following functions in this window:

Acknowledge alarms: Unacknowledged alarms are acknowledged, but the entries stay in the alarm list.

The switch contact for the alarm is reset.

Delete alarms: All entries in the alarm list, including snapshots, are deleted.

Delete data: All previously recorded data is reset and the network analysis is restarted. The

device information (IP address, PN name) and configured settings are retained.

New measurement: This item is to be applied in the event of alternating use in different PROFINET

systems. By selecting this function, all previous entries including the node list are

deleted, and the network analysis is restarted. Any configuration settings made

are retained.

Hints

Web interface and selection functions

PROFINET-INspektor®NT - User Manual 20

Hint:

By regenerating the participant list, it is necessary to select the automatic deactivation

of new participants again, if desired. Settings for the configuration of monitored

connections can also be reset by pressing an optional selection field with the start of a

new measurement. Otherwise, the previously selected connections will continue to be

monitored.

Timeline

The timeline offers you a compact visual overview of the state of the network over the course of time. If

different network statuses are analysed within the course of the monitoring period, the point in time when

the respective status change started is presented as a new node (maximum 50 entries). Detailed

information accumulated within this time frame can be accessed by selecting one such node. The minimum

time period for a status change (new nodes) is one minute.

Figure 9: Timeline entry

The individual status changes can be adjusted for each node separately (See point 3.5.2.2

Device status) in order to adapt the display to the plant conditions.

Table of contents

Other Indu-Sol Diagnostic Equipment manuals