Indu-Sol PROFI-TM Professional User manual

Diagnostic and Service Tools for PROFIBUS

Your partner and specialist for field bus systems, Industrial Ethernet and PROFInet

PROFI-TM Professional

USER MANUAL

Indu-Sol GmbH • Blumenstrasse 3 • D - 04626 Schmoelln • Germany

Phone: +49 34491 5818-0 • Fax: +49 34491 5818-99 • e-mail: info@indu-sol.com • www.indu-sol.com

© Copyright 2010 Indu-Sol GmbH

No part of this manual may be reproduced, photocopied, stored on a retrieval

system, transmitted, processed or translated without the express prior written

consent of Indu-Sol GmbH.

Contents

1

Introduction 6

1.1

General 6

1.2

Test Functions 6

1.3

Operating Modes of the Tool 6

1.4

PC-Software PROFIBUS Diagnostics Suite 7

2

Delivery Scope 8

3

Optional Accessories 9

3.1

D-sub adapter cable for testing live systems 9

3.2

Adapter Set for M12 Connection Technology 9

3.3

Fieldbus Shield Digital Leakage Current Clamp 9

3.4

Portable Power Supply 10

3.5

Active Measuring Point „PBMA“ IP20 – Active Terminator 11

3.5.

Active Measuring Point „PBMX“ IP67 – Active Terminator 12

4

Connectors and Controls 13

5

Power Supply and Auto Power On 14

5.1

Power-Up Behavior without USB Connection 14

5.2

Power-Up Behavior when USB Connected 15

6

Software Installation 16

6.1

Connection to a PC 16

7

Connection to PROFIBUS 16

7.1

Basics 16

7.1.1

Warning notice for testing a live bus 16

7.1.2

Connection types 17

7.1.3

Adapter cable 17

7.1.4

Strain relief 18

7.1.5

Test locations 18

7.2

Simple Connection for Tests During System Shutdown 19

7.3

Connection for Testing a Live Bus 20

7.3.1

Anschlussart D-Sub-Stecker mit Service-Buchse 21

7.3.2

Direct cable connection 22

Connection via M12 connector 23

7.4

Master Simulator and Topology Scan 23

7.4.1

Special case: Active devices at both ends of the bus 25

8

Display and Control in Stand-Alone Mode 26

8.1

Main Display 26

8.2

Operating Concept 28

8.3

Functions 29

8.3.1

Live Status function 29

8.3.1.1

Segment status 29

8.3.1.2

Station status 30

8.3.2

Quick Test function 31

8.3.3

Trend function 31

8.3.4

Master Simulator function 31

8.3.5

Settings and Help functions 32

9

Firmware Update 32

10

Maintenance and Servicing 32

11

Troubleshooting 33

12

Specifications 34

13

General Notes 35

13.1

Lithium Battery 35

13.2

CE Conformity 35

Introduction Manual

Page 6 © 2010

1 Introduction

1.1 General

The PROFI-TM Professional is a powerful tool that allows full testing of

PROFIBUS DP segments. The tool reliably detects even transient faults that

occur only sporadically.

Using the integrated master simulator, you can also test the bus if the PLC is

currently not in operation, or individually check “suspicious” bus stations.

The tool is powered either through an external AC adapter, by direct connec-

tion to 24 VDC or through an optional portable power supply unit.

1.2 Test Functions

The PROFI-TM Professional automatically detects the baud rate or open

circuit voltage as soon as you connect it to a PROFIBUS DP segment. The

following standard tests are available for simultaneously analyzing the bus

physics and bus communication:

•Quick test

•User-controlled test

•Long-term trend

Additional features (network status):

•Master simulator

•Topology scan

Expert tests (optional):

•Frame analysis

•Oscillogram analysis

•Trigger input/output

1.3 Operating Modes of the Tool

You can connect the PROFI-TM Professional to a PC or notebook, or run it in

stand-alone mode. The PC mode provides all standard and expert tests. You

can also select individual stations you want to test. The stand-alone mode

currently provides the live status and the master simulator mode. In addition,

for the future it is planned to make available the quick test and long-term trend

functions as well as the transfer of test results to the PC.

Introduction Manual

Indu-Sol GmbH Page 7

1.4 PC-Software PROFIBUS Diagnostics Suite

The PROFIBUS Diagnostics Suite allows the display and detailed analysis of

test results on the PC.

Simply connect the PROFI-TM Professional to the USB interface of a PC or

notebook. You can then use the included “PROFIBUS Diagnostics Suite” PC

software (see separate manual) to do the following:

•Perform tests and analyses

•Manage the test results with minimum effort

•Create test reports

Delivery Scope Manual

Page 8 © 2010

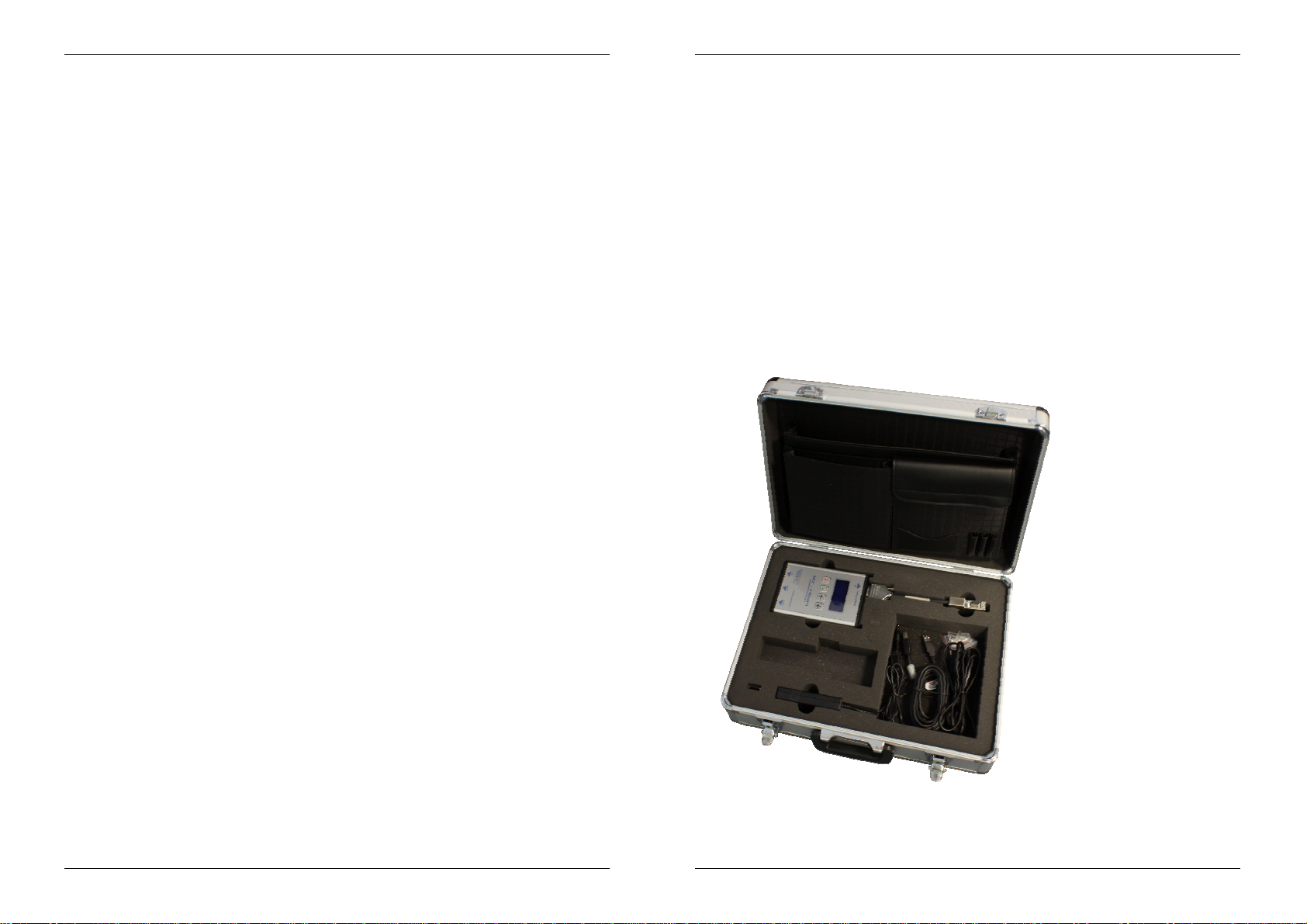

2 Delivery Scope

The PROFI-TM Professional comes in a carrying case comprising:

•Test tool with RS485 interface

•Wide-range power supply with European and US mains power cables

•Connecting cable for direct power supply with 24 VDC

•D-sub adapter cable 2 (BC-600-PB-CB-DSUB-2 for PROFIBUS DP -

blue)

•USB cable, 3 m

•Terminal block for trigger input/output

•CD-ROM with driver software, PC software and detailed integrated

help system in English and German

•PROFI-TM Professional user manual and Getting Started manual for

the PROFIBUS Diagnostics Suite PC software

PROFI-TM Professional with carrying case

Optional Accessories Manual

Indu-Sol GmbH Page 9

3 Optional Accessories

3.1 D-sub adapter cable for testing live systems

This D-sub adapter cable (BC-600-PB-CB-DSUB-1) is optimized for reduced

influence on live PROFIBUS DP segment operations. Thereby it is most

suitable for testing of running plants. The risc of critical influences on bus

operation which can cause a plant standstill is significantly reduced. Attention:

Using this cable it is not possible to use the both active functions master

simulator and topology detection (see page 22).

Fig 1: D-sub adapter cable with reduced influence on bus operation PB-DSUB-1

Order no: 00110189

3.2 Adapter Set for M12 Connection Technology

Using the M12 adapter set, you can connect the PROFI-TM Professional to

field devices with M12 connectors. The set comprises an M12 adapter cable

with special pin layout and an M12 terminating resistor that you can screw on,

if required.

Fig. 1: Special adapter for M12

Order no.: 00010580

3.3 Fieldbus Shield Digital Leakage Current Clamp

When routing PROFIBUS cables in high-interference environments, electro-

magnetic interference can affect the signal quality. By measuring the shield

currents with the digital leakage current clamp, you can locate EMC problem

areas and take appropriate countermeasures. The digital leakage current

Optional Accessories Manual

Page 10 © 2010

clamp is supplied in a handy case, including measuring cables. There is also

an empty compartment for the fieldbus shield digital leakage current clamp in

the carrying case of the PROFI-TM Professional.

Fig. 2: Fieldbus Shield Digital Leakage Current Clamp PB C3

Order no.: 00010612

3.4 Portable Power Supply

The portable power supply unit allows up to 4 hours of portable operation. The

power supply kit also includes a charger and a carrying case. Attention: Mains

connector type of charger station available for Europe only.

Fig. 3: MoSt Portable Power Supply

Order no.: 00010405

Table of contents

Other Indu-Sol Diagnostic Equipment manuals