Indu-Sol PROFInet-INspektor User manual

Diagnostic and service tools for PROFINET

Your partner and specialist for field bus systems, Industrial Ethernet and PROFINET

PROFInet-INspektor®

MANUAL

Indu-Sol GmbH • Blumenstrasse 3 • D - 04626 Schmoelln • Germany

Telephone: +49 34491 5818-0 • Fax: +49 34491 5818-99 • E-Mail: info@indu-sol.com • www.indu-sol.com

List of revisions

Date Revision Change(s)

08/06./2011

0 First version

25/10/2011 1 Revised version

05.02.2012 2 Revised version

04.04.2012 3 Revised version

27.08.2012 4 Revised version

© Copyright 2011 Indu-Sol GmbH

We reserve the right to make changes without prior announcement. Our

products are subject to constant improvement. We also reserve the right to

change the scope of supply as regards form, configuration and equipment.

No claims can be derived from the data, figures and descriptions of this

documentation. Any reproduction, processing and translation of this

document or any extract thereof are subject to written approval by Indu-Sol

GmbH. All rights pursuant to the copyright law shall be expressly reserved

to Indu-Sol GmbH.

Attention!

This device may only be started and operated by qualified personnel.

Qualified personnel within the meaning of the safety information

contained in this manual are persons who are authorized to start, ground

and mark devices, systems and circuits in accordance with the safety

standards. .

Table of contents

1 General 6

1.1

Scope of supply 6

1.2

Safety information 6

1.3

Purpose of use 6

2 Installation 7

2.1

Connecting the voltage supply 7

2.2

Connecting to PROFINET 7

3 Electrical connections 8

3.1

Voltage supply 9

3.2

Web interface 9

3.3

COM 10

3.4

Mirror Port 12

3.5

NETWORK IN 12

3.6

NETWORK OUT 12

3.7

RESET button 12

3.8

LED functions 13

3.8.1

PWR 13

3.8.2

LAN 13

3.8.3

RUN 13

3.8.4

ERROR 13

3.8.5

ALARM 13

4 Web interface 14

4.1

Display of web interface 14

4.2

Parameters of web interface 15

4.2.1

External diagnosis 15

4.2.2

Internal diagnosis 15

4.2.3

Utilization 15

4.2.4

Data throughput 15

4.2.5

Refresh rates – telegram jitter 16

4.2.6

Connection attempts 16

4.2.7

Error telegrams 16

4.2.8

Package types 16

4.3

The network statistics 17

4.4

Buttons and possible settings 17

4.4.1

Buttons on start page 18

4.4.2

Threshold values and alarms 19

4.4.3

Last cycle 19

4.4.4

Designation of subscribers 19

4.4.5

System settings 20

5 Technical data 21

6 CE Declaration of Conformity 22

7 Notes 24

General

sh. 6 of 26

1 General

Read the entire content of this document carefully before you install

and start up this device.

1.1 Scope of supply

The following components: are included in the delivery:

•PROFInet-INspektor

®

- PIT hardware

•24V voltage supply connector

•Software CD

•Installation manual

Check for completeness prior to start-up.

1.2 Safety information

Never open the housing of the PROFInet-INspektor

®

.

If the device is assumed to be defective, send it back to the supplier.

Warranty will expire immediately if the housing is opened.

1.3 Purpose of use

The PROFInet-INspektor

®

is designed to permanently monitor the

PROFINET in automation systems.

Never use the device in explosion-hazardous areas.

Installation

sh. 7 of 26

2 Installation

The PROFInet-INspektor

®

is snapped horizontally onto a TS35 DIN

mounting rail in the switchgear cabinet.

The PROFInet-INspektor

®

is cooled conventionally by heat exchange

with the ambient air.

When installing the device make sure that the venting slots of the

device are not obstructed by other components. An all round

distance of 30 mm to other devices should be ensured.

2.1

Connecting the voltage supply

Provide the PROFInet-INspektor

®

with the necessary voltage of 24

V DC, Observe the polarity. The PE terminal can be used as

protective earth.

2.2

Connecting to PROFINET

Now, that the voltage supply has been connected you have to

connect the PROFInet-INspektor

®

with the PROFINET. To this end

connect the outgoing line of the controller with the "Network IN"

interface and route the "Network OUT“ interface to the other field

devices..

If the device is connected via an ETMA (TAP) , keep in mind that the

incoming line needs to be a crossover cable because otherwise the

internal pair allocation of the interfaces will be incorrect and the

analysis cannot be started.

The PROFINET-INspektor

®

starts automatically analysing the

PROFINET data traffic.

Device names will only be recognized in the run-up phase of the

PROFINET, however.

Electrical connections

sh. 8 of 26

3 Electrical connections

Fig. 1 is a schematic representation of the PROFInet-INspektor

®

Fig. 1: Front view of the PROFInet-INspektor

®

Electrical connections

sh. 9 of 26

3.1 Voltage supply

The PROFInet-INspektor

®

is supplied with 24V DC. The required

terminal strip is included in the scope of supply. The voltage supply

connection is shown in Fig. 1 as "DC 24V".

The L+ terminal is supplied with +24V and the M terminal with 0 V.

It is also necessary to provide a PE connection. Where a strong

electromagnetic radiation is present in the environment of the

PROFInet-INspektor

®

the earthing screw under the web interface

port should be additionally connected.

The voltage supply cables should have a minimum cross section of

0.75mm² and max.1.5mm².

The PROFInet-INspektor

®

has an internal overvoltage protection.

The latter triggers at voltages above 30 V and can be replaced by

Indu-Sol GmbH only.

IMPORTANT:

Under normal operating conditions the PROFInet INspektor

®

has a

power consumption of 500mA. In the starting phase, however, 3 A

will be needed for a short period of time. Please keep that in mind

when you choose the power pack.

3.2 Web interface

The web interface is the connection for data evaluation. It is a

10Base-T/100Base-TX RJ45 interface.

Electrical connections

sh. 10 of 26

3.3 COM

The serial COM-interface is not sourced on the PROFInet-

INspektor

®

.

Electrical connections

sh. 11 of 26

Signal inputs and outputs

The six-pole input and output interface is assigned as follows:

OUT

IN

Input 1: Reset PROFInet-INspektor

®

- PIT

Input 2: Alarm acknowledgement (Reset the switch contact including

clearing of alarm list)

Input 3: Alarm acknowledgement (Reset the switch contact

with no clearing of alarm list)

Output:

- floating relay contact

- max. 24V DC +20%

- max. 1 A

- Polarity is not an issue

3 inputs:

- max. 24V DC ±20%

- inactive < 3V

- active > 10V

- maximum power 0.15mA

- electrically isolated

GND:

- frame potential of inputs

1

2

3

GND

OUT

OUT

Electrical connections

sh. 12 of 26

3.4 Mirror Port

The mirror port has a 1000Base-TX RJ45 interface. All telegrams of

the PROFINET can be recorded at this port by an Ethernet telegram

analyzer. .

IMPORTANT:

THE PC USED FOR DATA RECORDING MUST HAVE

1000BASE-TX RJ 45 INTERFACE (GIGABIT).

3.5 NETWORK IN

The NETWORK IN port renders the connection between the control

system and the PROFInet-INspektor

®

. To this end it is necessary to

connect the control system directly with the INspektor

®

via a RJ45

PROFINET cable.

3.6 NETWORK OUT

The NETWORK OUT port connects the PROFInet-INspektor

®

with

the entire system network.

IMPORTANT:

The "NETWORK IN"AND "NETWORK OUT"PORTS ARE FIRMLY

CONNECTED WITH EACH OTHER. IT MEANS THAT THE

PROFINET NETWORK KEEPS RUNNING EVEN IF THE POWER

FAILS OR THE PROFINET INSPEKTOR IS DEFECTIVE.

3.7 RESET button

A RESET button is provided on the rear side of device. This button

can be used to reset all settings to the initial status. For this purpose

press the button for at least 10 seconds.

IMPORTANT:

‘ANY RESETTING OF THE DEVICE ALSO RESETS THE

LICENCE. DO NOT FORGET TO SAVE IT BEFOREHAND.

Web interface

sh. 13 of 26

3.8 LED functions

3.8.1 PWR

The POWER LED indicates the status of the voltage supply.

A green light means that 24 V are available.

If it fails to light up, it is an indication of absent power supply or an

internal defect and that the overvoltage protection has triggered

respectively. Whatever the cause, it will be necessary to return the

device for repair.

3.8.2 LAN

The LAN LED lights up as soon as the web interface is connected

with an active Ethernet subscriber.

3.8.3 RUN

The RUN LED lights up green as soon as the device is fully

operational.

3.8.4 ERROR

The ERR LED lights up red when an internal device defect occurs.

3.8.5 ALARM

The ALARM LED lights up red in case of an alarm. The light is

green as long as there is no alarm.

Web interface

sh. 14 of 26

4 Web interface

4.1 Display of web interface

To access the web interface and the recorded data of the PROFInet-

INspektor

®

, open the web interface using the internet browser and the IP

address of the device (Default: 192.168.212.212).

Fig. 1: Web interface

It is now possible to view and check the most important parameters of the

PROFINET system to be analyzed.

Said parameters are given in the central table of the website.

Shown are all PROFINET devices involved in the PROFINET traffic. The

default display gives the MAC address and the name of the device (if a

PROFINET restart has been made). In the ”Events” dropdown menu the

parameters given in the table can be allocated to the individual subscribers.

Web interface

sh. 15 of 26

The table columns show the timing of the events. The ”Last minute” column

shows the current condition of the PROFINET network. The ”Last cycle”

column shows the most recent cycle set (1- 120 hours). The ”History”

column gives all data from the beginning of the analysis and after Delete

data/List respectively.

4.2 Parameters of web interface

4.2.1 External diagnosis

If an PROFINET I/O device detects a problem that occurs

externally at the device (no load voltage, actor-sensor short circuit

etc.), this device keeps on communicating but sends an alarm to

the controller to report this condition

4.2.2 Internal diagnosis

An internal diagnosis of a field device will be communicated if the

device has an internal fault, the configuration is no longer in

conformity or the device suffers serious defects. In most cases it

results in a restart of the device.

4.2.3 Utilization

The utilization describes the use of the bandwidth which is 100

Mbit/ for PROFINET. In other words: 20 Mbit/s are transmitted at a

utilization rate of 20%. Indu-Sol’s experience has shown that the

utilization rates should not be greater than 20%. For the

acceptance of a system the network quality in terms of with

"utilization"must be verified through a permanent recording of the

telegrams.

4.2.4 Data throughput

The term "data throughput"in the PROFINET means an amount of

data per unit of time that can be processed by the relevant control

system (related to the process image). As a standard value 4,500

Byte/ms should not be exceeded for this purpose. The value

obtained should be documented as reference value.

Web interface

sh. 16 of 26

4.2.5 Refresh rates – telegram jitter

The refresh rate is a firmly set value (for every device) in the control

system (e.g.1ms) that determines the refresh interval of data

between the control system and the IO device. Essential for the

actual refresh rate is the line depth, i.e. the installed network

structure and the number of device transitions. The rising number

of device transitions causes a variance in the running time of the

telegrams that is called ‚jitter‘. The measurement of the refresh

rate is to verify that the telegram jitter up and down does not

exceed half a refresh rate.

4.2.6 Connection attempts

The Connection Attempts parameter shows how often a device

attempted in vain to contact the controller after a failure.

4.2.7 Error telegrams

It gives the number of error telegrams arriving at the PROFInet-

INspektor

®

(checksum error and package fragments)

4.2.8 Package types

Different

packages are counted to get a full view of all

communication in the network. It may also be evaluated in a

graphical manner by using the network statistics item.

Web interface

sh. 17 of 26

4.3 The network statistics

The Network Statistics item is designed to count again the different

package types and display them graphically. The ratio of PROFINET

data to other data should not be less than 100:1.

Fig. 2: Network statistics

4.4 Buttons and possible settings

Buttons and Extended Settings are available to reset data or make

extended settings,

Web interface

sh. 18 of 26

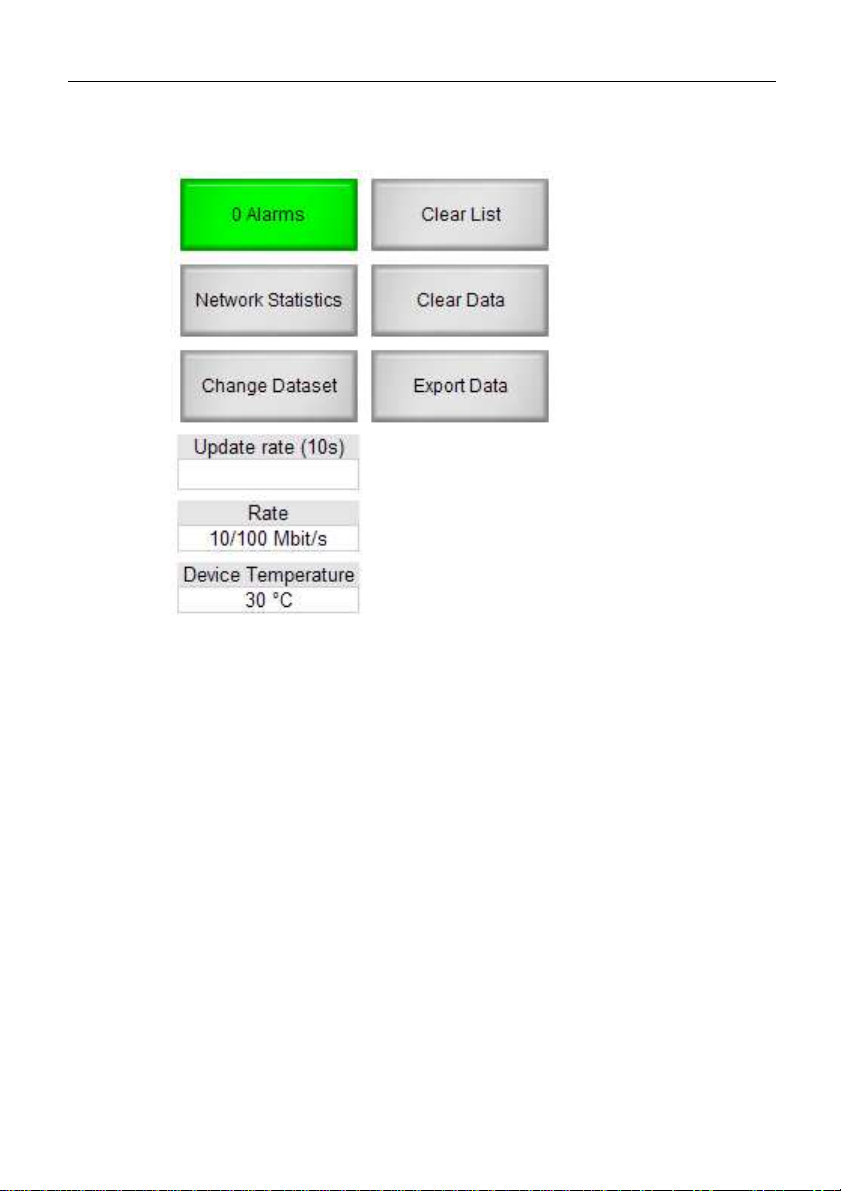

4.4.1 Buttons on start page

Fig. 3: Buttons of start page

Alarms -> Shows alarm list

Network statistics -> Shows network overview

Change data record -> Changes the current data record (4 data

records in ring buffer)

Clear list -> Entries in table are set to 0, devices and their names

are maintained, however.

Clear data -> Entries in table are reset including all devices and

names.

Export data -> Listing of recorded data

Web interface

sh. 19 of 26

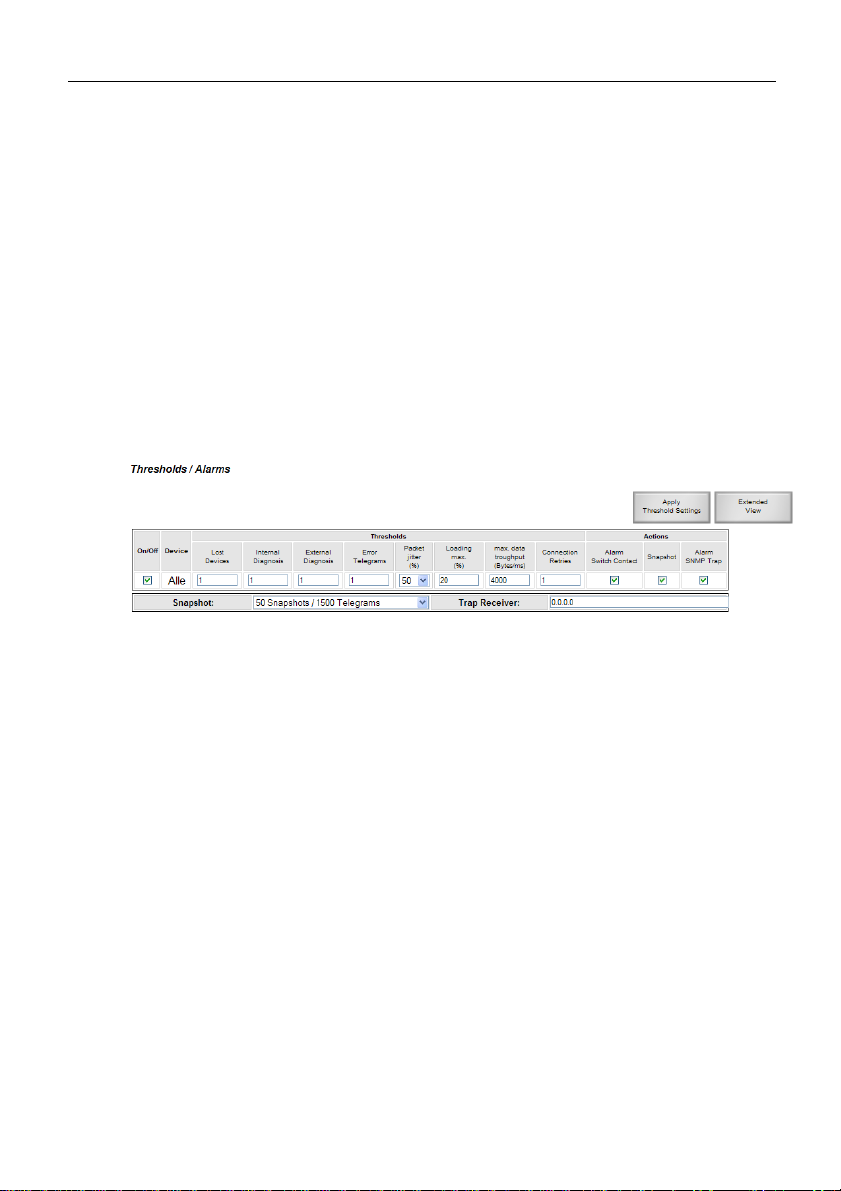

4.4.2 Threshold values and alarms

What is an alarm?

An alarm is triggered as soon as a preset or default threshold value

is exceeded. This event results in a graphic display on the website

and the device, the sending of an Ethernet trap and the switching

of the floating contact.

In the list of threshold values and alarms the threshold values and

the associated triggering of alarms can be set for all subscribers

together or each individual subscriber.

Fig. 4: Threshold values and alarms

4.4.3 Last cycle

The Last Cycle only refers to the set period of analysis but not to

the ”bus cycle”

The time span of the last cycle can be set from one hour to

maximum 120 hours.

4.4.4 Designation of subscribers

At the run-up of a PROFINET network the subscriber names of all

devices are displayed. If these names are not informative, a restart

is impossible or an alias name is to be displayed, it can be done

now. Controller names are not recognized during the run-up and

must therefore get an alias name.

Web interface

sh. 20 of 26

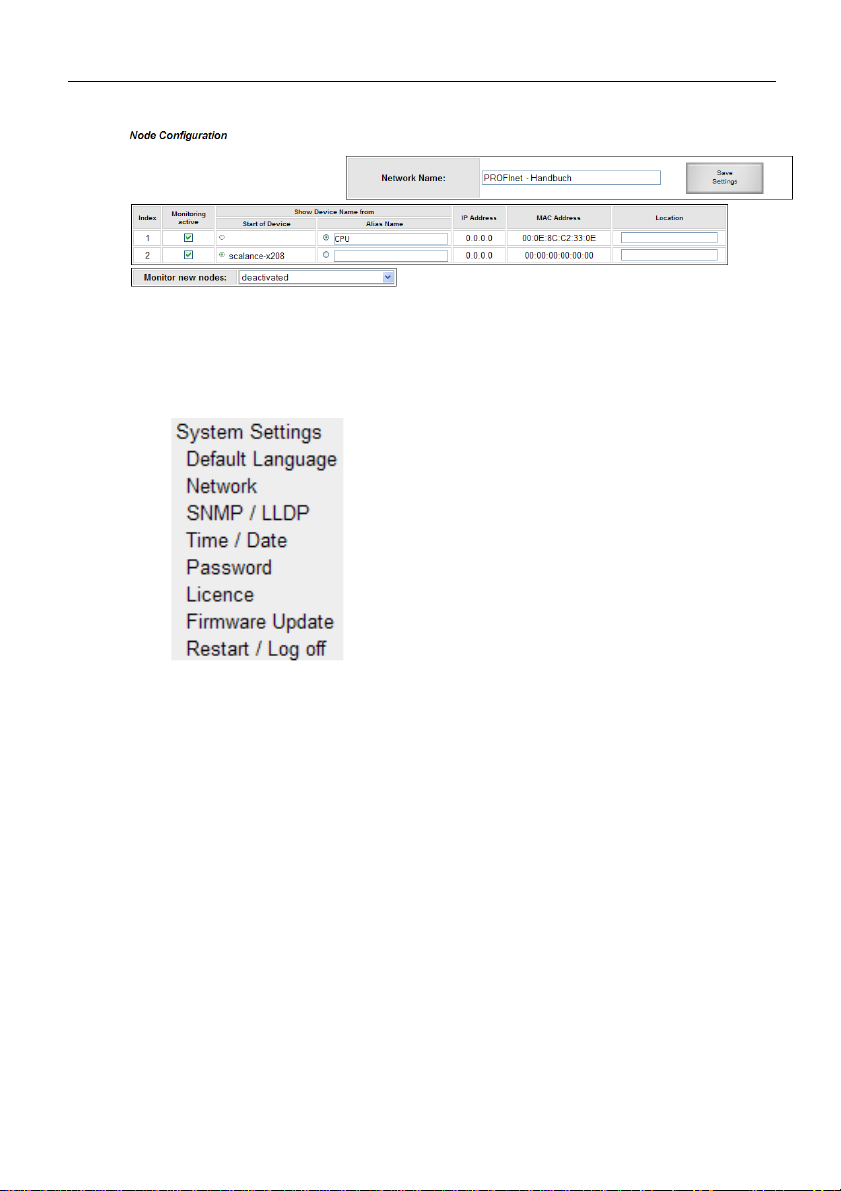

Fig. 5: Designation of subscribers

4.4.5 System settings

Under System Settings all settings of the device can be adjusted.

Fig. 6: System settings

Default language -> to define the language of the website when

selected.

Network -> to set the network parameters

SNMP/LLDP -> to set the SNMP name and parameters

Time/Date -> to set date and time

Password -> to set the password for all users incl. setting of

password prompt.

License -> view of license and possible upgrade by input of a

license code

Firmware update -> to load new firmware

Restart/Logout: to logout active user or device restart.

Table of contents

Other Indu-Sol Diagnostic Equipment manuals