Inductosense WAND User manual

Document: 1.04.04 Rev6

Document: 1.04.04 Rev6

WAND Data Collector

User Manual

Document: 1.04.04 Rev6

Disclaimer

ThisproductsuppliedbyInductosenseLtd.InductosenseLtddoesnotwarrantthatit

issuitedtoallenvironmentsandapplications.InductosenseLtdmakesnowarrantyor

representation,eitherimpliedorexpressed,withrespecttothequality,performance,

merchantability, or tness for a particular purpose.

InductosenseLtdhasmadeeveryeorttoensurethismanualisaccurateanddisclaims

liabilityforanyinaccuraciesoromissionsthatmayhaveoccurred.Informationinthis

manualissubject to change without noticeanddoesnotrepresentacommitment

onthepartofInductosenseLtd.InductosenseLtdassumesnoresponsibilityforany

inaccuracies that may be contained in this manual and makes no commitment to

updateorkeepcurrenttheinformationinthismanual,andreservestherighttomake

improvements to this manual at any time without notice. If you nd information in

this manual that is incorrect, misleading, or incomplete, we would appreciate your

comments and suggestions.

No part of this document can be reproduced, transferred, distributed or stored in

any format without prior permission of Inductosense Ltd.

PleasecontactInductosenseLtdifyouhaveanyqueriesregardingthismanualorthe

product.

Inductosense Ltd.

UnitDX, St.Phillips Central, Albert Road, Bristol, U.K.

Document: 1.04.04 Rev6

How to use this manual

The WAND Data Collector (referred to as WAND from this point forward) manu-

al has been laid out to reect the menu bar that appears on the WAND screen.

This booklet includes:

Introduction to WAND Page 4

Description of Key Features Page 4

Powering up Page 5

Measure Measure

Settings

Device

Settings History

Page 7

How to take

thickness

measurements

Page 10

Conguring the

WAND for a

measurement

Page 12

Conguring

WAND for use

Page 14

Retrieving stored

data

Other instruction manuals in the WAND series:

WAND IDM Software Manual

WAND TMS - Sensor Installation Manual

Document: 1.04.04 Rev6

Introduction

TheWANDisusedtoactivatetheInductosenseThicknessMonitoringSensors(TMS)

in order to take ultrasonic thickness measurements from structures. The WAND

powersandsubsequentlyacquiresthethicknessdatafromtheinstalledsensors.The

TMS sensors can be installed on thickness/corrosion monitoring locations (CMLs/

TMLs). Measurements from the TMS sensors are displayed on the WAND’s screen

andcanalsobeanalysedusingtheInductosenseDataManagement(IDM)software.

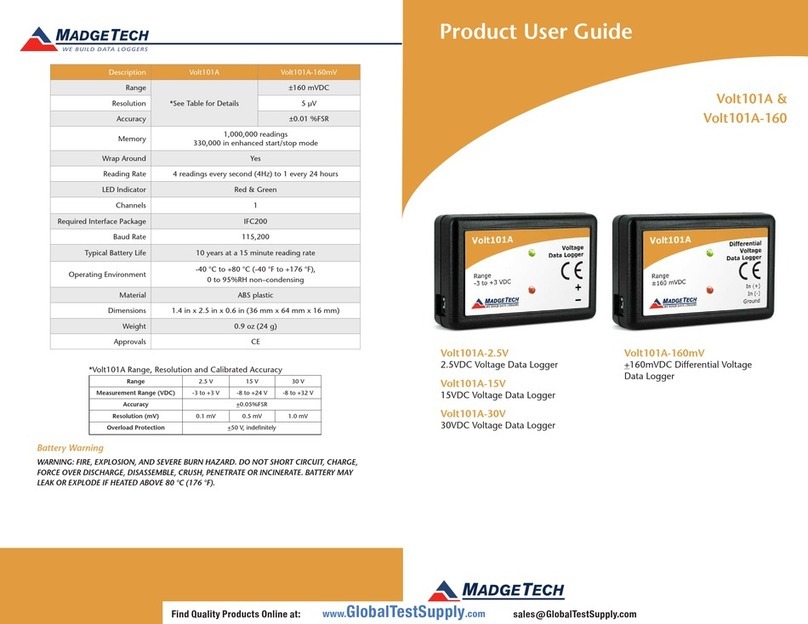

Description of Key Features

Figure 1: The Key Features of the WAND Data Collector

Transmission Coil Screen

Scan Button

On/Off Button

Enter Button

Navigation Button

Data & Power Connector

Document: 1.04.04 Rev6

Powering-up the WAND

To switch the WAND on press the ON/OFF button. Once the WAND is turned

on, a user sign-in page will be displayed. A user can sign-in to the device by either

scanning a user RFID card or by entering a PIN Number against a specied user

name.

• When using an RFID card, simply hold the card under the WAND and

depress the scan button.

• With a USER ID and PASSWORD, press the enter button to reveal a list of

recorded users..

• Navigate to the appropriate user using the navigation buttons and select by

pressing the ENTER button.

• Navigate to the PIN eld and press the Enter Button

• Enterthe4-digitPINnumberbyscollingthroughtthenumbers(upanddown

buttons) and move to the next number using the left and right buttons.

• Once the PIN has been entered press the enter button

• If the PIN number entered is succesful the screen will change to the

MEASUREMENT screen

Figure 2: The Sign-in Screen

• If the PIN number is incorrect

an ‘Error’ message will appear.

• Clear the error message by

pressing the enter button and

retry the PIN.

Document: 1.04.04 Rev6

Start using the WAND

Prior to initial use of the WAND, it is recommended to check and conrm the

MEASUREMENT and the DEVICE SETTINGS. The settings are accesed via the Menu

Bar.

To open the Menu Bar, press the UP navigation button.

The LEFT and RIGHT arrows can be used to move between the four measurement

options (see Figure 3 below) and the Enter button will select the required option.

To exit the menu press the scan button

Figure3:ThedevicenavigationMenucanbeopenedusingtheUP

button from any screen after login is completed successfully.

Document: 1.04.04 Rev6

Measure Measure

Settings

Device

Settings History

Figure 4: The Measurement Screen

The Measurement Screen (Figure 4 below) is used to display the ultrasonic A-scan,

the location of the TMS sensor and the the velocity of ultrasound in the material

and the calculated thickness.

Tip:

Whenthe scan buttonisdepresseda reducedultrasonicA-scanisdisplayedalong-

sideabar showingthesignaltonoise ratio. Thisfeatureis designed toenable users

to achieve optimal alignment of the WAND to the TMS sensor.

When the scan button is released the full ultrasonic signal is shown on the screen

along with location from the RFID. This signal is the average of the scans taken

while the scan button was held down (if Averaging is ENABLED) or the last reading

(is Averaging is DISABLED). For more on Averaging, see Measurement Settings.

Document: 1.04.04 Rev6

Acquiring measurements using the WAND and Assigning

RFIDs to TMS Sensors in the eld

STEP ONE

Place theWAND above the RFID, press the Scan button. If the RFID has been detected, the

locationindicatordisplaystheRFIDtag(“RFID/N/A”if theRFIDhasnotbeenassigned,“RFID

/nameof location”if it hasbeen). Otherwise,thelocation indicatorwilldisplay“N/A”only. In

that case, release the button, reposition the probe and press the button again.

STEP TWO

OncetheRFIDisacquired,keepthescanbuttonpresseddown.Forthebestsignal,thetrans-

missioncoilontheprobeshouldbepositionedabovethesensor.Theultrasonicsignalshould

appearin themeasurementwindow,andthe colourbar onto the right of the scan showing

signaltonoiseratioshouldbehigh.Oncetheprobeisinapositioninwhichthesignalappears,

and the signal intensity is high, release the scan button. If the message“too close”appears,

increase the distance from the probe to the sensor slightly.

STEP THREE

Savethemeasurementby pressing theenter button. If the RFID has alreadybeen assigned,

you will see a save conrmation message. Press the enter button again to go back to the

measure screen. If the sensor history has been ENABLED (See MEASUREMENT SETTINGS)

you will automatically see a screen showing a list of that sensor’s previous measurements

STEP FOUR

If the RFIDhas notbeen assignedpreviously(inthe IDMsoftware,and then importedtothe

probe, or directly in the eld), a window will open to assign it in the eld.

Thewindowallowstheusertodenethematerial,calibrationvalue(manualUTreading),and

locationnameassociatedwith theRFID. Thesettingsareselectedusingupand downon the

Document: 1.04.04 Rev6

navigation pad and the enter button.

STEP FIVE

Select a standard material in the list or enter a new custom material velocity.

STEP SIX

Ifavailable,enterthereferencemanualUTmeasurementintheCal.Valuesetting(Pressenter

to set the Cal.Value setting, then use up and down to change digits, left and right to cycle

through the digits, press enter when done). This value cannot be set to 0. If there is no

reference value, set to another value and make a note of this. It can be changed later in the

IDM software.

STEP SEVEN

Enteralocationname.ThiscanbechangedlaterintheIDMsoftwareifmistakesaremade,or

if location names are simplied due to the input method.

STEP EIGHT

Once the settings for the RFID have been set, press the left navigation button to nish the

RFID assignment and save the measurement.

SubsequentmeasurementstakenbytheWANDwillassociatealldatafromtheTMSsensoto

this RFID.

Document: 1.04.04 Rev6

Measure Measure

Settings

Device

Settings History

Figure 5: Measure settings screen

The ‘Measure Settings’ menu options allows users to dene the measurement

parameters against which the thickness measurements will be recorded in the

WAND.

Figure 5 is a screenshot of this menu option and displays the criteria that can be

congured. ItshouldbenotedthatMaterialandPeakDetctioncanalsobeapplied

inretrospecttotheindividual(andgroupsof )measurementsoncetheyhavebeen

uploaded to the IDM software.

Use the UP and DOWN buttons to navigate between the criteria and the ENTER

button to select. Within each criteria, use the UP and DOWN buttons to navigate

between the options and the ENTER button to select.

Press the scan button to return to the measurement screen.

Document: 1.04.04 Rev6

The Measurement Settings Criteria

Waveform

There are three options for displaying the waveform. These are RAW, ENVELOPE

and BOTH

Material

Selectfromthestandardvelocitiespre-installedintheWAND. Newvelocitiescanbe

entered either directly into the WAND or via the IDM software.

Peak detection

TheultrasonicthicknesscanbecalculatedfromtheA-scanusingeithertherstpeak

or a measurement between two peaks (peak-to-peak).

Sensor history

EnablingthisoptionwilldisplaythehistorytableforeachTMSsensorwhenathickness

reading is saved.

Averaging

Averaging can be DISABLED or ENABLED. When ENABLED, the WAND will

average over 8 measurements per second when the scan button is depressed. The

thicknessmeasurementdisplayedwillbetheaverageofallmeasurementstakenwith

the scan button depressed.

Minimum thickness

A minumum thickness value can be set. The WAND will then not calculate any

thicknessvaluesbelowthatthreshold. Thisisrecommendedforstructures>50mm

Document: 1.04.04 Rev6

Measure Measure

Settings

Device

Settings History

The‘DeviceSettings’menuoptionsallowsuserstocongureoperatingparameters

of the WAND.

Figure 6 is a screenshot of this menu option and displays the criteria that can be

congured. There are two columns of options. Only the left hand column can be

congured; the right hand column displays xed device settings.

Use the UP and DOWN buttons to navigate between the criteria and the ENTER

button to select. Within each criteria, use the UP and DOWN buttons to navigate

between the options and the ENTER button to select.

Press the scan button to return to the measurement screen.

Figure 6: Device settings screen

Document: 1.04.04 Rev6

Congurable Device Settings

RFID En.

The RFID functionality can be ENABLED or DISABLED.

Shutdown:

This can be used to set the inactivity time after which the device will shut down.To

optimise battery life it is recommended not to set the inactivity time to ‘never’.

Units:

METRIC or IMPERIAL units can be selected.

Time zone:

The user can select the desired time zone for the location.

Set Time:

The time on the probe can be changed (24 hour-minute-second).

Set Date:

The date can be edited (Day/Month/Year).

Document: 1.04.04 Rev6

Measure Measure

Settings

Device

Settings History

The History screen can be used to display the last 5 A-scans.

Use the UP and DOWN buttons to navigate between the records and the ENTER

button to select. The A-scan will be displayed along with the calculated thickness

and location.

With the A-scan displayed, the LEFT and RIGHT buttons will zoom in and out

respectively.

To select another record, return to the HISTORY screen via the Menu Bar and

repeat the steps above.

If there are other thickness measurements from the same TMS sensor stored on

the WAND these can be viewed by pressing enter.

Document: 1.04.04 Rev6

FCC Compliance Statement:

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interfer-

ence that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are de-

signed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment gener-

ates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense must only be used in industrial

environments and not residential ones.

Document: 1.04.04 Rev6

Indusctosense Limited

Unit DX, St Philips Central

Albert Road, Bristol, BS2 0XJ

United Kingdom

Oce: +44(0)1174034047

www.inductosense.com

@inductosense

RegisteredinEnglandandWaleswithregisterednumber09689612andVAT

registered number 227006245

Table of contents