2 Industrial Air Technology Corp.

1.0 GENERAL INFORMATION

Industrial Air Technology Industrial Silencers are designed

for continuous duty in an industrial environment. They are

engineered for predictable performance and trouble free

operation. Each silencer is thoroughly inspected by trained

factory personnel prior to shipping. When properly installed

and maintained, your silencer will provide many years of

trouble free operation. This manual applies to all Industrial

Air Technology silencers. (Specially engineered silencers for

unique applications may require additional instructions, and

will be included with the silencer.) Read and adhere to the

instructions in this manual and retain for future reference.

2.0 RECEIVING AND INSPECTION

All silencers ship f.o.b. factory. Silencers are prepared

for shipment according to the uniform freight classication

rules of the carriers. The equipment is carefully inspected

and when possible tested before shipment and it is the

responsibility of the carrier that it is in perfect condition upon

arrival. When the carrier accepts a shipment and signs the

bill of lading, it becomes responsible for any subsequent

shortages or damage, evident or concealed, and any claim

must be made against the carrier.

Immediately upon receipt of a shipment, carefully inspect

for damage and shortage. If any damage and/or shortage is

detected or suspected, the carrier must be asked to conduct

an inspection. The consignee’s representative should not

accept shipment without a notation on the delivery receipt

indicating items not delivered or apparent extent of damage.

When a shipment is opened and damage found which was

not evident externally (concealed damage), it is mandatory

that the consignee request an immediate inspection by the

carrier. Promptly le a claim against the nal carrier.

2.1 HANDLING

The silencer should only be lifted by the lifting eyes or

mounting supports. Lifting decisions must be left to trained

personnel.

2.2 STORAGE

Any silencer stored for a period of time must be protected

from dirt and moisture. Use of a tarp to cover the unit will aid

in keeping it clean and dry. Do not use a black plastic tarp, as

it will promote condensation. Preferably, silencers are kept

indoors while in storage and protected from the elements.

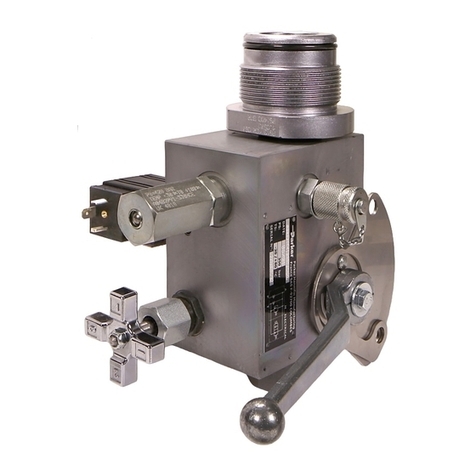

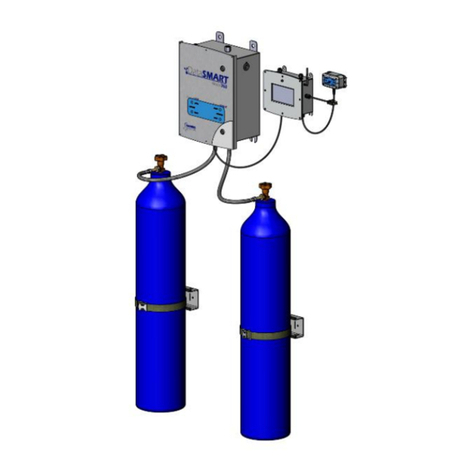

3.0 INSTALLATION

Remove the skid, crate, and packing materials carefully. The

silencer and ductwork must be adequately supported; a fan

is not designed to provide support for a silencer. Reference

images below.

In most instances, exible connections are recommended

between the silencer and the fan to avoid loading on the fan

from the weight of the silencer, and transmission of vibration.

Reference image below.

Flexible

Connectors

1.0 General Information

2.0 Receiving and Inspection

2.1 Handling

2.2 Storage

3.0 Installation

4.0 Maintenance

5.0 Troubleshooting

Contents