TechDoku_CC1000_VCC1000_CC3000_VCC3000_GenPM_GB_86025010_86025110.doc

Contents

Contents...........................................................................................3

1General information............................................................1–1

1.1 Scope of delivery and responsibilities..................................1–1

1.2 Liability, warranty and guarantee.........................................1–1

1.3 Responsibility of operating company...................................1–1

1.4 EC-conformity.....................................................................1–2

1.5 Observation of the product..................................................1–2

2Safety...................................................................................2–1

2.1 Intended use.......................................................................2–1

2.2 Demands on staff, duty for utmost care...............................2–2

2.3 Protective measures ...........................................................2–2

2.3.1 Concept of safety................................................................2–3

2.3.2 Protective gear....................................................................2–3

2.3.3 Safety equipment................................................................2–3

2.3.4 Main switch with emergency stop function ..........................2–4

2.3.5 Safety markings on the unit.................................................2–4

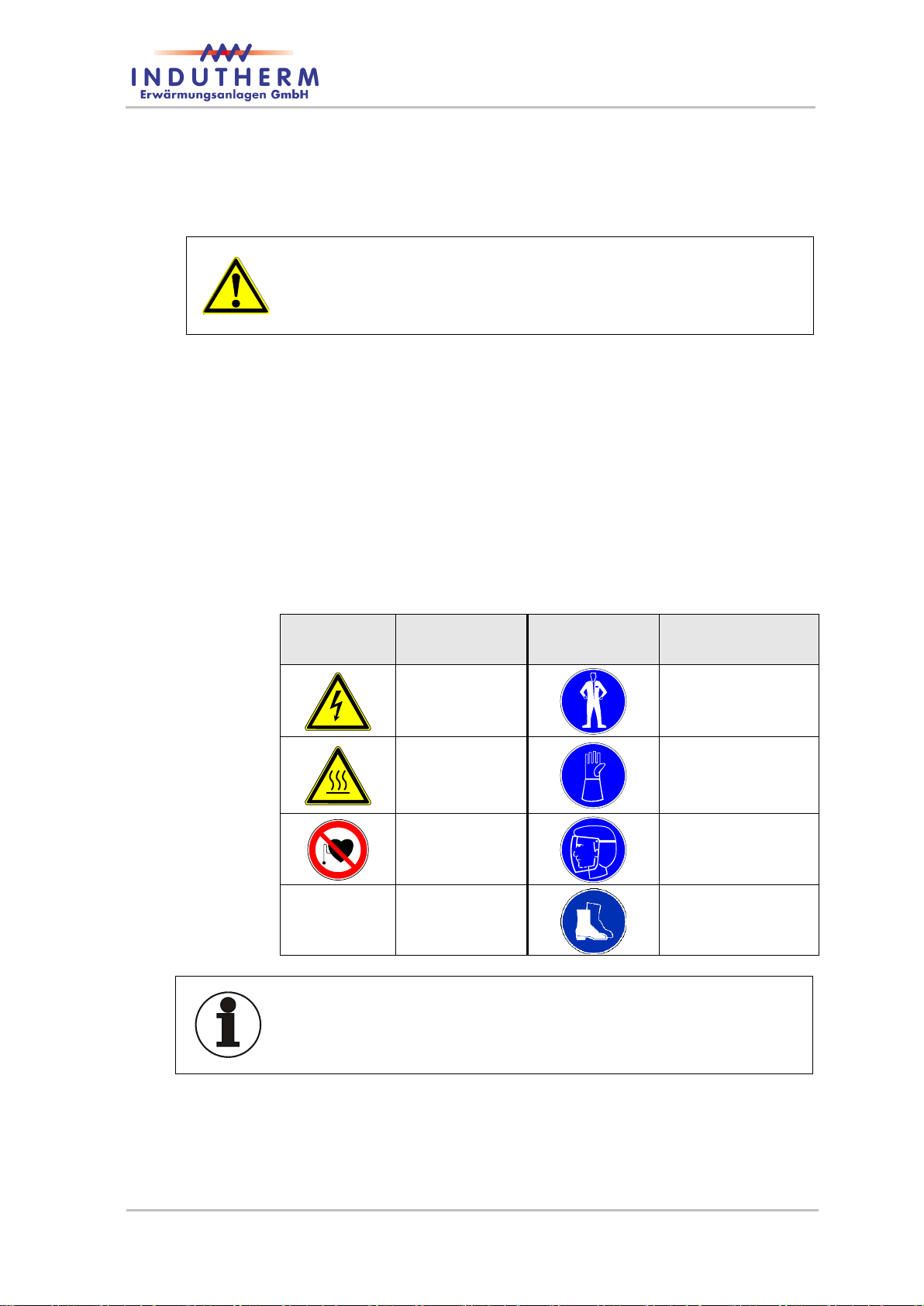

2.4 Safety marking....................................................................2–5

2.5 Safety advices.....................................................................2–6

2.6 Residual risks....................................................................2–10

2.7 Behaviour in an emergency...............................................2–10

3Technical data.....................................................................3–1

4Description of the system ..................................................4–1

4.1 Components of the system..................................................4–1

4.2 Schematic representation....................................................4–2

4.3 Backside connections .........................................................4–5

4.4 Setup of the crucible chamber.............................................4–6

4.5 Additional operating elements.............................................4–7

4.6 Special options..................................................................4–11

4.6.1 Granulation tank................................................................4–11

4.6.2 Hinged window..................................................................4–12

4.6.3 Refill system......................................................................4–13

4.7 Description of function.......................................................4–14

5Transport.............................................................................5–1

6Mounting and commissioning ...........................................6–1

6.1 Safety advices for mounting................................................6–1

6.2 Mounting process................................................................6–1

6.3 Apply supply connections....................................................6–2

6.3.1 Power supply ......................................................................6–2

6.3.2 Cooling water......................................................................6–2

6.3.3 Protective gas.....................................................................6–3

6.3.4 Vacuum for VCC.................................................................6–3