86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 2

Contents

Contents..........................................................................................................................2

1Introduction.............................................................................................................3

1.1 General description of the VC400 .......................................................................3

1.2 Machine components ..........................................................................................3

1.3 Technical data.....................................................................................................4

1.4 General information.............................................................................................5

2Putting into operation..............................................................................................7

2.1 Set-up directions..................................................................................................7

2.2 Mains supply........................................................................................................7

2.3 Cooling water.......................................................................................................7

2.4 Protective gas (Argon or Nitrogen) ......................................................................8

2.5 Vacuum ...............................................................................................................8

2.6 Gas out................................................................................................................8

2.7 Vacuum pump socket..........................................................................................8

2.8 RS232 Connector................................................................................................8

3Safety .....................................................................................................................9

3.1 Intended use........................................................................................................9

3.2 Demands on staff, duty for utmost care.............................................................10

3.3 Protective measures..........................................................................................10

3.4 Safety marking...................................................................................................13

3.5 Safety advices...................................................................................................14

3.6 Residual risks ....................................................................................................17

3.7 Behaviour in an emergency situation.................................................................17

4Operation..............................................................................................................18

4.1 Operating elements ...........................................................................................18

4.2 Casting ..............................................................................................................23

4.3 Possible causes for dissatisfying casting results...............................................26

4.4 Configuration of flask.........................................................................................27

4.5 Granulating........................................................................................................28

5Consumable parts ................................................................................................29

5.1 Assembly drawing VC400..................................................................................29

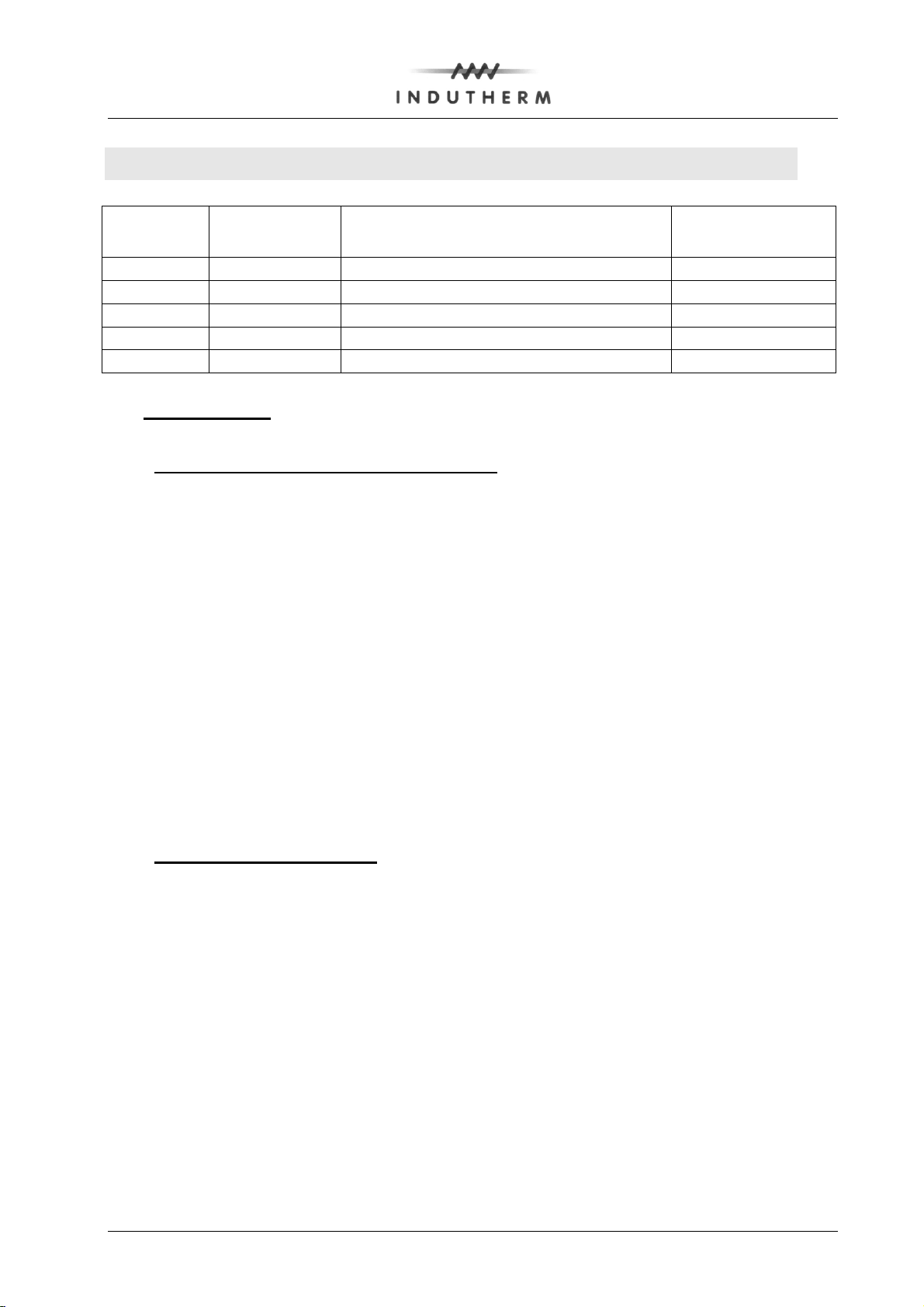

5.2 Consumables and spare parts list .....................................................................30

6Service..................................................................................................................33

6.1 Troubleshooting.................................................................................................33

6.2 Diagram casting flasks without flange ...............................................................34

6.3 Diagram casting flasks with flange ....................................................................34

6.4 Maintenance......................................................................................................35

6.5 Declaration of conformity...................................................................................36

7Connection diagrams............................................................................................38

8Test result chart....................................................................................................41

9Software documentation.......................................................................................42