Inel YYGL35RE-10/17 User manual

P. I. E. INEL Sp. z o. o., ul. Mostowa 1, 80-778 Gdańsk, [email protected] www.inel.gda.pl

Operating instructions

Obstacle detection motor with built in radio receiver and

electronic limit switches

YYGL35RE-10/17

YYGL45RE-20/15

1. SAFETY GUIDELINES

1.1 Basic guidelines

The obstacle detection motor is delivered in a condition allowing

for safe installation and operation, provided that all guidelines

herein as well as relevant safety and accident prevention

regulations are observed. Only qualified and licenced personnel

is allowed to install and repair electrical devices. It is prohibited to

make any changes or modifications to the drive. Warranty repairs

may be conducted only by the manufacturer. Use only original

spare parts and accessories during post-warranty repairs.

Operational safety of the drive can only be ensured if it is used for

its intended purpose. Do not exceed limit values given in

technical information.

1.2 Additional safety regulations

Observe relevant safety and accident prevention regulations

when installing, commissioning and maintaining the drive. The

following must be given special consideration:

1. Fire safety regulations.

2. Accident prevention regulations.

1.3 General notes on risks and safety measures

These notes are general guidelines for the use of INEL devices in

combination with other devices. These guidelines must be strictly

observed when installing and operating the devices.

Warning - against possible damage to the drive,

roller blind, roller blind cassette, elevation etc. if no

relevant safety measures are taken:

• Check if all screw connections are secure before

installing the drive and setting limit switches

Danger - means that there is a threat to life and

limb of the user if no relevant safety measures are

taken:

Check the compatibility of the permissible voltage

of the device with the local power supply before connecting.

Observe applicable safety and accident prevention

regulations.

Use an isolation switch allowing for safe power supply

disconnection (e.g. fuse cut-off switch) installed in such a

way that all connections can easily be cut out.

Inspect wires and cables regularly for damaged insulation

and conductor continuity.

If any damage is identified, cut off power immediately and

replace the damaged wiring.

1.4 Warning

Do not allow children to play with control devices.

Keep the remote control out of reach of children.

Observe the moving roller blind and keep people away until

it fully opens or closes.

The users of the roller blind must be instructed in its

operation and existing risks related to its usage. Persons

are deemed to have been trained if the employer,

administrator or owner allowed them to use the roller blind

and instructed them in its operation.

It is not permitted to dispose of waste equipment

together with other waste. Dispose only in specially

designated areas. The household plays a key role in the

recycling of waste equipment. By correct sorting of waste,

including waste equipment and batteries, household members

ensure that the equipment is not disposed together with

household waste, but in specially designated areas, and thus

may be used again after recycling.

2. INSTALLATION INSTRUCTIONS

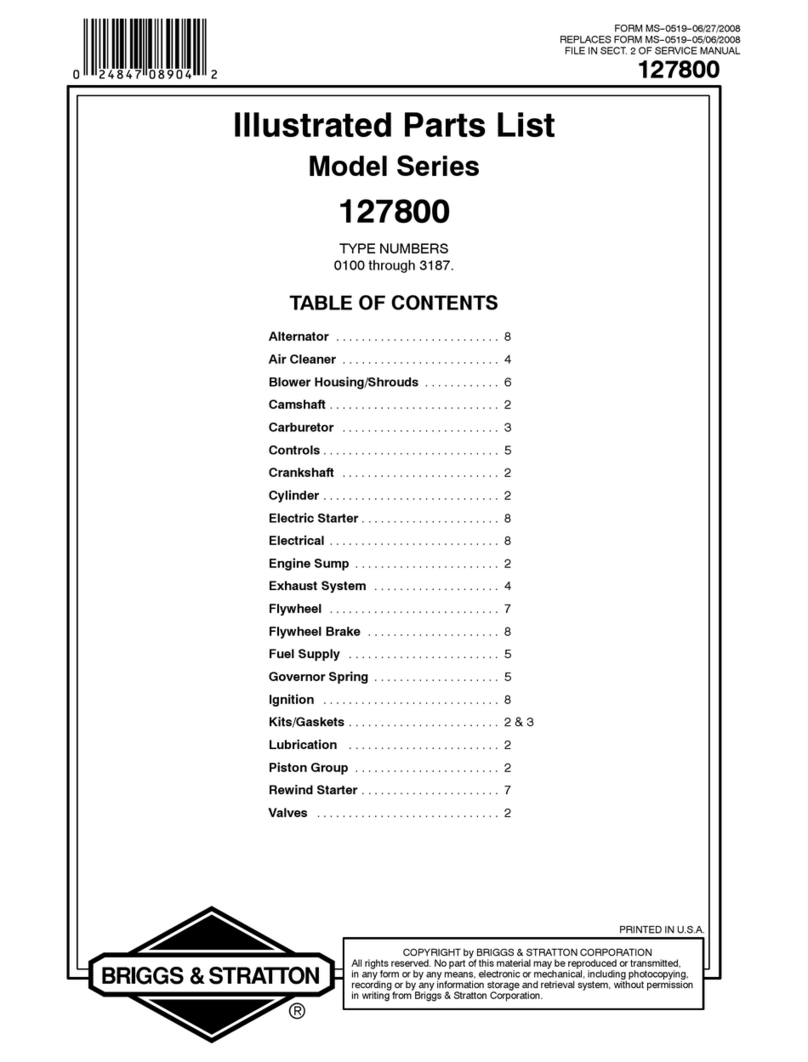

2.1 Safety regulations

Only persons with appropriate authorisation may install the

drive.

The weight of the roller blind may not exceed the maximum

load of the drive specified in the selection table (see the end

of the instructions)

Routing the cable properly (loop aimed downwards) will

protect the drive against any water damage.

Do not drill holes in motor housing.

Protect the motor against contact with any liquids.

Avoid crushing and impacting the motor, protect the motor

against shock.

Do not connect more than one on/off switch to a single

motor.

Do not connect more than one motor to a single on/off

switch.

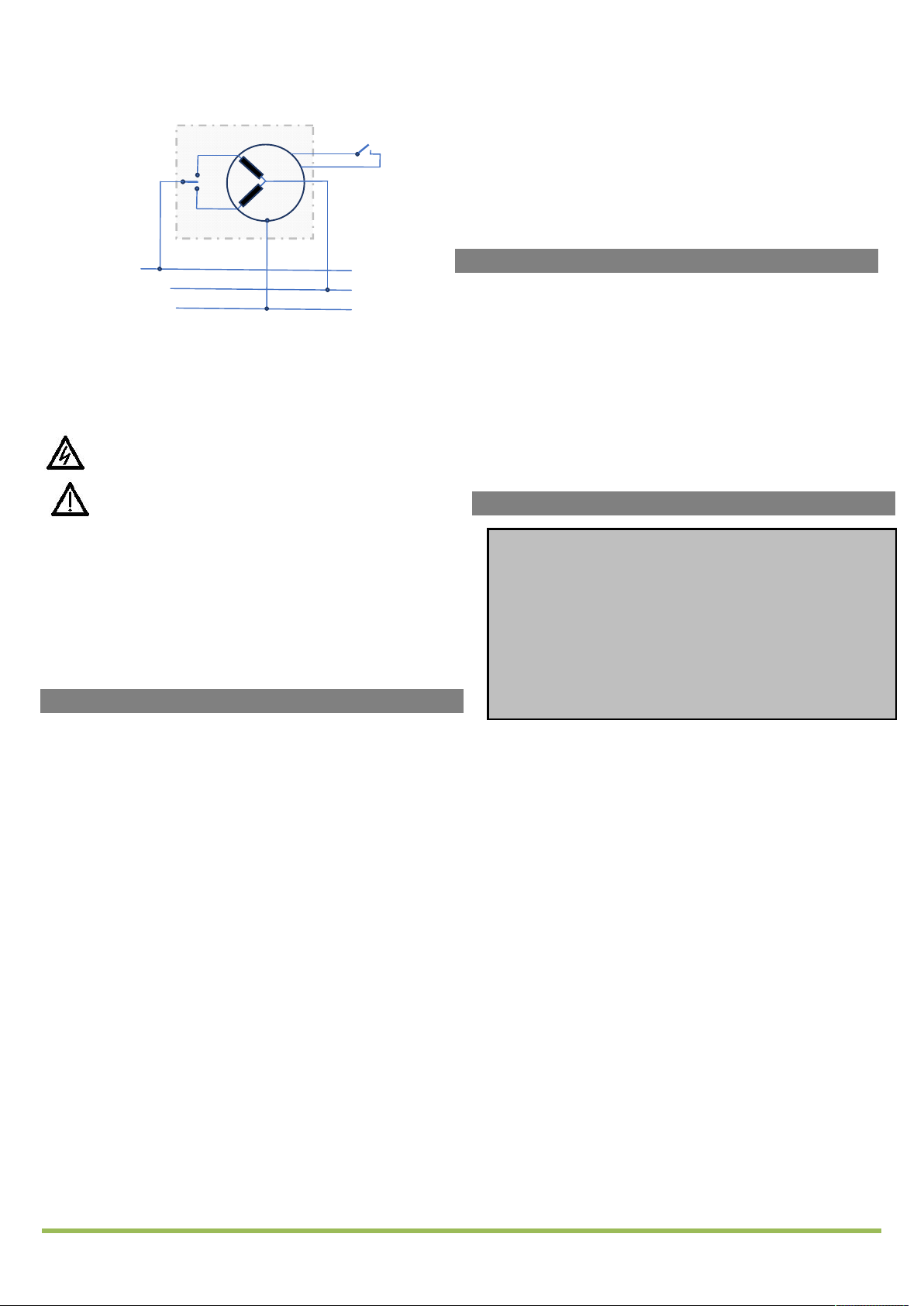

Figure 1

2.2 Installing the motor

Fix the mounting bracket (A) to the side of the roller blind

cassette, connect the adapter (D) to the thrust ring of the

motor (C).

Place an appropriate driver provided with the motor (E) on

the motor axis, secure it with a pin (F), and slide the entire

motor to the roller tube (G).

WARNING: The motor is fitted with an internal thermal cut-out

which allows the roller blind to work continuously for ca. 4 min.

After this time the temperature inside the motor will exceed the

permissible value, which will cause power cut-out. Subsequent

vertical movement of the roller blind will only be possible after the

motor cools down (it can take up to twenty minutes). Using this

cut-out greatly increases the life of the drive

Figure 2

NO

YES

P. I. E. INEL Sp. z o. o., ul. Mostowa 1, 80-778 Gdańsk, [email protected]

www.inel.gda.pl

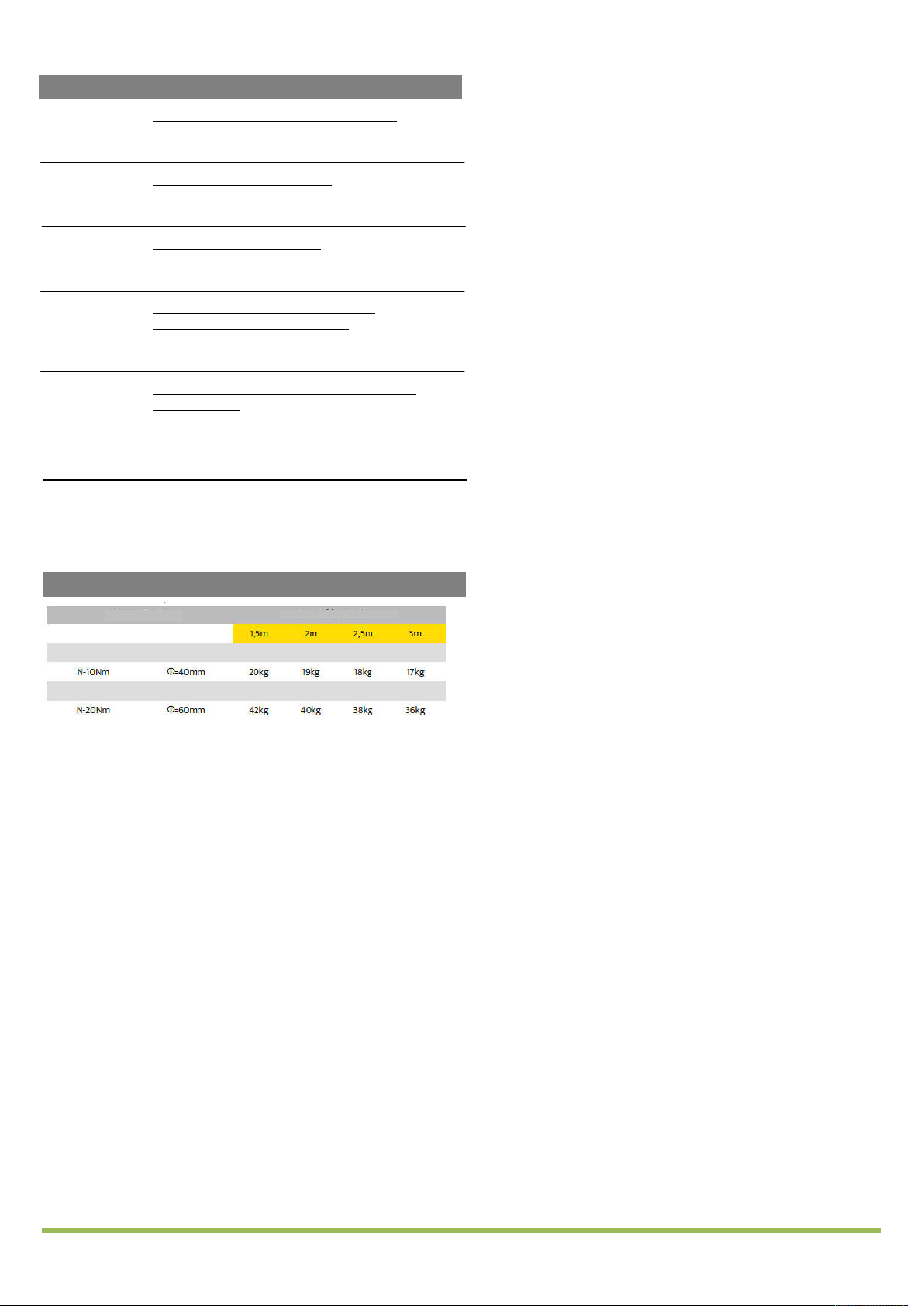

2.3 Electrical connections

A monostable switch can be connected to the motor, which will

short the control signal (black wire) with ground (grey wire) when

pressed.

The switch operates in a loop: up - stop - down - stop.

DISCONNECT POWER SUPPLY BEFORE MAKING

ANY CONNECTIONS!

Improper roller blind installation will cause the

motor to stop unexpectedly.

In order for the obstacle detection drive to function properly,

the following is required:

1. Use a special driver provided with the motor (figure 2-E)

2. Ensure that the curtain can move freely in the guides and

the cassette. This movement may not be obstructed (e.g.

by increase of the roller blind cassette temperature,

mosquito net etc.)

3. REGISTERING REMOTE CONTROLS

The motor is compatible with the following remote controls: PIL-

01/04NS, 01/05/09/19PM, PIL-19/99PMT, PIL-01/05/09/19DL,

PIL-19/99DLT, PIL-01PT.

Our drives allow for two methods of entering the remote control

registration mode:

3.1. Each time after connecting to mains each drive will

enter the registration mode for 10 seconds.

After the motor is received from the manufacturer or if the

remote control is lost, a new remote can be registered as

follows:

Connect the drive to the mains: 230 VAC. The motor will make

two up-down movements. Within 10 seconds from connecting

to the mains, press the ▲ and ▼ buttons on the remote control

at the same time for the selected channel

The drive will make a short up and down movement. Within the

next 10 seconds register the channel by pressing ▲.

The registration will be confirmed by a short up-down

movement.

WARNING: The procedure will erase all previously

registered channels from the memory. This will allow to

register a remote control with a drive without another

registered remote control (new drive or lost/stolen remote).

3.2. Entering the registration mode with a previously

registered remote control.

If a remote control has already been registered, subsequent

channels of the same or another remote can be registered

without disconnecting from the mains. On the registered

remote,

press the ▲ and ▼ buttons at the same time.

The roller blind will move up and down. It will remain in

registration mode for the next 10 seconds. During that time, in

order to register a new channel of the same or another remote,

select the desired channel on the remote and press the ▲

button.

This way you can register any channel to any drive, but only if

you have a previously registered remote control.

4. INVERTING MOVEMENT DIRECTION

If you need to invert the movement of the roller blind (roller blind

movement direction does not match the directions on the

remote control), you must enter programming mode (with a

previously registered remote).

Press the ▲ and ▼ buttons on the remote at the same time, the

motor will make a short up-down movement, then press STOP,

the motor will make another short up-down movement. Press ▲

and ▼ again, and then STOP, the motor will move up-down-

down-up.

WARNING: Changing motor direction will delete limit

positions.

5. PROGRAMMING

In the factory mode and during limit position set-up the drive

will move with a 1-second pause immediately after start - this

means that no limit positions have been set.

5.1. BEFORE PROGRAMMING

A. Check whether the direction of roller blind movement

matches the buttons on the remote control (if they are

opposite, use the remote to switch them around). See

section 4.

B. Place the lower edge of the curtain at half the height of

the guides. Starting the programming procedure too

near the roller blind cassette may damage it.

WARNING! Programming always starts with the set-up of

the upper limit.

5.2. AUTOMATIC LIMIT PROGRAMMING

The programming procedure may be performed

automatically only if blocking hangers and stoppers are

used, and a sill is mounted in the window. The length of the

curtain must be adjusted to the length of the guides.

1. Press and release the "↑" button on the remote, the

drive will move upwards.

2. At the top, the drive will stop on the stoppers, after 3

seconds it will set the upper limit and switch movement

direction. At the bottom the drive will stop as soon as it

reaches the sill and set the lower limit, after which it will

Before drive startup/programming check the condition of

the curtain, guides and roller blind cassette and whether

there is a sill mounted in the window!

The roller blind cassette and guides should be free from

any contaminants and ensure unrestricted curtain

movement throughout the entire length. If the guides are

contaminated with building materials or are too tight, they

can cause damage to the drive and the roller blind, which

is not covered by the warranty.

Figure 3

N - neutral

PE - protective

L -

brown

yellow-green

black

blue

grey

P. I. E. INEL Sp. z o. o., ul. Mostowa 1, 80-778 Gdańsk, [email protected]

www.inel.gda.pl

return to the upper limit and confirm that programming is

finished.

WARNING! Stopping the motor with a remote control

during automatic programming will automatically enter

the SEMI-AUTOMATIC programming mode.

5.3. SEMI-AUTOMATIC LIMIT PROGRAMMING

UPPER LIMIT

Upper limit in the desired position (if no stoppers are

present):

a. Press and release the "↑" button on the remote control.

b. Press the STOP button on the remote control in the desired

upper limit position. You may correct this position after

switching the remote into shutter mode.

c. To confirm the upper limit, press the STOP button on the

remote. The roller blind will confirm the registration of the

upper limit by making two sequences of short down-up

movements.

d. At this point start programming the lower limit.

OR

Upper limit by overload (if stoppers are used):

a. Press and release the "↑" button on the remote control.

b. Press the STOP button after the drive stops (if the button is

not pressed within 3 s the drive will enter automatic

programming mode). You may correct this position after

switching the remote into shutter mode.

c. To confirm the upper limit, press the STOP button on the

remote. The roller blind will confirm the registration of the

upper limit by making two sequences of short down-up

movements.

d. At this point start programming the lower limit.

LOWER LIMIT

Lower limit in the desired position:

a. Press and release the "↓" button on the remote control.

b. Press the STOP button on the remote control in the desired

lower limit position. You may correct this position after

switching the remote into shutter mode.

c. To confirm the lower limit, press the STOP button on the

remote. The roller blind will confirm the registration of the

lower limit by making three sequences of short up-down

movements.

d. Press and release the "↑" button on the remote, the roller

blind will start moving towards the upper limit, where it will

confirm the end of programming.

OR

Lower limit on sill:

a. Press and release the "↓" button on the remote control.

b. The drive will stop on the sill. You may correct this position

after switching the remote into shutter mode.

c. Press and release the STOP button to confirm the lower

limit. The roller blind will confirm the registration of the

lower limit by making three sequences of short up-down

movements.

d. Press and release the "↑" button on the remote, the roller

blind will start moving towards the upper limit, where it will

confirm the end of programming.

In the semi-automatic lower limit programming phase (on sill),

the motor will attempt to detect the type of hangers used. After

the drive detects the sill, it will make another 1/4 revolution. If

no overload is detected at this point (lower RPM), it will move

back by 1/4 revolution (no blocking hangers detected). If

overload is detected during the 1/4 revolution, the motor will

stop at the position of overload (blocking hangers detected).

Press the "↑" to set the limit.

6. RETURN TO FACTORY MODE

Press the ▲ and ▼ buttons on the remote at the same time, the

motor will make a short up-down movement, then press STOP.

The motor will make another short up-down movement.

Perform this operation 4 times.

7. OBSTACLE DETECTION OPERATING PRINCIPLE

Before limit positions are set (factory mode), the motor will

only detect decreased rpm caused by overload. The

obstacle detection function will be activated only after both

limit positions are set.

Obstacle detection works only for downward movement.

During upward movement, the drive will stop if decreased

rpm are detected.

If the roller blind stops unexpectedly (an obstacle appears),

the drive will move in the opposite direction in order to

release curtain tension, allowing you to remove the obstacle.

P. I. E. INEL Sp. z o. o., ul. Mostowa 1, 80-778 Gdańsk, [email protected]

www.inel.gda.pl

8. TROUBLESHOOTING

Problem: The motor does not react to commands

Cause: Thermal cut-out was activated

Solution: Wait for 10-20 minutes

Problem: Curtain fins do not close fully

Cause: The curtain is blocked in the guides

Solution: Check the roller blind guides and curtain slats

Problem: The motor stops on its own

Cause: The curtain is blocked in the guides

Solution: Check the roller blind guides and curtain slats

Problem: Blocking hangers were not detected

in semi-automatic programming

Cause: Roller blind curtain too long.

Solution: Shorten the curtain to appropriate size.

Problem: The motor does not detect obstacles when

moving down.

Cause: Limits programmed wrong way.

Solution: Reset the drive to factory mode, then repeat the

programming procedure, starting from the upper

limit.

WARNING! Pauses between individual presses of the remote

control buttons should be at least 1 second long! This

applies both to the programming and operating mode (after

programming limit positions).

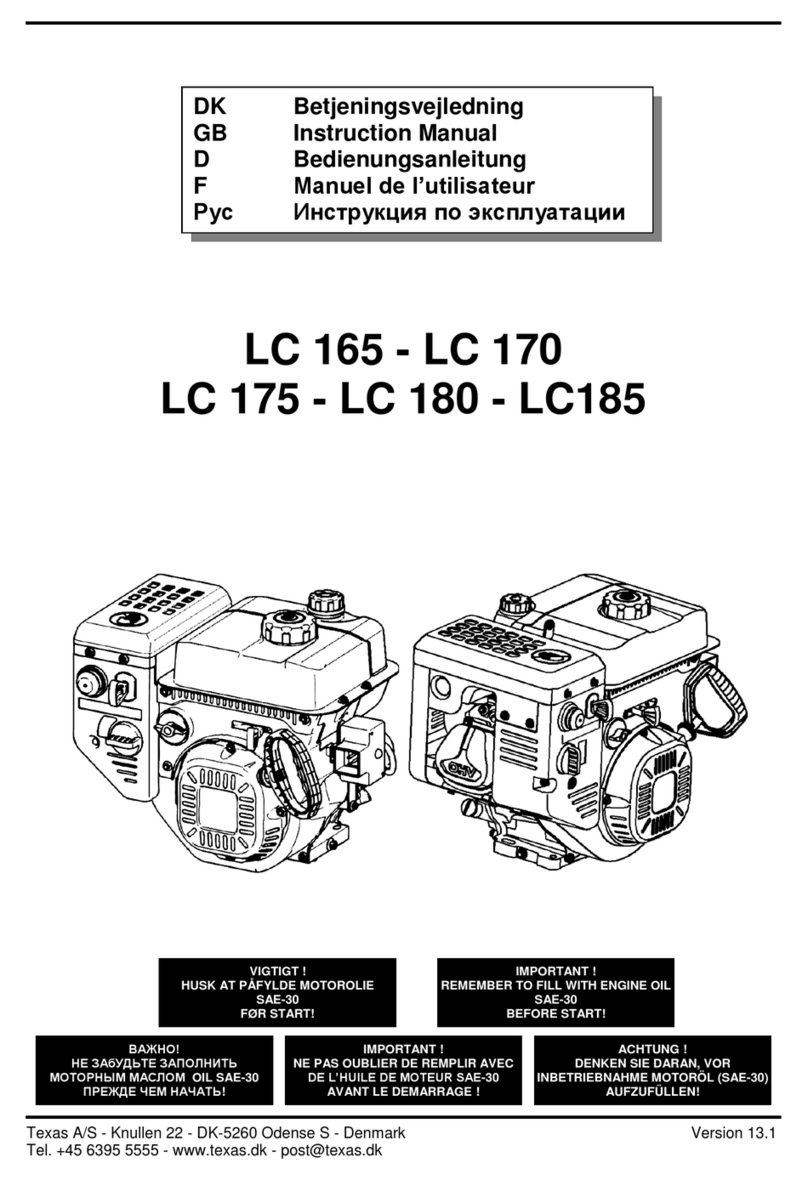

9. MOTOR SELECTION TABLE

TORQUE

ROLLER BLIND LENGTH

This manual suits for next models

1

Other Inel Engine manuals

Popular Engine manuals by other brands

Texas

Texas LC 165 instruction manual

Beckhoff

Beckhoff AM8100 Series operating instructions

DELTA DORE

DELTA DORE TYMOOV radio RP2 Series quick start guide

Nissei

Nissei GTR ECO Series Detailed instruction manual

Westerbeke

Westerbeke 63B FOUR Operators manual and installation guide

HIOTH TECHNOLOGY

HIOTH TECHNOLOGY CT-HAZB1033-JY user manual