P. I. E. INEL Sp. z o. o., ul. Mostowa 1, 80-778 Gdańsk,

[email protected] www

.inel.gda.pl

Operating instructions

Obstacle detection motor with electronic limit switches

YYGL35E-10/17

YYGL45E-20/15

1. SAFETY GUIDELINES

1.1 Basic guidelines

The obstacle detection motor is delivered in a condition allowing

for safe installation and operation, provided that all guidelines

herein as well as relevant safety and accident prevention

regulations are observed. Only qualified and licenced personnel is

allowed to install and repair electrical devices. It is prohibited to

make any changes or modifications to the drive. Warranty repairs

may be conducted only by the manufacturer. Use only original

spare parts and accessories during post-warranty repairs.

Operational safety of the drive can only be ensured if it is used for

its intended purpose. Do not exceed limit values given in technical

information.

1.2 Additional safety regulations

Observe relevant safety and accident prevention regulations

when installing, commissioning and maintaining the drive. The

following must be given special consideration:

1. Fire safety regulations.

2. Accident prevention regulations.

1.3 General notes on risks and safety measures

These notes are general guidelines for the use of INEL devices in

combination with other devices. These guidelines must be strictly

observed when installing and operating the devices.

Warning - against possible damage to the drive,

roller blind, roller blind cassette, elevation etc. if no

relevant safety measures are taken:

• Check if all screw connections are secure before

installing the drive and setting limit switches

Danger - means that there is a threat to life and limb

of the user if no relevant safety measures are

taken:

Check the compatibility of the permissible voltage

of the device with the local power supply before connecting.

Observe applicable safety and accident prevention

regulations.

Use an isolation switch allowing for safe power supply

disconnection (e.g. fuse cut-off switch) installed in such a

way that all connections can easily be cut out.

Inspect wires and cables regularly for damaged insulation

and conductor continuity.

If any damage is identified, cut off power immediately and

replace the damaged wiring.

1.4 Warning

Do not allow children to play with control devices.

Keep the remote control out of reach of children.

Observe the moving roller blind and keep people away until

it fully opens or closes.

The users of the roller blind must be instructed in its

operation and existing risks related to its usage. Persons are

deemed to have been trained if the employer,

administrator or owner allowed them to use the roller blind

and instructed them in its operation.

It is not permitted to dispose of waste equipment

together with other waste. Dispose only in specially

designated areas. The household plays a key role in the

recycling of waste equipment. By correct sorting of waste,

including waste equipment and batteries, household members

ensure that the equipment is not disposed together with

household waste, but in specially designated areas, and thus may

be used again after recycling.

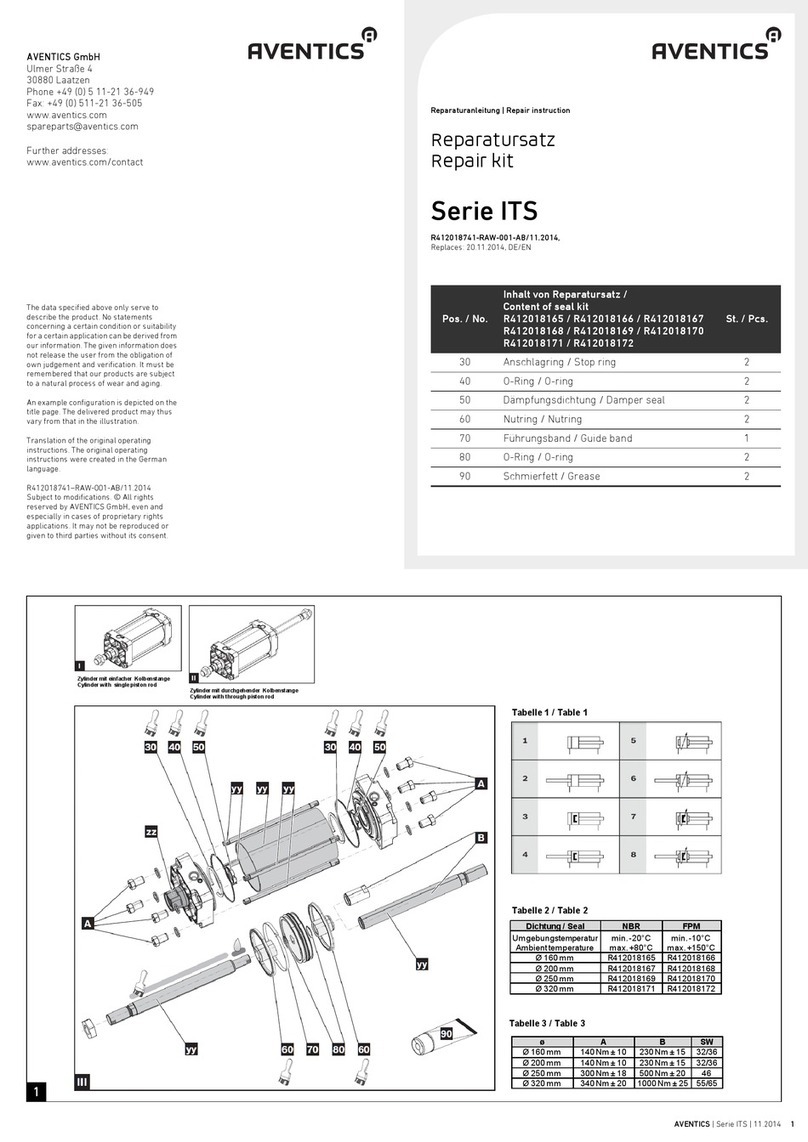

2. INSTALLATION INSTRUCTIONS

2.1 Safety regulations

Only persons with appropriate authorisation may install the

drive.

The weight of the roller blind may not exceed the maximum

load of the drive specified in the selection table (see the end

of the instructions)

Routing the cable properly (loop aimed downwards) will

protect the drive against any water damage.

Do not drill holes in motor housing.

Protect the motor against contact with any liquids.

Avoid crushing and impacting the motor, protect the motor

against shock.

Do not connect more than one on/off switch to a single

motor.

Do not connect more than one motor to a single on/off

switch.

Figure 1

2.2 Installing the motor

Fix the mounting bracket (A) to the side of the roller blind

cassette, connect the adapter (D) to the thrust ring of the

motor (C).

Place an appropriate driver provided with the motor (E) on

the motor axis, secure it with a pin (F), and slide the entire

motor to the roller tube (G).

WARNING: The motor is fitted with an internal thermal cut-out

which allows the roller blind to work continuously for ca. 4 min.

After this time the temperature inside the motor will exceed the

permissible value, which will cause power cut-out. Subsequent

vertical movement of the roller blind will only be possible after the

motor cools down (it can take up to twenty minutes). Using this

cut-out greatly increases the life of the drive

Figure 2