INELCO GRIDERS Ultima-Tig-Cut Installation and operating instructions

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 2

Translation of the original EU statement of compliance

Manufacturer: INELCO GRINDERS A/S

Industrivej 3, 9690 Fjerritslev, Denmark

Phone + 45 96 50 62 33, Fax. + 45 96 50 62 3

SE/VAT No: DK 32652964

E-mail: info@inelco-grinders.com

hereby declare that

Machine: ULTIMA-TIG-CUT

Type: UT110

Serial no.: see page 2

Year of production: see page 2

is produced in accordance with the provisions of the Commission’s Directive

on harmonization of national legislation’s on machinery 2006/42/EU, EMC-directive

2014/30/EU and RoHS2 directive 2011/65/EU.

Authorized to create the technical file: Anders Thy, Industrivej 3, DK-9690 Fjerritslev

ULTIMA-TIG-CUT is developed and produced according to the following international

norms:

EN 12100:2010, EN 50581:2012, EN 61029-1: 2009+A11,

EN 61000-6-4: 2005, EN 61000-6-2: 2007

Person responsible: Name: Anders Thy

Date: 01.12.2019

Signed: ____________________

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 3

Contents

1. General machine description................................................................................................4

2. What is included...................................................................................................................4

3. Operational elements...........................................................................................................5

4. Initial operation and transport...............................................................................................5

5. Safety procedures................................................................................................................6

6. Fastening of the electrode in the electrode holder................................................................6

7. Setting the grinding angle.....................................................................................................6

8. Electrode cutting ..................................................................................................................7

9. Maintenance ........................................................................................................................9

10. Replacement of the grinding disc .......................................................................................11

11. Replacement of the cutting disc .........................................................................................11

12. Field of application.............................................................................................................12

13. Technical specifications .....................................................................................................12

14. Training..............................................................................................................................12

15. Safety data sheet for grinding fluid.....................................................................................12

16. Spare parts overview..........................................................................................................13

17. Working table.....................................................................................................................16

18. Accessories........................................................................................................................17

IMPORTANT SAFETY INSTRUCTIONS

When installing and operating the machine the safety rules

enclosed

SUPPLIER’S DIRECTIONS

should be read and strictly observed.

This instruction manual and the accompanying supplier’s

instruction for use must be accessible at all times to staff engaged

in the installation, operation and maintenance of the machine.

DISPOSAL

Do not dispose electrical equipment in your ordinary waste disposal. The European

guideline 2012/19/EU on Electrical Equipment Waste and its implementation in national

laws requires such used equipment to be separately collected and recycled in an

environmentally friendly manner

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 4

1. General machine description

ULTIMA-TIG-CUT is a patented grinder and cutting devise with diamond discs for wet grinding and

cutting of tungsten electrodes for TIG welding. It is very easy and safe to use.

The diamond disc grinds the tungsten electrodes correctly in the longitudinal direction of the electrode,

and the variable angle adjustment allows you, not only to grind in the right angle, but also to grind the

tip flat, if needed.

Cutting function with the diamond-cutting disc, gives an exact and sharp cut of the tungsten electrode

in the precise length, without any risk of damaging the electrode.

The grinding liquid in the closed grinding and cutting chambers ensures that no harmful dust particles

slips out into the surroundings. The cooling effect of the grinding liquid also mean, that there are no

discoloration of the tungsten electrode due to heat.

The harmful grinding dust is collected automatically in the special dust collector and hence can be

disposed correctly.

The included electrode holder and electrode clamps, in combination with stick-out adjustment, reduces

the waste of electrodes, and ensures a uniform grinding result at each grinding.

The ULTIMA-TIG-CUT can be used in a room with an ambient temperature of 0° C to +40° and a

relative humidity of up to 50% at 40° C and 90% at 20° C. The machine are tested acc. protection class

IP21.

2. What is included

Upon reception und unpacking please, check that the following items are included in the package:

ULTIMA-TIG-CUT machine

2 dust collectors with liquid (Item No. 75494500)

2 x 250 ml bottles off grinding/cutting liquid (Item No. 75491200)

Tungsten electrode holder (Item No. 75520023)

Pickup (Item NO. 75500170)

Pickup Release (Item no. 75520021)

Electrode clamps for Ø1,6 - Ø2,4 and Ø3,2 mm

Clamps for cutting Ø1,6 - Ø2,4 and Ø3,2 mm

2 x Tip collector (Item No.75520049+75520050)

Worktable, incl. bolts and nuts for mounting

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 5

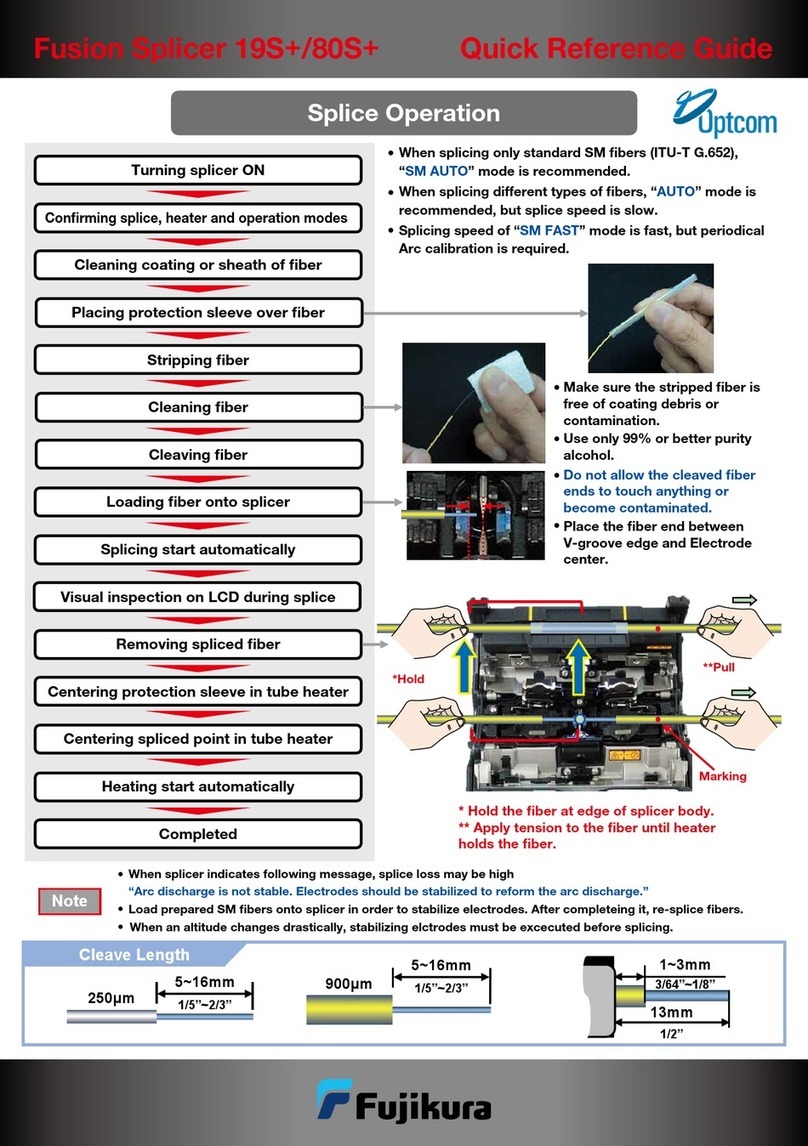

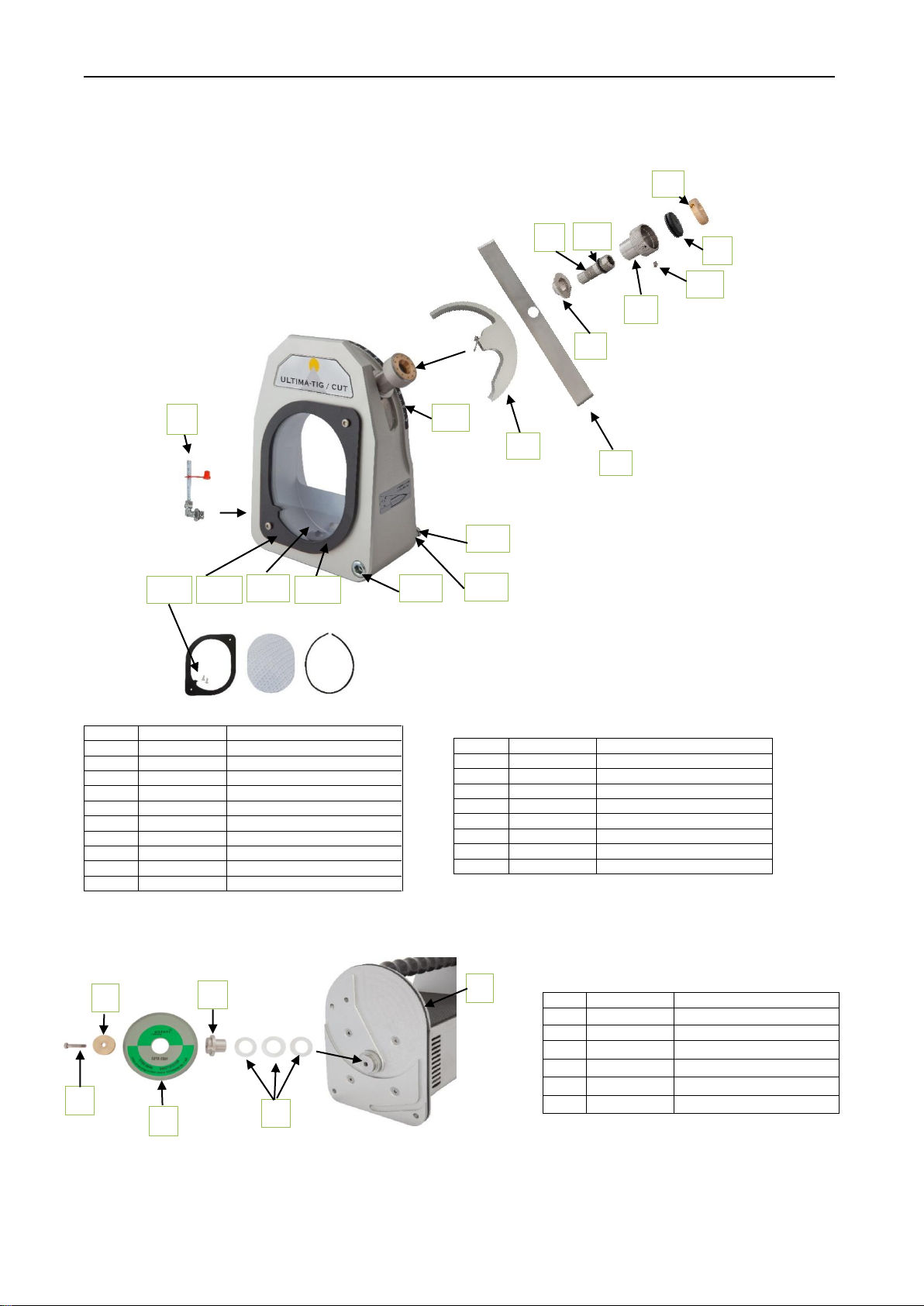

3. Operational elements

1. Power Switch

2. Degree scale

3. Electrode holder

4. Tightening screw to flatten the tip of the electrode

5. Stick-out adjustment

6. Length adjustment for cutting

7. Pickup

8. Tip collectors

9. Pickup release

10. Reset button

11. LED

12. Handle for cutting

4. Initial operation and transport

Remove the protective foil on the enclosed worktable and mount the worktable as shown in the

drawing in the back of this manual. Fasten the grinder on the worktable and place it securely on a

workbench or table.

IMPORTANT: The ULTIMA-TIG-CUT cannot run without grinding liquid!

The ULTIMA-TIG-CUT grinder does not contain grinding liquid on delivery. Before starting the

machine the first time, mount the supplied dust collectors and fill extra grinding liquid from the bottle

provided through the tube until the correct liquid level has been reached (please see mark on the

inspection cover frame). (See drawing and photos in the back of this manual)

Check that the switch is in the OFF position. (“O” on the switch)

Connect the machine to the mains voltage specified on the nameplate.

IMPORTANT: Only use single-phase power supply outlet WITH an earth connection.

12

4 2 6

1

3

5

9

8

7

11

10

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 6

5. Safety procedures

Never use the product if the grinding disc is damaged

Use only diamond discs recommended by Inelco Grinders A/S

Use the product only when all parts of the chamber is mounted

Use only the grinder with EP770 grinding liquid from Inelco Grinders A/S

Only grind Tungsten electrodes with electrode holder

Always use an appropriate size clamp to the electrode for grinding.

6. Fastening of the electrode in the electrode holder

Select the size of the electrode clamp that match the diameter of the electrode and mount it loosely

in the electrode holder. Then insert the electrode into the clamp, so that approximately 20 mm of the

electrode is sticking out of the clamp. Tighten the clamp with your fingers, but not so tightened that

the electrode cannot slide in the clamp.

Insert the electrode with the electrode holder into the stick-out setting (10),

placed below on the right front side of the grinding (see picture), until it stops.

Tighten the electrode with a smooth turn of the electrode holder clockwise.

Only fasten the electrode as tight, as it does not slide in the electrode clamp.

If the electrode is too tight fasten, you risk damage of the clamp.

On the back of the stick-out adjustment, there is a regulator screw (see

picture), which can be adjusted to determine the length of the electrode

sticking out of the clamp. The manufacturer has set the regulation screw to

grind approx. 0,3 mm in order to obtain the highest number of grindings per

electrode as possible.

This means, that you can re-grind the electrode up to 450 times. It is

necessary to adjust the stick-out as the diamond wheel wears down.

It is often not necessary to break off metal drops on the electrode before grinding. The metal drops

do not melt together with the electrode; the grinding process will remove them.

7. Setting the grinding angle

Adjust the grinding angle by placing the cursor (1) at the desired grinding

angle. Tighten the electrode guide by tightening the screw (2).

Note: the grinding angle equals half the tip angle!

2

1

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 7

After the tungsten electrode is inserted in the electrode holder, it is inserted in

the angle adjust unit until the electrode almost touches the diamond disc. Start

the machine at the on/off switch and turn the electrode holder in a calm and

steady pace andwith light pressure until the electrode holder cannotgo further

in. Keep turning the electrode holder for at least five rounds to get the best

possible grinding result.

It is not necessary to press the electrode hard against the diamond

wheel, a light pressure and the rotation of the grinding disc is sufficient

to grind the electrode.

Pull the electrode holder back a little, so that the electrode does not touch the grinding disc. Turn off

the grinder and pull out the electrode holder after the grinder has stopped turning.

Removed the electrode from the electrode holder by re-inserting the electrode into the stick-out

adjustment and turn it counterclockwise. Then pull out the electrode.

To create a flat tip on the electrode after grinding:

Setting grinding angle to 90° (while grinder is turned off)

Put the electrode holder with the electrode in the angle adjustment again

Turn the tightening screw on the angle setting down until you feel the tip of the electrode

touches the grinding wheel.

Then turn the tightening screw down. A point on the brass bearing on top of the screw

corresponds to remove 0.1 mm off the tip.

Pull the electrode away from the grinding disc.

Start the grinder and gently push down the electrode holder in a turning movement and

the tip is flattened.

Turn off the grinder and pull out the electrode holder.

8. Electrode cutting

Turn off the machine after grinding the electrode.

Loosen the electrode in the stick-out (1) on the cutting

console, pull out the electrode and tighten the electrode clamp,

using your fingers.

Set the cutting length, using the screw (2) for length stop

(4). The cutting length is the same as the distance between

the cutter console (3) and the length stop (4). Measure the

cutting length, using a caliper (not included). The cutting length

can be also adjusted by turning the Brass pin (5) on the

length stop.

1

2

4

3

5

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 8

Place the electrode holder in the stick-out on the cutting console and tighten the

electrode by turning the electrode holder.

Mount the clamp for the correct electrode diameter in the

Pickup (6) by pushing in the back part of the Pickup

and using your fingers to screw the clamp in. Please note

that the clamps for the Pickup are different (flat) from the

clamps for the electrode holder.

Warning: If the clamps for the electrode holder are used

in the Pickup, the clamps will be damaged by the cutting disc.

Mount the Pickup in the hole on the back of the cutting

console (7). Make sure the Catch for Pickup (8)

is holding the Pickup in place.

Place the electrode holder in the electrode guide (9),

and push it in, while releasing the Pickup with your fingers

(for short electrodes),

or with the Pickup release (10) (for long electrodes)

where the electrode pass through the Pickup, ensuring

that the electrode tip is secured in the Pickup.

After the electrode holder is in place, tighten the clamp for

the Pickup to ensure that the Pickup is kept in place during

cutting.

To avoid grinding liquid splashing out of the electrode guide on the

grinding part, the Pickup release (10) can be placed in the

electrode guide.

6

8

7

9

10

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 9

Turn on the machine.

Push in the handle (11) and slowly turn it clockwise

until the electrode is completely cut through and the handle

reaches the stop. Turn the handle back slowly until it comes

back out. To minimize burrs on the electrode tip, hold the

electrode holder tight during cutting, using the other hand.

Important: Turn the handle all the way to the right to make

sure that the electrode is cut through.

Turn off the machine.

Loosen the screw for the Clamp, release the clamp and remove

the Pickup.

Remove the burrs on the electrode tip, using the Deburring

block (12) before removing the tip from the Pickup.

The cutting length can be fine adjusted using the tightening screw on

the electrode guide. One round equals 1 mm. This adjustment is also

needed when long electrode clamps are used in the electrode holder,

when grinding and cutting short electrodes, to prevent the cutting disc

from damaging the electrode clamp.

For cutting off a damaged tip on an electrode, which has not been

grinded, use one of the supplied tip collectors instead of the Pickup

module. Choose the tip collector suitable for the diameter of the

electrode.

9. Maintenance

The ULTIMA-TIG-CUT must always have sufficient grinding liquid, in order to

secure an optimum collection of dust and cooling of the grinding process. A mark

on the glass frame of the grinding chamber indicate the correct amount of grinding

liquid (measured while the grinder is off). Check amount of grinding liquid regularly

and top up if necessary. To ensure a long service life of the grinder and the

diamond discs use original ULTIMA-TIG- CUT grinding liquid.

Replaced the grinding fluid heavily contaminated with dust.

11

12

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 10

Deposit grinding fluid and/or containers containing dust in accordance with national

regulations depending on the grinding dust content. Please see the data sheet of the selected

electrodes.

Daily Inspection

In order to secure free movement of the angle adjustment, move it all the way back and forward every

day. Not following this procedure, the machine will gradually collect dust inside the grinding chamber,

and as a result, the angle setting will be stuck and it is impossible to change the grinding disc. Also

make a daily check of the free movement of the arm for cutting.

Monthly/1000 grind service

Clean the grinding chamber when the LED lights yellow or at least once every

month following these steps:

1. Drain out the grinding fluid through the hose into an empty container.

2. Set the angle adjustment to 90°.

3. Remove the two screws, the frame and the inspection cover.

4. Wipe off thegrinding chamber with a cloth or paper towel. Eventually

remaining stuck dust can carefully be scraped off.

5. Mount the inspection cover and frame and top up with grinding liquid.

6. Reset the service counter by turning on the grinder and pressing and

holding the pushbutton for 3 seconds.

If the grinding liquid does not come out of the hose, it may be due to grinding

dust inside the grinding chamber blocking the hole. To get the grinding dust

away, press a little air or grinding fluid through the hose, using the grinding

fluid bottle.

Quarterly/5000 grind service

When the LED blinks yellow or at least once every three months clean the

inside of the grinding chamber following these steps:

The power to the ULTIMA-TIG must be turned off –pull out the plug.

1. Drain out the grinding fluid through the hose into an empty container.

2. Set the angle adjustment to 90°.

3. Remove the dust collector under the grinding chamber.

4. Place a support under the motor housing, ~20mm tall. Remove the three torx screws on

the back of the grinding chamber and the two bolts under the table. Now you can remove

the grinding chamber from the motor housing.

5. Clean out the grinding dust inside the grinding chamber. Dismantle the angle adjust unit if

necessary. Make sure the angle adjust unit can slide smoothly all the way back and forth.

6. When assembling the parts add bearing grease to all moving parts, screws and gaskets

except for the Inspection cover mounting.

7. Check the O-ring on the backplate before mounting the grinding chamber.

8. Mount and tighten the torx screws and the two bolts.

9. Carefully check the dust collector before mounting and top up with new grinding fluid.

10. Reset the service counter by turning on the grinder and pressing and holding the

pushbutton for 5 seconds.

Clean the Ultima-TIG-CUT thoroughly each time the grinding disc is replaced, when the dust

collector is full, or earlier if necessary. Perform cleaning as mentioned above.

Clean the Cutter module on the inside when changing the cutting disc. (See section 11)

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 11

Please ensure that the person cleaning the ULTIMA-TIG-CUT wears the appropriate safety gear e.g.

rubber gloves and protection glasses.

It can be difficult to remove the grinding dust from the aluminum parts without damaging the parts;

boiling hot water is an effective way to dissolve the grinding dust. Do not use chemicals, solvents or

high pressure cleaning.

Check the main cable regularly. Only qualified personnel must replace it. If necessary, contact Inelco

Grinders A/S or your local distributer for service.

10. Replacement of the grinding disc

Please follow the procedure below when disassembling the machine:

The power to the ULTIMA-TIG-CUT must be turned off –pull out the plug.

Tap of the grinding liquid from the grinding chamber; remove the two screws, the cover frame and

the plastic inspection cover. Set the grinding angle at 90°.The disc is now assessable. Unlock the

center screw (Note: Left-hand screw). Remove the U-wheel and the Grinding disc and mount a new

grinding disc.

11. Replacement of the cutting disc

Empty the liquid from the chamber and remove the dust collector.

Loosen the cutter module from the working table.

Remove the three screws from the back of the cutting house, and pull the

house away from the back plate.

Remove the four small

screws that holds the

cutting disc and remove the

cutting disc.

Replace the new cutting disc and mount the Plastic cogwheel, Washer and the screws again.

Clean all parts with water and make sure to collect this in the return bottle. Deposit the wastewater as

described under section 9. 20171448/16246

Apply grease on the inside of the console and on the edge of the rear plate where the two parts

meet each other. This facilitates the remounting and contributes to reseal the device.

Push the house back on to the rear plate and be careful to position the bar with the two wheels so

that the teeth on the plastic wheels fit on to the teeth of the cogwheel on the motor axel.

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 12

Also, make sure that the seal on the rear plate is correctly in place and not twisted while sliding the

house into place. Mount the three screws to fasten the house to the rear plate, mount the dust

collector and top up with additional liquid. The correct level of liquid is marked by (~~~) on the lover

square inspection cover.

12. Field of application

Only use the devise for grinding and cutting of tungsten electrodes.

13. Technical specifications

The Ultima-TIG-CUT are covered by Wolfram grinder patent application No. 95942059.7

Current class: (single-phase alternating current) 1x120V or 1x220-240V AC. Depending on themodel.

Please see the nameplate on the grinder for the power supply.

Safety protected with protective earth. Directive 2006/95/EU

14. Training

No special education is required to operate the ULTIMA-TIG-CUT. However, persons who are to

operate the ULTIMA-TIG machine should read the instruction manual thoroughly beforehand and to

have received basic training in use of the machine.

15. Safety data sheet for grinding fluid

Please go to the following link http://www.inelco-grinders.com/specifications to find the MSDS data

sheet for the grinding fluid.

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 13

16. Spare parts overview

Pos.

Item No.

Description

1

75522500

Drain/filling pipe

2a

44490901

Frame

2b

44490700

Plastic Inspection Cover

2c

44520009

Packing ring f. insp.cover

2d

40320410

Retaining screw M4x10

3

75520001

Angle adjust unit

4

44520007

Metal strip

5

44520008

Degree scale bush

6

44520022

Stretching screw

6a

44470312

O-ring ø12x2

Pos.

Item No.

Description

7

44520004

Tightening screw

7a

40310404

Pointed screw M4x6

8

44470124

Rubber pack

9

44520027

Bronze bearing Outward

10

44520024

Screw f. stick-out

11

40040670

Screw M6x70

12

44520028

Spring f. stick-out

13

62189220

Degree scale

Pos.

Item No.

Description

1

44520017

Bush f. wheel

2

41530530

U-wheell UT

3

44520018

Weather ring f. bush (set)

4

44490512

Diamond disc

5

44496525

Screw M5 lefthand

6

44520010

Packing ring f. rear plate

3

4

6

6a

a

8

9

7a

a

2a

2c

1

5

7

2b

10

11

12

13

2d

3

1

2

4

5

6

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 14

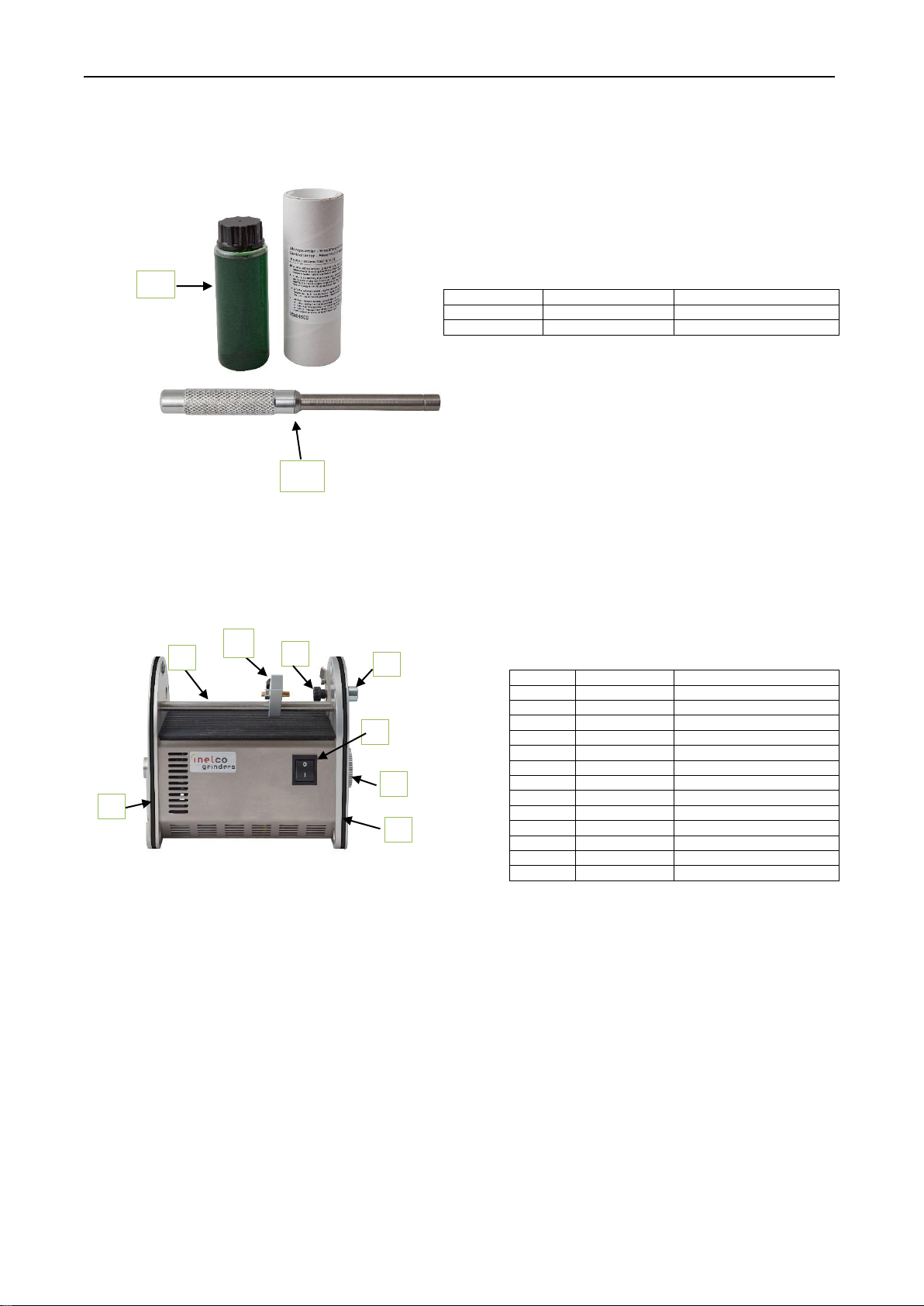

Pos.

Item No.

Description

1

75520023

Electrode holder

2

75494500

Liquid container W95/1-45

Pos.

Item No.

Description

1

44520106

Rod for length stop

2a

44520107

Arm for length stop

2b

44520109

Brass pin f. length stop

2c

41110605

Nut M6

2d

44493210

Screw BT16P M4x16

3a

44520112

Screw for pickup

3b

44520045

Catch for pickup

3c

40110511

Screw M4x12

3d

41512304

Plate disc rustproof ø4

4

17110027

Power switch

5

44520130

Stick-out bolt cut

6

44520103

Transmission cogwheel

7

44520010

Packing ring f. rear plate

1

2

1

2

3

4

5

6

7

7

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 15

Pos.

Item No.

Description

1

44520060

Deburring block

2

44520031

Cutter console

3a

44520047

Guide f. elektrode holder

3b

44520048

Locknut

3c

44520004

Tightening screw

3d

44470124

Rubber (membrane)

3e

44520027

Bronze bearing Outward

3f

40310404

Pointed screw M4x6

4a

44520070

Hub for arm Cut

4b

44520036

Space ring for spring

4c

44520037

Spring

4d

44520034

Handle Cut

4e

40310610

Pointed screw M6x10

4f

40310524

Torx screw M4x12 (3 pcs.)

4g

40310520

Guide screw for arm

5

75522500

Drain/filling pipe

6

44520125

Inspec. cover f. liquid level

7

40310524

Torx screw M4x12 (2 pcs.)

8

44520126

Gasket f. liquid Insp. cover

9

44510290

Inspection cover

Pos.

Item No.

Description

1

44490522

Cogwheel (2 pcs .)

2

44470216

O-ring f. shaft ø8x1

3

44520038

Shaft for arm

4

44490521

Plastic disc

5

44490523

Washer f. gear(2 pcs )

6

44490520

Cutting disc

7

40310610

Pointed screw M6x10

8

40310521

Torx screw M3x12 (8 pcs.)

9

75520068

Cutting arm

10

75500168

Cutting module

3

1

4

5

6

2

7

8

9

10

3a

3b

3c

3d

3e

3f

5

1

6

2

8

7

4e

4c

4b

4a

4d

4g

4f

9

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 16

17. Working table

Pos.

Item No.

Description

1

75500170

Pickup

2

44525158

Clamp Cut. Ø0,8

2

44525171

Clamp Cut. Ø1,0

2

44525162

Clamp Cut. Ø1,6

2

44525172

Clamp Cut. Ø2,0

2

44525164

Clamp Cut. Ø2,4

2

44525173

Clamp Cut. Ø3,0

2

44525165

Clamp Cut. Ø3,2

2

44525174

Clamp Cut. Ø4,0

Pos.

Item No.

Description

1

75520049

Tip collector Ø 2,5

2

75520050

Tip collector Ø 4,2

Pos.

Item No.

Description

1

40040610

Bolt stainless M6x10

2

41711106

Tooth lock washer ø6

3

44470029

Rubber lead-in ring ø9

4

44470124

Rubber pack (membrant)

5

44529001

Desk console

6

41110605

Nut M6

7

44529002

Stiffening plate

1

2

1

2

3

4

2

1

5

2

2

6

6

7

1

1

1

2

INELCO GRINDERS A/S ULTIMA-TIG-CUT

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 17

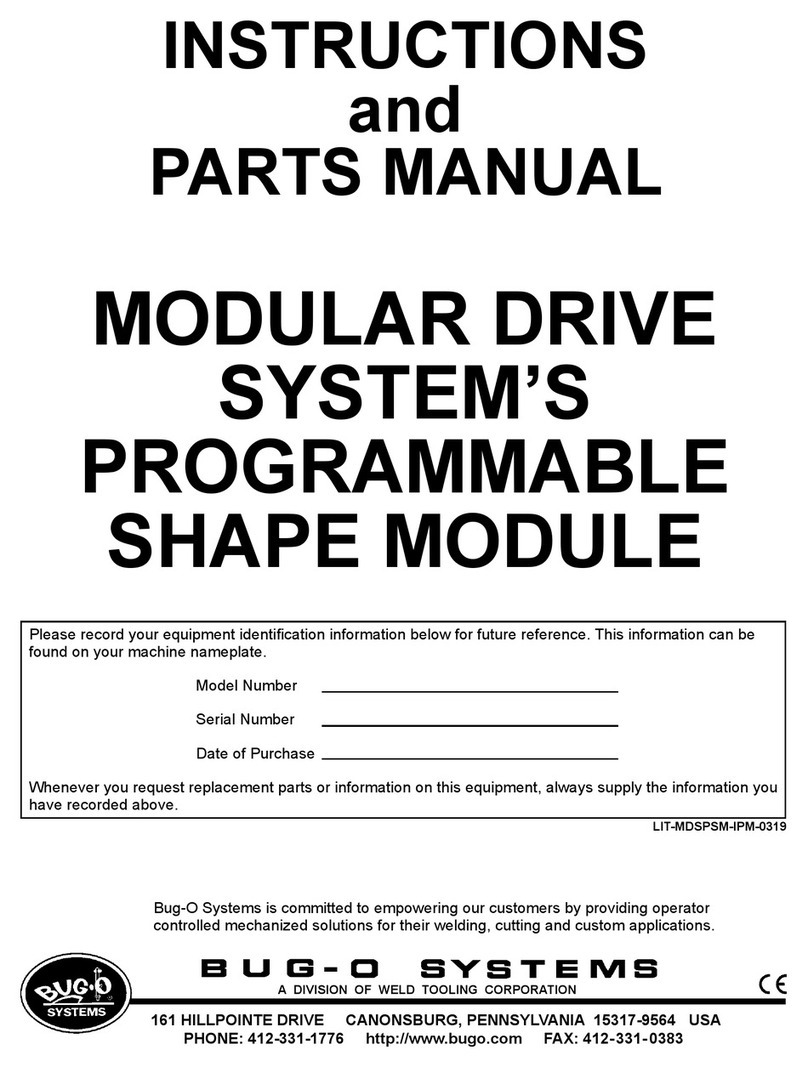

18.Accessories

Item No.

Electrode Clamp

Item No.

For short electrodes

44510158

Electrode clamp, Diameter 0,8 mm

44511162

Electrode clamp, Diameter 1,6 mm

44510171

Electrode clamp, Diameter 1,0 mm

44511164

Electrode clamp, Diameter 2,4 mm

44510161

Electrode clamp, Diameter 1,2 mm

44511165

Electrode clamp, Diameter 3,2 mm

44510163

Electrode clamp, Diameter 1,5 mm

44511171

Electrode clamp, Diameter 1,0 mm

44510162

Electrode clamp, Diameter 1,6 mm

44511172

Electrode clamp, Diameter 2,0 mm

44510172

Electrode clamp, Diameter 2,0 mm

44511173

Electrode clamp, Diameter 3,0 mm

44510164

Electrode clamp, Diameter 2,4 mm

44511174

Electrode clamp, Diameter 4,0 mm

44510173

Electrode clamp, Diameter 3,0 mm

44510165

Electrode clamp, Diameter 3,2 mm

44510174

Electrode clamp, Diameter 4,0 mm

75491200 75491201 75494000 75491301 75491300 75491305 4449122

AutoGrind for automated grinding on the

Ultima-Tig-CUT can be retrofitted.

Ask your dealer for more information.

Item No.

Grinding Liquid –EP770

75491200

Grinding liquid, 250 ml

75491201

Liquid disposal bottle 250ml

75494000

Grinding liquid, 5 litre

75491301

Grinding Liquid Con. 250 ml

75491300

Grinding liqiud Conc. 3 L for 60 L

75491305

Grinding Liquid conc. 4,5 L

44491225

Tap for 5 L canister

Table of contents

Popular Welding System manuals by other brands

WilTec

WilTec TIG180 Operation manual

Bug-O Systems

Bug-O Systems MDS Series Instructions and parts manual

Kühtreiber

Kühtreiber MAKin 200 TIG HF user manual

PlasmaPart

PlasmaPart Cut 45CI Eclipse Operation & safety manual

Air Liquide

Air Liquide SAF-FRO DIGIWAVE II Instruction for operation and maintenance

Lincoln Electric

Lincoln Electric Idealarc DC-600 Operator's manual