Lincoln Electric OPTIMARC CV/CC505 User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric InvertecV350-PIPE User manual

Lincoln Electric

Lincoln Electric 10630 User manual

Lincoln Electric

Lincoln Electric CobraMAX K2252-1 User manual

Lincoln Electric

Lincoln Electric SQUARE WAVE TIG 175 PRO User manual

Lincoln Electric

Lincoln Electric AutoDrive 4R90 User manual

Lincoln Electric

Lincoln Electric OERLIKON CITOCUT 60 User manual

Lincoln Electric

Lincoln Electric RANGER 305D SVM175-A User manual

Lincoln Electric

Lincoln Electric CLASSIC SVM194-A User manual

Lincoln Electric

Lincoln Electric 70112 User manual

Lincoln Electric

Lincoln Electric COMMANDER SVM153-A User manual

Lincoln Electric

Lincoln Electric AIR VANTAGE 500 User manual

Lincoln Electric

Lincoln Electric INVERTEC V160-S User manual

Lincoln Electric

Lincoln Electric RANGER 10708 User manual

Lincoln Electric

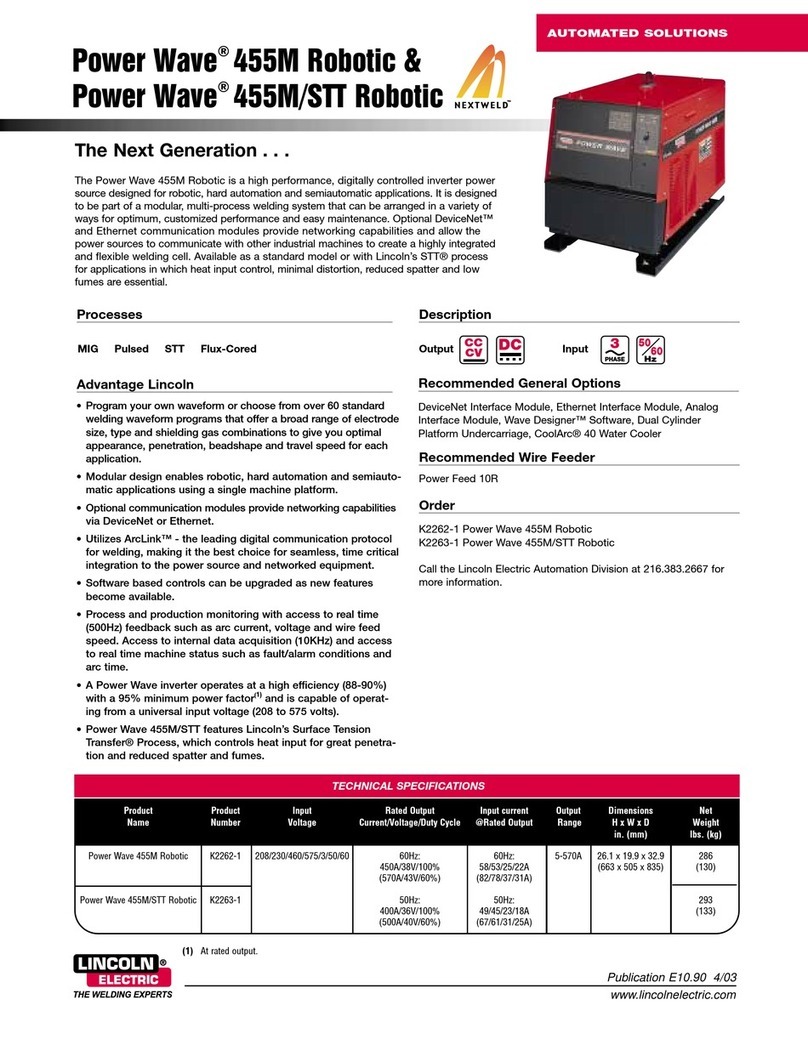

Lincoln Electric POWER WAVE 455TM IM583-A User manual

Lincoln Electric

Lincoln Electric Multi-Weld 350 User manual

Lincoln Electric

Lincoln Electric Vantage 322 User manual

Lincoln Electric

Lincoln Electric SPIRIT II Series User manual

Lincoln Electric

Lincoln Electric S350 CE User manual

Lincoln Electric

Lincoln Electric RANGER 275 User manual

Lincoln Electric

Lincoln Electric RANGER SVM168-B User manual