InelControl ORS-01IC User manual

ORS-01IC controller for sliding gate control units

Installation and operation manual

1 Safety guidelines

General guidelines

ORS-01IC receiver is factory configured to

guarantee safe installation and operation, provided

that all guidelines in this user manual and the safety

and accident prevention regulations relevant to the

application (e.g. sliding gate) are followed.

Installation and repairs must be carried out by

trained and qualified professional only.

Do not modify or change the ORS-01IC receiver in

any way. All warranty repairs must be carried out by

the manufacturer. Use genuine spare parts and

accessories only.

The operational safety of the ORS-01IC receiver

can only be guaranteed if the device is used as

intended. The limit values provided in the

specifications must not be exceeded under any

circumstances.

Additional safety regulations

Follow the safety and accident prevention

regulations relevant for a specific application (e.g.

sliding gate) when installing, commissioning and

maintaining the control unit. In particular, observe

the following:

1. Fire safety regulations

2. Accident prevention regulations

General information on hazards and safety

measures

The following are the general guidelines for use of

INEL controllers with other devices. Follow the

guidelines when installing and operating the

devices.

Caution - Failure to take precautions may result

indamage to the control unit or property.

•Check if all screw connections are

secure before installing the control unit and

setting the limit positions.

Danger - Failure to take precautions may

result in injury or death.

•Follow the safety and accident prevention

regulations relevant to the application (e.g.

sliding gate).

•ORS-01IC must be installed with the

required safety and protection devices. The

control units including crushing protection

systems with a sensor installed at the gate

(contact with the obstacle) must not cause

any injuries due to the movement of the

sliding gate.

•For INEL devices with permanent power

connection to the controller, in addition to

fuse protection, use an isolation switch for

safe power supply disconnection (e.g. fuse

cut-off switch) for all connections.

•Inspect the power wires and cables

regularly for damaged insulation and

conductor continuity.

•Turn off the power supply before replacing

damaged cables.

•Check if the local voltage supply

parameters correspond to the device

specification.

Warning - important for the safety of

personnel:

•do not let children play with the control

devices;

•keep the control devices out of reach of

children;

•observe the gate in motion at all times and

keep other people away until it is fully

opened or closed;

•Provide training and instructions for the

users on device operation and related

risks. The operator is deemed to have

been trained if the employer, administrator

or owner of the device have instructed and

authorised the operator to operate the

device.

2 Waste disposal

Do not dispose of with household

waste. Dispose of waste in accordance

with the relevant legislation.

Households play a key role in the

recycling of waste electrical and

electronic equipment. Waste sorting,

including waste equipment and batteries,

guarantees that the equipment is not disposed of

with domestic household waste but is handed to a

designated collection point for the recycling of

electrical and electronic waste.

3 Properties

ORS-01IC controller is one of the InelControl system

devices used to control a driveway gate or garage door

control unit. It is a single-channel receiver with a

decoder and return channel. The radio link operates at

868.30 MHz.

Specifications

Operating frequency

868,30 MHz

Number of channels

1

Radio range

>100 m

Supply voltage

12 VDC or 24 VAC

Standby power input

36 mA

Protection rating

IP44

Enclosure (surface-mounted box)

ABB 00808

Dimensions

75 x 75 x 39 mm

Weight

90 g

4 Description

The commands send from the app installed on your

smartphone to the InelControl control unit (locally -

over the Access Point network, home Wi-Fi network or

remotely over the Internet) will result in a signal being

sent by the control unit. The signal received by ORS-

01IC activates a relay with a contact connected to the

OUT output. The output is connected to the manual

control input and corresponds to the manual operation

of the gate switch. The gate control panel on your

smartphone includes a single control button for manual

control. Open and closed position sensors must be

installed to allow gate control and status indication.

The sensors may include NO type reed switches

installed at the gate and connected to the CON1

(closed) and CON2 (open) inputs. The open or closed

position signal is sent over via the return channel to the

InelControl control unit and to the smartphone app.

If the reed sensors are not installed, the remote control

of a gate will be disabled.

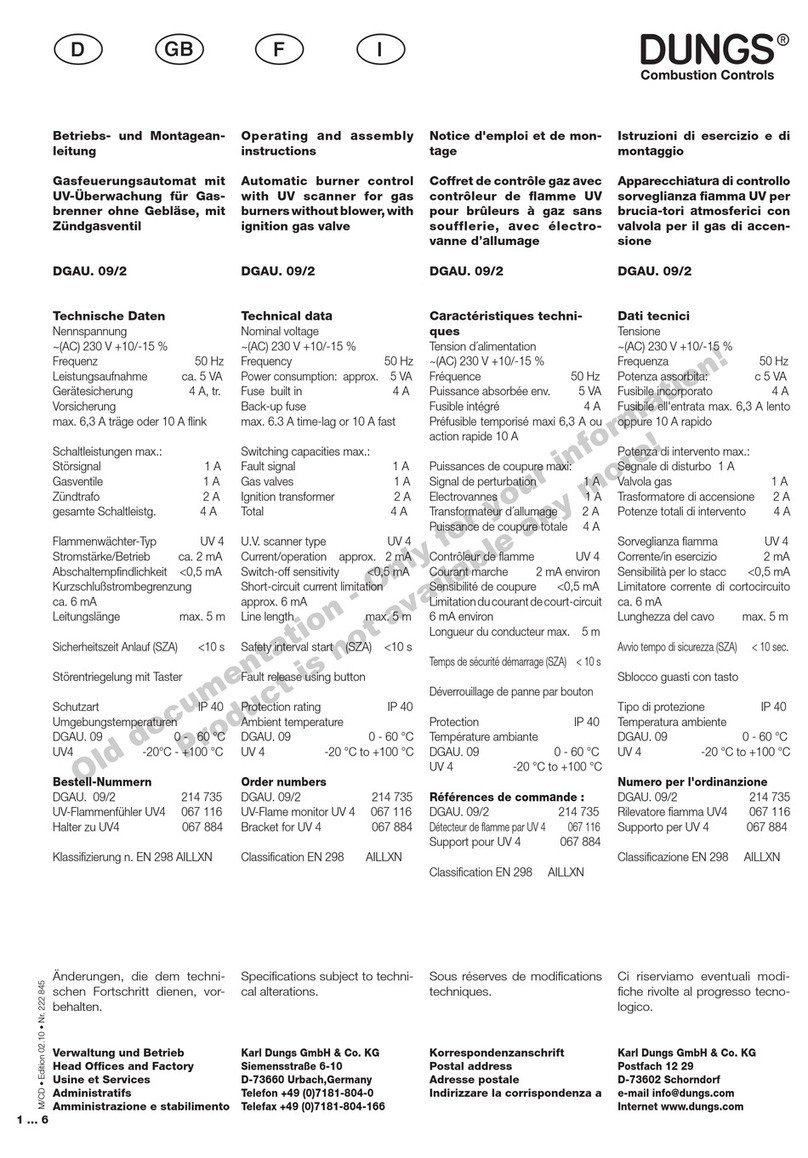

Fig. 1 Controller with cover removed

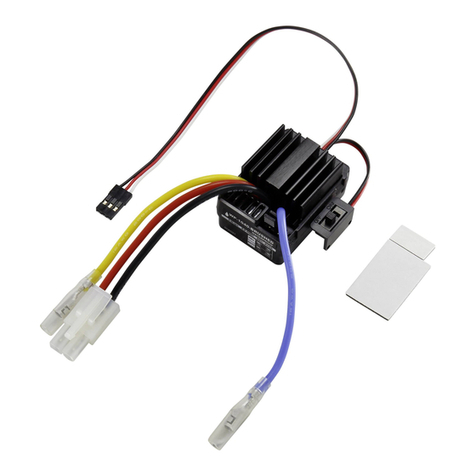

Fig. 2 Power

supply

5 Installing the controller

Caution! The device must be installed by a qualified

sliding gate installer.

5.1. Sliding gate

Installing the controller:

5.1.1 Installing the reed switches

The first and the most important task to ensure correct

operation of the controller in the system is to install the

reed switches.

Fig. 3 shows the operation of reed switches in the sliding

gate.

Fig. 3 Operation of open / closed switches:

a) sliding gate closed –reed switch Z closed,

b) sliding gate open –reed switch O closed

Installing the sliding gate reed switches:

5.1.2 Determining the minimum distance dmin

between the reed switches.

A minimum distance providing selectivity (to prevent

activation of reed switch Z placed opposite reed switch O,

and vice versa). The test requires an ohmmeter with

circuit continuity measurement function (with buzzer).

Place the reed switches (O and Z) in a plastic tray in

contact with each other. Touch the reed switch O with a

magnet and connect the ohmmeter to the reed switch Z

outputs. If the ohmmeter shows that the reed switch Z is

activated, move it away from the reed switch O until it

deactivates. The distance reached at the moment the

reed switch deactivates is a minimum distance between

the reed switches.

5.1.3 Preliminary installation of the reed switches

and magnets in the sliding gate

Note: turn off the power supply before completing step 2

and 3.

Place a plastic tray with the reed switches (horizontal)

and magnets at the same level. Install the reed switches

near the sliding gate control unit and install the magnets

at the toothed bar or the sliding gate spokes. If the

magnets are already installed, adjust the height of the bar

with reed switches. The gap sbetween the magnet and

the reed switch should provide reliable operation of the

reed switches and smooth sliding gate movement. For

B-1 type reed switches by Satel, the gap should not

exceed 3 cm. The gap can be adjusted with plastic

spacers or blocks.

5.1.4 Positioning the magnets in relation to the

reed switches

▪Open the sliding gate,

▪attach the tray with the reed switches with

reed switch O (CON2) opposite magnet O.

The reed switch should not be fixed in the

tray. Connect the ohmmeter to the reed

switch. Gently move the reed switch left and

right to determine the middle of its operating

range. Fix the reed switch in place.

▪Close the sliding gate. Move reed switch Z

(CON1) in the tray and place it opposite

magnet Z. Do not fix the reed switch.

Connect the ohmmeter to the reed switch.

Gently move the reed switch left and right to

determine the middle of its operating range.

Fix the reed switch in place.

5.1.5 Installing and connecting the controller

Install the controller and the tray with reed switches

inside the sliding gate control unit. If this is not

feasible, install the controller and the tray with reed

switches close to the sliding gate control unit. Secure

the controller, the reed switches and the insulated

cables against mechanical damage and weather

conditions.

Fig. 4 shows the connection diagram. Route the

cables to the controller enclosure by the grommets to

ensure proper sealing and arrange in loops to

prevent water ingress.

Connect the OUT output to the manual control input

of the sliding gate control unit.

The controller may be supplied with 12 V DC or 24 V

AC (from the sliding gate control unit or the external

power supply). Fig. 2 shows the wiring diagram for

both cases. Fig. 5 shows 12 V power supply from the

control unit.

The cables must not block the control unit’s

enclosure and must not affect its weather protection

components.

Fig. 4 Controller wiring diagram

5.1.6 Registering and configuring the controller

in InelControl system

To register and configure of the controller in InelControl

system, see “Control unit user manual and InelControl

system configuration”.

The device will be automatically detected by the system.

Press and hold S1 on the controller board for approx. 1

second. If the device is not automatically detected,

change the controller position and try again.

After configuring the controller, check the received signal

level in Advanced device information tab in InelControl

app. For correct communication, the level should be min.

-90 dBm

5.2 Sectional gate

Similar to the sliding gate, installation of reed switches is

required.

Fig. 5 shows the operation of reed switches in the

sectional gate.

The magnet is attached to the carriage (C) and the reed

switches are attached to the bar (R).

The reed switches are at a distance that will prevent

nonselective operation. Choose the optimal position of

the reed switches in relation to the magnet (see the

sliding gate section).

Install he controller near the gate control unit. Fig. 4

shows the wiring diagram.

Fig. 5 Operation of open/close switches of the sectional gate:

a) door closed - reed switch Z closed,

b) door open –reed switch O closed

Popular Controllers manuals by other brands

Sunricher

Sunricher SR-1009FA user manual

GFA

GFA LB 700 installation instructions

Plaid Systems

Plaid Systems Spruce PS-SPRWIFI16-01 instruction manual

Sensus

Sensus 461-S Installation and maintenance instructions

Honeywell

Honeywell UDC 6300 Replacement Instruction

Allen-Bradley

Allen-Bradley Micro800 installation instructions

SANKI

SANKI MFC-S3B-F instruction manual

Madas

Madas RG/2MT X Series Technical manual

ELCOS

ELCOS CIM-256/10 Instruction and user's manual

AUGIER Energy

AUGIER Energy OCEM DIAM3200 Series Installation & maintenance

Danfoss

Danfoss EKC 316A Reference manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series installation manual