inergy Flex 1500 User manual

FLEX USER MANUAL v 1.2

1. When you unbox your Flex Modular

System, PLEASE DO NOT throw away

the packaging. It may come in handy

down the road in case of damage from

shipping or handling, or any issues

requiring a return.

2. Before stacking your Flex modules

together, remove the plastic protectors

from the large connector on the bottom

of each module and the foot protectors

from all but the bottom module. These

protectors (see right) prevent damage in

shipping and are removable to allow the

modules to stack properly.

DO NOT attempt to stack the Flex

modules with these protectors in place.

Doing so may cause damage to the

connection points.

You can use these protectors on the

bottom module in your stack to protect

fragile surfaces, but be aware they are

designed to be removed and may fall off

on their own. If you choose to afx them

permanently to one module, be aware

that module will always need to be the

bottom module of your Flex system.

3. Next, charge your Flex Modular

System to 100% by plugging a Standard

Wall Charger (included) into the DC port

on the left side of your Flex Battery.

For more pro tips on how to keep your

battery in the best shape possible, see

the Flex Battery section of this manual.

For instructions on connecting multiple

Flex Batteries together, see Using

Your Flex system with Multiple Flex

Batteries.

4. 4. When your Flex Batteries are fully

charged, plug a device into each output

to make sure that nothing was damaged

in shipping and handling.

5. Keep your Flex modules connected

together as much as possible, so the

batteries remain equalized.

01

FIRST THINGS FIRST

FAILURE TO FOLLOW THE ABOVE SAFETY TIPS MAY RESULT IN PERMANENT DAMAGE TO YOUR FLEX MODULAR

SYSTEM, RISK OF FIRE, WARRANTY VOID, AND/OR BODILY HARM. IF YOU HAVE ANY QUESTIONS, PLEASE

CONTACT OUR U.S.-BASED TECH SUPPORT TEAM (SEE CONTACT US).

NEVER connect an input exceeding 90

volts, e.g. the open circuit voltage (VOC)

on solar panels, to the blue EC8 charging

port (right side) on the Flex 1500, Flex

DC, or Flex MPPT Supercharger.

NEVER exceed output and input

connector ratings. Failure to do so may

result in unit damage, re, or electrical

shock. You can nd these ratings under

Tech Specs.

NEVER store a Flex Battery in hot

environments, such as a hot vehicle.

Lithium batteries are sensitive to

extremely high temperatures. For more

information see Tech Specs.

NEVER touch, stick metal objects into,

or otherwise come in contact with the

AC outlet terminals on the Flex 1500.

Doing so risks death, serious injury, and

electrical shock. These outlets supply

power identical to that of a normal home

wall outlet and, while ungrounded, still

present many of the same dangers.

NEVER operate the Flex system in wet

conditions. Allow any condensation to

dry completely before powering-up or

charging your Flex system. If your Flex

system does get wet, contact us to

ensure it’s safe before attempting to use

it again.

NEVER attempt to repair your Flex

system or replace the internal

battery yourself; any manipulation or

disassembly of any Flex module will

void all warranties, including the 10-

Year No “B.S.” or 10-Year Pro-Rated

Warranties. Any tampering with the

warranty stickers (black dot with Inergy

logo) may also void the warranty. For

questions about repair/service, please

contact our U.S.-based Tech Support

team (see Contact Us). There are no

user-serviceable parts inside.

ALWAYS keep your Flex system clean

and dry. Regularly inspect for dirt, dust,

or moisture. Clean connectors with

canned air for electronics. Never use an

air compressor to clean or dust-off your

system.

NEVER use a generic or off-brand

charger to charge your Flex Battery.

Use only the Inergy-supplied charger

specically for this device.

02

IMPORTANT SAFETY GUIDELINES

NEVER connect your Flex AC outlets to

another power source. Doing so will

permanently damage your device and

void your warranty. These outlets are

output only, and any such damage is

easily detected when diagnosing Flex

system failures.

BE AWARE that the Standard Wall and

Quick Wall chargers can get hot when in

use. Charge your Flex system in a well-

ventilated, dry area. We recommend

placing your charger on top of the Flex

system while charging; the aluminum

case works as an effective heat sink for

the charger.

TAKE CARE not to leave anything

plugged into the DC outputs that are

unsafe if left to run unattended (cooking

equipment, and heaters), or other loads

you don’t want draining your battery

unexpectedly.

NEVER use or store any Flex module

or Flex Battery in any orientation other

than standing straight up. The Flex

Modular System is designed to be

stored and operated while sitting on a

at, secure surface.

ALWAYS secure the Flex system with

straps or cords when using it in a

vehicle to protect against excessive

vibration or impacts?

FAILURE TO FOLLOW THE ABOVE SAFETY TIPS MAY RESULT IN PERMANENT DAMAGE TO YOUR FLEX MODULAR

SYSTEM, RISK OF FIRE, WARRANTY VOID, AND/OR BODILY HARM. IF YOU HAVE ANY QUESTIONS, PLEASE

CONTACT OUR U.S.-BASED TECH SUPPORT TEAM (SEE CONTACT US).

03

IMPORTANT SAFETY GUIDELINES

FIRST THINGS FIRST

IMPORTANT SAFETY GUIDELINES

TABLE OF CONTENTS

GETTING TO KNOW YOUR FLEX

Flex 1500 Power Station

Flex DC Power Station

MPPT Supercharger

Flex Battery

Using Your Flex system with Multiple Flex Batteries

Expand Your Apex or Kodiak Power Station with the Flex Battery

CHARGING YOUR FLEX MODULAR SYSTEM

General Information

Charging with Solar Panels

Inergy Ascent Panels (or Other MC4 Panels Connected in Series)

Legacy Inergy Panels With EC8 Connectors

Solar Charging with the MPPT Supercharger

Charging with the Grid (110-120VAC Wall Socket)

Charging with Your Vehicle’s 12VDC System

01

02

04

07

14

04

TABLE OF CONTENTS

USING YOUR INERGY FLEX MODULAR SYSTEM

Flex 1500 Power Station with AC and Regulated DC Output

Flex DC Power Station with Regulated DC Output

Using the Flex Battery

Getting the Most out of your Flex system

Using the Flex in Extreme Cold Weather

Reading the LCD Displays

Flex power consoles

Flex Battery

Flex MPPT Supercharger

TECH SPECS

Flex 1500 Power Station (AC and DC Output)

Flex DC Power Station (DC–Output)

Flex Battery

Flex MPPT Supercharger

FAQs

23

26

33

39

05

TABLE OF CONTENTS

WARRANTY INFORMATION

Warranty Period

“No Lemon” Policy

Remedy

Limited to Original Consumer / Buyer

Exclusions

How to Receive Service

CONTACT US

47

49

06

TABLE OF CONTENTS

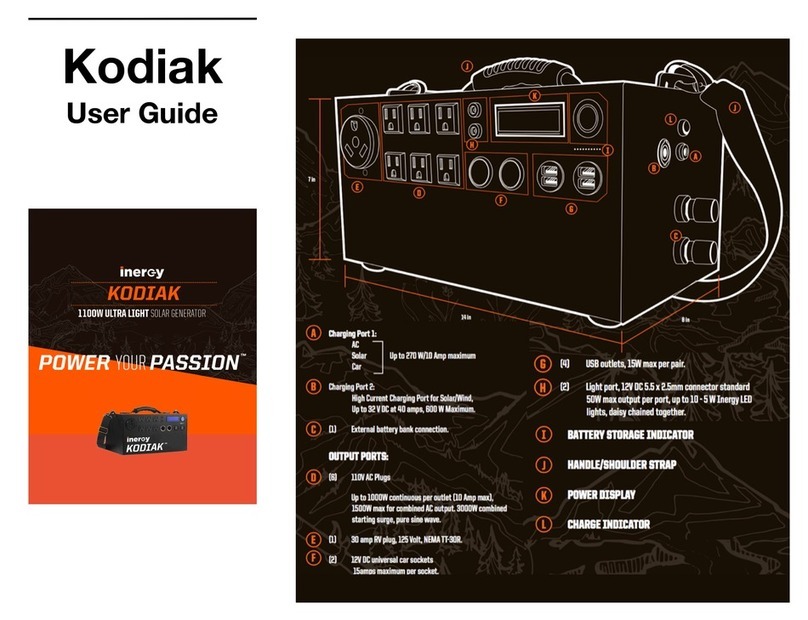

Currently, the Flex Modular System is

made up of four unique Flex modules:

1. Flex 1500 Power Console

2. Flex DC Power Console

3. Flex Battery

4. Flex MPPT Supercharger

With these modules, you can create a

Flex system that is perfectly tailored

to your present needs and save

money in the future by replacing/

adding individual modules instead of

purchasing an entirely new system.

07

GETTING TO KNOW YOUR FLEX

Flex 1500 Power Station

Most people will start with a Flex 1500

Power Station, which is the combination

of the Flex 1500 Power Console and a

single Flex Battery.

From there, you can choose to expand

your battery storage capacity and

solar charging rate by adding more

Flex Batteries and additional MPPT

solar inputs with the Flex MPPT

Supercharger. The possibilities are

almost endless.

08

GETTING TO KNOW YOUR FLEX

Flex DC Power Station

People who use only DC power, such

as off-grid or van life enthusiasts,

may choose the Flex DC Power

Station, which is the combination

of the Flex DC Power Console and a

single Flex Battery.

09

GETTING TO KNOW YOUR FLEX

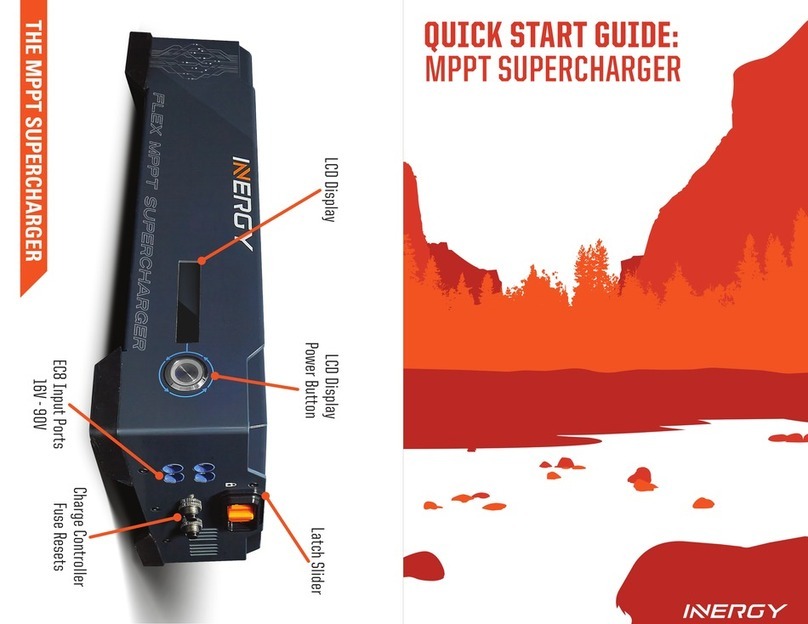

Flex MPPT Supercharger

The Flex MPPT Supercharger includes two advanced maximum power point tracking (MPPT) charge controllers, each

equivalent to the MPPT input of the Power Console, giving you more input options and faster solar charging. Rapidly charging

and discharging your battery can affect the cycle life of lithium-ion batteries. For more information, see CHARGING YOUR FLEX

MODULAR SYSTEM.

10

GETTING TO KNOW YOUR FLEX

11

GETTING TO KNOW YOUR FLEX

Flex Battery

The Flex Battery is a lithium-ion, low-

voltage battery containing a smart

BMS (battery management system).

The Flex Battery is capable of smart

charge and discharge management,

self temperature regulation, advanced

safety features, and other features to

provide the high power density you’ve

come to expect from Inergy, along with

industry-leading safety standards and

controls.

Each Flex Battery is self-managed,

which means that your system can continue operating in the event of a failure of any/all extra batteries in the system. Each

battery displays its individual state-of-charge (SoC), voltage, and power measurements on the built-in LCD screen. Batteries

are automatically activated by a Flex power console, but you can use the built-in button to activate the display manually.

We’re rm believers in simplicity, and have kept the number of buttons in the Flex system to a minimum.

If you intend to charge your system

before using it, place the lowest charge

battery on the top of the stack. As the

top battery charges and the voltage

increases, the others will enable as

they come within range. The order of

the other batteries is not important.

If you intend to discharge your system

rst, place the battery with the highest

charge on top instead. As you use

power from the top battery, the voltage

will drop, and the lower batteries will

enable when within range. The order of

the lower batteries is not important.

The best practice for connecting

multiple batteries to your Flex power

console is to charge all batteries to

100% before stacking them. Once

If you have any questions, please call us (see Contact Us), and we’ll be happy to help you. 12

you can still connect them, though

they won’t enable until the voltages

get within range. As you use the Flex

system, the batteries will automatically

enable and equalize. Once connected,

the power console display will show

the combined state of charge for all

batteries in the stack.

The top battery in the stack acts as

the master, providing initial power to

the Flex system. Flex Batteries stacked

below the master will automatically

enable when the voltage is within

range of the master. If your batteries

are too far out of range and you don’t

have time to wait, you can speed up the

process of connection by following a

few simple steps:

Using Multiple Flex Batteries

To expand your Flex Modular System’s

overall battery capacity, simply add

more Flex Batteries to your stack.

Having multiple batteries reduces the

strain on each, resulting in longer cycle

life for your batteries. Each stack can

have up to ve (5) Flex Batteries. To

connect more than ve batteries, you’ll

need to add a Flex Stack Base, allowing

you to connect an additional stack to

the system. Do not connect more than

ve (5) Flex Batteries in one stack.

When you add Flex Batteries in a stack,

they will automatically connect to each

other when their voltages are within

range of each other (about 0.8V). If

your battery voltages are too far apart,

GETTING TO KNOW YOUR FLEX

ATTENTION: Failure to follow the above safety information may result in re, property damage, or bodily harm.

Permanent damage to your Flex Battery, Flex-to-Ring-Terminal Adapter, Kodiak, or Apex can occur,

voiding your warranty.Contact us if you have any questions.

13

they’re connected, we recommend

leaving them together, so the packs

remain in balance with each other.

Expand Your Apex or Kodiak with

the Flex Battery

You can use the Flex-to-Ring-Terminal

Adapter to connect a Flex Battery to

your Kodiak or Apex portable power

station. By connecting one Flex Battery

to your Apex or Kodiak with the Flex-

to-Ring-Terminal Adapter, you can

increase the total storage capacity by

that of the Flex Battery.

To add even more storage capacity,

simply stack additional Flex Batteries

(up to ve per stack). The Flex Batteries

will measure the Apex or Kodiak battery

level, and automatically enable when

their respective voltages get within

range (about 0.4V) of each other. Once

the batteries automatically enable,

they will act as one expanded battery.

We suggest you charge all batteries to

100% before connecting them. If you

wish to add more than ve batteries,

please call us for additional information.

(See Contact Us)

Never connect any other type of battery

to the Kodiak or Apex with the Flex

Battery at the same time.

Never connect external lithium

batteries not supplied by Inergy to the

Kodiak or Apex.

GETTING TO KNOW YOUR FLEX

faster than most systems, but this can

still take up to a few hours to reach

100%. You may see the SoC remain at

~99% until balancing nishes.

You can still use the Flex system

without charging up those last few

percentage points, but you won’t get

the max capacity until the system

reaches 100%. Just give your unit a full

overnight charge every now and then to

ensure the maximum charge capacity is

reached.

Charging for Long-Term Storage

If you intend to store your battery for

an extended period of time, we strongly

recommend you check the state of

charge once every three months. If the

state of charge dips below 30%, we

14

CHARGING YOUR FLEX MODULAR SYSTEM

as the power console is powered on).

Note: If the Flex Battery is too warm

or cold, it won’t allow charging until it

reaches a safe temperature (see Tech

Specs).

Cell Balancing

Lithium battery packs with multiple cells

can become unbalanced after heavy

use, or going a long time between full

charges. This means that one cell group

is at a higher or lower state of charge

(SoC) than the others.

In order to resolve this imbalance, the

battery needs to be charged while

the intelligent management system

automatically balances each cell group.

The Flex Battery employs a rapid cell

balancing system which is over 10x

General Information

When charging your Flex system,

the power console LCD screen will

indicate an estimated charge time

and the amount of power being sent

to the battery. This estimated charge

time is based on the power input and

output numbers at that moment, and it

will change as the average charge or

discharge rates uctuate. The power

console LCD combines the states of

charge of all batteries in your Flex

system as a percentage of the total

combined capacity.

When more than one battery is

successfully connected, any charge

input will charge all batteries, even the

Standard Wall Charger input (so long

ATTENTION: Do not allow your Flex system to remain in storage at a low state of charge for a long time. This may damage

your Flex Battery and void your warranty.

recommend charging it to about 50%

before putting it back into storage. The

ideal battery SoC range for long-term

storage is 30 - 50%.

Charging With Solar Panels

Solar energy is as simple as pointing

panels at the sun. However, there are

many variables that can affect the

panel’s performance, and there are a

few rules involved. For help on charging

with solar panels and conguring your

solar arrays correctly, please call us

(see Contact Us) and we’ll be happy

to help you out. Here are a few of the

most common variables that affect

performance, and some tips and tricks

to help you maximize your results:

Ideal Time of Day

As a general rule of thumb, the brighter

the sun is shining, the better solar

panels will work. Panels operate at peak

efciency when the sun is most direct—

typically around midday. Solar panels

run off of light, not heat. In fact, solar

panels produce the most during cold,

clear days rather than in extremely hot

conditions. Even on a windy day, solar

panels can still operate at peak output.

Cloud cover will signicantly reduce

the efciency of the panels, though

they will still continue to generate some

electricity.

Time of Year

The amount of daylight changes with

the seasons, as the sun moves closer

and farther away from you. During

summer months overall solar production

is generally higher. Although the winter

months have fewer daylight hours,

cold temperatures positively affect

the panel’s performance. In fact, cold

temperatures in clear conditions can

generate the most solar production

overall.

Panel Placement

Place your solar panel where it will get

as much direct sunlight as possible.

Shade on one or more panels can

affect the performance of the whole

string. Take care to avoid trees and

other shade that may move with the sun

throughout the day.

Peak Your Panels

Pointing your panel directly at the sun

NOTE: Inergy solar panels are rated at maximum output in ideal conditions. Real output may vary based on your

unique situation. 15

CHARGING YOUR FLEX MODULAR SYSTEM

16

panels’ open circuit voltage, please call

us. (See Contact Us.)

Clean Your Panels

Solar panels function through the

interaction of many individual cells (see

right). Output can be greatly affected

with even the slightest obstruction to

a single cell of the panel. Make sure

the panel is free of any dirt, debris, or

other objects like stickers and decals.

Protective coatings can also greatly

reduce panel performance, including

clear lms, plastic sheet/paneling, and

even glass.

Panel Wiring - Series vs Parallel

Wiring your panels right is key to

getting the best efciency in your

unique situation. You can wire panels in

and adjusting them throughout the day

will yield the best results. The angle will

vary from month to month, but an angle

of 30-60 degrees from at is generally

considered ideal. As long as you point

your panels at the sun, you should get

good results.

Safety Tips

The Flex is designed for use with and

rated for Inergy-brand solar panels,

but you can use off-brand solar panels

if you have them. You should not mix

different types and ratings of panels;

always use identical panels in a string.

As a hard rule, any string of solar

panels must not exceed the open circuit

voltage (VOC) rating of the Flex system

(see Tech Specs). If you have any

questions or doubts about your solar

CHARGING YOUR FLEX MODULAR SYSTEM

parallel (connecting all positive wires

together, as well as all negative) or

series (connecting the positive wire of

one panel to the negative wire of the

next).

There’s another way, series-parallel,

which is a single series string of

multiple identical parallel strings, which

is a bit more complex. Simply-put, you’ll

DO NOT use the 5.5mm x 2.5mm charging port on the Flex Battery for solar charging. Doing so may cause serious

damage to your Flex Battery, and it will void your warranty. It can result in fire, electrical shock, and

personal harm.

CHARGING YOUR FLEX MODULAR SYSTEM

corresponding connectors on each end

of your string of solar panels. You should

end up with a closed loop (a completed

series connection).

You will know the Flex Modular System

is charging from your solar panels when

the LCD screen indicates a charge input

under SOLAR and an estimated charge

time on the center of the display. The

estimated charge time will uctuate as

the amount of power input and output

from the system uctuates.

It can take up to 30 seconds for charging

to begin, while the smart charger

detects your panels and the input

voltage stabilizes.

17

panels in series, always follow this

process when connecting them to your

Flex system:

Step 1. Plug the blue EC8 connector of

your 30’ EC8-to-MC4 Ascent Panel Cable

into the blue EC8 connector on your Flex

Power Station.

Step 2. Connect the male and female MC4

connectors on your solar panels in one

continuous string, male to female and

so on. When you are done connecting

your panels, you will have one open male

connector on one end of your string, and

one open female at the other end.

Step 3. Connect the MC4 connectors

on your EC8-to-MC4 cable to the

generally get the highest efciency

with a series conguration, but you

may want parallel or series-parallel if

you’re wanting to capture more energy

with more panels in low-light conditions

without over-voltaging the system on a

normal day. Refer to the Inergy blog for

more detailed information, where we

dive deeper into the pros and cons of

each conguration.

Inergy Solar Panels (or Other MC4

Panels) Connected in Series

Connecting solar panels in series

increases the voltage of the string. A

VOC over 45V can be dangerous, risking

electrical shock and personal harm if

not handled properly. When using solar

WARNING: DO NOT connect your EC8-to-MC4 adapter cable to your solar panel string before plugging the EC8

connector into your Flex Power Station. Connecting the EC8 connector rst decreases the risk of

severe electrical shock. Always follow the process described above. When disconnecting your

solar panels, always go in reverse order, removing the EC8 connector last.

CHARGING YOUR FLEX MODULAR SYSTEM

18

STEP 1 STEP 2 STEP 3

Male MC4

EC8 Port on the Flex Female MC4

Leftover

Panel Leads

30 FT EC8 to

MC4 Cable

30 FT EC8 to

MC4 Cable

NOTE: When charging with solar panels, you should use only the blue EC8 input port on the right panel of the Flex

1500 or Flex DC power console. Do not use the DC ports on the front of the unit, which are output-only.

CHARGING YOUR FLEX MODULAR SYSTEM

19

You will know the Flex Modular System

is charging from your solar panels when

the LCD screen indicates a charge input

under SOLAR and an estimated charge

time on the center of the display. The

estimated charge time will uctuate as

the amount of power input and output

from the system uctuates.

It can take up to 30 seconds for

charging to begin, while the smart

charger detects your panels and the

input voltage stabilizes.

Legacy Inergy Panels With EC8

Connectors

If using legacy Inergy panels with EC8

connectors, always use the following

process when connecting your panels:

Step 1. Plug one of the blue EC8

connectors on your 30’ EC8 Solar Panel

Cable into the blue EC8 connector on

your Flex Power Station.

Step 2. Connect the other end of your

30’ cable to one of the EC8 leads on

your Solar Storm or Linx panels.

Step 3. Connect additional cables as

desired using the 6’ EC8 Solar panel

cables between panels.

Table of contents

Other inergy Inverter manuals

Popular Inverter manuals by other brands

Sumitomo

Sumitomo HF-520 Series Technical manual

Mitsubishi Electric

Mitsubishi Electric FR-A760 Series instruction manual

Defort

Defort DCI-300 user manual

Mitsubishi Electric

Mitsubishi Electric FR-S500 Series instruction manual

Growatt

Growatt SPA 1000TL Installation & operation manual

Simphoenix

Simphoenix V800 Series manual

GMDE

GMDE 1KVA user manual

SolarEdge

SolarEdge Home Battery 48V installation guide

Unitronics

Unitronics UMI-S0 Series Technical Specifications and Installation Guidelines

REFU

REFU REFUsol 08K Installation and operating manual

Emergi-Lite

Emergi-Lite EMIU-125W instruction manual

Srne

Srne HF4830S80-145 user manual