CONTENTS

1. Introduction ...................................................................................... 1

1.1. Preface ....................................................................................1

1.2. Safety Introduction ...................................................................... 1

1.3. General Precautions ..................................................................... 3

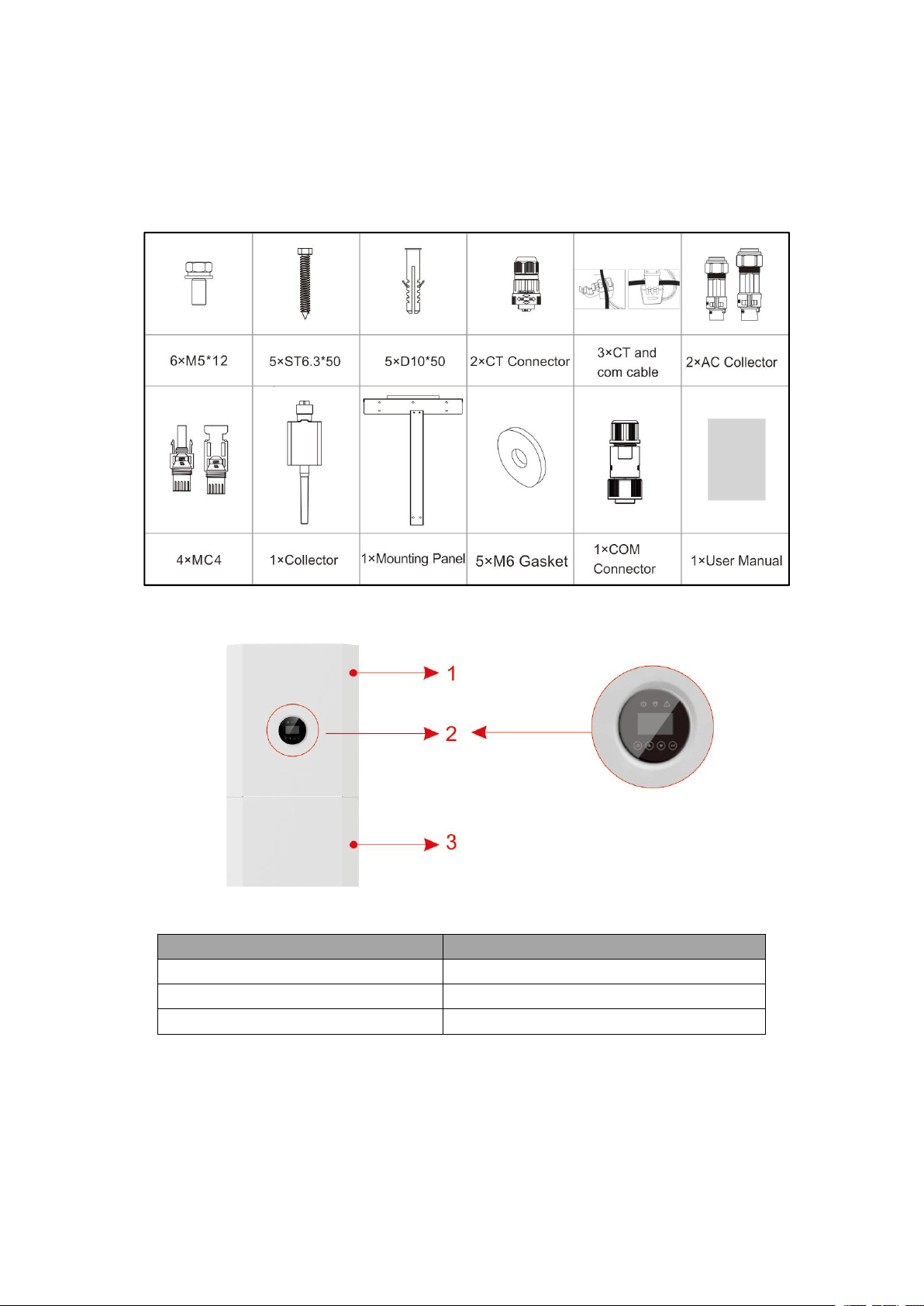

1.4. Parts List ................................................................................. 4

1.5. System Appearance ......................................................................4

1.6. Liability Limitation ...................................................................... 7

2. Installation ....................................................................................... 8

2.1. Installation Site and Environment ...................................................... 8

2.2. Installation ..............................................................................10

2.3. Electric Connection .................................................................... 11

2.4. External CT Connection ............................................................... 15

2.5. DRED Port Connections (optional,only for DRM function) ...................... 16

2.6. COMM Port Connections ............................................................. 17

2.7. METER+DRY Port Connections ..................................................... 17

2.8. Single Line Diagram ................................................................... 19

3. System Operation .............................................................................. 21

3.1. Switch On .............................................................................. 21

3.2. Switch Off .............................................................................. 22

3.3. Emergency Procedure ..................................................................22

4. EMS Introduction And Set Up ................................................................ 23

4.1. Function Description ...................................................................23

4.2. Display and Setting .................................................................... 23

4.2.1. General settings ...................................................................... 23

4.3. Configuration Menus Overview .......................................................26

5. Stick Logger Quick Guide .................................................................... 34

5.1. Download APP ......................................................................... 34

5.2. Stick Logger Installation .............................................................. 34

5.3. Logger Status ...........................................................................34

5.4. Abnormal State Processing ............................................................ 35

5.5. Usage Methods and Notices for Reset Button ........................................36

6. SOLARMAN Smart APP ..................................................................... 38

6.1. Registration .............................................................................38

6.2. Create a Plant ...........................................................................38

6.3. Add a Logger ...........................................................................38

6.4. Network Configuration ................................................................ 39

7. Alarm Code and Error Code .................................................................. 42

7.1. Alarm Code ............................................................................ 42

7.2. Error Code ..............................................................................42

8. Fault Diagnosis and Solutions ................................................................ 44

9. Product Specifications .........................................................................47