Inficom SQM-160 User manual

OPERATING MANUAL

SQM-160

™

Multi-Film Rate/Thickness Monitor

PN 074-511-P1E

C

over

P

age

OPERATING MANUAL

PN 074-511-P1E

Titl

e

P

age

SQM-160

™

Multi-Film Rate/Thickness Monitor

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that produce them.

INFICON® is a trademark of INFICON Inc.

SQM-160™ and INFICON® are trademarks of INFICON GmbH.

Visual Basic®, Windows®, and Excel® are registered trademarks of Microsoft Corporation.

Java® is a registered trademarks of Oracle and/or its affiliates.

Inconel® is a registered trademark of Inco Alloys International, Huntington, WV.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2015 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

Warranty

www.inficon.com [email protected]

TOC - 1

PN 074-511-P1E

SQM-160 Operating Manual

Table Of Contents

Cover Page

Title Page

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Chapter 1

Introduction and Specifications

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Definition of Notes, Cautions, and Warnings . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.2 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.3 Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.3 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.3.1 Returning SQM-160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.2 Film Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.4.3 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.4 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.5 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.6 Configurations and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.6.1 SQM-160 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.6.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6.2.1 Oscillator Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.2.2 Rack Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.2.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Chapter 2

Installation

2.1 Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Parts Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

TOC - 2

PN 074-511-P1E

SQM-160 Operating Manual

2.1.2 Ground Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Establishing Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Rack Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Full Rack Extender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1.1 Inventory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Rack Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.2.1 Inventory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3 Rear Panel Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4 System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1 Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5 I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Chapter 3

Operation

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Menu Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4 Film Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6 Sensor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.7 Sensor Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.8 Sensor Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.9 Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.10 Crystal Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.11 Zero Thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.12 Shutter Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.13 Dual Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.14 Rate Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.15 Time Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.16 Thickness Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.17 Simulate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.18 Defaulting the Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.19 Relay Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.20 Analog Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.21 Depositing a Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

TOC - 3

PN 074-511-P1E

SQM-160 Operating Manual

Chapter 4

SQM-160 Comm Software

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2.1 Update of an Older Version of SQM-160 Comm . . . . . . . . . . . . . . . . . . . . .4-2

4.3 Start the SQM-160 V2 Comm software. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.1 Menu Bar Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4.1.1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.4.1.2 Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.4.1.3 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.1.4 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.2 Main Window Control Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5 Data Log Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.5.1 Log File Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.5.2 Duration Pane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.5.3 Time Range Pane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.5.4 Sampling Interval Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.6 Films Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.7 System Parameters Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.8 Communications Setup Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.8.1 Establishing Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

4.8.2 Command Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.9 Configure Graph(s) Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.10 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Chapter 5

Communications

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 RS-232 Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1.2 USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.3 Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.3.1 How to Set Up the Network Protocol on the Computer . . . . . . . . . . . . . . . .5-2

5.1.3.1.1 Accessing Network Settings in Windows XP . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.1.3.1.2 Accessing Network Settings in Windows 7 and Windows 8. . . . . . . . . . . . . 5-6

5.1.3.2 How to change the SQM-160 IP address. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2 SQM-160 Comm Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.3 SQM-160 Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.3.1 Command Packet (Host to SQM-160 Message) . . . . . . . . . . . . . . . . . . . . . 5-9

5.3.2 Response Packet (SQM-160 to Host Message). . . . . . . . . . . . . . . . . . . . . 5-10

TOC - 4

PN 074-511-P1E

SQM-160 Operating Manual

5.3.3 Calculating the CRC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.4 Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.1 Command: @ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.4.2 Command: A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.4.3 Command: B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.4.4 Command: C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.4.5 Command: D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.4.6 Command: J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.4.7 Command: L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.4.8 Command: M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.9 Command: N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.10 Command: O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.11 Command: P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.12 Command: R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.13 Command: S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.14 Command: T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.4.15 Command: U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.4.16 Command: W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.4.17 Command: Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.4.18 Command: Z. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.5 CRC Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.5.1 Visual Basic® 5/6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.5.2 Java® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.5.3 C++. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Chapter 6

Troubleshooting and Maintenance

6.1 Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.3 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4 Persistent Crystal Fail Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Chapter 7

Calibration Procedures

7.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Determining Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

TOC - 5

PN 074-511-P1E

SQM-160 Operating Manual

Chapter 8

Measurement and Theory

8.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.1.3 Z-match Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Appendix A

Material Table

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

TOC - 6

PN 074-511-P1E

SQM-160 Operating Manual

This page is intentionally blank.

1 - 1

PN 074-511-P1E

SQM-160 Operating Manual

Chapter 1

Introduction and Specifications

1.1 Introduction

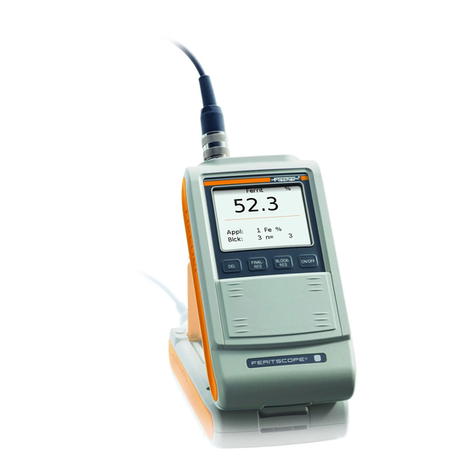

Figure 1-1 SQM-160 multi-film rate/thickness monitor

SQM-160™uses proven INFICON®quartz crystal sensor technology to measure

rate and thickness in a thin film deposition process. Two sensor inputs are standard

and four additional sensor inputs are optional. Two recorder outputs provide both

analog rate and thickness signals.

Sensor inputs are assigned to different materials, averaged for accurate deposition

control in large systems or configured for a dual sensor. The rate sampling mode

allows a shuttered sensor to extend sensor life in high rate processes. Rate

displays of 0.1 Å/s or 0.01 Å/s are user-selectable. In addition, frequency or mass

displays can be selected. Four relay outputs allow SQM-160 to control source or

sensor shutters, signal time and thickness setpoints, and signal crystal failure.

Digital inputs allow external signals to start/stop and zero readings.

SQM-160 comes with an RS-232 port and Windows®software that allows

instrument setup from a computer. The software can be used to set and store all

parameters, operate SQM-160, and save process data in a .txt file that can be

imported into Excel®. Universal Serial Bus (USB) or Ethernet options add to the

communications flexibility.

1 - 2

PN 074-511-P1E

SQM-160 Operating Manual

1.1.1 Related Manuals

Quartz crystal sensors are covered in separate manuals. The following manuals

are available on the Thin Film Instrument and Sensor Manuals CD

(PN 074-5000-G1), part of the ship kit:

PN 074-154 - UHV Bakeable Sensor

PN 074-156 - Front Load Single and Dual Sensors

PN 074-157 - Sputtering Sensor

PN 074-643 - ALD Sensor

PN 147-800 - Cool Drawer Single and Dual Sensors

1.2 Instrument Safety

1.2.1 Definition of Notes, Cautions, and Warnings

When using this manual, please pay attention to notes, cautions,

and warnings found throughout. For the purposes of this manual they are defined

as follows:

NOTE: Pertinent information that when followed is useful in achieving maximum

SQM-160 efficiency.

CAUTION

Failure to heed these messages could result in damage

to SQM-160.

WARNING

Failure to heed these messages could result in

personal injury.

WARNING - Risk Of Electric Shock

Dangerous voltages which could result in personal injury

are present.

1 - 3

PN 074-511-P1E

SQM-160 Operating Manual

1.2.2 General Safety Information

WARNING

Do not open the SQM-160 case. Refer all maintenance to

qualified personnel.

There are no user-serviceable components within the

SQM-160 case. Dangerous voltages may be present

whenever the power cable or external input/relay

connectors are present.

WARNING

SQM-160 contains delicate circuitry, susceptible to

transient power line voltages. Disconnect the power

cable whenever making any interface connections.

Refer all maintenance to qualified personnel.

1 - 4

PN 074-511-P1E

SQM-160 Operating Manual

1.2.3 Earth Ground

SQM-160 is connected to earth ground through a sealed three-core

(three-conductor) power cable, which must be plugged into a socket outlet with

a protective earth terminal. Extension cables must always have three conductors

including a protective earth terminal.

WARNING

Never interrupt the protective earth circuit.

This symbol indicates where the protective earth ground

is connected inside SQM-160.

Never unscrew or loosen this connection.

Disconnecting the protective earth terminal or

interrupting the protective earth circuit, whether inside or

outside of SQM-160, may render SQM-160 dangerous.

1.3 How To Contact INFICON

Worldwide customer support information is available under Support >> Support

Worldwide at www.inficon.com.

Sales and Customer Service

Technical Support

Repair Service

When experiencing a problem with SQM-160, please have the following

information readily available:

The Sales Order or Purchase Order number of the SQM-160 purchase

The version of SQM-160 firmware

The version of Windows operating system

A description of the problem

An explanation of any corrective action that may have already been attempted

The exact wording of any error messages that may have been received

1 - 5

PN 074-511-P1E

SQM-160 Operating Manual

1.3.1 Returning SQM-160

Do not return any component of SQM-160 to INFICON before speaking with a

Customer Support Representative and obtaining a Return Material Authorization

(RMA) number. SQM-160 will not be serviced without an RMA number.

Packages delivered to INFICON without an RMA number will be held until the

customer is contacted. This will result in delays in servicing SQM-160.

If returning SQM-160 with a crystal sensor or another component potentially

exposed to process materials, prior to being given an RMA number, a completed

Declaration Of Contamination (DOC) form will be required. DOC forms must be

approved by INFICON before an RMA number is issued. INFICON may require

that the component be sent to a designated decontamination facility, not to the

factory.

1.4 Specifications

1.4.1 Measurement

Sensor Inputs . . . . . . . . . . . . . . . . . . Two standard, Four additional (optional)

Measurement Frequency Range . . . 6.5 to 1.0 MHz (adjustable)

Reference Frequency Accuracy . . . . 0.002%

Reference Frequency Stability . . . . . ±2 ppm (total, 0 to 50°C)

Thickness Display Resolution . . . . . 1 Å

Frequency Resolution1. . . . . . . . . . . Standard: ±0.30 Hz @ 6 MHz

High Resolution option: ±0.03 Hz @ 6 MHz

Thickness and Rate

Resolution/Measurement2. . . . . . . . Standard: ±0.37 Å

High Resolution option: ±0.037 Å

Measurement Interval. . . . . . . . . . . . 0.10 to 2.0 s (adjustable)

1Resolution given for 0.10 s measurement interval

2Tooling/Density = 100/1, fundamental frequency = 6 MHz, 0.10 s

measurement interval

1 - 6

PN 074-511-P1E

SQM-160 Operating Manual

1.4.2 Film Parameters

Stored Films . . . . . . . . . . . . . . . . . . . 99

Density . . . . . . . . . . . . . . . . . . . . . . . 0.50 to 99.99 g/cm3

Tooling . . . . . . . . . . . . . . . . . . . . . . . 10 to 399%

Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . 0.10 to 10.00

Final Thickness . . . . . . . . . . . . . . . . 0.000 to 9999 kÅ

Thickness Setpoint. . . . . . . . . . . . . . 0.000 to 9999 kÅ

Time Setpoint . . . . . . . . . . . . . . . . . . 0:00 to 99:59 mm:ss

Sample/Hold. . . . . . . . . . . . . . . . . . . 0 to 5999 s

Sensor Average . . . . . . . . . . . . . . . . 1 to 6, depending on sensors installed

1.4.3 System Parameters

Measurement Period . . . . . . . . . . . . 0.10 to 2.00 s

Simulate Mode . . . . . . . . . . . . . . . . . On/Off

Display Mode . . . . . . . . . . . . . . . . . . Thickness in kÅ (THCK)

Thickness in µm (NANM)

Frequency in Hz (FREQ)

Mass in µg/cm2(MASS)

Rate Resolution . . . . . . . . . . . . . . . . 0.01 Å/s (HI)

0.1 Å/s (LO)

Measurement Filter . . . . . . . . . . . . . 1 to 20 readings

Relay 2 Mode . . . . . . . . . . . . . . . . . . Time Setpoint (TIME)

Dual Sensor Shutter (DUAL)

Sensor 2 Shutter (SNS2)

Relay (1 to 4) . . . . . . . . . . . . . . . . . . Normally Open (nO)/Normally Closed (nC)

Rate Sampling . . . . . . . . . . . . . . . . . On/Off

RS-232 Baud Rate . . . . . . . . . . . . . . 2.4, 4.8, 9.6, 19.2, 38.4, 57.6, 115.2 kbps

Etch Mode . . . . . . . . . . . . . . . . . . . . On/Off

Crystal Tooling (1 to 6) . . . . . . . . . . . 10 to 399%

Frequency Min/Max . . . . . . . . . . . . . 1.0 to 6.4 MHz/1.1 to 6.5 MHz

Analog Output Bounds

Rate Min/Max . . . . . . . . . . . . . . . -99 to 999 Å/s

Thickness Min/Max. . . . . . . . . . . 0.0 to -9999 kÅ

Table of contents

Popular Measuring Instrument manuals by other brands

Channel Master

Channel Master 1009IFD operating instructions

Diamond Engineering

Diamond Engineering DAMS 000 Series user manual

Fisher

Fisher FERITSCOPE FMP30 Operator's manual

F&F

F&F CLG-03 manual

Agilent Technologies

Agilent Technologies ESA Series User's/Programmer's Reference

VDO

VDO TU00-0752-5607150 installation instructions