Sigma Metalytics Precious Metal Verifier User manual

User Manual

ATTENTION

The Precious Metal Verifier is a scientific instrument.

There are important conditions to consider when

using the device which can impact your results. To

get proper readings from your device, please review

this manual carefully.

You can find more information on our website at www.sigmametalytics.com

Sigma Metalytics and the Precious Metal Verifier make no claim,

guarantee, or promise that measurements made by the Precious

Metal Verifier indicate any sample is or is not the selected metal

or alloy, whether the reading is within or is not within the bounds

consistent with the selected metal or alloy. To ensure accuracy,

read the instructions and special conditions which can alter the

reading from outside to within the expected bounds or from

within to outside the expected bounds. The readings given by

the Precious Metal Verifier are INFORMATIONAL ONLY and any

judgment about or action taken on any sample is entirely the

responsibility of the user.

CONTENTS

DeviceDiagram........................................2

Instructions..............................................3

Alloy Explanations

Gold................................................4

Silver................................................5

Other&Bullion....................................6

ResultsInterpretations................................7

Sensor Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ImportantNotesfor Testing..... ..... ..... ..... ...10

Battery Charging & Power Management. . . . . 12

Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Usage Considerations . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

DEVICE DIAGRAM

NOTE

The sample must entirely cover the black circle on the face of

the device for reliable onboard readings. When using a Wand,

the sample must entirely cover the face of the Wand.

3

Instructions

1. Press POWER to turn on the device. Wait until the display reads:

Remove Sample

Push RUN/CAL →Start

If you are using a Wand, connect it now. The green LED on the testing

platform will illuminate to indicate which sensor is in use. Press SENSOR

SELECT to switch between the Wand and the Onboard Sensor.

2. Clear all samples from the device. Press RUN/CAL to calibrate the

device. Ensure there are no samples on the device when you press

RUN/CAL. If you have a Wand plugged in, ensure the face of the Wand

is at least 1 inch away from any metal. Wait until the display reads:

Ready: Place Sample

3.Select the alloy type you would like to test. Use the UP ARROW and

DOWN ARROW buttons to select different categories of alloys and the

LEFT ARROW and RIGHT ARROW buttons to select specific alloys within

a category. See the chart below for the menu layout.

Gold ◄►

Pure .999+, 91.7% 22K bal Cu, 90% bal Cu, American Eagle, Krugerrand,

98.6%, Britannia 90-12

▲▼

Silver ◄►

99.99% Pure, 99.9% Pure, 92.5% Sterling, 90% US pre 1900, 90% US pre

1945, 90% US Coin 1960, 96% Britannia, 80% Canadian

▲▼

Other ◄►

Platinum, Palladium, Rhodium, Copper, Calibrator

▲▼

Bullion ◄►

Silver .9999, Gold .9999, Platinum, Palladium

4.Once the desired alloy is selected, press the RUN/CAL button. Ensure

there are no samples on the device when you press the RUN/CAL

button. The display will then read:

Ready: Place Sample

5.Place your sample on the sensor or touch the Wand to the sample

if using the Wand. Make sure your sample meets the minimum

requirements to get an accurate test (Page 8). The device will display

the results of the test. See Page 7 for interpreting the results.

4

Alloy Explanations

Gold

Gold-Pure .999+

Gold samples that are 99.9% or higher purity. This includes 99.99%

and 99.999%. These purities are sometimes written as .999, .9999, and

.99999.

Gold-91.7% 22K balCu

Gold samples that are 91.7% gold with balance copper. These samples

are sometimes advertised as 91.67% gold or 22k gold. Balance copper

means that the other 8.33% in the sample is copper.

Gold-90% bal Cu

Gold samples that are 90% gold with balance copper. Balance copper

means that the other 10% in the sample is copper.

Gold-American Eagle

American Gold Eagles are 91.67% gold, 3% silver, and 5.33% copper. The

American Gold Eagle has a very specific alloy used only in this type of

coin. Even though American Gold Eagles have 1 ozt of gold in them, they

are actually 91.67% gold with silver and copper as the balance metals,

which is why they weigh more than 1 ozt in total.

Gold-Krugerrand

Gold Krugerrands are 91.67% gold and 8.33% copper. While this is

technically the same setting as the 91.7% 22K balCu setting, we added

a second option for ease of use because gold Krugerrands are very

popular on the market.

Gold-Britannia 90-12

Between 1990 and 2012, Gold Britannia coins were minted with a 91.7%

gold and 8.3% silver alloy. Gold Britannia coins in 1987-1989 used a

91.67% gold and 8.33% copper alloy and can be tested with 91.7% 22K

balCu setting. Gold Britannia coins from 2013 to present are minted as

99.99% pure gold and can be tested with the Pure .999+ setting.

5

Alloy Explanations

Silver

Silver-99.99% Pure

Silver samples that are 99.99% purity. This includes 99.99% and 99.999%.

These purities are sometimes written as .9999 and .99999.

Silver-99.9% Pure

Silver samples that are 99.9% purity. This is only 99.9%, and higher

purity samples should be read on the higher purity setting. This purity

is sometimes written as .999.

Silver-92.5%Sterling

Silver samples that are 92.5% silver with balance copper. Balance

copper means that the other 7.5% in the sample is copper.

Silver-90%US pre1900

The U.S. government used to mint coinage in 90% silver and 10%

copper alloys. The pre-1900 setting takes into account impurities and

contamination present in older coins that the mint was either unable to

remove or unaware existed at the time of minting. 90% silver samples

that were minted before 1900 should be tested on this setting.

Silver-90%US pre1945

The U.S. government used to mint coinage in 90% silver and 10%

copper alloys. The pre-1945 setting takes into account impurities and

contamination present in older coins that the mint was either unable to

remove or unaware existed at the time of minting. 90% silver samples

that were minted between 1900 and 1945 should be tested on this

setting.

Silver-90% Coin 1960

The U.S. government used to mint coinage in 90% silver and 10% copper

alloys. The coin 1960 setting takes is designed for 90% silver, 10% copper

coins minted from 1946 to present day. 90% silver samples that were

minted between 1946 and present day should be tested on this setting.

Silver-96% Britannia

Between 1997 and 2012, Silver Britannia coins were minted with a 95.8%

silver and 4.2% copper alloy. Silver Britannia coins from this era should

be tested on this setting. Silver Britannia coins from 2013 to present day

are minted from 99.9% pure silver alloy.

Silver-80% Canadian

Certain Canadian silver dollars and commemorative coins were

minted with an 80% silver and 20% copper alloy. Coins with that alloy

can be tested on this setting. Note that not all Canadian silver coins

were minted with this alloy.

6

Alloy Explanations

Other & Bullion

Other-Platinum

Platinum samples that are 99.9% or higher purity. This includes 99.99%

and 99.999%. These purities are sometimes written as .999, .9999, and

.99999.

Other-Palladium

Palladium samples that are 99.9% or higher purity. This includes 99.99%

and 99.999%. These purities are sometimes written as .999, .9999, and

.99999.

Other-Rhodium

Rhodium samples that are 99.9% or higher purity. This includes 99.99%

and 99.999%. These purities are sometimes written as .999, .9999, and

.99999.

Other-Copper

Copper samples that are 99.9% or higher purity. This includes 99.99%

and 99.999%. These purities are sometimes written as .999, .9999, and

.99999.

Other-Calibrator

If you would like to check if your device is properly calibrated and

providing accurate results, select this setting and place the aluminum

Calibration Disk (included with your device) on any Wand or the

onboard sensor. The result should come up in the brackets. If it does

not, please contact us to troubleshoot and setup and repair and

recalibration if necessary. Your calibration disk made read one or two

steps away from the center, that is normal.

Bullion-Silver 99.99%

Large Silver samples (20 ozt or greater) that are 99.99% or higher

purity. This includes 99.99% and 99.999%. Use the Bullion Wand with

this setting.

Bullion-Gold 99.99%

Large Gold samples (20 ozt or greater) that are 99.99% or higher purity.

This includes 99.99% and 99.999%. Use the Bullion Wand with this

setting.

Bullion-Platinum 99.99%

Large Platinum samples (20 ozt or greater) that are 99.99% or higher

purity. This includes 99.99% and 99.999%. Use the Bullion Wand with this

setting.

Bullion-Palladium 99.99%

Large Platinum samples that are 99.99% or higher purity. This includes

99.99% and 99.999%. Use the Bullion Wand with this setting.

7

Results Interpretation

When testing a sample, brackets will be displayed. The location of the box cursor

relative to the brackets indicate the results of the test.

Sample is consistent with the selected alloy type

The box cursor will fall anywhere inside of the brackets if the sample’s characteristic

resistivity is consistent with the selected alloy type. The box cursor may not be in

the exact center of the brackets. That is okay. A result anywhere in the brackets

means the sample is consistent with the selected alloy type. Even on a good

result, test the size and weight of the sample to confirm it is the right density.

Sample is slightly inconsistent with the selected alloy type

If the box cursor falls outside of the brackets, to either the right or to the left, that

indicates that the sample is slightly inconsistent with the selected alloy type. There

could be reasons for a genuine sample to read outside of the brackets, including

but not limited to the sample being:

• Embossed or has high relief or design

• Very cold or very warm relative to the temperature of the device

• Too far away from the sensor

• Too thin or too small for the current sensor (see sensor selection)

• Off center from the sensor

• Very slightly impure, like higher than usual iron content

Confirm that the test is being performed properly. If everything is correct, this is a

questionable sample.

Sample is inconsistent with the selected alloy type

The further the box cursor is outside of the brackets, the less consistent the

sample’s characteristic resistivity is with the selected alloy type and the more

questionable the sample is. Further testing, more research, and analysis by other

non-destructive methods is highly recommended.

An arrow indicates that a sample is off the scale in that direction. This indicates

the sample is highly inconsistent with the selected alloy type.

8

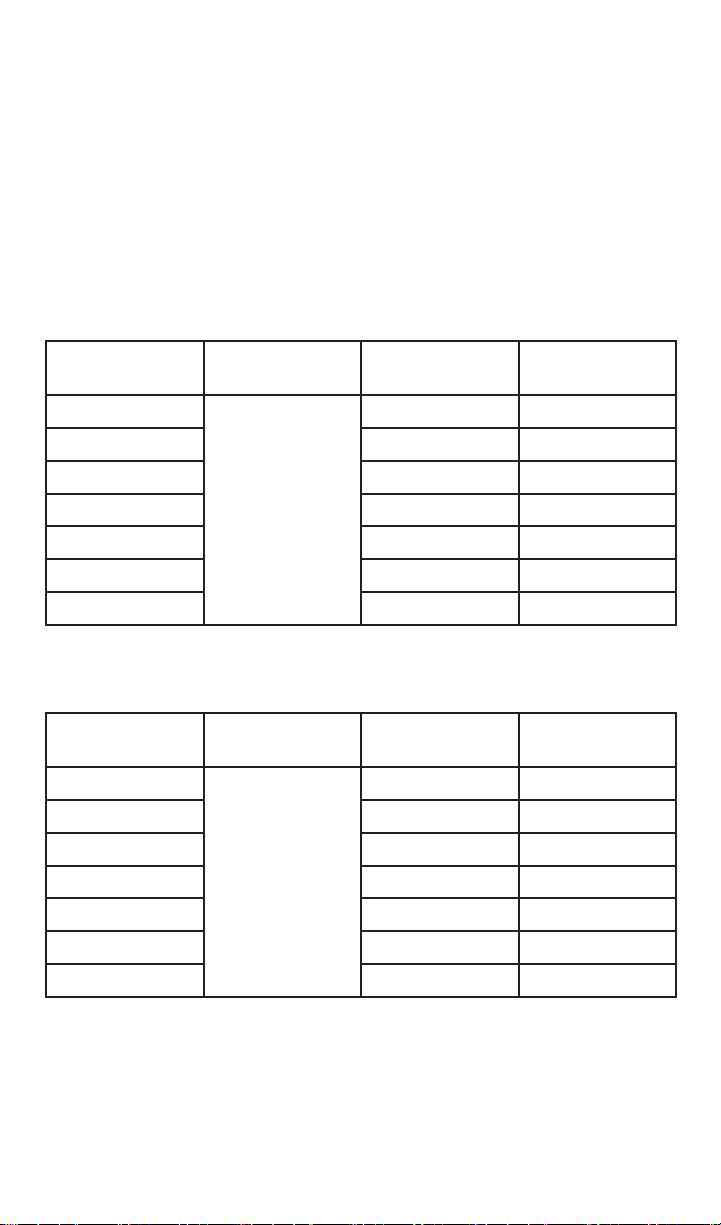

Sensor Selection

Samples must be tested using the appropriate sensor to get reliable

results. Using an incorrect sensor can lead to false negatives and false

positives. Use the specifications below to choose the correct sensor for

your sample.

Placing the included calibration disk behind the sample during testing

can enhance the reliability and allows the sensor to test thinner samples.

The column indicating “with Cal Disk” is the minimum testable thickness

when using testing with the calibration disk behind the sample.

Onboard Sensor

Category Min. Diameter Min. Thickness Min. Thickness

(with Cal Disk)

Gold 99.9%+

24.0 mm

1.1 mm 0.8 mm

Gold Alloys 2.4 mm 1.7 mm

Silver 99.9%+ 1.0 mm 0.8 mm

Silver Alloys 1.1 mm 0.8 mm

Platinum 2.4 mm 1.7 mm

Palladium 2.4 mm 1.7 mm

Rhodium 1.6 mm 0.9 mm

Small Wand

Category Min. Diameter Min. Thickness Min. Thickness

(with Cal Disk)

Gold 99.9%+

8.0 mm

0.8 mm 0.4 mm

Gold Alloys 1.7 mm 1.0 mm

Silver 99.9%+ 0.8 mm 0.4 mm

Silver Alloys 0.8 mm 0.4 mm

Platinum 1.7 mm 1.0 mm

Palladium 1.7 mm 1.0 mm

Rhodium 1.1 mm 1.0 mm

9

Sensor Selection, Continued

If a sample is providing odd or unreliable test results with a certain sensor,

trying testing with one sensor smaller. This can sometimes provide more

reliable results.

Small samples can warm up very quickly with handling which may

interfere with testing results. If a sample is a different temperature than

the device, place both the sample and the device on the same counter

and let them come to room temperature for about 10 minutes before

testing again.

Large Wand

Category Min. Diameter Min. Thickness Min. Thickness

(with Cal Disk)

Gold 99.9%+

18.0 mm

0.8 mm 0.4 mm

Gold Alloys 1.7 mm 1.0 mm

Silver 99.9%+ 0.8 mm 0.4 mm

Silver Alloys 0.8 mm 0.4 mm

Platinum 1.7 mm 1.0 mm

Palladium 1.7 mm 1.0 mm

Rhodium 1.1 mm 1.0 mm

Bullion Wand

Category Min. Diameter Min. Thickness Min. Thickness

(with Cal Disk)

Gold 99.9%+

24.0 mm

4.5 mm 3.3 mm

Gold Alloys 7.0 mm 6.5 mm

Silver 99.9%+ 4.0 mm 3.3 mm

Silver Alloys 4.5 mm 3.3 mm

Platinum 7.0 mm 6.5 mm

Palladium 7.0 mm 6.5 mm

Rhodium 6.3 mm 3.7 mm

10

Important Notes for Testing

Density Testing

It is critically important to confirm a sample’s density in addition

to testing its resistivity. Every precious metal alloy has a unique

combination of density and resistivity; by only testing one aspect, the

sample is only partially confirmed to be consistent with the genuine

alloy. The PMV Original is only testing resistivity and it is up to the user

to confirm density separately.

There are many ways to confirm a sample’s density is correct.

Whatever method you use, the sample should be the right weight and

the right size for the alloy. If your sample has published specifications,

the simplest way to confirm density is to weigh it and size it (measure

thickness and diameter or length and width) and confirm that your

sample matches the published specifications.

Correct Alloy Setting

Some alloys are unique to specific types of coins, and it is important to

test a sample on the correct alloy setting. For example, the American

Gold Eagle has a unique alloy of 91.67% gold, 3% silver, and 5.33%

copper. It will only test properly on the American Gold Eagle setting, not

the other 91.67% gold settings.

Modern Sandwich Coins on 90% Silver Settings

Modern sandwich coinage will read within the acceptable range on

the 90% Silver Bal Cu setting. Modern coinage is designed to have

the same resistivity to ensure they work in coin machines with older

coinage. The best way to ensure your quarters are 90% silver is to check

their density (weight and size) in addition to the resistivity test. Below

are the specifications for both modern and pre-1965 quarters.

Checking Calibration

If the PMV is giving inconsistent results or odd readings, and the tests

are being performed correctly (on the correct alloy setting, using

the correct sensor, sample is within minimums, etc.), then check the

device’s calibration (Page 6). If the device’s calibration is not correct,

then contact us immediately for service. If the device’s calibration is

correct, then the sample is highly questionable.

Magnetic Samples

Samples that are highly magnetic will cause the device to enter a

constant re-calibration state when placed on the sensor. If the device

is repeatedly asking for recalibration when a sample is placed on the

sensor, then use a magnet check if the sample is magnetic. Genuine

precious metal pieces are not magnetic.

11

Conditions that Affect Readings

Thin Samples

The sensor’s signal may over-penetrate very thin samples and cause

inaccurate readings. Refer to the minimum thicknesses information

to make sure the sample meets the minimums for the sensor in use.

Place the calibration disk behind the sample and/or switch to a smaller

sensor if necessary.

Small Samples

It is important to use the correct sensor size for the sample size. If the

sample does not meet the minimum requirements for a sensor, the

device will not provide accurate readings.

Samples with High Relief

Samples with very deep stamping, molded samples with large designs,

and other high-relief samples may cause inaccurate readings. Try

to take a reading from a flat area of the sample to ensure the test is

accurate. Most coins and bars will not have this problem.

Bars

Some bars may only partially meet the minimum requirements for

the sensors. For example, a long, narrow bar may be longer than the

sensor minimum, but may not be wide enough for accurate testing. A

bar must meet the sensor minimums in width and length in order to be

accurately tested.

Cases

Cases made of plastic and/or cardboard should not affect the test

results. However, cases with metal in them will interfere with the testing

results.

Similarly, very thick cases may also cause the device to not read the

sample if the sample is too far away from the sensor. This is more

common in cases with a small or thin sample in a thick case. For

example, a 1/4 oz gold piece in a case that normally holds a 1 oz gold

piece may be difficult to read due to the case size.

12

Battery Charging

The PMV contains a rechargeable lithium-ion battery. The battery is

high-capacity and the devices uses a battery management system to

protect the health of the battery and the device.

When the battery is low, the green LED next to the POWER button will blink

slowly.

To charge the unit, connect the included USB cable to the USB port on the

side of the PMV (see Device Diagram). The device can also be charged

by plugging the USB cable directly into a computer.

The PMV will still charge when powered off. Whether the PMV is off, the LED

will not illuminate while charging. When the PMV is on, the LED will blink

and stop blinking when it is fully charged.

If the PMV has not been used for a while, it can take up to 12 hours to fully

charge the battery. If the device has been unused for a long period of

time, plug it in and charge it overnight before using it.

The charger connector may not appear to be fully “seated” or sit flush

with the device. This is normal. As long as a firm connection is made,

the device will charge. Do not over-press the charger port, as this may

cause damage to the internal circuitry.

Power Management

The PMV has built-in features to improve battery life and protect the

health of the device.

The device’s display will dim after one minute of no use. Placing a coin on

the sensor or pushing any button will restore the backlight.

The device will automatically turn off after five minutes of no use. Power

on the device like normal to get back to testing.

When the device powers on, it will check the battery’s charge level. If the

charge level is below a certain percent, the battery management system

will turn the device off to protect the microprocessor. If this happens, plug

the device in to charge for at least 6 hours.

13

Measurement Mode

The PMV Measurement Mode allows the user to see the mathematical

result of the resistivity test for a sample rather than the box and bracket

result. The result is close to the resistivity value of metal being tested, but

slightly different. Identical metals will have identical values, which allows

unknown alloys or samples to be categorized as similar or different.

To enable Measurement Mode:

1. Turn off the PMV. Press and hold the SENSOR SELECT button. While

holding this button, press the POWER button. The display will then read:

Remove Sample

Push RUN/CAL →Start

2. Release the SENSOR SELECT button. Make sure the device is clear of any

samples and press the RUN/CAL button. The display will then read:

Measurement Mode

Ready: Place Sample

3.Place the sample on the sensor. Instead of the normal box and bracket

results, the PMV will display, with the sample’s results displayed:

Measurement Mode

Value =

4.To return to normal operation, power off the device and power on

again without holding down any button.

14

Use Considerations

USE WITH CAUTION

It is not our recommendation or intention for the Precious Metal Verifier

(PMV) to be the sole means for identification of counterfeit coins and bars.

Our measurement of a material’s electrical characteristic (resistivity or

conductivity) is necessary, but not by itself sufficient for such a purpose.

We recommend that you check the item being measured against its

specified weight, and size along with the resistivity measurement. You

should use your normal visual checks of the material as well.

Other materials have the same resistivity as pure gold, and as such

can look like gold on the PMV. These materials will be less dense than

gold, so they will be larger or weigh less than the specified value. If you

check material that looks good on the PMV, but has the wrong weight or

dimensions, then you should not accept the material as consistent with

the correct metal.

Do not try to use the PMV to determine what a material is. The PMV will

only provide the electrical characteristic (resistivity or conductivity) of

the metal, not the atomic structure. Correct use is to have an expectation

of the material type (gold, silver, platinum, etc.), and alloy content (22K,

coin silver, sterling, .999 pure, etc.), and to verify that the material being

tested is consistent with your expectation.

Used in this way, the PMV is a great asset in avoiding counterfeit products

Table of contents

Other Sigma Metalytics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

MPFiltri

MPFiltri LPA2 user guide

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 5000 instruction manual

parktool

parktool TM-1 instructions

Promax

Promax HD Ranger + user manual

PerkinElmer

PerkinElmer QuantaSmart 1694267 Reference manual

B+K precision

B+K precision 889B manual