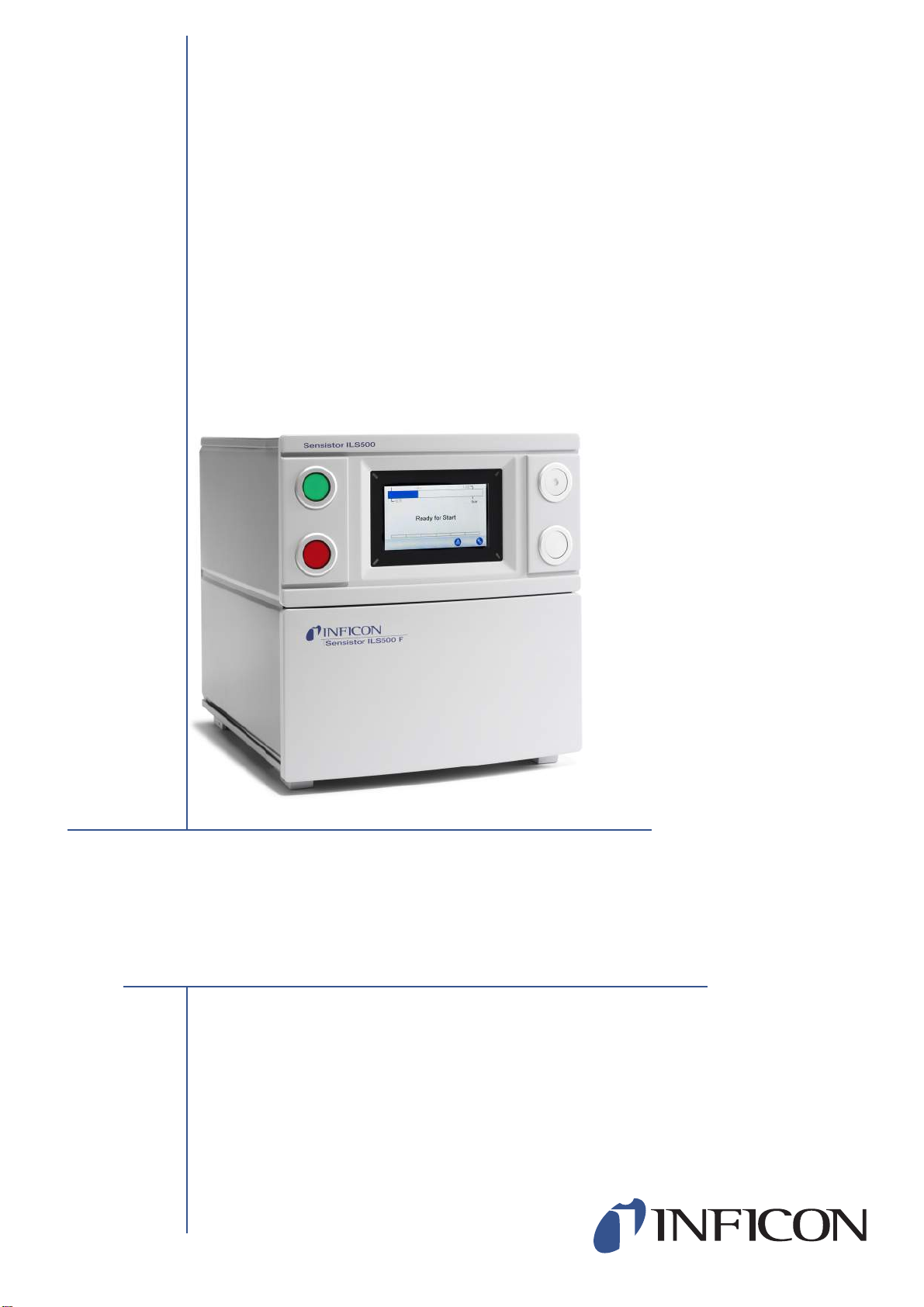

Inficon Sensistor ILS500 F User manual

Sensistor ILS500 F

O P E R A T I N G M A N U A L

ninp69e1-a (1410)

Leak Detection Filler

Type no. ILS.210.306

Content 3

ninp69e1-a (1410)

Content

1 General Information 8

1.1 About This Manual 8

1.2 Introduction to the ILS500 F 8

1.3 Disposal 9

2 Equipment and Storage 10

2.1 Supplied Equipment 10

2.2 Required Equipment 11

2.3 Storage 11

3 ILS500 F Description 12

3.1 Front View 12

3.2 Rear View (Electrical) 13

3.3 Configuring Ports and Interfaces (Electrical) 14

3.4 Rear View (Pneumatical) 15

3.5 Configuring Ports and Interfaces (Pneumatical) 16

3.6 Labels 16

4 Setup 18

4.1 Placement of the ILS500 F 18

4.2 Electrical Connections 19

4.3 Pneumatic Connections 21

4.4 Connect External Leak Detector 25

4.5 Set Up Test Area 25

5 Menu System 27

5.1 ILS500 F Display 27

5.2 Passwords 29

5.3 Menu Overview 30

6 Using the ILS500 F 35

6.1 Test Sequence 35

6.2 Run a Test 36

7 Recipes 38

7.1 Recipe Overview 38

7.2 Create a Recipe 39

7.3 Test Settings 40

7.4 Optimizing the Test Cycle 46

8 Troubleshooting 50

8.1 Fault Symptoms 50

8.2 Perform Hardware Test 50

9 Maintenance Instructions 62

9.1 Maintenance Plan 62

Content 4

ninp69e1-a (1410)

9.2 Maintenance 63

9.3 Functional Verification 69

10 Service 70

11 Technical Data 71

11.1 Electrical Specifications 71

11.2 Pneumatic Specifications 72

11.3 Other Data 73

11.4 Interfaces and Connectors 74

12 Spare Parts and Accessories 84

13 Support from INFICON 85

13.1 How to Contact INFICON 85

13.2 Returning Components to INFICON 85

14 Declaration of Conformity 86

15 Declaration by the Manufacturer 87

Appendix

A: Parameter Index 88

5

ninp69e1-a (1410)

General Safety Precautions

Definitions of Warning, Caution and Notice

General Safety

Failure to observe the following precautions could result in serious personal

injury:

Warning

Indicates procedures that must be strictly observed to prevent hazards to persons.

Caution

Indicates procedures that must strictly be observed to prevent damage to or destruction

of the instrument

.

Notice Indicates special requirements the user must comply with.

Warning

Tracer Gases can be flammable or asphyxiating. Use only ready-made Tracer Gas

mixtures.

Warning

Since the tracer gas mix contains no oxygen, releasing large amounts of the gas in a

confined space may lead to asphyxiation.

Warning

Compressed gases contain a great deal of stored energy. Always carefully secure

gas bottles before connecting a pressure regulator. Never transport gas bottles with

a pressure regulator fitted.

6

ninp69e1-a (1410)

Failure to observe the following precautions could result in damage to the

equipment:

Warning

Pressurizing objects at too high pressures can lead to the object bursting. This in

turn can result in serious injury or even death. Never pressurize objects that have

not previously been burst-tested or have otherwise been approved for the test

pressure you intend to use.

Caution

If the tracer gas filler suffers external damage, it must be checked and repaired by a

service organization authorized by INFICON.

Caution

Always switch power off before connecting or disconnecting any cable.

Notice Before connecting the tracer gas, confirm that the connectors or test

object is designed for operating at the test pressure to be used.

7

ninp69e1-a (1410)

Safety ILS500 F

INFICON can not take any responsibility for the consequences arising from

inappropriate use of certain test pressures.

Warning

The ILS500 F must never be introduced to pressures higher than that approved for

the object to be tested and never beyond the ILS500 F specification.

Warning

Be sure to have a pressure relief valve in case of accidental tracer gas pressure

increase.

Warning

When dealing with high pressures, a blast protection is needed between the Test

Ports and the Test Object.

Warning

When dealing with test objects that cannot stand high pressure increase, make sure

to mount a flow control valve on the Test Ports.

Warning

Make sure not to confound Compressed Air and Tracer Gas.

Notice The ILS500 F has no internal emergency stop circuit. ILS500 F is

prepared for integration into an external emergency stop circuit.

Check that all relevant legislation and safety standards are complied with

before putting the ILS500 F into service. See further information under

Installation.

General Information 8

ninp69e1-a (1410)

1 General Information

Please read this Operating Manual carefully before putting your Sensistor ILS500 F

into service. When reading, please pay particular attention to the WARNINGS,

CAUTIONS and NOTICES found throughout the text.

1.1 About This Manual

The purpose of this manual is to:

•Describe the working principles of the ILS500 F and its different parts

•Show examples of different types of test stations

•Teach the reader how to set up the ILS500 F for different test purposes

1.1.1 Document History

1.2 Introduction to the ILS500 F

The Sensistor ILS500 F is a stand alone tracer gas filler with all necessary functions

integrated in one very compact housing.The purpose of the ILS500 F is to make it

possible to set up a fully automatic leak test system quickly, to a low cost.

The ILS500 F can also be combined with both hydrogen and helium INFICON leak

detectors.

If a ISH2000 Hydrogen Leak Detector is connected to the ILS500 F, via the Probe

Control Port and Leak Detector Port, the ILS500 F has the same functionality as

ILS500. For information on how to setup this configuration, please contact INFICON.

1.2.1 Intended Use

ILS500 F is designed for indoor use only.

All functions are accessible and programmable using a touch panel, a PC or via the

Internet. The test sequence is controlled by an integrated controller.

Revision Date Remark

a 10-2014 First edition

Notice ILS500 F is not compatible with AP29, AP55, and AP57.

9General Information

ninp69e1-a (1410)

1.2.2 Available Configurations

Sensistor ILS500 F

The actual configuration is shown on the ILS500 F display during start-up and in the

menu when clicking Setup >> Info.

1.3 Disposal

Sensistor ILS500 F

Standard For common tracer gas leak detection

High Pressure (HP) When a higher tracer gas pressure is needed.

According to EU legislation, this product must be recovered for

separation of materials and may not be disposed of as unsorted

municipal waste.

If you wish you can return this INFICON product to the manufacturer

for recovery.

The manufacturer has the right to refuse taking back products that

are inadequately packed and thereby presents safety and/or health

risks to the staff.

The manufacturer will not reimburse you for the shipping cost.

Shipping address:

INFICON AB

Westmansgatan 49

582 16 Linköping

Sweden

Equipment and Storage 10

ninp69e1-a (1410)

2 Equipment and Storage

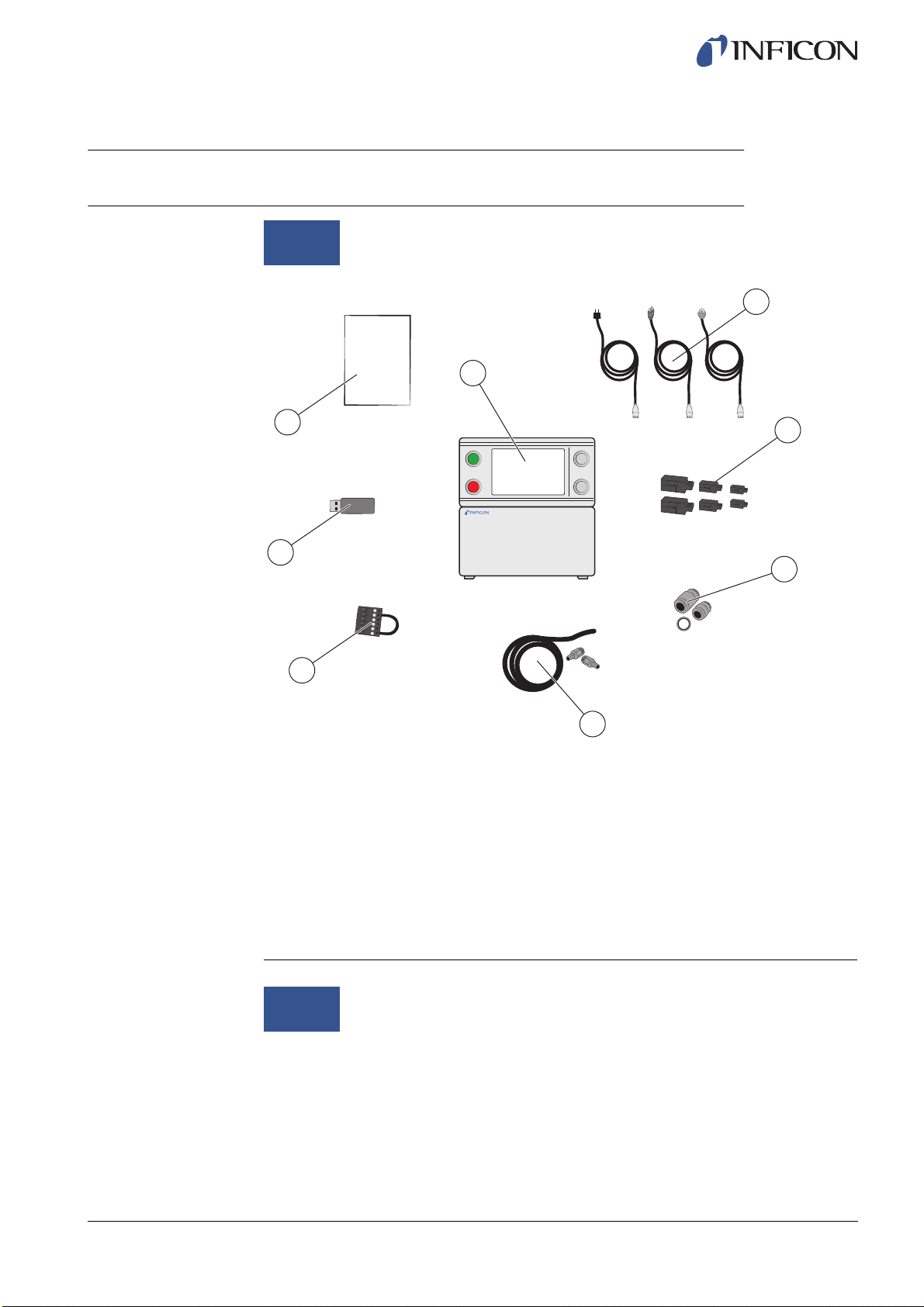

2.1 Supplied Equipment

Supplied Equipment

Accessories to the ILS500 F can be found on page 84.

Notice When receiving the equipment, check that it has not been damaged

during transport.

1 ILS500 F

2 Power Cables (EU, UK, US)

3 Screw Terminal Connectors for External I/O Signals

4 Thread Converter Set (ISO to NPT Conversion)

5 Hose Connection Kit

6 Safety Override Loopback

7 USB flash drive with relevant manuals

8 Operating Manual Sensistor ILS500 F (this manual)

2

8

7

6

1

3

4

5

ILS500 F

OM

Notice Some pneumatic ports are plugged upon delivery. Store the removed

plugs. They are used for future hardware testing.

11 Equipment and Storage

ninp69e1-a (1410)

2.2 Required Equipment

Required Equipment

2.3 Storage

For prolonged storage, factors such as temperature, humidity, saline atmosphere etc.,

may damage the detector elements.

Please contact your local representative for more information.

1 Tracer Gas

2 Compressed Air

3 Two-Step Gas Regulator

4 Compressed Air Filter

5 Exhaust Hose

6 Emergency Stop Circuit (recommended)

13

24

5 6

ILS500 F Description 12

ninp69e1-a (1410)

3 ILS500 F Description

ILS500 F is manually controlled using the START and STOP buttons and the menu

system of the touch panel. The screen also shows the steps of the test sequence

graphically and in plain text.

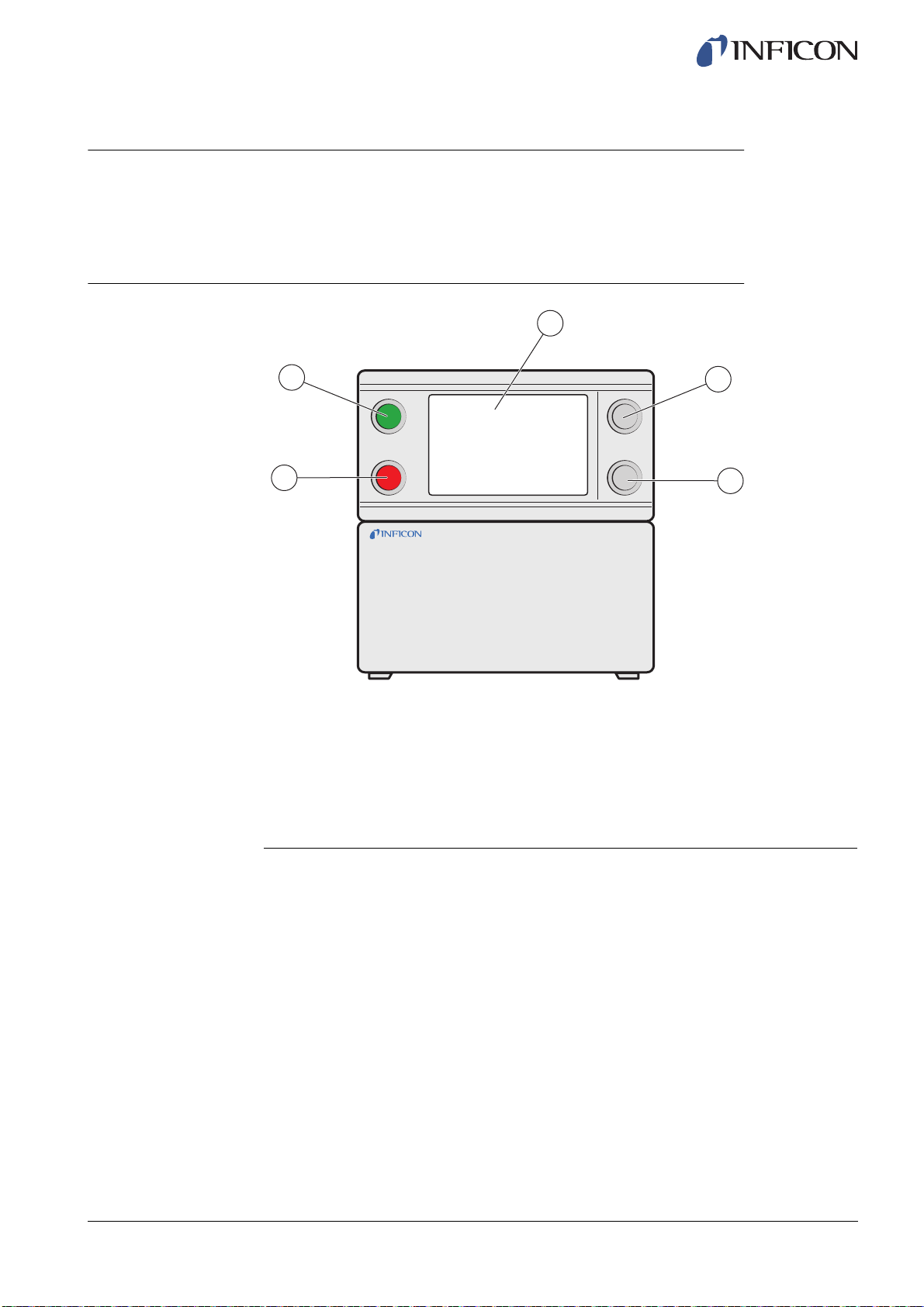

3.1 Front View

ILS500 F Front View

1 Red lamp

2 Green lamp

3 ILS500 F Touch panel

4 START button

5 STOP button

1

2

3

4

5

13 ILS500 F Description

ninp69e1-a (1410)

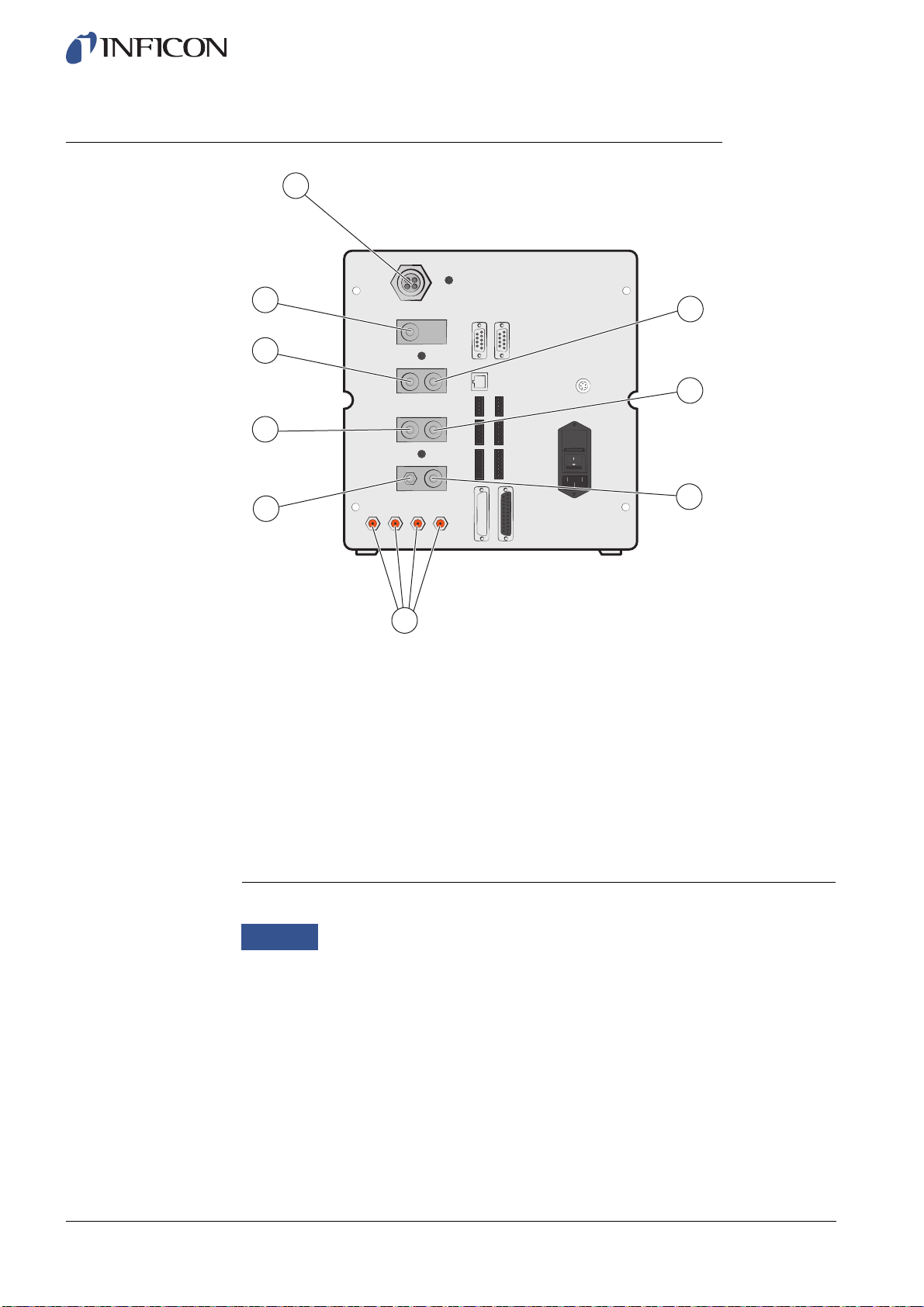

3.2 Rear View (Electrical)

Rear View (Electrical)

For more information, see on page 71.

1 Leak Detector (for connection of ISH2000 or T-Guard)

2 Safety Interface

3 Fuses

4 Power Switch

5 Power Input

6 Probe Control Port (for connection of ISH2000)

7 Control Output

8 Tooling Interface

9 Status Output

10 Inputs 1 and 2 (optional)

11 Ethernet

12 Printer Port/RS232

12 1

11

7

8

9

10

5

2

3

4

6

ILS500 F Description 14

ninp69e1-a (1410)

3.3 Configuring Ports and Interfaces (Electrical)

Port/Interface Connect

Leak Detector ISH2000 or T-Guard.

Safety Interface Emergency Stop Circuit.

Power Input Power Cable.

Probe Control Port Pin-to-pin cable

(for external mounting of ISH2000 Leak Detector).

Control Output Optional External Valves.

Tooling Interface External sensors for tooling control.

Status Output Light Tower etc.

Input 1 (optional) Analogue Input

(not supported by std software).

Digital Input

(not supported by std software).

Input 2 Active Holder for Hand Probe

(if ISH2000 Leak Detector is connected).

Ethernet Ethernet

(remote view and control of touch panel).

Printer Port/RS232 Serial Printer.

Logging Device

(e.g. PC).

Remote Control

(START, STOP etc.).

15 ILS500 F Description

ninp69e1-a (1410)

3.4 Rear View (Pneumatical)

Rear View (Pneumatical)

1 Optional Port

2 Test Port 2

3 Compressed Air Input

4 Tooling Valve Outputs 1-4

5 Vacuum Gauge Vent

6 Test Port 1

7 Tracer Gas Input

8 Plugged Port

9 Exhaust

1

5

6

9

8

7

4

3

2

Notice Do not remove the plug from the plugged port in pos. 8.

ILS500 F Description 16

ninp69e1-a (1410)

3.5 Configuring Ports and Interfaces (Pneumatical)

3.6 Labels

Device Label

Tooling Label

Port/Interface Port Thread

Exhaust Barb Fitting:

ID 25 mm (1 in.)

Tracer Gas Input

Test Port 1

Test Port 2

Compressed Air Input

BSP 3/8" (NPT 3/8" adaptor included)

BSP 3/8" (NPT 3/8" adaptor included)

BSP 3/8" (NPT 3/8" adaptor included)

BSP 3/8" (NPT 3/8" adaptor included)

Tooling Valve Outputs 1-4 Hose Connectors:

OD 4 mm (0.16 in.)

17 ILS500 F Description

ninp69e1-a (1410)

Pneumatical Label Electrical Label

Setup 18

ninp69e1-a (1410)

4 Setup

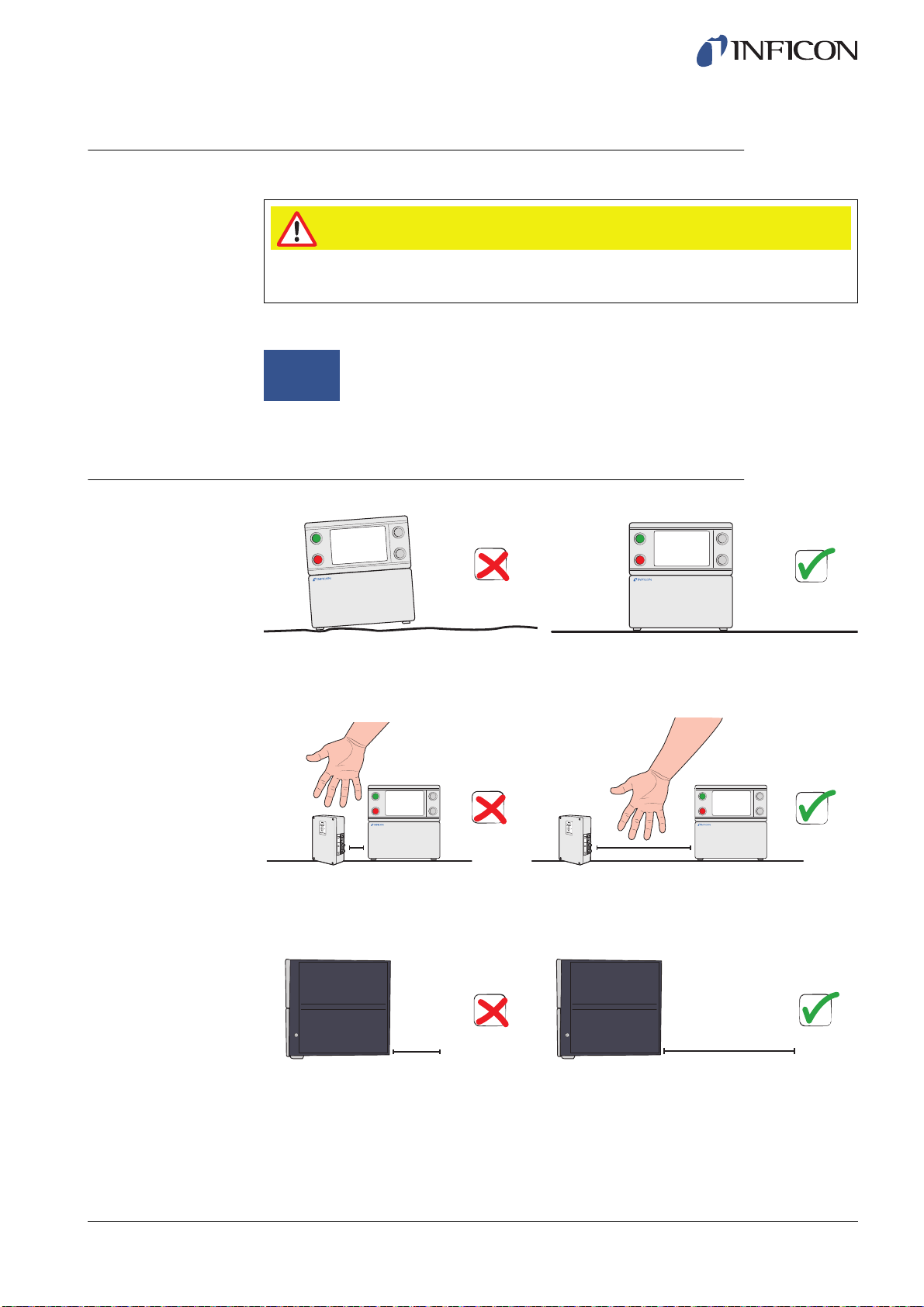

4.1 Placement of the ILS500 F

Place the ILS500 F on a flat surface, as close as possible to the test fixture and

ventilation system.

Some free space must be provided around the ILS500 F to enable maintenance and

service access.

Ensure that there is at least 350 mm (14 in.) of free space behind the ILS500 F to

enable removal of service hatches, connection of supplies, test fixture etc.

Caution

Check that you comply with all relevant legislation and safety standards before

putting your ILS500 F into service.

Notice Start-up time for the leak detectors can be up to 10 minutes, depending

on the condition.

≥350 mm (14 in.)

19 Setup

ninp69e1-a (1410)

4.2 Electrical Connections

4.2.1 Setting Up an Emergency Stop

You have the following two options to prepare the ILS500 F for start:

•Connect the ILS500 F through an external emergency stop relay.

•Short circuit the SAFE SPLY terminal to “+24 V” on the Safety Connector.

Use the Safety Override Loopback delivered with the unit.

Notice The front feet under the ILS500 F can be flipped out to raise the front for a

better viewing angle.

Caution

To short-circuit is not recommended and should only be made for preliminary testing

before connecting compressed gases or test tooling with moving parts.

Notice ILS500 F will not start testing unless an emergency circuit has been

installed. This is ordered separately. For more information, see on page

84.

Setup 20

ninp69e1-a (1410)

4.2.2 Connecting to Mains

1Plug the Power Cable into the Power Inlet of the ILS500 F and into the nearest

socket.

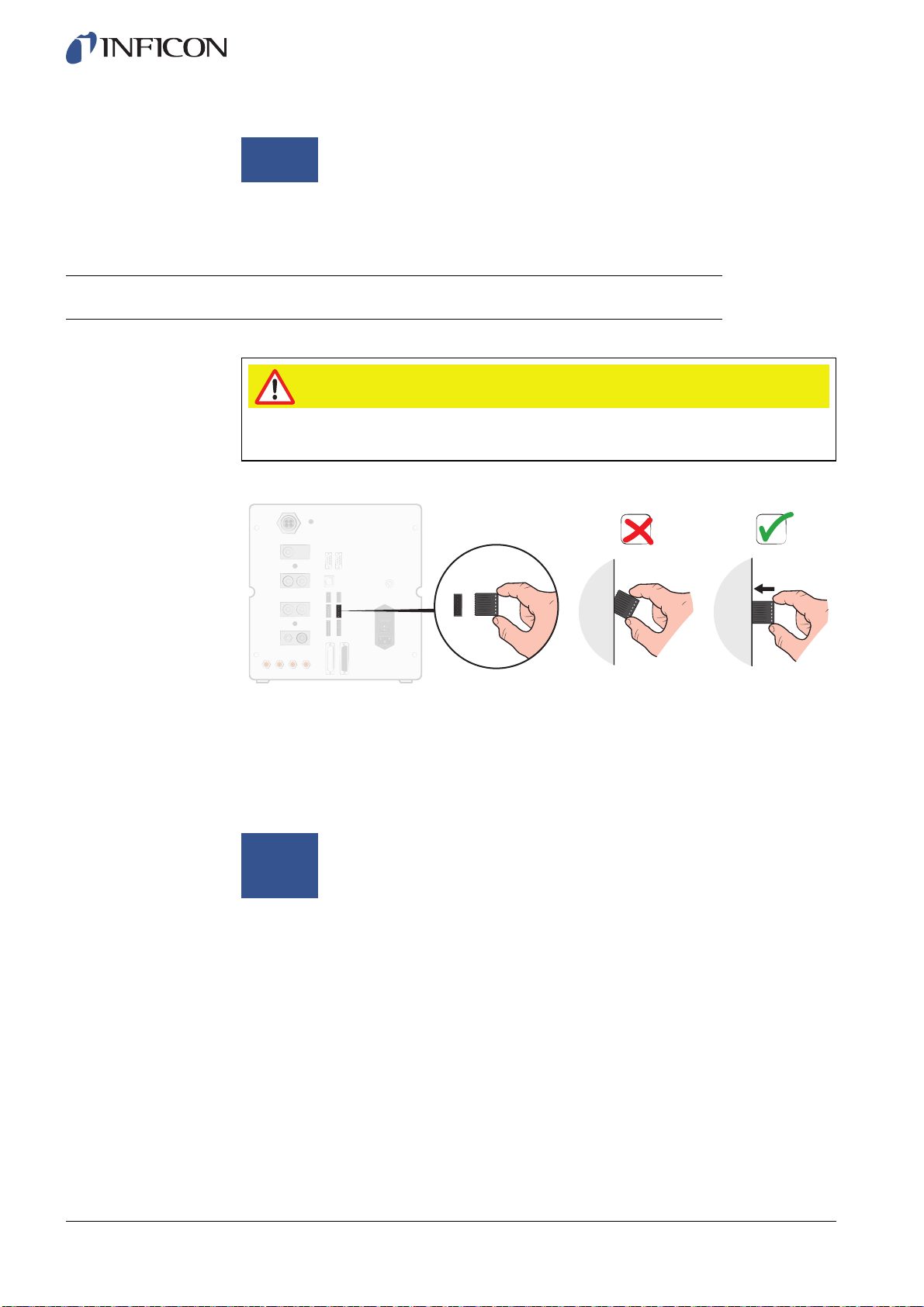

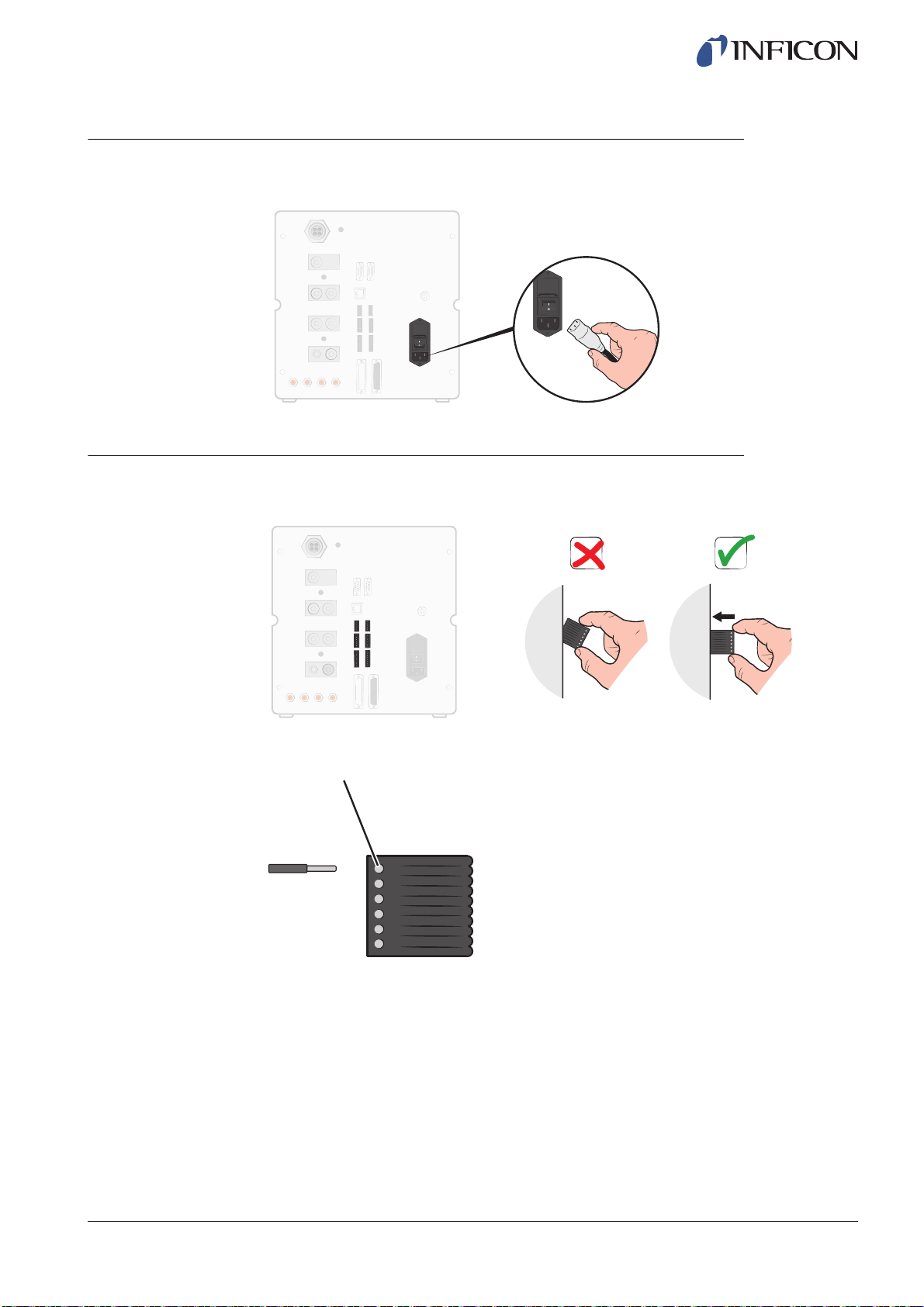

4.2.3 Connecting Extra Features

When using the ports for Options, Status, Tooling and Control, make sure to mount the

connectors as shown below.

For more information about the connection ports, see on page 71.

Top pin is number 1

Other manuals for Sensistor ILS500 F

1

Table of contents