Voith ARGO HYTOS Ecoline UMPC2 045 User manual

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 1

www.argo-hytos.com

Read safety and operating instructions before use.

Note: The indicated data only serve to describe the product.

Specifications regarding the use of this product are only examples and suggestions.

Catalog specifications are no guaranteed features.

The information given does not release the user from his / her own assessments and inspection.

Our products are subject to natural wear and aging process.

© All rights are reserved by ARGO-HYTOS Polska, even in the event of industrial property rights.

Any right of disposal such as copying and distribution rights shall remain with us.

The picture on the title page shows a configuration example.

The delivered product may thus differ from the illustration.

Oil Service Unit

Ecoline UMPC2 045

Manual

Safety and operating instructions

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 2 www.argo-hytos.com

Content

Filter and Recirculating Pump Unit UMPC 045

Content.......................................................................................................................................................................... 2

1. About this documentation........................................................................................................................................... 4

1.1 Applicability of this documentation ................................................................................................................................. 4

1.2 Required and supplementary documentation .................................................................................................................. 4

1.3 Presentation of information ............................................................................................................................................ 4

1.3.1 Safety instructions .......................................................................................................................................................... 4

1.3.2 Symbols .......................................................................................................................................................................... 5

1.3.3 Terms ............................................................................................................................................................................. 5

1.3.4 Abbreviations .................................................................................................................................................................. 5

2. Safety instructions........................................................................................................................................................ 6

2.1 About this chapter .......................................................................................................................................................... 6

2.2 Intended use .................................................................................................................................................................. 6

2.3 Improper use .................................................................................................................................................................. 6

2.4 Reasonable foreseeable misuse ....................................................................................................................................... 6

2.5 Qualification of personnel ............................................................................................................................................... 6

2.6 General safety instructions .............................................................................................................................................. 7

2.7 Product and technology related safety instructions .......................................................................................................... 7

3. General instructions ..................................................................................................................................................... 8

4. Scope of delivery.......................................................................................................................................................... 9

5. About this product ..................................................................................................................................................... 10

5.1 Component overview ................................................................................................................................................... 10

5.2 Identification of the product .......................................................................................................................................... 12

6. Transport and storage................................................................................................................................................ 13

6.1 Transport ...................................................................................................................................................................... 13

6.2 Storage ......................................................................................................................................................................... 13

7. Assembly..................................................................................................................................................................... 14

8. Commissioning ........................................................................................................................................................... 15

8.1 After switching on ........................................................................................................................................................ 15

8.2 In case of power failure ................................................................................................................................................ 15

8.3 Venting ......................................................................................................................................................................... 15

9. Menu structure and functions................................................................................................................................... 16

9.1 Pump ON/OFF ............................................................................................................................................................... 17

9.2 Actual time ................................................................................................................................................................... 17

9.3 Profile management ...................................................................................................................................................... 17

9.4 Flow functions .............................................................................................................................................................. 18

9.4.1 Flow regulation ............................................................................................................................................................ 18

9.4.2 Auto flow (AF) function................................................................................................................................................. 19

9.4.3 Dosing function............................................................................................................................................................. 20

9.5 Temperature and relative humidity results ..................................................................................................................... 20

9.6 Cleanliness class functions............................................................................................................................................. 21

9.6.1 Cleanliness standard...................................................................................................................................................... 21

9.6.2 Auto switch-off (AS) function ....................................................................................................................................... 21

9.6.3 Alarms .......................................................................................................................................................................... 22

9.6.4 Charts ........................................................................................................................................................................... 23

9.7 Measurement data ........................................................................................................................................................ 23

9.7.1 General data memory ................................................................................................................................................... 23

9.7.2 Quick report memory .................................................................................................................................................... 24

9.8 Printing of results .......................................................................................................................................................... 24

9.9 Quick reports................................................................................................................................................................. 25

9.10 Dosing function ............................................................................................................................................................ 25

9.11 System setting............................................................................................................................................................... 25

9.11.1 Print and report settings ............................................................................................................................................... 25

9.11.2 Measurement options.................................................................................................................................................... 26

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 3

www.argo-hytos.com

9.11.3 Errors history ................................................................................................................................................................ 26

9.11.4 Info ............................................................................................................................................................................... 26

9.12 Filter element status ..................................................................................................................................................... 27

9.13 Error indication.............................................................................................................................................................. 27

10. Operation.................................................................................................................................................................... 28

10.1 Filtering of hydraulic fluids when refilling ...................................................................................................................... 29

10.2 Filtering of liquids in the bypass flow ............................................................................................................................ 30

10.3 Pumping of hydraulic fluids (e.g. waste oil, filter is bypassed) ........................................................................................ 31

10.4 Monitoring the oil cleanliness when filling machines and systems ................................................................................. 32

10.5 Monitoring the oil cleanliness when cleaning machines and systems in the bypass flow ................................................ 33

11. Repair and maintenance ............................................................................................................................................ 34

11.1 Maintenance overview .................................................................................................................................................. 34

11.2 Changing the filter element .......................................................................................................................................... 34

11.3 Removing the filter element .......................................................................................................................................... 35

11.3.1 Removing the filter element from the cover .................................................................................................................. 35

11.3.2 Attaching the filter element .......................................................................................................................................... 35

11.3.3 Installing the filter element ........................................................................................................................................... 36

11.4 Checking / changing the suction filter element (pump protection filter) ........................................................................ 36

11.4.1 Removing the suction filter ........................................................................................................................................... 36

11.4.2 Installing the suction filter ............................................................................................................................................. 36

11.5 Checking / cleaning OPCom protective filters ................................................................................................................ 37

12. Decommissioning ....................................................................................................................................................... 38

13. Disassembly ................................................................................................................................................................ 39

14. Disposal....................................................................................................................................................................... 40

14.1 Environmental protection .............................................................................................................................................. 40

15. Extension and conversion.......................................................................................................................................... 41

16. Troubleshooting.......................................................................................................................................................... 42

16.1 Basic procedure ............................................................................................................................................................. 42

17. Technical specifications .............................................................................................................................................. 44

17.1 Drawing ....................................................................................................................................................................... 44

17.2 Technical data ............................................................................................................................................................... 45

17.3 Operating conditions .................................................................................................................................................... 46

17.4 Hydraulic circuit diagram ............................................................................................................................................... 46

18. Appendix..................................................................................................................................................................... 47

18.1 Declaration of conformity ............................................................................................................................................. 47

18.2 Spare parts .................................................................................................................................................................... 48

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 4 www.argo-hytos.com

Title Document number Document type

Data sheet UMCP2_2203

1. About this documentation

1.1 Applicability of the documentation

This documentation is applicable for the following product:

›Oil Service Unit UMPC2 045

This documentation is written for technicians, operators, service engineers and system operators.

This document contains important information for safe and appropriate assembly, transport, activation, operation, usage, servicing,

dismantling and simple troubleshooting.

›Read this document completely and in particular Chapter 2, “Safety Instructions”, before you work with the product.

1.2 Required and supplementary documentation

Do not commission the product until you have received the documentation marked with the book icon and before you have under-

stood and complied with the information therein.

Table 1: Required and supplementary documentation

1.3 Presentation of information

So that this document can help you to work quickly and safely with your product, we use standardized safety instructions, symbols,

terms and abbreviations. For better understanding, these are explained in the following sections.

1.3.1 Safety instructions

In this documentation, safety instructions are faced with a sequence of actions which would result in the danger of personal injury

or damage to equipment. The measures described to avoid theses hazards must be observed.

Safety instructions are as follows:

›Warning signal: draws attention to the danger

›Signal word: indicates the severity of the danger

›Type and source of danger: specifies the type and source of the danger

›Consequences: describes the consequences in the event of non-compliance

›Action: indicates how the danger can be avoided

SIGNAL WORD

Type and source of danger

›Consequences of the danger

›Escaping or averting the danger

›Rescue (optional)

Table 2: Hazard classes according to ANSI Z536.6-2006

Warning sign, signal word Meaning

DANGER Indicates a dangerous situation which results in death or serious injury if not avoided.

WARNING Indicates a dangerous situation which may result in death or serious bodily injury if not avoided.

CAUTION Indicates a dangerous situation which may result in light to moderate injury if not avoided.

NOTE Indicates property damage: The product or surrounding could be damaged.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 5

www.argo-hytos.com

1.3.3 Terms

In this documentation the following terms are used:

Table 4: Terms

1.3.4 Abbreviations

In this documentation the following abbreviations are used:

Table 5: Abbreviations

Term Meaning

Term Meaning

UMPC Pumping unit with condition monitoring

1.3.2 Symbols

The following symbols indicate notes which are not safety-relevant but increase the intelligibility of the documentation.

Table 3: Meaning of symbols

Symbols Meaning

If this information is not observed, the product cannot optimally be used or operated.

>Singular, independent action step / instruction

1.

2.

3.

Numbered instruction

The numbers indicate that the action steps follow one another.

This symbol indicates danger to equipment, material and environment.

This symbol indicates the risk of personal injury (minor injury).

This symbol indicates the risk of personal injury (death, serious bodily injury).

This symbol specifies that protective gloves should be worn.

This symbol specifies that safety shoes should be worn.

This symbol specifies that protective goggles should be worn.

This symbol specifies that the unit should be disconnected from the power supply.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 6 www.argo-hytos.com

2. Safety instructions

2.1 About this chapter

This product was manufactured according to the generally recognized standards of engineering. Nevertheless, there is a danger of

injury or damage if you do not observe this chapter and the safety instructions in this documentation.

›Read this document thoroughly and completely before working with the product.

›Retain this document and ensure that it is available for all users at all times.

›Always include the necessary documentation when passing the equipment along to a third party.

2.2 Intended use

This product is a hydraulic component.

You may use the product for the following:

›for filtration of hydraulic fluids in the bypass flow on machines and systems, taking account of the technical data.

›for filtration of hydraulic fluids during filling of machines and plants, taking into account the technical data

›for pumping of hydraulic fluids (e.g. waste oil, filter element is bypassed), taking into account the technical data

›for monitoring the oil cleanliness in the bypass flow during cleaning or filling of machines and plants

This product is intended for professional use only and not for private use.

"Intended use" also includes that you have completely read and understood this documentation, in particular Chapter 2

"Safety Instructions".

2.3 Improper use

Any other use than the intended use described, is improper and inadmissible.

If unsuitable products are installed or used in safety-related applications, unintended operating states may occur in the application,

which may cause personal injury and / or property damage.

Therefore only use this product in safety-related applications if this use is explicitly specified and permitted in the product documentation,

e.g. in explosion protection areas or in safety-related parts of a control system (functional safety).

ARGO-HYTOS Polska assumes no liability for damages resulting from improper use. The risks associated with improper use are solely

with the user.

2.4 Reasonable forseeable misuse

The delivery of the following media is forbidden:

›others than listed in Chapter 18.1 "Technical data"

especially:

›flammable liquids such as petrol or thinner (explosion hazard)

›foodstuffs

›sludge and sediment

The operator alone is liable for damages resulting from improper use.

2.5 Qualification of personnel

The operations described in this document require fundamental knowledge of mechanics and hydraulics as well as knowledge of the

appropriate technical terms. In order to ensure safe use, these operations may therefore only be carried out by a correspondingly

skilled worker or an instructed person under the guidance of a skilled worker.

A skilled worker is someone who can - based on his / her technical education, knowledge and experience as well as knowledge of

the respective regulations of the jobs assigned to him / her - recognize possible dangers and ensure appropriate safety measures.

A skilled worker must observe the relevant technical regulations.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 7

www.argo-hytos.com

2.6 General safety instructions

›Observe the valid regulations for accident prevention and environmental protection.

›Observe the safety regulations and requirements of the country in which the product is used / applied.

›Only use ARGO-HYTOS products that are in technically perfect condition.

›Observe all instructions on the product.

›People who assemble, operate, disassemble or maintain ARGO-HYTOS products may not do so under the influence of alcohol,

other drugs or medications that affect the responsiveness.

›Only use manufacturer-approved accessories and spare parts, in order to prevent personal danger due to unsuitable

spare parts.

›Observe the technical data and ambient specifications specified in the product documentation.

›If unsuitable products are used or installed in safety-relevant applications, unintended operating states may occur in the application,

which can cause personal injury and / or material damage. Therefore only use the product in safety-relevant applications if this use

is explicitly specified and permitted in the product documentation.

›You may only put the product into operation, when it has been established that the final product (e.g. a machine or system), into

which the ARGO-HYTOS products have been installed, complies with the country-specific regulations, safety regulations and

standards of the application.

2.7 Product and technology related safety instructions

CAUTION

Leaked hydraulic oil

Environmental hazard / risk of slipping.

›In case of spills, cover the oil-covered surface immediately with an oil-binding medium.

›Then immediately dispose of the oil-binding medium according to the national environmental regulations.

Ignition hazard

Risk of electrostatic charge by poorly conducting hydraulic fluid.

›If the electrical conductivity of the hydraulic fluid is not known, please contact the manufacturer of the

hydraulic fluid.

Risk of burns

Contact temperatures according to DIN EN563 (3) and DIN EN13202 (4) may be exceeded during

operation.

›Allow the off-line filter unit to cool down before touching it.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 8 www.argo-hytos.com

3. General instructions

For prevention of material damage and product damage

CAUTION

Danger due to improper handling

Property damage

›The off-line filter unit may only be used in accordance with Section 2.2, “Intended use”.

Leakage or spillage of hydraulic fluid

Environmental pollution and ground water contamination.

›Use oil binding agents in order to bind leaked hydraulic oil.

Risk of burns

Contact temperatures according to DIN EN563 (3) and DIN EN13202 (4) may be exceeded during

operation.

›Allow the off-line filter unit to cool down before touching it.

Contamination due to fluids and foreign bodies

Premature wear, malfunction, risk of damage, property damage.

›Ensure cleanliness during installation in order to prevent foreign bodies, such as welding beads or metal chips,

from entering the hydraulic lines, leading to premature wear or malfunction.

›Make sure that connections, hydraulic lines and attachment parts (e.g. gauges) are free from dirt and chips.

›Prior to commissioning, check that all hydraulic and mechanical connections are connected and tight,

and that all gaskets and seals of the plug connectors are correctly assembled and undamaged.

›For removal of lubricants and other contaminants, use residue-free industrial wipes.

›Make sure that all connections, hydraulic lines and attachment parts are clean.

›Ensure that no contaminants enter when closing the connections.

›Make sure that no detergents enter the hydraulic system.

›Do not use cotton waste or faying cleaning rags for cleaning.

›Do not use hemp as sealing agent.

Improper cleaning

Premature wear, malfunction, risk of damage, property damage.

›Close all openings with appropriate protective fittings to prevent penetration of detergents.

›Do not use aggressive cleaning agents for cleaning. Clean the product with a suitable cleaning fluid.

›Do not use a high-pressure cleaner.

›Do not use compressed air to clean function interfaces such as seal areas.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 9

www.argo-hytos.com

4. Scope of delivery

This package includes:

›1 Oil Service Unit UMPC2 045

›1 Operating manual

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 10 www.argo-hytos.com

5.1 Component overview

5. About this product

Fig.1: Component overview

Transport rack

Ball valve

Suction hose

Hose holder

Pump with drive motor

Printer (option)

Touch Display

Touch display

The touch display is a control panel for steering the unit and visualizing the results. The control menu is described in chapter 9.

Printer

The built-in printer is an optional accessory which is used for printing of measurement reports.

Ball valve

The 3-way ball valve allows to determine whether the oil cleanliness monitoring is to be performed before or after the filter.

Safety button

The purpose of an emergency button is to stop the unit quickly when there is a risk of injury or the workflow must be stopped.

Hose holder

On both sides of the unit there are hose holders onto which the pressure hoses (suction and pressure side) can be wound for better

transport in case of non-use.

Cable holder

On the front of the unit there is a cable holder, onto which the 230V or 400V power cable can be wound for better transport in case

of non-use.

Pump drive / electric motor

The pump unit driven by an electric motor is responsible for media conveyance.

Safety button

Filter housing

with filter element

Return hose

Cable holder

Filter cover

USB port

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 11

www.argo-hytos.com

Transport rack

The transport rack is equipped with two wheels. This hand truck enables the unit to be transported without difficulty even

to inaccessible / narrow areas.

Filter cover

The filter cover closes the filter housing and serves, inter alia, for venting.

Filter housing with filter element

The filter housing contains the replaceable filter elements.

Changing the filter elements is described in "11.2 Changing the filter element" on page 34.

Suction hose

The suction hose is used to transfer the fluid from outside to the oil service unit.

Return hose

The return hose is used to transfer the fluid from the oil service unit to the outside.

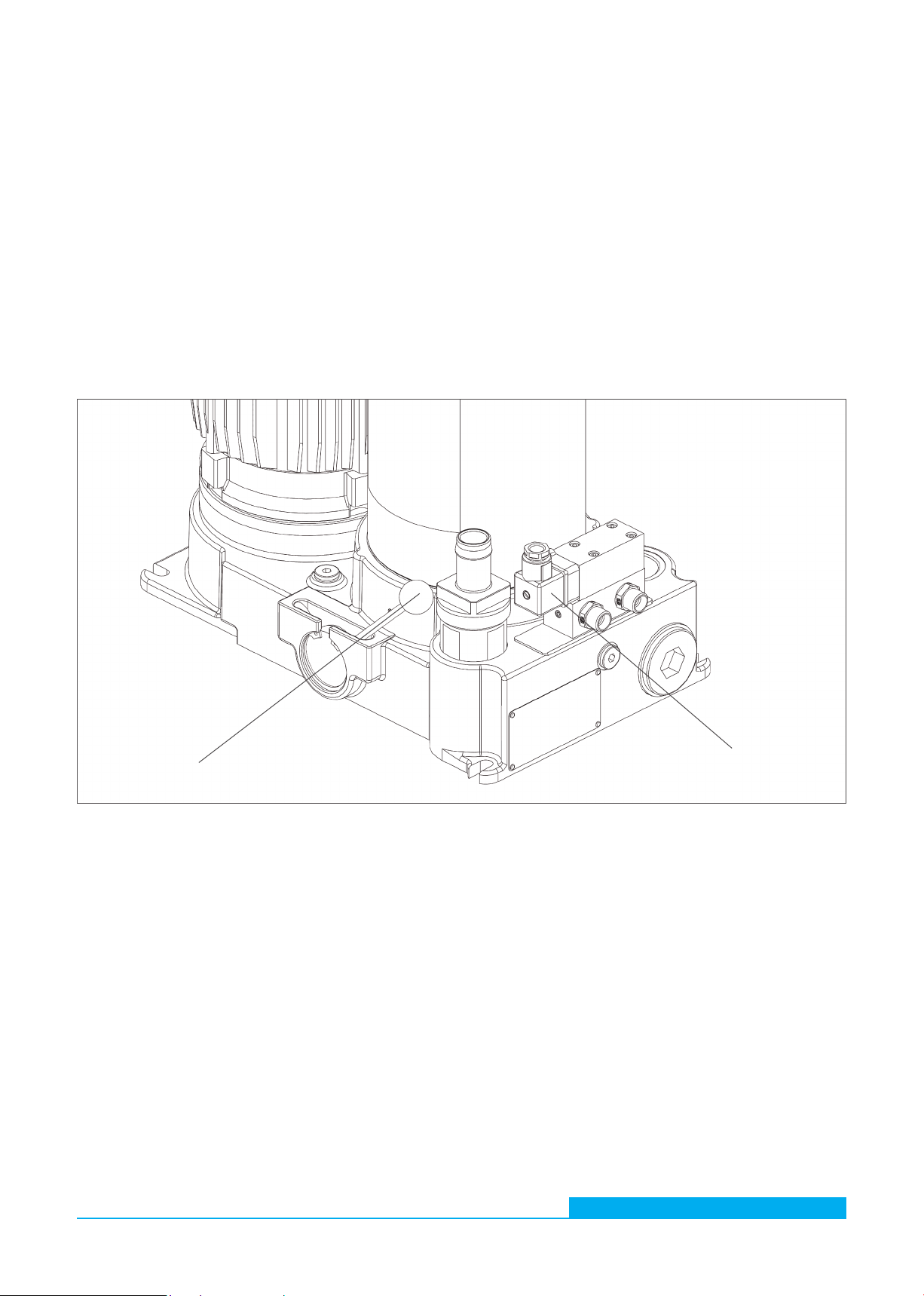

Fig.2: Component overview 2 (transport rack removed)

Switching lever

Differential

pressure

switch

Switching lever

This lever is used to switch the unit from "pumping" mode to "filtering".

Differential pressure switch

This switch monitors the pressure of the medium before and after the filter.

So if the pressure difference is too high (due to a dirty filter element), there will be an indication for the user on the main screen - see

also chapter 9.12.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 12 www.argo-hytos.com

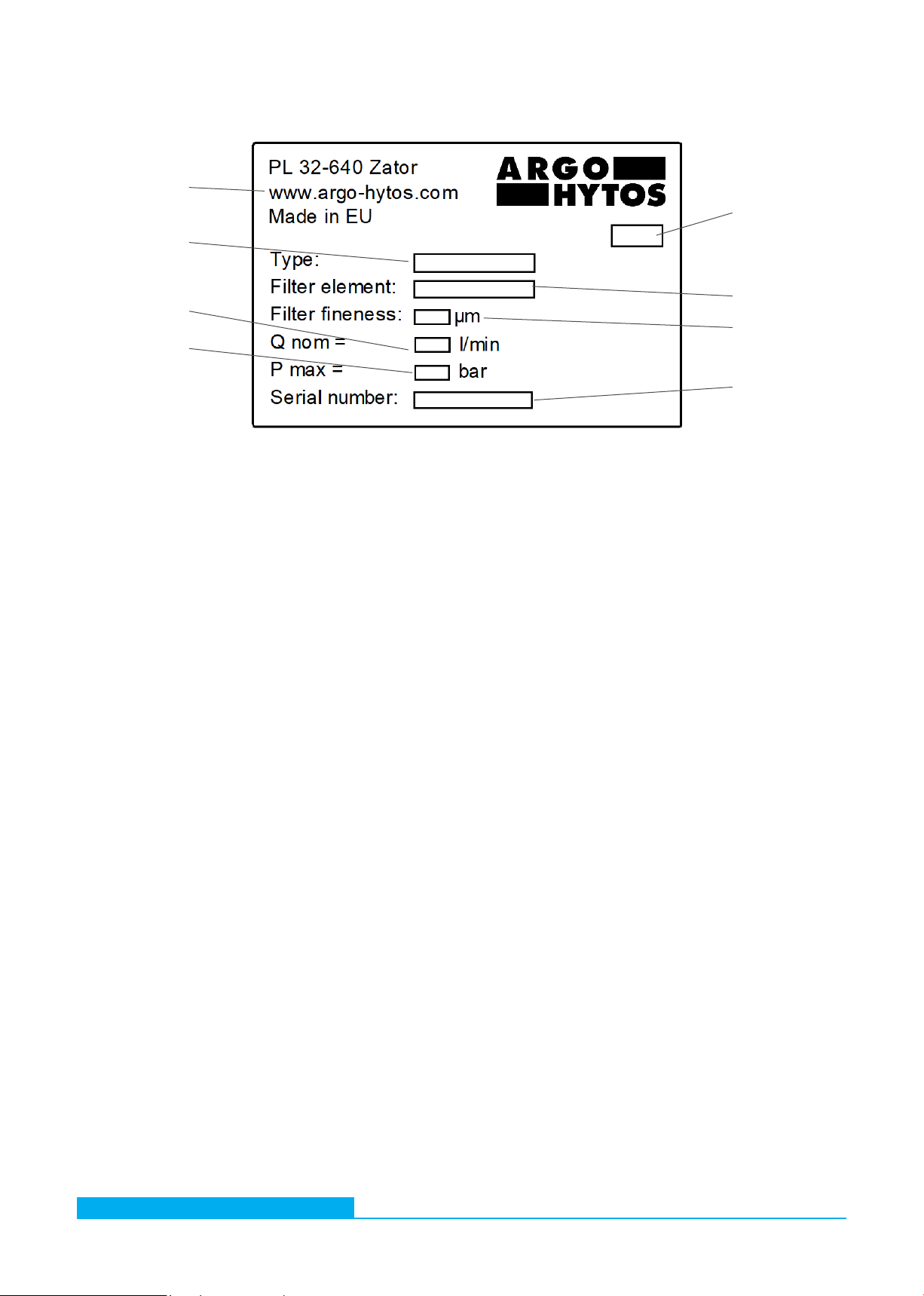

5.2 Identification of the product

Producer

address Manufacturing

date (encrypted)

Filter element type

Type

Filter element fineness

Nominal

flow volume

Serial

number

Fig.3: Nameplate

Max.

operating pressure

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 13

www.argo-hytos.com

6. Transport and storage

6.1 Transport

The unit should be transported horizontally as there is always a certain amount of oil inside the filter unit (in the filter as well as in

the pump), which will leak out during other transport and lead to soiling.

Observe the notes in Chapter 2 "Safety instructions".

Ensure that the unit is in a safe position (tipping hazard).

To prevent the leakage of residual oil, seal hoses at the open connections before transport.

During transport, secure the suction hose and the pressure hose in the brackets provided for this purpose in order to avoid possible

leakage of residual oil.

6.2 Storage

The UMPC2 045 filter unit should be stored in a confined space to protect it from humidity and condensation.

Fig. 4: Transport rack

The unit is mounted on a transport rack with two wheels.

This hand truck enables the unit to be transported without difficulty (weight: ~95 kg) even to inaccessible / narrow areas.

For transport, the unit can be rolled over the wheels by pushing the handle (see arrow) and transported to the destination.

DANGER

Risk of injury

Danger of chemical reactions

Chemical substances in the immediate vicinity of the filter unit can react and lead to the destruction of the device

and to injuries to persons in the immediate vicinity of the device.

›Storage in the immediate vicinity of chemically active substances such as acids, alkalis, salts, organic solvents

and rechargeable batteries is prohibited.

The ambient temperature during storage of the filter unit UMPC 045 should be between +0 °C and +50 °C at a maximum humidity

of 80%.

Before storage over a period of more than 6 months, the device should be filled with oil in order to preserve it against corrosion.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 14 www.argo-hytos.com

7. Assembly

Let - prior to commissioning - an electrician check whether:

›the mains voltage matches with the voltage specified on the type plate of the motor,

›the power source has appropriately been secured (16 A),

›the cross-section is of sufficient size,

›cable and connection to the power source are in perfect condition.

The following steps are to be followed in detail:

›connect the 230V (or 400V) voltage plug to the local power supply.

WARNING

Risk of functional impairment

Faulty power supply

›Always consider the country-specific regulations.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 15

www.argo-hytos.com

8. Commissioning

8.1 After switching on the motor-pump unit

›Check the filter unit for leaks.

›Check that the device is properly vented.

8.2 In case of power failure

In order to prevent unintentional starting of the unit, always switch off and unplug the unit.

8.3 Venting

To bleed the unit, carefully loosen the screw (2) on the ventilating valve (1). Clean the oil which will escape during the venting

process. Tighten the screw (2) on the ventilating valve (1)

NOTE

Do NOT leave the unscrewed ventilating valve - there is a risk of oil spillage through opened ventilating valve.

2

1

Fig.5: Venting

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 16 www.argo-hytos.com

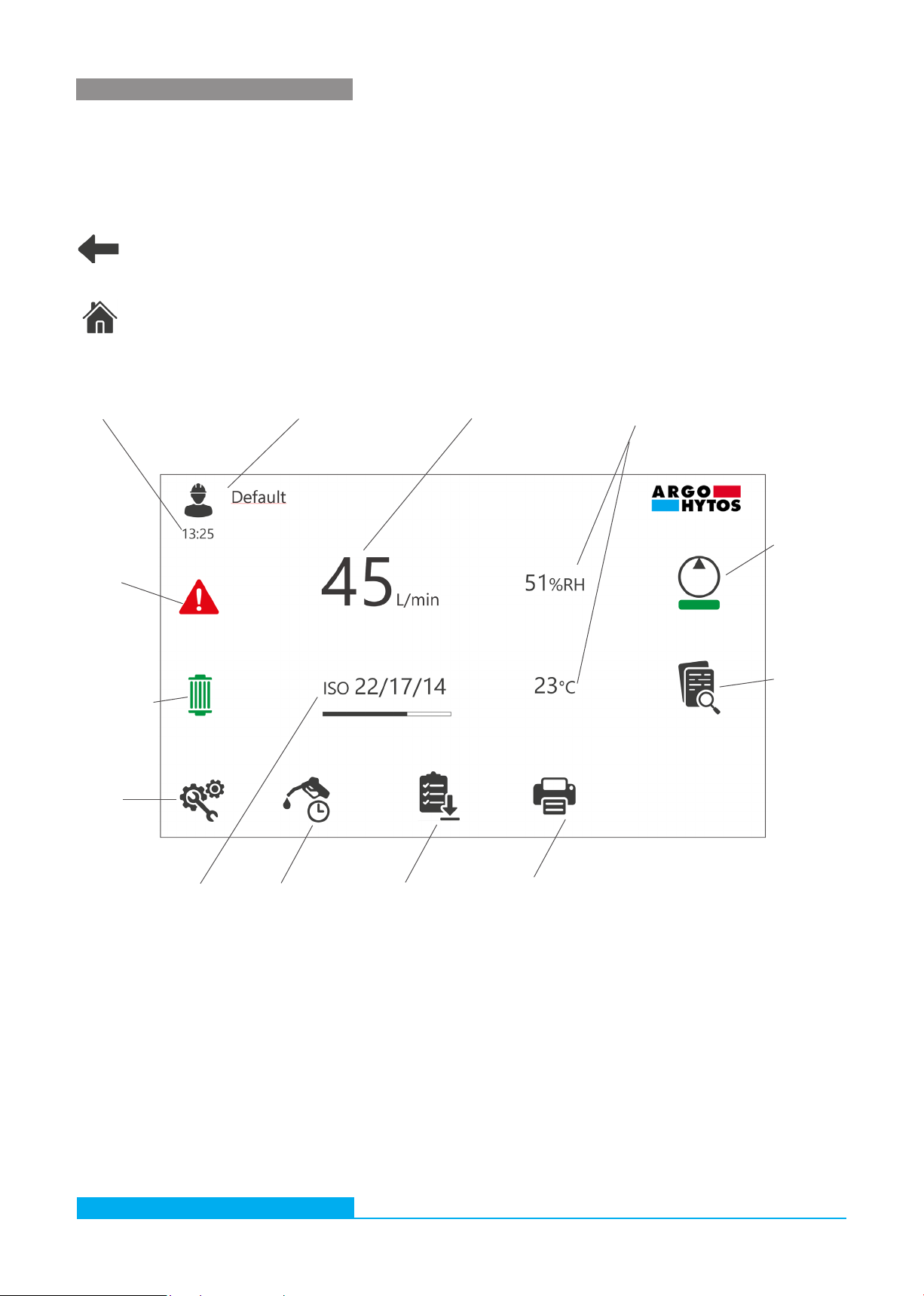

Fig.6: Start screen

Profile managementActual time Flow functions Temperature and relative

humidity

Pump

ON/OFF

Measure-

ment

data

Error

indication

Filter element

status

System

settings

Cleanliness class

functions

Dosing function Quick report Print

9. Menu structure and functions

The home screen of the touch display is shown in Fig. 6 By clicking on the appropriate field / icon, it is possible to activate the given

function or to go to the next screen with submenu. This chapter provides a description of the individual submenus and functions

included in the steering algorithm.

There are two navigation buttons for switching between the screens of the display:

back to the previous screen

back to the home screen

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 17

www.argo-hytos.com

9.1 Pump ON/OFF

Field for switching-on and off the motor-pump unit. The bar below the pump symbol changes its color from green into red when the

motor pump unit is running.

9.2 Actual time

Non-clickable field.

Shows the current time. The correct time can be set under the "System settings" button - see chapter 9.11.

9.3 Profile management

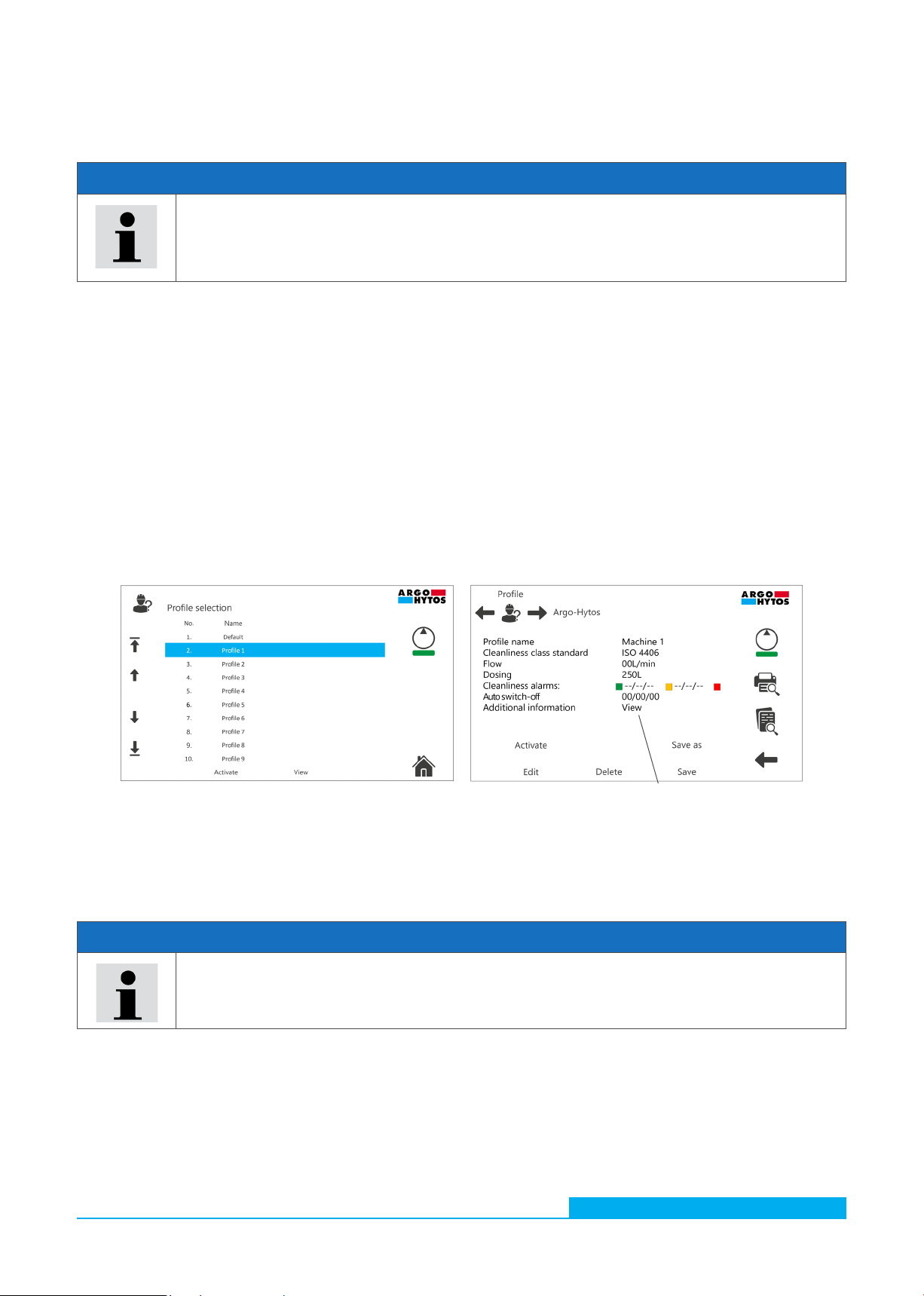

Through this field there is a possibility to activate, view and / or edit single profiles.

The UMPC2 unit may be used for servicing of many systems which require completely different parameters and device settings.

Changing of working conditions does not result in the loss of the defined parameters. Operator can save the current settings in the

individual profile. Profiles can be defined for different customers, machines, working stations etc. Each profile consists of a name and

a set of individual settings. In the first step, the user gets to the "Profile selection" screen - Figure 7.1. In this screen, the selected

profile can be activated. The "View" button displays the profile editing screen - see Figure 7.2.

There is a default profile defined by the manufacturer. The name and settings of this profile cannot be changed.

Fig. 7.1: Profile selection screen Fig. 7.2: Profile ediition screen

NOTE

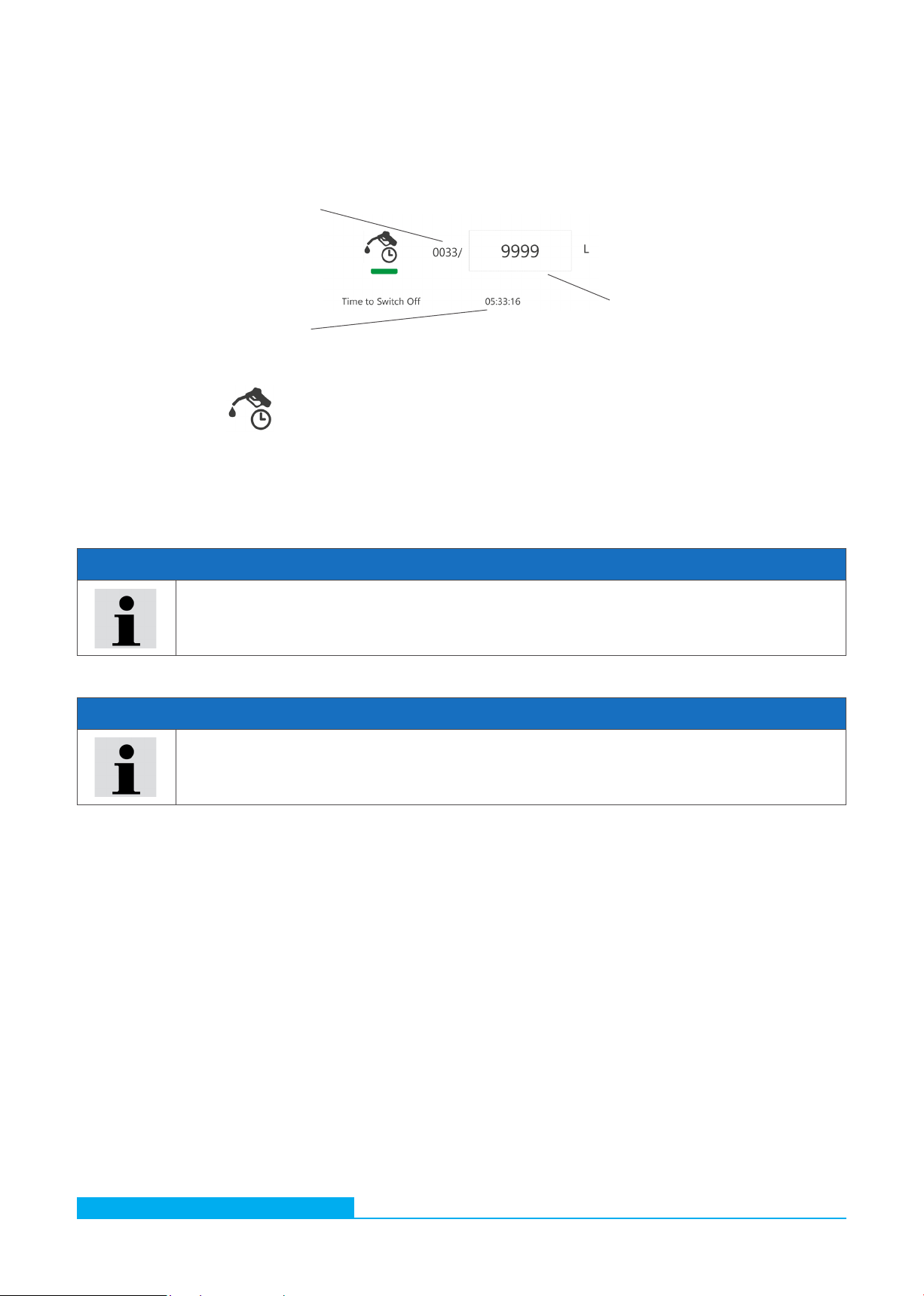

To stop the unit quickly in case of risk of injury, the safety button must be used. After the device has been

switched off with the safety button, the system requires some time (approx. 15-20 seconds) to be ready to be

switched on again.

The time counter that appears on the pump symbol indicates the remaining time until the system is ready for

activation.

Clickable field

to see full text of

additional information

NOTE

The operator can temporarily change all settings of the UMPC2. In doing so, the settings of the selected profile

are not changed until the changes are saved with the SAVE key. The settings of the DEFAULT profile cannot be

changed.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 18 www.argo-hytos.com

In the "Profile" screen there are two additional buttons described below.

By clicking on this icon the printout / report preview is displayed. For more information about print / report

settings see chapter 9.11.1.

By clicking on this icon the "General data memory" is displayed. This button is also available in the home

screen. Each profile has its own general data memory. For more information see chapter 9.7.1.

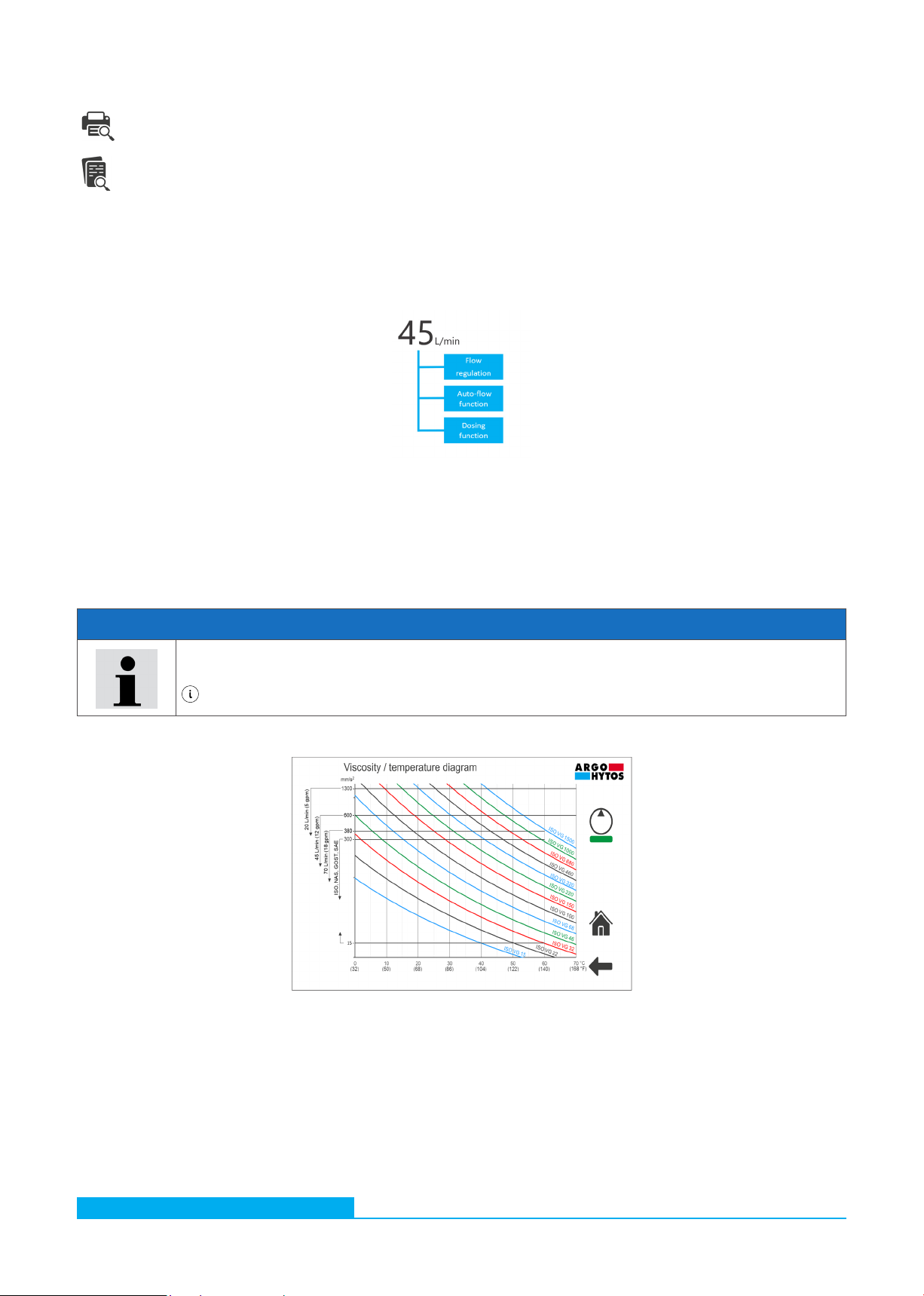

9.4 Flow functions

Clickable field with the submenu showed in the Fig. 8.

Fig. 8: Submenu of flow functions

9.4.1 Flow regulation

Through this field there is a possibility to regulate the flow in the range of 20 -70 l/min.

NOTE

For flow regulation, the viscosity of hydraulic fluid must be taken into consideration. Compare the permissible

viscosity range of the device with the viscosity / temperature diagram which is available after clicking on the icon

in the flow regulation screen. See the Fig. 9.

Fig. 9: Screen with viscosity / temperature diagram

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 19

www.argo-hytos.com

9.4.2 Auto flow (AF) function

Function can be activated by clicking in the "Auto-Flow" field showed in the Fig. 10.

Fig. 10: Flow functions screen

The combination of letters AF with green bar is displayed in the home screen as an indication that the Auto-flow function is active,

see Fig.11.

Fig. 11: Auto-Flow function active

When the AF function is active, the flow of the UPMC2 unit is automatically reduced. The signal to activate the flow reduction

comes from the electrical clogging indicator. After detecting a certain pressure drop across the filter element, the flow rate is reduced

by approximately 5 l/min. For example, the initially defined flow of 50 l/min is reduced to approx. 45 l/min.

Working in this mode allows optimal utilization of the filter element. The dirt-holding capacity of 45 l/min defined for the nominal

flow rate is relatively larger at the reduced flow rate (pressure drop is lower at the smaller flow rate). So even if there is a signal from

the clogging indicator at a flow rate of 60 or 50 l/min, this signal may not be active at a flow rate of 20 l/min. Oil filtration can be

continued with the same filter element.

"Auto-flow" activation button

After clicking on the flow rate value, the system

settings screen is activated. From this level, the

unit of flow can be changed from liters/min to

gallons/min and vice versa.

Subject to change · Filter and recirculating pump unit UMPC2 045 · 0322 · EN

Page 20 www.argo-hytos.com

9.4.3 Dosing function

With this function the operator can define the amount of oil to be transferred. To set a dose of oil, click on the field for volume

definition showed in Fig.12. The keyboard will be activated and the required value can be entered.

Fig. 12: Dosing function settings

After clicking on the icon the function is activated. The green bar is displayed under the "Dosing" icon and two counters

are activated. The first counter, the "volume counter", shows the actual amount of transferred oil versus the pre-set value. The

second counter, the "time counter" shows the time remaining until the pump is stopped. When the pre-set volume is reached, the

pump of the UMPC2 is stopped automatically.

Current settings of this function can be permanently saved in the selected profile - see chapter 9.3.

NOTE

When working with the dosing function, the following sequence is recommended: Set the dosing value ->

activate the function -> activate the pump.

NOTE

The actual values can differ by approx. 3 % from the values set with the dosing function.

If the dosing function is activated for the unit with filter element but without oil filling, approximately 10 liters of

oil are required to fill the internal volume of the unit. This should be taken into account when setting the dosing

quantity.

9.5 Temperature and relative humidity results

Displays the current results of the temperature and relative humidity of the oil. If you click on one of these fields, the results will be

displayed in the form of charts. A separate submenu for managing the diagrams is shown in Fig.13.

Field for dosing volume definition

Volume counter

Time counter

Table of contents

Popular Service Equipment manuals by other brands

CEMO

CEMO DT-Mobil PRO PE 980l operating instructions

Bosch

Bosch DAS 3000 Unpacking, Assembly, Initializing

Speed Clean

Speed Clean BucketDescaler Operating & maintenance instructions

stellar labs

stellar labs TireMan 4110 owner's manual

Prolux

Prolux 600 215 Operating instruction

EDS

EDS LeakSeeker 89 Operation manual