TDR Eco Clever User manual

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

What’s In This User Guide?

Getting started - repair a disc right now

Getting to know your machine and how it works

Advanced features you will want to know

Maintenance and other useful information

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

Getting Started

Initial setup

Basic operation

Inspecting a repaired disc

Parts of the machine

With the machine you will nd an initial set up guide

which includes a list of contents and also explains the

setup of the machine.

Choose a disc for repair. For this rst disc we will run

a light (average) repair cycle.

The disc should come out of the machine clean and

dry. Have a look at the repaired side, the light repair

should have made a visible improvement.

If a more heavily damaged disc was chosen the disc

may need an additional repair. Now, using the cycles

1-4, try dierent levels of damage to get a better

understanding of what the machine can do.

For Blu-ray and heavily damaged discs (Level 5)

please refer to the Advanced Features section.

1. Press ‘mode/stop’ to open the front door.

2. Place the disc shiny side up on the turntable.

3. Gently close the door.

4. Press the ‘3’ button (light repair).

AL 12 - if this shows on the display please check that

the pad holders are positioned correctly. For any other

alarm codes or issues please consult the Maintenance

and Information sheet or contact Technical Support.

Polish/

Water entry

and splash

back tray

Operation panel

Front door latch

Pad turret

Positioning of the

pad holders and

polishing pads.

Disc turntable

This is where the disc is

positioned for the repair. It

sits with shiny side facing up.

Front

Back

Display

Stage

MODE/

STOP

button

The LCD indicates:

Repair cycle options

Time remaining

Warnings

Waste exit

Please ensure the tube is connected

during operation.

Power

switch,

fuse and

AC inlet

Fan

Feed tubes

Compound

pump Water

pump

Place shiny

side up

on the

turntable

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

Getting To Know The Machine

Understanding the repair cycle Setting up consumables Replacing the pads

The Eco Clever is a multi stage disc repair machine.

In other words, during the repair cycle the machine

uses dierent grade pads in stages to repair the disc.

Sound complicated? Don’t worry the Eco Clever does

all of these stages automatically.

Inside the machine there are four colour coded

abrasive pads from coarse to ne.

The machine automatically engages each pad in

sequence. The coarsest pad will remove the most of

the scratch whereas the nest pad produces the high

quality nish.

You will have also received blue and violet pads and a

violet pad holder with the machine. Please put these

aside as they will be used in Advanced Features

later.

With the door open, press the corresponding cycle

button to display the counter reading.

To reset the counter press the button again and hold

it down until the counter changes to zero.

Press any button to cancel the alarm. Then change

the relevant pad. Once the pad has been changed

you need to reset the counter on the machine.

The basic setup for the machine uses pads with red,

green, yellow, and black coloured velcro and these

will have been pre-installed.

Each pad is attached using Velcro to a matching

coloured pad holder. The pad holder is then held in

the machine by a magnet.

Try removing and replacing the pad holders.

On the turret there is a coloured label showing where

the corresponding coloured pad should go.

When a pad needs changing the machine displays an

alarm code. These codes are:

Button Repair Mode Description

4 Medium Raised scratches

3 Light Narrow scratches

2 Very Light Light scus

1 Clean/Polish Dirt/ngerprints

ST LED Time LED Description

Al 01 Exchange Pad #1

02 Exchange Pad #2

03 Exchange Pad #3

04 Exchange Pad #4

05 Change Compound

Match each coloured pad holder to the

corresponding colour tab:

Pad changing sequence:

Refer to Advanced operation for deep gouges. (level 5)

Clean/Polish

Light

Very Light

1. Lift o pad holder

3. Attach new pad

2. Remove used pad

4. Re-attach pad holder

Yellow tab

indicates

yellow

pad holder

location

See

Advanced

Features

for violet

pad use

Medium

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

Getting To Know The Machine

Topping up polish and water Priming the pumps

Polish supply

On the back of the machine is a small

bottle which contains a thick white

polish. Ensure that this bottle is at

least 1/3 full before operation.

Make sure that the tube inside the

bottle reaches the bottom of the

bottle. The bottle feeds polish to the

pump marked with a blue dot.

Water supply

In each cycle the machine uses

water as a coolant and to remove

the waste product. Added to the

water is a small amount of additive

which helps with the process.

Using the syringe supplied add 5ml of additive for

every 1 litre of water in the container. (if you are

ling the bottle from empty add 20ml of additive and

ll the bottle to the 4 litre line).

For best results use mineral or deionised water.

Coming from the pump with the red dot will be a long

tube with a stone lter on the end. Feed the tube in

to the top of the water bottle ensuring that the stone

lter reaches the bottom of the bottle.

Step 1 - Preparation

1. When priming pumps place a tissue under the drip

feeds as shown to stop the turntable getting wet.

Step 2 – Pump operation mode

Waste collection

Ensure that the tube coming from the front of the

machine has a clear run to the waste bottle otherwise

the waste could back up. You should cut down the

waste tube so that it does not sag or kink.

Empty the waste bottle every time you ll the water

bottle.

Your machine will have already arrived with the polish

and water pumps primed and ready to go. However it

is important to understand how to do this yourself.

2. Press and hold MODE/STOP and ‘5’ at the same

time. A ‘P’ will appear in the ‘ST’ display.

3. To exit this mode press MODE/STOP.

4. Once you are in Pump Operation Mode it is simple

to prime each pump.

5. Press ‘1’ again to stop the pump when you see

water coming out of the drip feed.

If you are not going to use the machine for a while it

is important to clear the polish tube of polish so that

it doesn’t dry in the tube.

6. Press ‘2’ again to stop the pump when you see

polish coming out of the drip feed.

Press ‘3’ to start this process. It will return all of the

polish in the tube back to the bottle. Press ‘3’ again

to stop the pump.

Step 3 – Priming the water (Press 1)

Step 4 – Priming the polish (Press 2)

Clearing the polish tube

4ltr

20ml

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

Maintenance And Information

Troubleshooting Daily checks Ordering consumables

If the door won’t open

It can be opened manually by inserting a card into

the slot on top of the machine and moving the card

to the left to open the catch.

Understanding the display codes

Centre seal

Ensure that the rubber

has not deteriorated and

the part is still creating an

eective seal. Operating

with a poor seal could

damage the machine.

Pad xing plate

Ensure this is kept clean,

remove any rust left from

rusty pad holders.

Drain exit

Wipe clean regularly to

avoid blockages.

Pad holders

When changing pads check the pad holder to make

sure that the Velcro has not deteriorated.

Check the rear plate on the pad holder to ensure it is

clean and contains no rust. Occasionally apply a little

spray lubricant to the plate to deter rusting. After

time the pad holder will need replacing.

Consumable Packs

A single pack with the correct consumables for 500

repairs of either Light, Medium, or Heavy repairs.

Mega Pack Light: 5055378130830

Mega Pack Medium: 5055378130847

Mega Pack Heavy: 5055378130854

Red pad: 5055378101816

(Heavy)

Blue pad: 5055378101793

(Very Heavy)

Violet pad: 5055378101823

(Blu-ray)

Black pad: 5055378101786

(Bu)

Yellow pad: 5055378101830

(Light)

Green pad: 5055378101809

(Medium)

Polish (125ml): 5055378101847

(MSDS found at: totaldiscrepair.com/CleverSupport)

Water additive (200ml): 5055378101845

(MSDS found at: totaldiscrepair.com/CleverSupport)

Individual Items

Or you can purchase items individually

It is advised to replace this regularly.

ST TIME Comment

CD 01-05 Normal 1-5 operation mode

BD 01-04 Blu-Ray repair cycle selected

AL 11 Front door open

AL 12 Check Pad Holder

P1 -- Pump operation mode

(prime water)

P- 2- Pump operation mode

(prime polish)

P- -3 Pump operation mode

(reverse polish)

88 88 Initiation/setup leave for a

few seconds

E 1-5 21-90 Note error code and contact

Tech Support 0800 412 5424

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

Advanced Features

Deep scratch cycle Using the Blu-ray cycle Your notes...

In the starter pack you will nd a blue pad. This is

the deep scratch ‘heavy’ pad. This is if you have a

disc that you feel needs a longer repair than the

standard ‘4’ cycle will repair.

The machine can only hold four pads at a time and

so to run the fth, heavy cycle you need to exchange

the blue pad with the red pad for the 5th stage.

Please follow the sequence below for using the

‘5, heavy’ cycle:

Your Eco Clever disc repair machine has already

been installed with the Blu-ray software required to

repair Blu-ray discs. See the ‘Disc Types’ data sheet

for more information on the dierences with Blu-ray

discs.

Follow the procedure below to change your machine

to Blu-ray repairs:

1. Open the front door.

2. Remove yellow pad and holder from the turret.

3. Fit violet pad and holder in its place.

4. With the door open, press and hold MODE/STOP

button until changes to

5. Place disc on turntable, close door and select a

cycle based on level of damage - there is no level 5

in Blu-ray repair mode.

6. When you’ve nished, press and hold MODE/STOP

again to return to mode and replace the yellow

pad.

1. Remove the red pad holder from the machine and

remove the red pad from the holder.

2. Attach the blue pad on to the red pad holder and

replace the pad holder on to the machine.

3. Place the heavy damaged disc on to the platen as

normal, close the lid and press ‘5’.

4. The display will count down the ‘5’ cycle.

5. When it moves on to cycle 4 press any button. This

will pause the repair and open the drawer.

6. Now exchange the blue pad with the red pad, close

the door and press ‘4’.

7. The machine will now nish stages 4 to 1 as normal.

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

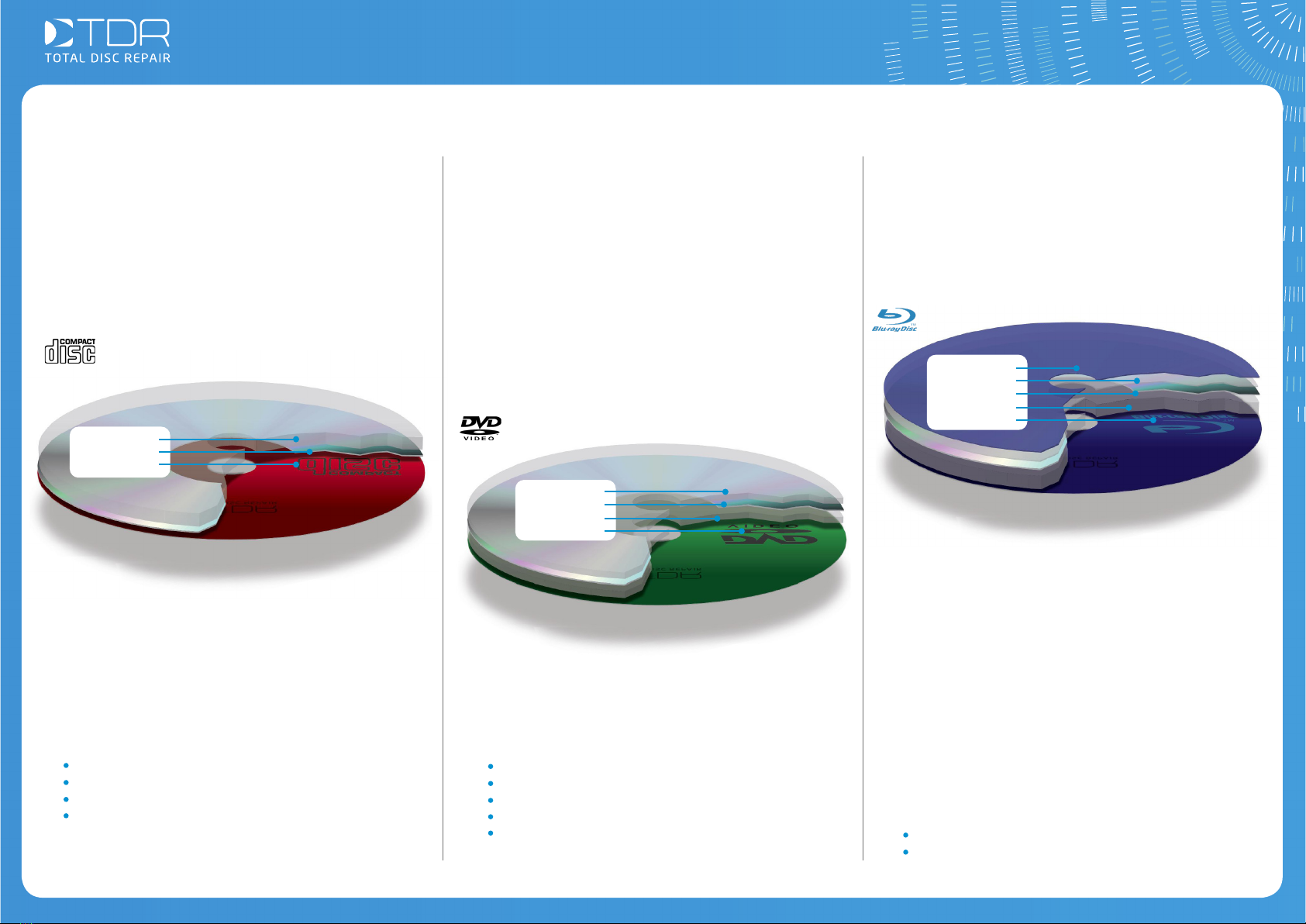

Hard coat

Polycarbonate

Data

Polycarbonate

Label

Polycarbonate

Data

Label

Polycarbonate

Data

Polycarbonate

Label

Disc Types

When discs were invented the process of

construction was quite simple. These are what

we call CD discs. To produce the disc, a solid

polycarbonate disc was made. Then the data layer

was applied to the top surface of the disc. To protect

this data layer, a lacquer, or label, was then applied

over the top of the data layer.

The early CDs were mainly used for audio and so

often a small scratch was not enough to disrupt

the data. However, as the data on discs became

more complicated it became more important to

protect the data layer. On DVD discs the data layer

is sandwiched in the middle of the disc between two

pieces of polycarbonate. This protects the data layer

and makes the disc virtually indestructible. The only

issue with this type of disc is that the two layers of

disc can separate around the hole in the centre of

the disc, although this is quite rare.

Because the data is so protected virtually all DVD

discs can be repaired by the disc repair process.

With the invention of High Denition (HD) there was

a need to carry more information on a disc and soon

the data space on a DVD was not enough. Sony

solved this with the invention of the Blu-ray disc.

It is essentially the same as a DVD with 2 main

dierences:

1. The polycarbonate on the bottom of the discs is

much thinner than a DVD and so the number of

times that the same disc can be repaired falls to

around 10-15.

2. The polycarbonate on the bottom of the disc

has a hard coated lacquer on top of it. This hard

coat reduces the chance of the disc being

scratched in the rst place, but nonetheless

scratches can still happen - just repair using the

Blu-ray pad as normal.

Formats:

Blu-ray lm

Playstation 3

This made the data layer quite vulnerable because

any scratch to the label could damage the data layer

beneath. If a scratch has reached the data layer

it is not repairable. Disc repair can only repair the

polycarbonate on the underside of the disc.

CDs DVDs Blu-rays

Formats:

Audio Books

Audio CDs

CD-ROMS

Playstation 1

Formats:

DVDs

Playstation 2

Xbox / Xbox 360

Wii

DVD ROM

©Total Disc Repair Ltd | www.totaldiscrepair.co.uk | Technical Support: 0800 412 5424 - support@totaldiscrepair.co.uk | Sales: 01202 489 500 - sales@totaldiscrepair.co.uk

Table of contents

Popular Service Equipment manuals by other brands

Magneti Marelli

Magneti Marelli ATF EXTRA PRO user manual

Hyundai

Hyundai Midtronics GRX-5100 instruction manual

Tronair

Tronair 01-1229-0011 Operation & service manual

ULTIMATE SPEED

ULTIMATE SPEED HG02236 Assembly and Safety Advice

CEMB

CEMB DWA1000CWAS manual

Invacare

Invacare TDX SP Assembly, installation and operating instructions