Inficon VSA100A User manual

Operating

M

Incl. EU Declar

a

tina29e1 (201

7

Vacu

VSA10

0

M

anual

ation of Confor

m

7

-05)

um

S

0A

m

ity

S

witc

h

h

1

2tina29e1 (2017-05) VSA100A.om

In all communications with INFICON, please specify the information on the product

nameplate.

This document applies to products with part number:

399-001

The part number (PN) can be found on the product nameplate.

We reserve the right to make technical changes without prior notice.

All dimensions are indicated in mm.

The references to diagrams, e.g. (4/5), consist of the fig. no. and the item no. in

that order.

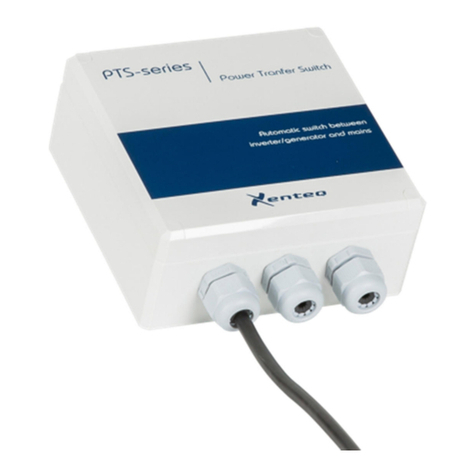

The Vacuum Switch VSA100A is used as a pressure safety switch in vacuum

systems.

The Vacuum Switch VSA100A is used as a pressure safety switch in vacuum

systems. It is used e.g. to automatically interrupt the gas supply when venting

vacuum systems with a purge gas at a pressure of 3 mbar below atmospheric

pressure.

Unpack the Vacuum Switch VSA100A immediately after delivery, even if it is to be

put into operation at a later date.

Before doing so, examine the shipping container for any external damage. Then

completely remove the packaging materials.

The shipping container and packaging materials must be kept in the event of com-

plaints about damage.

In order to ensure that no damages have been caused during transport carefully

examine Vacuum Switch VSA100A visually.

If any damage is discovered, report it immediately to the forwarding agent and

insurer. If the damaged part has to be replaced, please get in touch with the orders

department.

At a differential pressure of 6 mbar when pumping down or 3 mbar when venting

below atmospheric pressure, an elastic diaphragm actuates a changeover contact

which in turn may be used to directly switch any ancillary equipment. The electrical

connections are placed under a plastic cover.

Vacuum Switch VSA100A complete with cable, 3 m

Operating Manual German

Operating Manual English

Product Identification

Validity

Description

Intended Use

Unpacking and Checking

Design and Function

Scope of Delivery

tina29e1 (2017-05) VSA100A.om 3

Contents

Product Identification 2

Validity 2

Description 2

Intended Use 2

Unpacking and Checking 2

Design and Function 2

Scope of Delivery 2

Contents 3

1Safety 4

1.1 Symbols Used 4

1.2 Personnel Qualifications 4

1.3 General Safety Instructions 4

1.4 Liability and Warranty 4

2Technical Data 5

3Installation 6

3.1 Vacuum Connection 6

3.2 Electrical Connection 6

3.3 Start up 6

4Maintenance 7

5Returning the Product 7

6Disposal 8

EU Declaration of Conformity 9

For cross-references within this document, the symbol (→XY) is used.

4tina29e1 (2017-05) VSA100A.om

1 Safety

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or

minor equipment damage.

Notice

Skilled personnel

All work described in this document may only be carried out by persons who

have suitable technical training and the necessary experience or who have been

instructed by the end-user of the product.

•Adhere to the applicable regulations and take the necessary precautions for the

process media used.

Consider possible reactions between the materials (→5) and the process

media.

•Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do and consider the safety instructions in this document.

•Before beginning to work, find out whether any vacuum components are con-

taminated. Adhere to the relevant regulations and take the necessary pre-

cautions when handling contaminated parts.

Communicate the safety instructions to other users.

INFICON assumes no liability and the warranty becomes null and void if the end-

user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of changes (modifications, alterations etc.) to the product

•use the product with accessories not listed in the corresponding product

documentation.

1.1 Symbols Used

Symbols for residual risks

1.2 Personnel Qualifications

1.3 General Safety

Instructions

1.4 Liability and Warranty

tina29e1 (2017-05) VSA100A.om 5

2 Technical Data

Switching pressure 6 mbar

(

below atmospheric pressure)

Return switching pressure 3 mbar

(

below atmospheric pressure)

Switching inaccuracy ±2 mbar

Max. operating pressure (abs.) 2000 mbar

Operating temperature 0 to 85 °C

Helium permeation <1·10-6 mbar·l·s-1

Switching contact changeover contact

Switching capacity 100 mA / 24 V (ac)

30 mA / 24 V (dc)

Electrical connection standard cable 3 m

Vacuum connection DN 16 KF

Protection type IP 44

Materials in contact with the medium stainless steel 1.4305, 1.4310

stainless steel 1.4300 PTFE coated

EPDM

Internal volume 2

cm

3

Weight

315 g

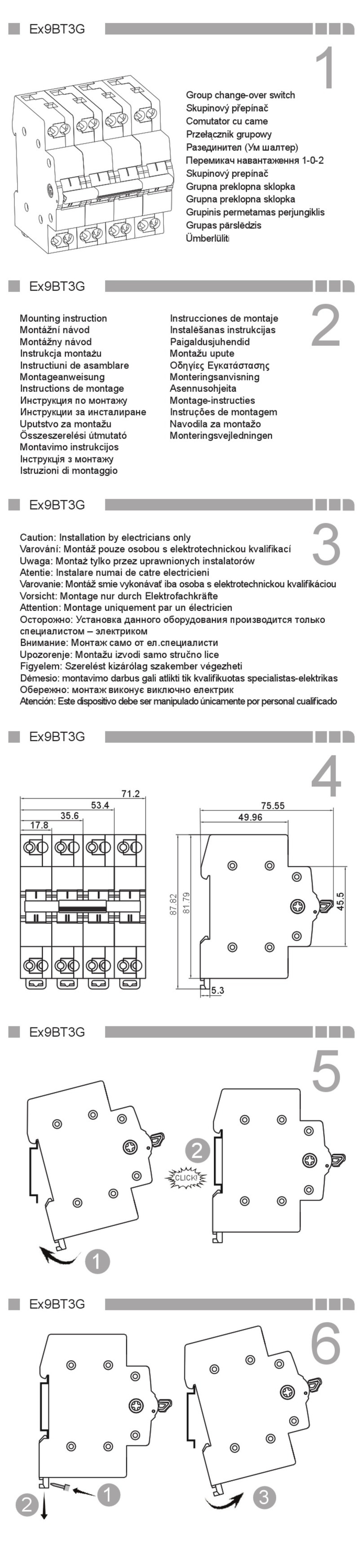

Fig. 1 Dimensional diagram VSA100A

Dimensions [mm]

6tina29e1 (2017-05) VSA100A.om

3 Installation

The VSA100A is connected to the vacuum system via a DN 16 KF small flange.

The VSA100A should preferably be mounted standing on its flange. Inclined

mounting is also permissible, including the horizontal position. Downward installa-

tion is not permissible because in such a case condensate may collect in the pres-

sure switch. This affects the measurements and may damage the pressure switch.

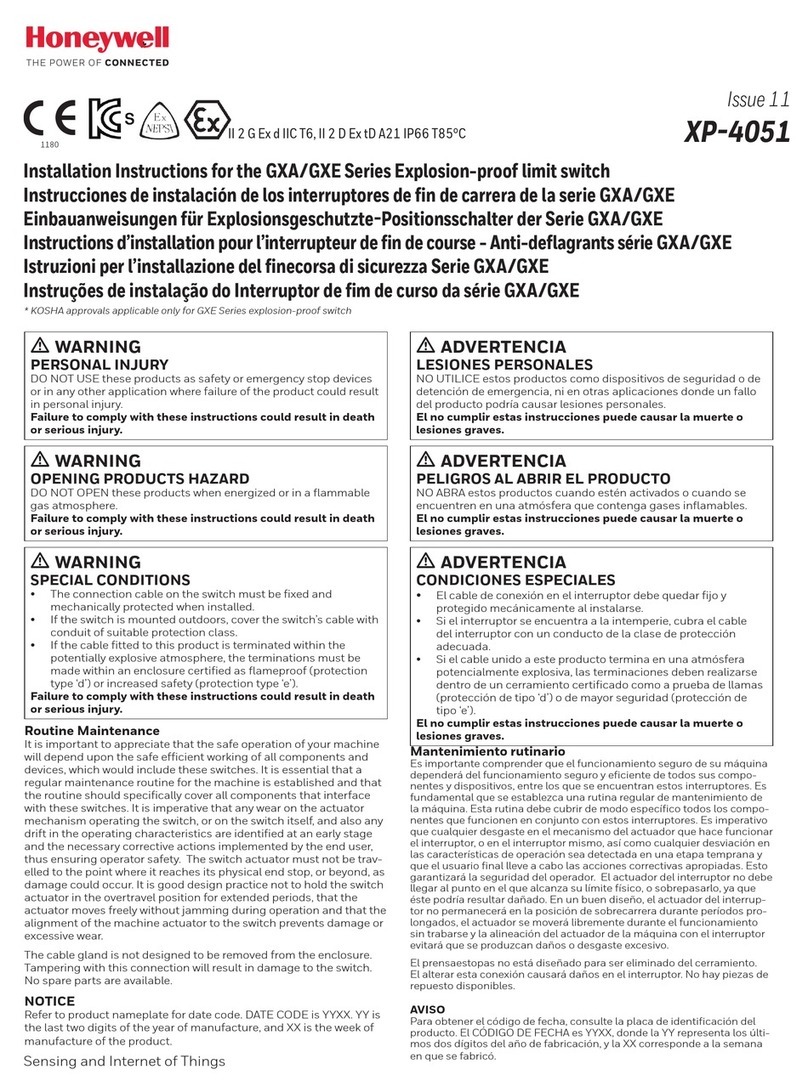

Fig. 2 Contact assignment of microswitch

The contact assignment is given in Fig. 2.

The VSA100A is supplied with a connected 3 m long standard cable. The length of

this cable may be changed.

The electrical connection terminals and the strain relief are accessible after un-

screwing the cross head screws and folding out the cap.

The contacts at the VSA100A are marked 1, 2 and 3 (see contact assignment

Fig. 2).

The supply line has to be fuse-protected with max. 100 mA by the end-user.

Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do.

When leak detecting with a helium leak detector, spraying the pressure switch with

helium may result in a helium proof. This is in general not due to a leak of the

VSA100A, but is permeation of helium through the EPDM diaphragm.

3.1 Vacuum Connection

3.2 Electrical Connection

3.3 Start up

tina29e1 (2017-05) VSA100A.om 7

4 Maintenance

The VSA100A requires no maintenance

5 Returning the Product

WARNING

WARNING: forwarding contaminated products

Products returned to INFICON for service or repair should preferably

be free of harmful substances (e.g. radioactive, toxic, caustic or

microbiological).

Adhere to the forwarding regulations of all involved countries and

forwarding companies and enclose a completed declaration of con-

tamination (Form under www.inficon.com).

Products that are not clearly declared as "free of harmful substances" are de-

contaminated at the expense of the customer.

When returning a product to INFICON, put it in a tight and impact resistant

package.

8tina29e1 (2017-05) VSA100A.om

6 Disposal

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health.

Before beginning to work, find out whether any parts are contami-

nated. Adhere to the relevant regulations and take the necessary

precautions when handling contaminated parts.

WARNING

WARNING: substances detrimental to the environment

Electronic components must be disposed of in accordance with special

regulations.

Dispose of such products in accordance with the relevant local regu-

lations.

After disassembling the product, separate its components according to the follow-

ing criteria:

Contaminated components (radioactive, toxic, caustic, or biological hazard etc.)

must be decontaminated in accordance with the relevant national regulations,

separated according to their materials, and recycled.

Such components must be separated according to their materials and recycled.

Separating the components

Contaminated components

Other components

tina29e1 (2017-05) VSA100A.om 9

EU Declaration of Conformity

We, INFICON, hereby declare that the equipment mentioned below complies with

the provisions of the following directives:

•2014/35/EU, OJ L 96/357, 29.3.2014

(Low Voltage Directive; Directive relating to electrical equipment designed for use within certain

voltage limits)

•2014/30/EU, OJ L 96/79, 29.3.2014

(EMC Directive; Directive relating to electromagnetic compatibility)

•2011/65/EU, OJ L 174/88, 1.7.2011

(RoHS Directive; Directive on the restriction of the use of certain hazardous substances in electrical

and electronic equipment)

Vacuum Switch

VSA100A

Harmonized and international/national standards and specifications:

•EN 61000-6-2:2005

(EMC: generic immunity standard for industrial environments)

•EN 61000-6-3:2007 + A1:2011

(EMC: generic emission standard for residential, commercial and light-industrial environments)

•EN 61010-1:2010

(Safety requirements for electrical equipment for measurement, control and laboratory use)

•EN 61326-1:2013; Group 1, Class B

(EMC requirements for electrical equipment for measurement, control and laboratory use)

INFICON AG, Alte Landstraße 6, LI-9496 Balzers

2 May 2017 2 May 2017

Dr. Bernhard Andreaus

Director Product Evolution Alex Nef

Product Manager

Product

Standards

Manufacturer / Signatures

10 tina29e1 (2017-05) VSA100A.om

Notes

tina29e1 (2017-05) VSA100A.om 11

Notes

LI–9496 Balzers

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

www.inficon.com

t i na29e1

Other manuals for VSA100A

1

Table of contents

Other Inficon Switch manuals