Inficon VSC150 User manual

OPERATING MANUAL

incl. Declaration of Conformity

Vacuum Switch

VSC150

Part Number

399-005

Vacuum Switch

VSC150

Part Number

399-005

tina42e1

OPERATING MANUAL

incl. Declaration of Conformity

tina42e1

General Note

The right of alterations in the design and the technical

data is reserved.

The illustrations are not binding.

2

2tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

General Note

The right of alterations in the design and the technical

data is reserved.

The illustrations are not binding.

Contents Page

1 Description . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 VSC150 Vacuum Switch . . . . . . . . . . . . . . . 5

1.2.2 SV Switching Amplifier . . . . . . . . . . . . . . . . 6

1.3 Technical Description . . . . . . . . . . . . . . . . . 6

1.3.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.2 Vacuum Switch Mode of Operation . . . . . . . 6

1.3.3 Switching Amplifier Mode of Operation . . . . 7

1.4 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Scope of Delivery . . . . . . . . . . . . . . . . . . . 8

1.4.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Connection to the Vacuum System . . . . . . . 9

2.2 Electrical Connection . . . . . . . . . . . . . . . . 10

2.2.1 Connection of the Vacuum Switch . . . . . . . 11

2.2.2 SV Switching Amplifier . . . . . . . . . . . . . . . 12

2.3 Design Versions and Switch Point Setting . 13

2.3.1 VSC150 Vacuum Switch . . . . . . . . . . . . . . 13

2.3.1.1 Setting Switching Pressures

Higher than 20 mbar . . . . . . . . . . . . . . . . 14

2.3.1.2 Setting Switching Pressures

Lower than 20 mbar . . . . . . . . . . . . . . . . . 14

2.4 Differential Pressure Adapter . . . . . . . . . . . 15

Page

2.4.1 Connecting the Differential Pressure

Adapter to the Vacuum Switch . . . . . . . . . 15

2.4.2 Switching Logic . . . . . . . . . . . . . . . . . . . . . 16

2.5 Typical Applications . . . . . . . . . . . . . . . . . . 16

2.5.1 Protection of a Gate Valve which

must only be Operated when

Pressure on both Sides

Becomes Equal . . . . . . . . . . . . . . . . . . . . 16

2.5.2 In a Vacuum System it must bei

Prevented that in Case of

Failure Gas Flows into the

Vacuum Chamber . . . . . . . . . . . . . . . . . . 17

2.5.3 Automatic Venting of a Vacuum Chamber . 17

2.5.4 Automatic Venting of a Vacuum

Chamber to a Slight Overpressure . . . . . . 18

2.5.5 Differential Pressure Monitoring,

Positive and Negative Going . . . . . . . . . . . 18

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Cleaning the Sensing Chamber . . . . . . . . . 19

3.2 Cleaning the Reference Chamber . . . . . . . 20

3.3 Service at INFICON . . . . . . . . . . . . . . . . . 20

4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . 21

EEC Declaration of Conformity . . . . . . . 22

Declaration of Contamina . . . . . . . . . . . . 23

3

3

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

Contents Page

1 Description . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 VSC150 Vacuum Switch . . . . . . . . . . . . . . . 5

1.2.2 SV Switching Amplifier . . . . . . . . . . . . . . . . 6

1.3 Technical Description . . . . . . . . . . . . . . . . . 6

1.3.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.2 Vacuum Switch Mode of Operation . . . . . . . 6

1.3.3 Switching Amplifier Mode of Operation . . . . 7

1.4 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Scope of Delivery . . . . . . . . . . . . . . . . . . . 8

1.4.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Connection to the Vacuum System . . . . . . . 9

2.2 Electrical Connection . . . . . . . . . . . . . . . . 10

2.2.1 Connection of the Vacuum Switch . . . . . . . 11

2.2.2 SV Switching Amplifier . . . . . . . . . . . . . . . 12

2.3 Design Versions and Switch Point Setting . 13

2.3.1 VSC150 Vacuum Switch . . . . . . . . . . . . . . 13

2.3.1.1 Setting Switching Pressures

Higher than 20 mbar . . . . . . . . . . . . . . . . 14

2.3.1.2 Setting Switching Pressures

Lower than 20 mbar . . . . . . . . . . . . . . . . . 14

2.4 Differential Pressure Adapter . . . . . . . . . . . 15

Page

2.4.1 Connecting the Differential Pressure

Adapter to the Vacuum Switch . . . . . . . . . 15

2.4.2 Switching Logic . . . . . . . . . . . . . . . . . . . . . 16

2.5 Typical Applications . . . . . . . . . . . . . . . . . . 16

2.5.1 Protection of a Gate Valve which

must only be Operated when

Pressure on both Sides

Becomes Equal . . . . . . . . . . . . . . . . . . . . 16

2.5.2 In a Vacuum System it must bei

Prevented that in Case of

Failure Gas Flows into the

Vacuum Chamber . . . . . . . . . . . . . . . . . . 17

2.5.3 Automatic Venting of a Vacuum Chamber . 17

2.5.4 Automatic Venting of a Vacuum

Chamber to a Slight Overpressure . . . . . . 18

2.5.5 Differential Pressure Monitoring,

Positive and Negative Going . . . . . . . . . . . 18

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Cleaning the Sensing Chamber . . . . . . . . . 19

3.2 Cleaning the Reference Chamber . . . . . . . 20

3.3 Service at INFICON . . . . . . . . . . . . . . . . . 20

4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . 21

EEC Declaration of Conformity . . . . . . . 22

Declaration of Contamina . . . . . . . . . . . . 23

1 Description

1.1 General

These Operating Instructions contain impor-

tant information on the functions, installation,

operation, and maintenance of the Vacuum

Switch and the switching amplifier.

Important remarks concerning operational safety and

protection are emphasized as follows:

Warning Indicates procedures that must be strict-

ly observed to prevent hazards to per-

sons.

Caution Indicates procedures that must be strict-

ly observed to prevent damage or des-

truction.

Note

Indicates special technical requirements that the user

must comply with.

The references to diagrams, e.g. (1/5), consist of the Fig.

No. and the Item No. in that order.

Unpack the Vacuum Switch and the switching amplifier

immediately after delivery, even if they are to be put into

operation at a later date.

Before doing so, examine the shipping container for any

external damage.

Then completely remove the packaging materials.

Note

The shipping container and packaging materials must be

kept in the event of complaints about damage.

Check for completeness (see Section 1.4).

Carefully examine the Vacuum Switch and the switching

amplifier visually.

If any damage is discovered, report it immediately to the

forwarding agent and insurer. If the damaged part has to

be replaced, please get in touch with the orders depart-

ment.

1.1.1 Purpose

The Vacuum Switch VSC150 in connection with the swit-

ching amplifier SV is used to produce pressure depen-

dent signals and for the control of valves and pumps.

4

4tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

1 Description

1.1 General

These Operating Instructions contain impor-

tant information on the functions, installation,

operation, and maintenance of the Vacuum

Switch and the switching amplifier.

Important remarks concerning operational safety and

protection are emphasized as follows:

Warning Indicates procedures that must be strict-

ly observed to prevent hazards to per-

sons.

Caution Indicates procedures that must be strict-

ly observed to prevent damage or des-

truction.

Note

Indicates special technical requirements that the user

must comply with.

The references to diagrams, e.g. (1/5), consist of the

Fig. No. and the Item No. in that order.

Unpack the Vacuum Switch and the switching amplifier

immediately after delivery, even if they are to be put into

operation at a later date.

Before doing so, examine the shipping container for any

external damage.

Then completely remove the packaging materials.

Note

The shipping container and packaging materials must be

kept in the event of complaints about damage.

Check for completeness (see Section 1.4).

Carefully examine the Vacuum Switch and the switching

amplifier visually.

If any damage is discovered, report it immediately to the

forwarding agent and insurer. If the damaged part has to

be replaced, please get in touch with the orders depart-

ment.

1.1.1 Purpose

The Vacuum Switch VSC150 in connection with the swit-

ching amplifier SV is used to produce pressure depen-

dent signals and for the control of valves and pumps.

The Vacuum Switch VSC150 can also be used as a dif-

ferential pressure switch.

Note the Technical Data given in section 1.2.

1.2 Technical Data

1.2.1 VSC150 Vacuum Switch

Switching range 0.5 to 2000 mbar

Overload limit 3000 mbar

Response sensitivity 0.1 mbar

Switching hysteresis 0.5 mbar

Temperature coefficient 0.4 % / K

of switching value

Ambient temperature,

briefly (max. 8 h) 120 °C

continuous 90 °C

Switching voltage 24 V

Switching current 10 mA

Connector protected plug-(DIN 43 650)

Protection type (DIN 40 050) IP 65

Vacuum connection DN 16 KF

Materials in contact with the medium:

Sensing volume stainless steel 1.4301; 1.4401

stainless steel 1.4310; 1.3541

FPM

Reference volume stainless steel 1.4301

stainless steel 1.4401; 1.3541

glass; gold

Sensing volume, approx. 41) cm3

Reference volume, approx. 20 cm3

Weight 1.3 kg

VSC150 Vacuum Switch

Switching pressure adjustable

between 0.5 and 2000 mbar Part Number 399-005

Differential Pressure Adapter

Connection DN 16 KF Part Number 399-007

Pressure switch adjustment Part Number 399-006

1) Including connection port

5

5

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

The Vacuum Switch VSC150 can also be used as a dif-

ferential pressure switch.

Note the Technical Data given in section 1.2.

1.2 Technical Data

1.2.1 VSC150 Vacuum Switch

Switching range 0.5 to 2000 mbar

Overload limit 3000 mbar

Response sensitivity 0.1 mbar

Switching hysteresis 0.5 mbar

Temperature coefficient 0.4 % / K

of switching value

Ambient temperature,

briefly (max. 8 h) 120 °C

continuous 90 °C

Switching voltage 24 V

Switching current 10 mA

Connector protected plug-(DIN 43 650)

Protection type (DIN 40 050) IP 65

Vacuum connection DN 16 KF

Materials in contact with the medium:

Sensing volume stainless steel 1.4301; 1.4401

stainless steel 1.4310; 1.3541

FPM

Reference volume stainless steel 1.4301

stainless steel 1.4401; 1.3541

glass; gold

Sensing volume, approx. 41) cm3

Reference volume, approx. 20 cm3

Weight 1.3 kg

VSC150 Vacuum Switch

Switching pressure adjustable

between 0.5 and 2000 mbar Part Number 399-005

Differential Pressure Adapter

Connection DN 16 KF Part Number 399-007

Pressure switch adjustment Part Number 399-006

1) Including connection port

1.2.2 SV Switching Amplifier

Mains supply 110 to 130 VAC

220 to 240 VAC

Mains frequency 50 / 60 Hz

Power consumption 3 VA

Output relay

Switching voltage, max. 250 V

Switching current, max. 5 A

Switching capacity, max. 500 VA

Response time 30 ms

Release time 7 ms

Control circuit 24 V / 10 mA

Ambient temperature, max. 50 °C

Weight 0.36 kg

SV Switching amplifier Part Number 399-008

1.3 Technical Description

1.3.1 Design

The VSC150 is a diaphragm absolute pressure switch.

He can also be used as a differential pressure switch.

Within both pressure switches there is a sensing cham-

ber (1/2) and a reference chamber (1/5) separated by a

highly sensitive sealed diaphragm made of stainless

steel (1/3). A pin (1/6) in the reference chamber (1/5) is

led to the outside and insulated (1/7). The ground

connected diaphragm acts as the opposite contact.

This contact configuration is so designed that the dia-

phragm contacts the pin when it is unstressed, i. e. with

equal pressure in sensing and reference chamber.

1.3.2 Vacuum Switch Mode of Operation

For switch-point setting, the adjusting valve (1/4) bet-

ween sensing chamber (1/2) and reference chamber

(1/5) is opened and closed again when the desired swit-

ching pressure is attained. If the pressure in the sensing

chamber drops below the set reference pressure by

more than 0.1 mbar, the contact opens and energizes a

heavy-duty relay in the connected SV switching ampli-

fier.

6

6tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

1.2.2 SV Switching Amplifier

Mains supply 110 to 130 VAC

220 to 240 VAC

Mains frequency 50 / 60 Hz

Power consumption 3 VA

Output relay

Switching voltage, max. 250 V

Switching current, max. 5 A

Switching capacity, max. 500 VA

Response time 30 ms

Release time 7 ms

Control circuit 24 V / 10 mA

Ambient temperature, max. 50 °C

Weight 0.36 kg

SV Switching amplifier Part Number 399-008

1.3 Technical Description

1.3.1 Design

The VSC150 is a diaphragm absolute pressure switch.

He can also be used as a differential pressure switch.

Within both pressure switches there is a sensing cham-

ber (1/2) and a reference chamber (1/5) separated by a

highly sensitive sealed diaphragm made of stainless

steel (1/3). A pin (1/6) in the reference chamber (1/5) is

led to the outside and insulated (1/7). The ground

connected diaphragm acts as the opposite contact.

This contact configuration is so designed that the dia-

phragm contacts the pin when it is unstressed, i. e. with

equal pressure in sensing and reference chamber.

1.3.2 Vacuum Switch Mode of Operation

For switch-point setting, the adjusting valve (1/4) bet-

ween sensing chamber (1/2) and reference chamber

(1/5) is opened and closed again when the desired swit-

ching pressure is attained. If the pressure in the sensing

chamber drops below the set reference pressure by

more than 0.1 mbar, the contact opens and energizes a

heavy-duty relay in the connected SV switching ampli-

fier.

1.3.3 Switching Amplifier Mode of Operation

Aswitching amplifier is required for each Vacuum

Switch. The output relay supplied with heavy-duty chan-

ge-over contact is energized when the pressure drops

below the value preset on the Vacuum Switch, i.e. if the

contact between diaphragm and contact pin in the refe-

rence chamber opens by flexing of the diaphragm. The

built-in slide switch (Fig. 5) must be set to the connected

type of Vacuum Switch.

7

7

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

1.3.3 Switching Amplifier Mode of Operation

Aswitching amplifier is required for each Vacuum

Switch. The output relay supplied with heavy-duty chan-

ge-over contact is energized when the pressure drops

below the value preset on the Vacuum Switch, i.e. if the

contact between diaphragm and contact pin in the refe-

rence chamber opens by flexing of the diaphragm. The

built-in slide switch (Fig. 5) must be set to the connected

type of Vacuum Switch.

9

(R)

(M)

10

9

(R)

(M)

8

7

6

5

4321

Fig 1 Schematic diagram of the Vacuum Switches

Key to Fig. 1

1 Adjusting Screw

2 Sensing chamber (M)

3 Diaphragm

4 Adjusting valve

5 Reference volume (R)

6 Contact pin

7 Current leadthrough

8 Electrical connection

9 Vacuum connection flange

10 Differential pressure adapter

9

(R)

(M)

10

9

(R)

(M)

8

7

6

5

4321

Fig 1 Schematic diagram of the Vacuum Switches

Key to Fig. 1

1 Adjusting Screw

2 Sensing chamber (M)

3 Diaphragm

4 Adjusting valve

5 Reference volume (R)

6 Contact pin

7 Current leadthrough

8 Electrical connection

9 Vacuum connection flange

10 Differential pressure adapter

1.4 Equipment

1.4.1 Scope of Delivery Part Number

Vacuum Switch VSC150 399-005

or

Switching amplifier SV 399-008

Operating Instructions tina42d1

tina42e1

1.4.2 Accessories

Clamping ring DN 16 KF, made of plastic *)

Centering ring DN 16 KF, made of

PTFE, with FPM O-ring *)

For pressure systems

(1000 to max. 3000 mbar abs.)

Outer centering ring

Clamping ring for ultra-

high vacuum disk DN 16 KF

*) For floating installation

8

8tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

1.4 Equipment

1.4.1 Scope of Delivery Part Number

Vacuum Switch VSC150 399-005

or

Switching amplifier SV 399-008

Operating Instructions tina42d1

tina42e1

1.4.2 Accessories

Clamping ring DN 16 KF, made of plastic *)

Centering ring DN 16 KF, made of

PTFE, with FPM O-ring *)

For pressure systems

(1000 to max. 3000 mbar abs.)

Outer centering ring

Clamping ring for ultra-

high vacuum disk DN 16 KF

*) For floating installation

2 Operation

2.1 Connection to the Vacuum System

The Vacuum Switch is mounted vertically. This ensures

that condensate can escape. Flange and gaskets must

be free of dust and grease. If the Vacuum Switch is to be

floated (electrically) it has to be separated from the

vacuum system by an insulating piece (Equipment see

Section 1.4.2).

9

9

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2 Operation

2.1 Connection to the Vacuum System

The Vacuum Switch is mounted vertically. This ensures

that condensate can escape. Flange and gaskets must

be free of dust and grease. If the Vacuum Switch is to be

floated (electrically) it has to be separated from the

vacuum system by an insulating piece (Equipment see

Section 1.4.2).

50

1

105

85

21

18

2

DN 16 KF

19

119

Fig. 2 Dimensional drawing (without differential pressure adapter)

Key to Fig. 2

1 Name plate

2 Label giving the switching

threshold

Height with differential

pressure adapter 133.5 mm

50

1

105

85

21

18

2

DN 16 KF

19

119

Fig. 2 Dimensional drawing (without differential pressure adapter)

Key to Fig. 2

1 Name plate

2 Label giving the switching

threshold

Height with differential

pressure adapter 133.5 mm

2.2 Electrical connection

Warning The terminals of the Vacuum Switch

must not be connected under any

circumstances to the mains voltage.

DANGER TO LIFE!

The housing potential may not exceed

the levels of protective low voltages

referred to ground.

10

10 tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2.2 Electrical connection

Warning The terminals of the Vacuum Switch

must not be connected under any

circumstances to the mains voltage.

DANGER TO LIFE!

The housing potential may not exceed

the levels of protective low voltages

referred to ground.

21,5

80

4,2

15 109

121

55,5

Pg 9

Pg 9

2150,5

163

Fig. 3 SV Switching amplifier (dimensional drawing)

21,5

80

4,2

15 109

121

55,5

Pg 9

Pg 9

2150,5

163

Fig. 3 SV Switching amplifier (dimensional drawing)

2.2.1 Connection of the Vacuum Switch

The Vacuum Switch is connected as follows:

-Unscrew fastening screw completely (4/3); lift-off

connecting box and gasket (4/2) from the Vacuum

Switch.

-Detach insert (4/4) applying a screwdriver at (4/5).

Note

Socket contact 3 (4/4) and protective ground conductor

are not connected!

See Fig. 5 for connection cables.

-Connect socket contact 1 (4/4) to terminalAon the swit-

ching amplifier (see fig. 5).

-Connect socket contact 2 (4/4) to terminal B on the

switching amplifier (see fig. 5).

Reassemble in the reverse order.

11

11

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2.2.1 Connection of the Vacuum Switch

The Vacuum Switch is connected as follows:

-Unscrew fastening screw completely (4/3); lift-off

connecting box and gasket (4/2) from the Vacuum

Switch.

-Detach insert (4/4) applying a screwdriver at (4/5).

Note

Socket contact 3 (4/4) and protective ground conductor

are not connected!

See Fig. 5 for connection cables.

-Connect socket contact 1 (4/4) to terminalAon the swit-

ching amplifier (see fig. 5).

-Connect socket contact 2 (4/4) to terminal B on the

switching amplifier (see fig. 5).

Reassemble in the reverse order.

12 3 4

5

2

13

Fig. 4 Vacuum Switch (electrical connection)

Key to Fig 4

1 Vacuum Switch

2 Gasket

3 Fastening serew

4 Insert

5 Point for screwdriver

Pin-out

1 Contact pin

2 Frame ground

12 3 4

5

2

13

Fig. 4 Vacuum Switch (electrical connection)

Key to Fig 4

1 Vacuum Switch

2 Gasket

3 Fastening serew

4 Insert

5 Point for screwdriver

Pin-out

1 Contact pin

2 Frame ground

2.2.2 SV Switching Amplifier

The diaphragm contact in the Vacuum Switch is unilate-

rally connected to ground and designed for a maxi-

mum load of 24 V / 10 mA.

The built-in slide switch (5/1) must be set to the connec-

ted type of pressure switch. For electrical installation the

switching amplifier SV 110 is delivered set for

220 ... 240 VAC. For mains voltages of 110 ... 130 VAC

change terminal bridge connectors as shown in Fig. 5.

When connecting to the mains the VDE 0100 re-

gulations must be observed. The connection of the

external consumer which is to be switched is shown in

Fig. 5.

12

12 tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2.2.2 SV Switching Amplifier

The diaphragm contact in the Vacuum Switch is unilate-

rally connected to ground and designed for a maxi-

mum load of 24 V / 10 mA.

The built-in slide switch (5/1) must be set to the connec-

ted type of pressure switch. For electrical installation the

switching amplifier SV 110 is delivered set for

220 ... 240 VAC. For mains voltages of 110 ... 130 VAC

change terminal bridge connectors as shown in Fig. 5.

When connecting to the mains the VDE 0100 re-

gulations must be observed. The connection of the

external consumer which is to be switched is shown in

Fig. 5.

2

1

VSC150

220....240 VAC

110....130 VAC

A B

123 4 1211

13

Key to fig. 5

1 Slide switch for selecting the type of

connected pressure switch

2 Signal connection (from the Vacuum Switch)

Cable cross section max. 1.5 mm2

Cable connection PG 9

Cable diameter

(outside dia.) 4.5 to 7 mm

Fig. 5 Connection diagram of the SV switching amplifier

2

1

VSC150

220....240 VAC

110....130 VAC

A B

123 4 1211

13

Key to fig. 5

1 Slide switch for selecting the type of

connected pressure switch

2 Signal connection (from the Vacuum Switch)

Cable cross section max. 1.5 mm2

Cable connection PG 9

Cable diameter

(outside dia.) 4.5 to 7 mm

Fig. 5 Connection diagram of the SV switching amplifier

2.3 Design Versions and Switch Point

Setting

Asuitable vacuum gauge or pressure gauge is required

for switch point setting.

2.3.1 VSC150 Vacuum Switch

With adjustable switching pressure in the range from 0.5

to 2000 mbar.

The adjusting valve (1/4) resp. (6/4) is freely accessible

and the user may set the switching pressure to any value

within the whole range.

Note

To avoid switching errors, pressure settings below

20 mbar should only be made under clean conditions

and using dry gas.

13

13

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2.3 Design Versions and Switch Point

Setting

Asuitable vacuum gauge or pressure gauge is required

for switch point setting.

2.3.1 VSC150 Vacuum Switch

With adjustable switching pressure in the range from 0.5

to 2000 mbar.

The adjusting valve (1/4) resp. (6/4) is freely accessible

and the user may set the switching pressure to any value

within the whole range.

Note

To avoid switching errors, pressure settings below

20 mbar should only be made under clean conditions

and using dry gas.

12

3

4 5

Key to Fig. 6

1 Protection Cap

2 Adjusting screw

3 Fixing screw of housing

4 Adjusting valve

5 Differential pressure adapter

Fig 6 Vacuum Switch with differential pressure adapter

12

3

4 5

Key to Fig. 6

1 Protection Cap

2 Adjusting screw

3 Fixing screw of housing

4 Adjusting valve

5 Differential pressure adapter

Fig 6 Vacuum Switch with differential pressure adapter

2.3.1.1 Setting Switching Pressures Higher than 20 mbar

Condition: Correct basic adjustment of the Vacuum

Switch.

Basic adjustment of the switch in the factory provided

that at equal pressure in sensing and reference chamber

the contact is just closed.

The diaphragm (1/3) touches the contact pin (1/6) in the

reference chamber (1/5).

Check this basic adjustment.

Open adjusting valve (1/4) resp. (6/4) using an Allan key

(size across flats 5 mm) by 2 anticlockwise turns.

The relay contact via terminals 11 and 12 in the connec-

ted SV switching amplifier must now be open (Fig. 5).

If not, remove protective cap (6/1) and turn adjusting

screw (6/2) carefully clockwise till the relay is de-energi-

zed and the above-mentioned contact is open.

Then replace protective cap (6/1).

Now set desired switch point as follows:

- At first produce desired pressure in the system.

-Then close adjusting valve (6/4) turning clockwise with

the dynamometric key.

Note

The amount of torque for the adjustment valve is

Md = 3.5 to 4 Nm.

-If the pressure in the sensing chamber drops by 0.1

mbar the contact between diaphragm and contact pin

opens by flexing of the diaphragm and the relay in the

connected switching amplifier is energized.

-The switch contact on terminals 11 and 12 (see Fig. 5)

is closed.

2.3.1.2 Setting Switching Pressures Lower than 20 mbar

The procedure is basically the same as described in

2.3.1.1.

Caution However, to avoid contamination of the

reference chamber it is essential to use

only extremely dry and clean gas. Other-

wise there is a risk that gas (vapor)

desorption from the chamber walls will

change the pressure in the reference

chamber.

The system must be pumped down to a pressure less

than 1·10-4 mbar.

Open adjusting valve (6/4) using an Allan key (size

across flats 5 mm) by 2 anticlockwise turns.

Bake out the Vacuum Switch using strip heaters for at

least 5 to 6 hours at approx. 120 °C, while pump down

continues uninterrupted.

14

14 tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2.3.1.1 Setting Switching Pressures Higher than 20 mbar

Condition: Correct basic adjustment of the Vacuum

Switch.

Basic adjustment of the switch in the factory provided

that at equal pressure in sensing and reference chamber

the contact is just closed.

The diaphragm (1/3) touches the contact pin (1/6) in the

reference chamber (1/5).

Check this basic adjustment.

Open adjusting valve (1/4) resp. (6/4) using an Allan key

(size across flats 5 mm) by 2 anticlockwise turns.

The relay contact via terminals 11 and 12 in the connec-

ted SV switching amplifier must now be open (Fig. 5).

If not, remove protective cap (6/1) and turn adjusting

screw (6/2) carefully clockwise till the relay is de-energi-

zed and the above-mentioned contact is open.

Then replace protective cap (6/1).

Now set desired switch point as follows:

- At first produce desired pressure in the system.

-Then close adjusting valve (6/4) turning clockwise with

the dynamometric key.

Note

The amount of torque for the adjustment valve is

Md = 3.5 to 4 Nm.

-If the pressure in the sensing chamber drops by 0.1

mbar the contact between diaphragm and contact pin

opens by flexing of the diaphragm and the relay in the

connected switching amplifier is energized.

-The switch contact on terminals 11 and 12 (see Fig. 5)

is closed.

2.3.1.2 Setting Switching Pressures Lower than 20 mbar

The procedure is basically the same as described in

2.3.1.1.

Caution However, to avoid contamination of the

reference chamber it is essential to use

only extremely dry and clean gas. Other-

wise there is a risk that gas (vapor)

desorption from the chamber walls will

change the pressure in the reference

chamber.

The system must be pumped down to a pressure less

than 1·10-4 mbar.

Open adjusting valve (6/4) using an Allan key (size

across flats 5 mm) by 2 anticlockwise turns.

Bake out the Vacuum Switch using strip heaters for at

least 5 to 6 hours at approx. 120 °C, while pump down

continues uninterrupted.

Then admit dry protective gas to the Vacuum Switch up

to a pressure of 20 mbar, check basic adjustment of the

Vacuum Switch as described in 2.3.1.1.

Close adjusting valve turning clockwise with the dyna-

mometric key.

Note

The amount of torque for the adjustment valve is

Md = 3.5 to 4 Nm.

Now produce desired pressure - between 0.5 and 20

mbar.

Remove protective cap (6/1) and turn adjusting screw

(6/2) carefully clockwise till the relay of the connected SV

switching amplifier is de-energized.

The contact via terminal 11 and 12 must now be open

(Fig. 5).

Then replace protective cap (6/1).

Later correction or change of the switch point between

0.5 and 20 mbar can be made anytime without readjust-

ment of the reference pressure of 20 mbar. Such a chan-

ge of the switch point is made exclusively by means of

the adjusting screw (6/2). The adjusting valve (6/4)

remains closed.

To reduce the switching pressure turn adjusting screw

(6/2) clockwise.

To increase the switching pressure turn adjusting screw

(6/2) counterclockwise.

2.4 Differential Pressure Adapter

The differential pressure adapter (6/5) consists of an

DN 16 KF flange with threaded tubulation and seal-off-

fitting. It is screwed onto the VSC150 Vacuum Switch

substituting the adjusting valve (6/4) and enables the

pressure switch to be used as a differential pressure

switch or a pressure balance indicator. Its operating

range is up to 2000 mbar. Differential pressures

(∆p = pR- pM) between + 5 and -20 mbar can be set up.

2.4.1 Connecting the Differential Pressure

Adapter to the Vacuum Switch

-Unscrew the adjusting valve (6/4) turning counterclock-

wise using Allan key (5 mm).

- Screw in differential pressure adapter (6/5).

Do not force!

-The connection ports of sensing chamber (1/2) and

reference chamber (1/5) are now separated.

(1/9) Connection of sensing chamber „M“;

(1/10) Connection of reference chamber „R“.

15

15

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

Then admit dry protective gas to the Vacuum Switch up

to a pressure of 20 mbar, check basic adjustment of the

Vacuum Switch as described in 2.3.1.1.

Close adjusting valve turning clockwise with the dyna-

mometric key.

Note

The amount of torque for the adjustment valve is

Md = 3.5 to 4 Nm.

Now produce desired pressure - between 0.5 and 20

mbar.

Remove protective cap (6/1) and turn adjusting screw

(6/2) carefully clockwise till the relay of the connected

SV switching amplifier is de-energized.

The contact via terminal 11 and 12 must now be open

(Fig. 5).

Then replace protective cap (6/1).

Later correction or change of the switch point between

0.5 and 20 mbar can be made anytime without readjust-

ment of the reference pressure of 20 mbar. Such a chan-

ge of the switch point is made exclusively by means of

the adjusting screw (6/2). The adjusting valve (6/4)

remains closed.

To reduce the switching pressure turn adjusting screw

(6/2) clockwise.

To increase the switching pressure turn adjusting screw

(6/2) counterclockwise.

2.4 Differential Pressure Adapter

The differential pressure adapter (6/5) consists of an

DN 16 KF flange with threaded tubulation and seal-off-

fitting. It is screwed onto the VSC150 Vacuum Switch

substituting the adjusting valve (6/4) and enables the

pressure switch to be used as a differential pressure

switch or a pressure balance indicator. Its operating

range is up to 2000 mbar. Differential pressures

(∆p = pR- pM) between + 5 and -20 mbar can be set up.

2.4.1 Connecting the Differential Pressure

Adapter to the Vacuum Switch

-Unscrew the adjusting valve (6/4) turning counterclock-

wise using Allan key (5 mm).

- Screw in differential pressure adapter (6/5).

Do not force!

-The connection ports of sensing chamber (1/2) and

reference chamber (1/5) are now separated.

(1/9) Connection of sensing chamber „M“;

(1/10) Connection of reference chamber „R“.

Caution Only the sensing chamber can be ope-

ned for cleaning. The reference cham-

ber can not be opened and must there-

fore be protected from contaminaton.

2.4.2 Switching Logic

With correct basic adjustment of the switch (see section

2.3.1.1) the following switching logic applies:

pR> pM= contact open

Relay in SV switching amplifier energized, contacts 11

and 12 closed.

pR≤pM= contact closed

Relay in SV switching amplifier de-energized, contacts

11 and 12 open.

Correction by means of adjusting screw (6/2) see section

2.3.1.1.

2.5 Typical Applications

2.5.1 Protection of a Gate Valve which must

only be Operated when Pressure on both

Sides Becomes Equal

Assembly as shown in the diagram, Fig. 7.

Connect port (1/10) of the Vacuum Switch always to that

side where higher pressure is to be expected.

Loop the control circuit of the gate valve via the break

contact, terminals 12 and 13 (see Fig. 5), of the swit-

ching amplifier relay. The basic adjustment as described

in Section 2.3.1.1 applies to the Vacuum Switch, i.e. the

diaphragm must just touch the contact pin (6/2) see sec-

tion 2.3.1.1.

When turned counterclockwise the contact opens.

When turned clockwise the contact closes.

16

16 tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

Caution Only the sensing chamber can be ope-

ned for cleaning. The reference cham-

ber can not be opened and must there-

fore be protected from contaminaton.

2.4.2 Switching Logic

With correct basic adjustment of the switch (see section

2.3.1.1) the following switching logic applies:

pR> pM= contact open

Relay in SV switching amplifier energized, contacts 11

and 12 closed.

pR≤pM= contact closed

Relay in SV switching amplifier de-energized, contacts

11 and 12 open.

Correction by means of adjusting screw (6/2) see sec-

tion 2.3.1.1.

2.5 Typical Applications

2.5.1 Protection of a Gate Valve which must

only be Operated when Pressure on both

Sides Becomes Equal

Assembly as shown in the diagram, Fig. 7.

Connect port (1/10) of the Vacuum Switch always to that

side where higher pressure is to be expected.

Loop the control circuit of the gate valve via the break

contact, terminals 12 and 13 (see Fig. 5), of the swit-

ching amplifier relay. The basic adjustment as described

in Section 2.3.1.1 applies to the Vacuum Switch, i.e. the

diaphragm must just touch the contact pin (6/2) see sec-

tion 2.3.1.1.

When turned counterclockwise the contact opens.

When turned clockwise the contact closes.

2.5.2 In a Vacuum System it must be Prevented

that in Case of Failure Gas Flows into the

Vacuum Chamber

Assembly as shown in the diagram, Fig. 7.

Also in this case, as in 2.5.1, the contact setting of the

Vacuum Switch should correspond to the basic adjust-

ment. Control the electrically operated valve (normally

closed) via the break-contact, terminals 12 and 13 (see

Fig. 5), of the SV switching amplifier. In case of power

failure this valve closes. When the power returns the

valve is not opened before the pressure in the sensing

volume and the reference volume of the Vacuum Switch

has become equal.

2.5.3 Automatic Venting of a Vacuum Chamber

End of venting at a minimum pressure of 20 mbar below

atmospheric pressure, max. at atmospheric pressure.

Assembly as in Fig. 8.

The venting valve (normally closed) is controlled via the

make-contact of the switching amplifier relay, terminals

11 and 12 (see Fig. 5). For venting up to atmospheric

pressure the basic adjustment of the Vacuum Switch

contact applies. If venting should end before, the swit-

ching pressure can be continuously lowered by 20 mbar

17

17

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

2.5.2 In a Vacuum System it must be Prevented

that in Case of Failure Gas Flows into the

Vacuum Chamber

Assembly as shown in the diagram, Fig. 7.

Also in this case, as in 2.5.1, the contact setting of the

Vacuum Switch should correspond to the basic adjust-

ment. Control the electrically operated valve (normally

closed) via the break-contact, terminals 12 and 13 (see

Fig. 5), of the SV switching amplifier. In case of power

failure this valve closes. When the power returns the

valve is not opened before the pressure in the sensing

volume and the reference volume of the Vacuum Switch

has become equal.

2.5.3 Automatic Venting of a Vacuum Chamber

End of venting at a minimum pressure of 20 mbar below

atmospheric pressure, max. at atmospheric pressure.

Assembly as in Fig. 8.

The venting valve (normally closed) is controlled via the

make-contact of the switching amplifier relay, terminals

11 and 12 (see Fig. 5). For venting up to atmospheric

pressure the basic adjustment of the Vacuum Switch

contact applies. If venting should end before, the swit-

ching pressure can be continuously lowered by 20 mbar

SV

VSC 150

M

R

Fig. 7 Differential pressure monitoring of a valve

M

SV

VSC 150

R

Fig. 8 Automatic venting between -20 mbar and

atmospheric pressure

SV

VSC 150

M

R

Fig. 7 Differential pressure monitoring of a valve

M

SV

VSC 150

R

Fig. 8 Automatic venting between -20 mbar and

atmospheric pressure

max. turning the adjusting screw (6/2) clockwise.

2.5.4 Automatic Venting of a Vacuum Chamber

to a Slight Overpressure

Assembly as in Fig. 9.

Loop the control circuit of the venting valve via the break

contact of the switching amplifier relay, terminals 12 and

13 (see Fig. 5). The switching pressure can be raised by

20 mbar max. above atmospheric pressure by turning

the adjusting screw (6/2) clockwise.

2.5.5 Differential Pressure Monitoring, Positive

and Negative Going

In an annealing plant with „holding vacuum“ pump down

and venting of the annealing pot and the vacuum fur-

nace must be regulated so that the differential pressures

in both directions will not exceed 10 mbar (Assembly as

shown in Fig. 10).

Starting from the basic adjustment set the two Vacuum

Switches by turning the adjusting screw (6/2) clockwise

so that at a pressure of 10 mbar in the reference cham-

ber against the pressure in the sensing chamber the

switch contact opens by flexing of the diaphragm. Con-

trol venting valves and pump valves each via the break

18

18 tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

max. turning the adjusting screw (6/2) clockwise.

2.5.4 Automatic Venting of a Vacuum Chamber

to a Slight Overpressure

Assembly as in Fig. 9.

Loop the control circuit of the venting valve via the break

contact of the switching amplifier relay, terminals 12 and

13 (see Fig. 5). The switching pressure can be raised by

20 mbar max. above atmospheric pressure by turning

the adjusting screw (6/2) clockwise.

2.5.5 Differential Pressure Monitoring, Positive

and Negative Going

In an annealing plant with „holding vacuum“ pump down

and venting of the annealing pot and the vacuum fur-

nace must be regulated so that the differential pressures

in both directions will not exceed 10 mbar (Assembly as

shown in Fig. 10).

Starting from the basic adjustment set the two Vacuum

Switches by turning the adjusting screw (6/2) clockwise

so that at a pressure of 10 mbar in the reference cham-

ber against the pressure in the sensing chamber the

switch contact opens by flexing of the diaphragm. Con-

trol venting valves and pump valves each via the break

SV SV

VSC 150

R

VSC 150

M

RM

Oven

Crucible

Fig. 10 Differential pressure monitoring, positive and

negative going

VSC 150

M

R

SV

Fig. 9 Automatic venting between atmospheric pressure

and + 20 mbar

SV SV

VSC 150

R

VSC 150

M

RM

Oven

Crucible

Fig. 10 Differential pressure monitoring, positive and

negative going

VSC 150

M

R

SV

Fig. 9 Automatic venting between atmospheric pressure

and + 20 mbar

contact, terminals 12 and 13, of the two SV switching

amplifiers.

As soon as during pump down or venting the differential

pressure between annealing pot and vacuum furnace in

either direction exceeds 10 mbar, the respective pump

valve or venting valve is closed. The valves open again

as soon as the differential pressure has dropped below

the set switching pressure. Switching pressures can be

varied between 0.5 and 20 mbar by means of the adju-

sting screw (6/2).

3 Maintenance

For the pressure switches maintenance work is normal-

ly not nesessary. Slight contamination of the sensing

chamber does not affect the switching performance and

accuracy. If for one reason or other cleaning should

become necessary, observe Sections 3.1 or 3.2.

3.1 Cleaning the Sensing Chamber

-Remove protection cap (6/1).

-Unscrew adjusting screw (6/2) by turning counterclock-

wise and extract the complete setting mechanism (ball

and compression spring).

-Unscrew the three housing screws (6/3) and open the

sensing chamber.

Caution Do not exert pressure on the diaphragm.

Do not use any mechanical cleaning

means like emery paper, steel wool or

steel brushes. Cleanse with solvents

- petroleum ether, benzin or alcohol -

and dry. Replace gasket, if necessary.

19

19

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

contact, terminals 12 and 13, of the two SV switching

amplifiers.

As soon as during pump down or venting the differential

pressure between annealing pot and vacuum furnace in

either direction exceeds 10 mbar, the respective pump

valve or venting valve is closed. The valves open again

as soon as the differential pressure has dropped below

the set switching pressure. Switching pressures can be

varied between 0.5 and 20 mbar by means of the adju-

sting screw (6/2).

3 Maintenance

For the pressure switches maintenance work is normal-

ly not nesessary. Slight contamination of the sensing

chamber does not affect the switching performance and

accuracy. If for one reason or other cleaning should

become necessary, observe Sections 3.1 or 3.2.

3.1 Cleaning the Sensing Chamber

-Remove protection cap (6/1).

-Unscrew adjusting screw (6/2) by turning counterclock-

wise and extract the complete setting mechanism (ball

and compression spring).

-Unscrew the three housing screws (6/3) and open the

sensing chamber.

Caution Do not exert pressure on the diaphragm.

Do not use any mechanical cleaning

means like emery paper, steel wool or

steel brushes. Cleanse with solvents

- petroleum ether, benzin or alcohol -

and dry. Replace gasket, if necessary.

Note

-Reassemble the setting machanism in the order com-

pression spring, ball and adjusting screw.

-When screwing in the adjusting screw grease the

O-ring slightly with Lithelen.

Reassemble Vacuum Switch. Set adjusting screw (6/2)

as described in section 2.3.

3.2 Cleaning the reference chamber

Cleaning of the reference chamber is only possible in

the VSC150 Vacuum Switch if the latter is used as a dif-

ferential pressure switch. The reference chamber cannot

be opened but can only be cleansed with solvents.

Proceed as follows:

-Unscrew the differential pressure adapter (6/5) and

inject solvent by means of a syringe. Let solvent act for

a while, shake and pour out.

-Repeat this procedure several times (if nesessary).

Then screw in differenbal pressure adapter again,

tightening uniformly!

-Dry the reference chamber by evacuating with a vacu-

um pump.

-Readjustment of the basic setting is only nesessary if

the measurement chamber has been opened.

3.3 Service at INFICON

Warning Contaminated products (e.g. radioac-

tive, toxic, caustic or microbiological

hazard) can be detrimental to health and

environment.

Products returned to Inficon should preferably be free of

harmful substances. Adhere to the forwarding regulati-

ons of all involved countries and forwarding companies

and enclose a duly completed declaration of contamina-

tion (see Annex).

Products that are not clearly declared as „free of harmful

substances“ are decontaminated at the expense of the

customer.

Products not accompanied by a duly completed declara-

tion of contamination are returned to the sender at his

own expense.

20

20 tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

Note

-Reassemble the setting machanism in the order com-

pression spring, ball and adjusting screw.

-When screwing in the adjusting screw grease the

O-ring slightly with Lithelen.

Reassemble Vacuum Switch. Set adjusting screw (6/2)

as described in section 2.3.

3.2 Cleaning the reference chamber

Cleaning of the reference chamber is only possible in

the VSC150 Vacuum Switch if the latter is used as a dif-

ferential pressure switch. The reference chamber cannot

be opened but can only be cleansed with solvents.

Proceed as follows:

-Unscrew the differential pressure adapter (6/5) and

inject solvent by means of a syringe. Let solvent act for

a while, shake and pour out.

-Repeat this procedure several times (if nesessary).

Then screw in differenbal pressure adapter again,

tightening uniformly!

-Dry the reference chamber by evacuating with a vacu-

um pump.

-Readjustment of the basic setting is only nesessary if

the measurement chamber has been opened.

3.3 Service at INFICON

Warning Contaminated products (e.g. radioac-

tive, toxic, caustic or microbiological

hazard) can be detrimental to health and

environment.

Products returned to Inficon should preferably be free of

harmful substances. Adhere to the forwarding regulati-

ons of all involved countries and forwarding companies

and enclose a duly completed declaration of contamina-

tion (see Annex).

Products that are not clearly declared as „free of harmful

substances“ are decontaminated at the expense of the

customer.

Products not accompanied by a duly completed declara-

tion of contamination are returned to the sender at his

own expense.

Table of contents

Other Inficon Switch manuals

Popular Switch manuals by other brands

turck

turck TBIL-M1-16DIP Instructions for use

ArcTiv Technologies

ArcTiv Technologies ATS Quick installation guide

Perle

Perle IDS-305G Hardware installation guide

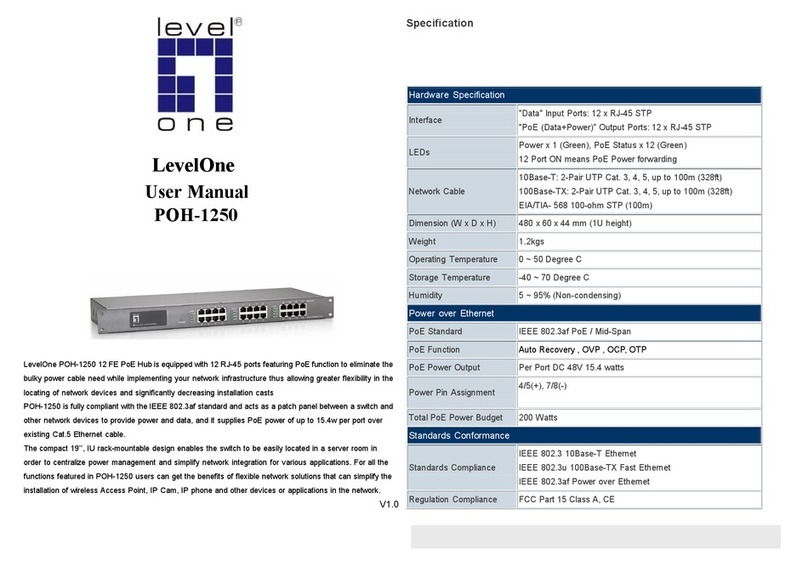

SMC Networks

SMC Networks 8126PL2-F installation guide

Allied Telesis

Allied Telesis x900-12X Series datasheet

LevelOne

LevelOne POH-1250 user manual