Infinite L-com SRWQ100-pH104-8701 User manual

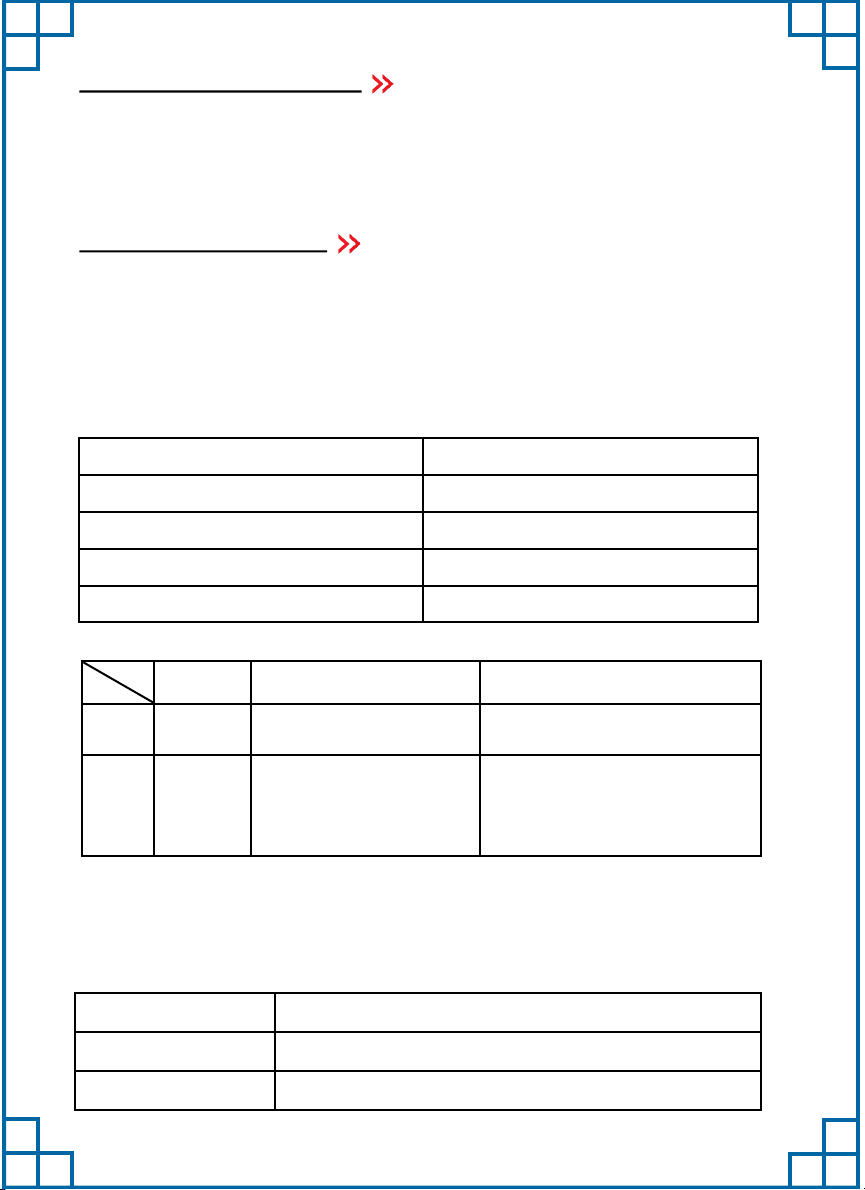

Table of contents

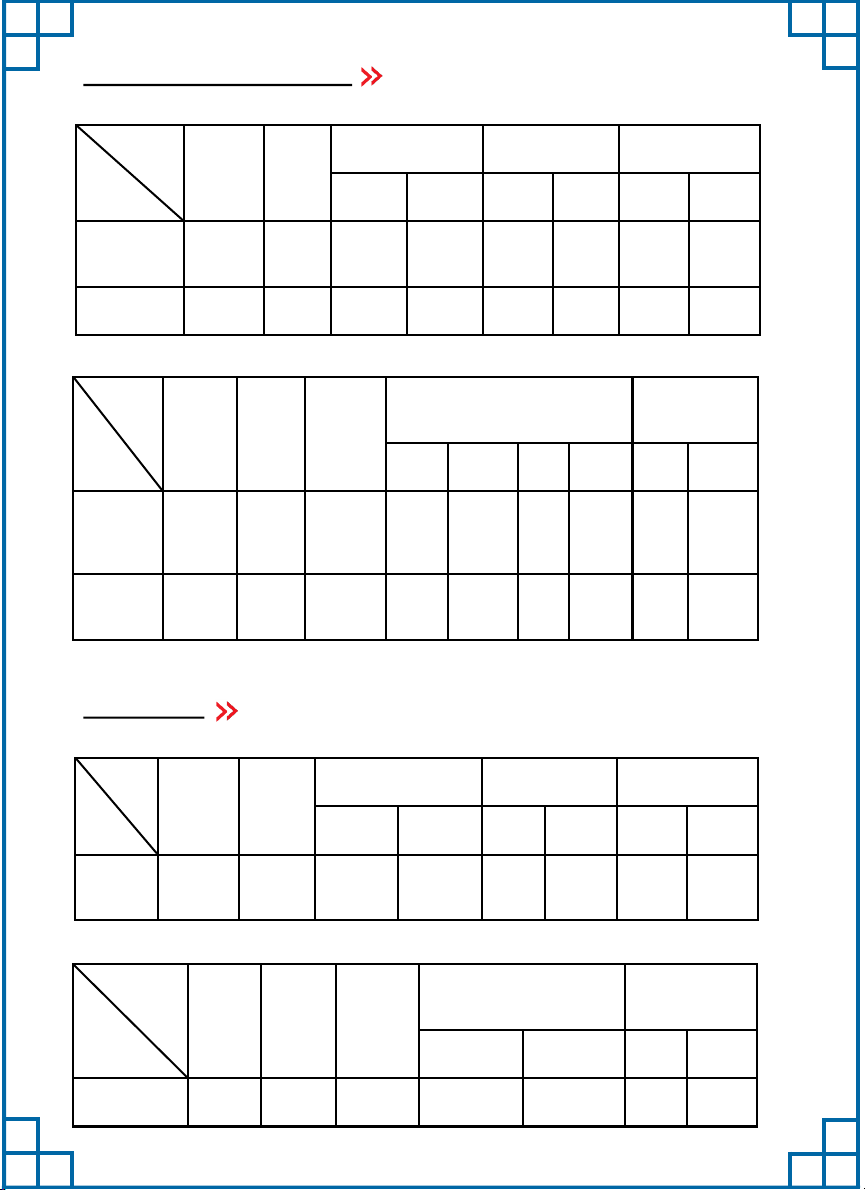

Other Infinite Accessories manuals

Infinite

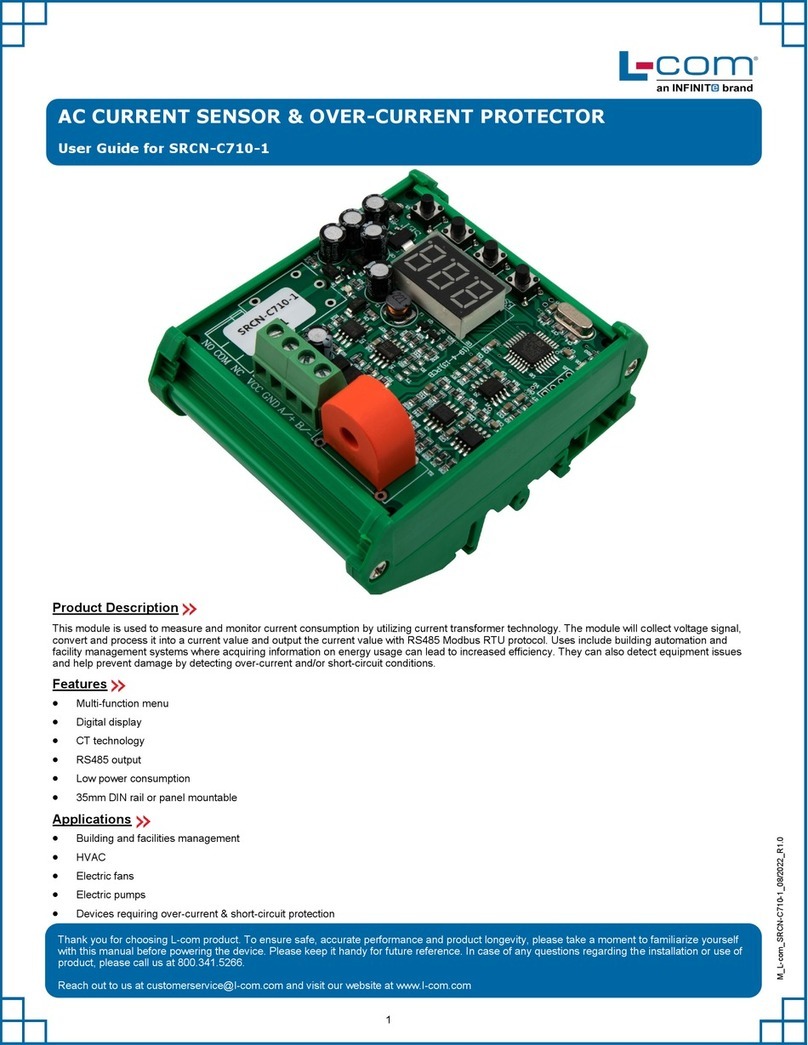

Infinite L-com SRCN-C710-1 User manual

Infinite

Infinite L-com SRCN-C711-1 User manual

Infinite

Infinite AERINOS User manual

Infinite

Infinite L-com SRCN-C420-3 User manual

Infinite

Infinite L-com SRAQ-G005 User manual

Infinite

Infinite L-com SRCN-C415-2 User manual

Infinite

Infinite AERINOS ADS-260 User manual

Infinite

Infinite L-Com SRTH600-901-2401 User manual

Infinite

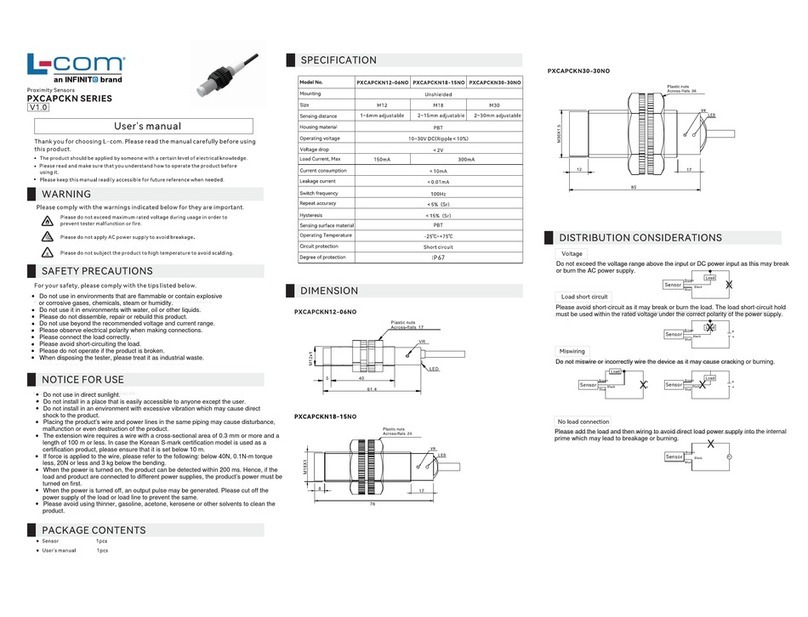

Infinite L-com PXCAPCKN Series User manual

Infinite

Infinite L-com SRCN-C413-3 User manual

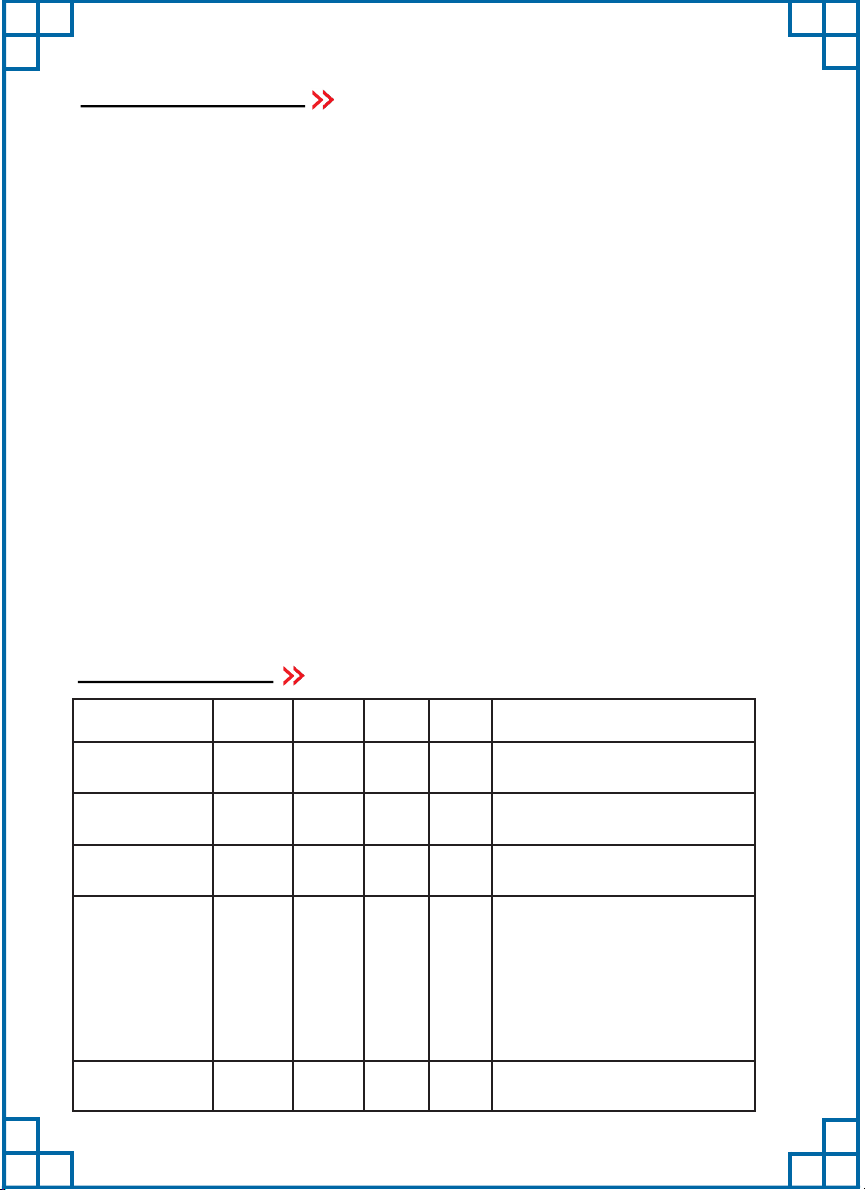

Popular Accessories manuals by other brands

PFlow Industries

PFlow Industries 21 Series owner's manual

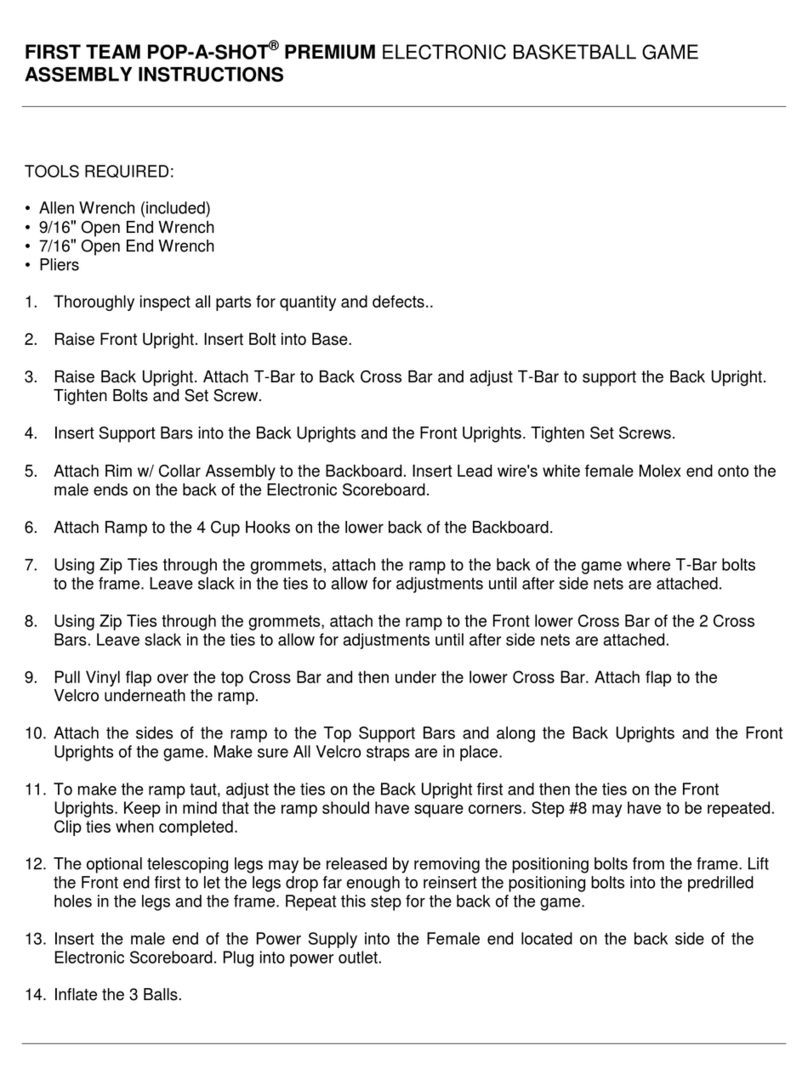

FIRST TEAM SPORTS

FIRST TEAM SPORTS POP-A-SHOT PREMIUM Assembly instructions

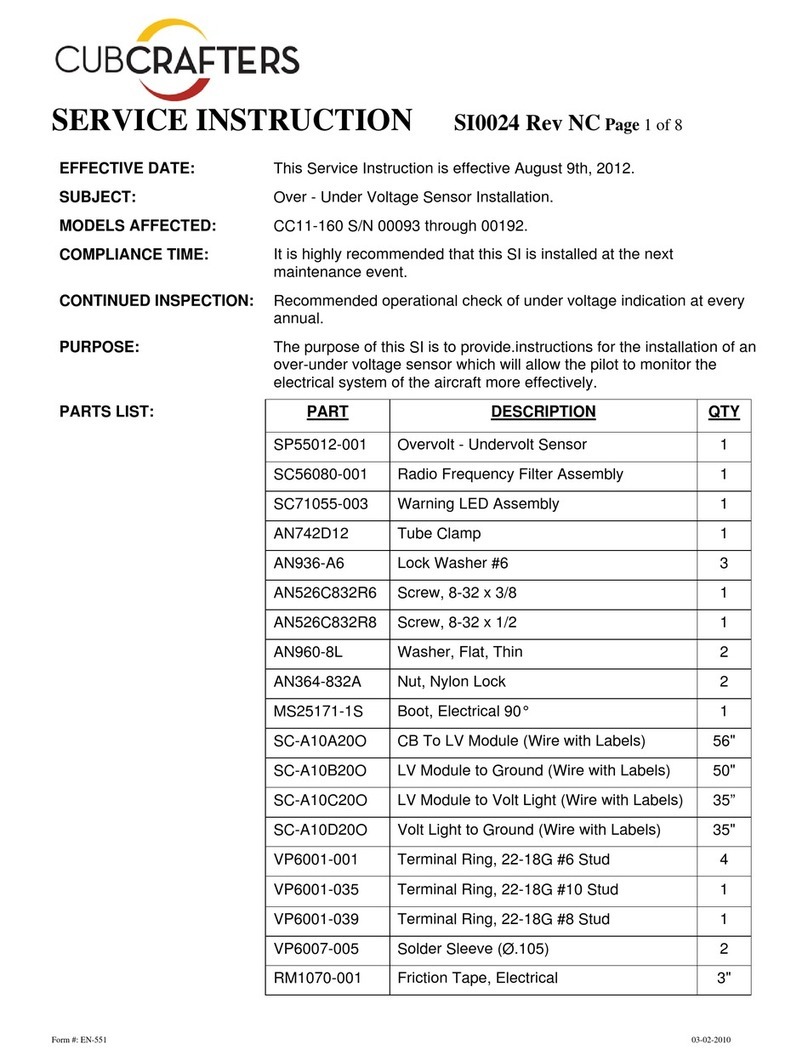

Cub Crafters

Cub Crafters CC11-160 Service instruction

Network Thermostat

Network Thermostat NetX NT-URS installation manual

Elecro Engineering

Elecro Engineering QUANTUM SPA - CLASSIC Installation & operating manual

Minebea Intec

Minebea Intec Maxxis 5 Count PR 5900/82 operating instructions