Infranor SMT-BD2/m User manual

1

SMT-BD2/m

SMT-BD2/m

gb

POSITIONER

FOR SINUSOIDAL

BRUSHLESS LINEAR AND

ROTATING AC MOTORS

2

SMT-BD2/m

WARNING

This is a general manual describing a series of servo amplifiers having output capability suitable for driving AC

brushless sinusoidal servo motors.

Instructions for storage, use after storage, commissioning as well as all technical details require the MANDATORY

reading of the manual before getting the amplifiers operational.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the amplifier manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

© INFRANOR, November 2007. All rights reserved.

Issue: 2.2

!

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the amplifiers (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (ElectroStatic Discharge)

INFRANOR amplifiers are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the amplifiers are not properly

stored and handled.

STORAGE

- The amplifiers must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the amplifier connectors and material with electrostatic potential

(plastic film, polyester, carpet…).

HANDLING

- If no protection equipment is available (dissipating shoes or bracelets), the amplifiers must

be handled via their metal housing.

- Never get in contact with the connectors.

ELIMINATION

In order to comply with the 2002/96/EC directive of the European Parliament and of the Council of

27 January 2003 on waste electrical and electronic equipment (WEEE), all INFRANOR devices

have got a sticker symbolizing a crossed-out wheel dustbin as shown in Appendix IV of the

2002/96/EC Directive.

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with standard waste.

3

SMT-BD2/m

Content

s

CONTENTS

CONTENTS............................................................................................................................................. 3

CHAPTER 1 - GENERAL DESCRIPTION ............................................................................................. 7

1-INTRODUCTION............................................................................................................................ 7

2-GENERAL DESCRIPTION............................................................................................................. 7

3-REFERENCE TO THE STANDARDS............................................................................................ 8

4-REFERENCE TO OTHER DOCUMENTS...................................................................................... 8

CHAPTER 2 - SPECIFICATIONS .......................................................................................................... 9

1-TECHNICAL SPECIFICATIONS.................................................................................................... 9

1.1 - Current ratings for the 220 VAC amplifier version................................................................. 9

1.2 - Current ratings for the 400 VAC amplifier version............................................................... 10

1.3 - Other specifications.............................................................................................................. 11

2-BLOCK DIAGRAM ....................................................................................................................... 13

3-MAIN PROTECTIONS ................................................................................................................. 14

3.1 - Displayed protections........................................................................................................... 14

3.2 - Fuse protection..................................................................................................................... 15

CHAPTER 3 - INPUTS - OUTPUTS.................................................................................................... 16

1-CONNECTORS LOCATION ....................................................................................................... 16

1.1 - RACK connectors................................................................................................................. 16

1.2 - Amplifier connectors............................................................................................................. 16

2-X5 SERIAL LINK CONNECTOR (SUB D9PINS MALE).................................................................. 16

3-X1 ENCODER FEEDBACK CONNECTOR (SUB D15 POINTS FEMALE)........................................ 17

3.1 - X1 connector for TTL incremental encoder configuration.................................................... 17

3.2 - X1 connector for TTL incremental encoder & HES configuration........................................ 18

3.3 - X1 connector for absolute single turn Sin/Cos encoder configuration................................. 19

3.4 - X1 connector for other Sin/Cos encoder configurations ...................................................... 20

4-X4 ANALOG INPUT &COMMAND CONNECTOR (SUB D25 PINS MALE).................................... 21

4.1 - Specification of the analog inputs / outputs.......................................................................... 22

4.2 - Specification of the logic inputs / outputs............................................................................. 22

5-X2 ENCODER OUTPUT &COMMAND CONNECTOR (SUB D25 PINS FEMALE)......................... 24

6-X6 LOGIC OUTPUTS CONNECTOR (SUB D9PINS FEMALE)....................................................... 25

7-X7 LOGIC INPUTS CONNECTOR (SUB D9PINS MALE).............................................................. 25

CHAPTER 4 - CONNECTIONS............................................................................................................ 26

1-CONNECTION DIAGRAMS......................................................................................................... 26

1.1 - Rack power supply and motor connection........................................................................... 26

1.2 - Amplifier i/o connections ...................................................................................................... 26

1.3 - RS-232 serial link connection............................................................................................... 28

2-WIRING (ACCORDING TO CEI 801 AND EN 55011 STANDARDS)...................................................... 28

2.1 - GND wiring and grounding................................................................................................... 28

2.2 - Motor and sensors cables .................................................................................................... 28

2.3 - Analog inputs and serial link cables..................................................................................... 28

3-360° SHIELD ON THE CONNECTORS....................................................................................... 29

CHAPTER 5 - ADJUSTABLE FUNCTIONS ........................................................................................ 30

1-HARDWARE ADJUSTMENTS..................................................................................................... 30

2-ADJUSTABLE PARAMETERS .................................................................................................... 31

CHAPTER 6 - COMMISSIONING......................................................................................................... 32

1-CHECKING THE AMPLIFIER CONFIGURATION....................................................................... 32

1.1 - Standard amplifier configuration ..........................................................................................32

1. 2 - Encoder configuration ......................................................................................................... 32

1. 3 - Hall EffectSensors configuration........................................................................................33

4

SMT-BD2/m

Contents

1. 4 - Motor thermal sensor configuration..................................................................................... 33

1.5 - Current loops adjustments.................................................................................................... 33

2-PUTTING INTO OPERATION...................................................................................................... 35

3-AMPLIFIER COMMISSIONING AND ADJUSTMENT.................................................................. 35

3.1 - Amplifier setup...................................................................................................................... 35

3.2 - Motor Hall EffectSensors adjustment .................................................................................. 36

3.3 - Absolute single turn Sin/Cos encoder adjustment................................................................ 36

3.4 - Amplifier parameter setting................................................................................................... 36

3.5 - Amplifier auto-tuning with an unbalanced load.................................................................... 37

3.6 - Saving of the amplifier parameters....................................................................................... 38

3.7 - Motor phasing at power up................................................................................................... 38

3.8 - Amplifier addressing ............................................................................................................. 38

3.9 - Parameters adjustment to a linear motor ............................................................................. 39

CHAPTER 7 - PROGRAMMATION......................................................................................................40

1-GENERAL DESCRIPTION........................................................................................................... 40

2-DESCRIPTION OF THE LOGIC I/OS........................................................................................... 40

2.1 - LOGIC INPUTS ................................................................................................................... 40

2.2 - LOGIC OUTPUTS ............................................................................................................... 41

3-POSITIONER PARAMETERS...................................................................................................... 42

3.1 - CONFIGURATION OF THE PROGRAMMABLES I/Os ...................................................... 42

3.2 - AXIS POSITION SCALING.................................................................................................. 42

3.3 - POSITIONER CONFIGURATION ....................................................................................... 43

3.4 - MANUAL MODE PARAMETERS........................................................................................ 44

4-EDITION OF ASEQUENCE......................................................................................................... 45

4.1 - HOMING SEQUENCE......................................................................................................... 46

4.2 - POSITIONING SEQUENCE................................................................................................ 47

4.3 - SPEED SEQUENCE ............................................................................................................47

4.4 - TORQUE SEQUENCE......................................................................................................... 48

4.5 - SEQUENCES CHAINNING.................................................................................................. 49

4.6 - PROGRAMMABLES OUTPUTS .......................................................................................... 50

4.7 - PROGRAMMABLE INPUTS................................................................................................. 51

5-PROGRAMME EXECUTION........................................................................................................ 51

6-SPEED AND TORQUE LIMITATION............................................................................................ 51

CHAPTER 8 - TROUBLESHOOTING.................................................................................................. 52

1-SYSTEM FAULT...........................................................................................................................52

2-STORED FAULTS........................................................................................................................ 52

2.1 - "BUSY" fault......................................................................................................................... 52

2.2 - "EEPROM" fault.................................................................................................................... 52

2.3 - "°C MOTOR" fault................................................................................................................. 53

2.4 - "UNDERVOLT." fault ............................................................................................................ 53

2.5 - "°C AMPLIFIER" fault ........................................................................................................... 53

2.6 - "POWER STAGE" fault......................................................................................................... 53

2.7 - "HES" fault ............................................................................................................................ 53

2.8 - "ENCODER" fault ................................................................................................................. 54

2.9 - "COUNTING" fault ................................................................................................................ 54

2.10 - "I2t" fault .............................................................................................................................. 56

2.11 - "POSITION" fault ................................................................................................................ 56

2.12 - "ADC" fault.......................................................................................................................... 56

3-OPERATING PROBLEMS ........................................................................................................... 56

3.1 - Motor supplied but no torque................................................................................................ 56

3.2 - Motor does not move............................................................................................................ 56

3.3 - Shaft locked, eratic oscillations or rotation at maximum speed ........................................... 56

3.4 - Discontinuous motor rotation with zero torque positions..................................................... 56

3.5 - Loud crackling noise in the motor at standstill...................................................................... 56

3.6 - Loud noise in the motor at standstill and when running....................................................... 56

4-SERVICE AND MAINTENANCE .................................................................................................. 57

5

SMT-BD2/m

Content

s

CHAPTER 9 - APPENDIX .................................................................................................................... 58

1-USE OF THE LIMIT SWITCHES &"CVO" INPUTS..................................................................... 58

2-USE OF THE "AMP. READY" &"POWER READY" OUTPUTS................................................... 58

3-FOLLOWING ERROR PROTECTION ......................................................................................... 58

4-I²TPROTECTION......................................................................................................................... 59

4.1 - Current limitation in Fusing mode.........................................................................................59

4.2 - Current limitation in Limiting mode.......................................................................................60

5-SERVO CONTROLLER STRUCTURE........................................................................................ 61

6-ASCII INSTRUCTIONS LIST........................................................................................................ 62

6.1 - OVERVIEW .......................................................................................................................... 62

6.2 - INSTRUCTIONS LIST.......................................................................................................... 63

7-USING ADISPLAY TERMINAL.................................................................................................... 67

7.1 - CONFIGURATION ............................................................................................................... 67

7.2 - USE ...................................................................................................................................... 67

8-AMPLIFIER TYPES...................................................................................................................... 69

6

SMT-BD2/m

___________________________________BLANK PAGE_______________________________

___________________________________BLANK PAGE_______________________________

7

CHAPTER 1 – General description

SMT-BD2/m

CHAPTER 1 - GENERAL DESCRIPTION

1 - INTRODUCTION

Series SMT-BD2/m digital servo modules are sinusoidal PWM power amplifiers that provide position, speed and

torque/force control for AC brushless motors (rotating or linear) equipped with encoder only or encoder with Hall

Effect Sensors (HES) for the position feedback.

The SMT-BD2/m digital servo drive is 220 VAC or 400 VAC main operated. The SMT-BD2/m plug-in system with

400 VAC power supply is available as a multiaxis version that can receive up to three axes in a standard 19" rack

including the power supply. The SMT-BD2/m plug-in system with 220 VAC power supply is available as a single-

axis block version or as a multiaxis version that can receive up to six axes in a standard 19" rack including the

power supply.

2 - GENERAL DESCRIPTION

Series SMT-BD2/m amplifiers have their own DC/DC converter to provide the appropriate supply voltage (+5 V,

+15 V, -15V). The source supply voltage for the logic board is the auxiliary 310 VDC supply voltage. The auxiliary

supply voltage allows to have the axis position value still available when the power supply voltage is turned off.

Each module is packaged as a 6 U "double Eurocard":

- one power board with IGBT transistors

- one logic board with DSP (Digital Signal Processing).

The SMT-BD2/m amplifier directly controls the motor torque/force, speed and position by means of the

information provided by an encoder feedback device. The sinusoidal current commutation based on encoder

feedback provides smooth motor torque/force control.

The SMT-BD2/m amplifier can be configurated for various encoder feedback types. The appropriate encoder

input configuration is selectable by jumpers.

♦ With an incremental encoder only, a motor phasing procedure must be executed at each amplifier power up

before the motor enabling.

♦ With an incremental encoder + HES feedback from the motor, the motor phasing procedure is no more

necessary and the servo motor can immediately be enabled after the amplifier power up.

♦ With an absolute single turn SinCos encoder feedback from the motor (Heidenhain ERN 1085 or compatible),

the servo motor can also immediately be enabled after the amplifier power up.

The SMT-BD2/m amplifiers are suited for axis positioning applications. Up to 128 control sequences including

axis homing, absolute or relative displacement, speed profile running and torque regulation can be programmed

and combined in order to solve various applications. The sequence chaining capability allows to define macro-

sequences for complex applications: several control sequences can be linked together in order to be automatically

executed one after the other. The control sequences are pre-programmed. So, the application programmation

simply consists in initializing the sequences parameters with the desired values. A control sequence can then be

selected by using the programmable logic inputs activation and its execution is started by using the START logic

input. The SMT-BD2/m amplifiers can operate in stand alone or in connection with a host controller (PC or PLC).

The motor position output is available as two A and B encoder type channels in quadrature, and one Z marker

pulse per revolution via RS422 line drivers. The ratio between the number of pulses on the motor encoder and the

number of pulses on the SMT-BD2/m amplifier encoder output is programmable.

The amplifier faults are displayed on the front panel and can also be read via the serial link.

All control parameters are programmable by means of the serial link and saved in an EEPROM. The auto-

configuration and auto-tuning functions allow an easy and quick commissioning of the amplifier.

The Visual Drive Setup software, which is IBM-PC compatible with the WINDOWS® operating system, makes

the amplifier commissioning and the application programmation easier. The Visual Drive Setup software also

includes a digitizing oscilloscope function that is particularly useful for the drive commissioning and maintenance.

8 CHAPTER 1 – General description

SMT-BD2/m

3 - REFERENCE TO THE STANDARDS

The 220 VAC version of the SMT-BD2/m amplifiers operating in the BF rack, which is equipped with the mains

filter BF-35 or 70, has been approved for its conformity with the Electromagnetic Compatibility standards:

• EN 55011, Group 1, Class A regarding the conducted and radiated radioelectric disturbances,

• CEI 801 - 2 - 3 - 4 regarding the immunity.

The 400 VAC version of the SMT-BD2/m amplifiers operating in the BF-400 rack, which is equipped with the

mains filter F400-35 or 70, has been approved for its conformity with the Electromagnetic Compatibility standards:

• EN 55011, Group 1, Class A regarding the conducted and radiated radioelectric disturbances,

• CEI 801 - 2 - 3 - 4 regarding the immunity.

Standard to be applied to the electrical equipments of industrial machines: EN 60204.1.

The SMT-BD2/m amplifiers have been "CE" marked since year 2002.

4 - REFERENCE TO OTHER DOCUMENTS

♦BF-400 rack – for the use of the 400 VAC amplifier version in a multiaxis rack.

♦BF rack – for the use of the 220VAC amplifier version in a multiaxis rack.

♦BM20A/BMM05F/05AF single-axis rack – for the use of the 220 VAC amplifier version in a single-axis rack.

9

CHAPTER 2 – Specifications

SMT-BD2/m

CHAPTER 2 - SPECIFICATIONS

1 - TECHNICAL SPECIFICATIONS

1.1 -CURRENT RATINGS FOR THE 220 VAC AMPLIFIER VERSION

Operating voltage DC bus 310 VDC (270 VDC < DC bus < 340 VDC max.)

Auxiliary supply voltage 310 VDC ( 200 VDC < Uaux < 340 VDC max.)

Motor terminal to terminal output voltage 200 Vrms for 310 VDC bus

Authorized output currents for current pulse mode operation (I2t protection in fusing mode)

AMPLIFIER

U rated

Imax (A rms)

Max. authorized rated current (Arms)

of the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

1*

FAN TYPE

2*

SMT-BD2/m - 220/04 240 4,4 2

SMT-BD2/m - 220/08 240 8,8 4

SMT-BD2/m - 220/12 240 13,8 6

SMT-BD2/m - 220/17 240 17,7 8,5

SMT-BD2/m - 220/30 240 30,8 10 12 15

SMT-BD2/m - 220/30r 240 30,8 10 15

SMT-BD2/m - 220/45 240 48,6 10 15 20

SMT-BD2/m - 220/45r 240 48,6 10 20 23

SMT-BD2/m - 220/60 240 61 10 19 25

SMT-BD2/m - 220/60r 240 61 12 26 30

SMT-BD2/m - 220/70 240 70 25 30 35

SMT-BD2/m - 220/100 240 100 25 30 35

Authorized output currents for continuous current mode operation (I2t protection in limiting mode)

AMPLIFIER TYPE

U rated

Imax (A rms)

Max. authorized continuous current (Arms) of

the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

1*

FAN TYPE

2*

SMT-BD2/m - 220/04 240 4,4 2

SMT-BD2/m - 220/08 240 8,8 4

SMT-BD2/m - 220/12 240 13,8 6

SMT-BD2/m - 220/17 240 17,7 8,5 8,5

SMT-BD2/m - 220/30 240 30,8 8,5 12 15

SMT-BD2/m - 220/30r 240 30,8 10 15

SMT-BD2/m - 220/45 240 48,6 8,5 15 18

SMT-BD2/m - 220/45r 240 48,6 10 20 23

SMT-BD2/m - 220/60 240 61 8,5 17 20

SMT-BD2/m - 220/60r 240 61 12 26 30

SMT-BD2/m - 220/70 240 70 17 30 35

SMT-BD2/m - 220/100 240 100 25 30 35

* Maximum ambient temperature = + 40° C, fan 1 = 56 l/s, fan 2 = 90 l/s.

Note: The SMT-BD2/m-X/Xr amplifier types are equipped with an additional heatsink in order to improve the heat

dissipation and increase their rated current. The width of these amplifier types is then 18 TE instead of 12 TE.

Minimum inductance between phases 1 mH

10 CHAPTER 2 – Specifications

SMT-BD2/m

Conformity with the standards: CE approval - EMC standards

with multiaxis power supply configuration Immunity: CEI standards 801- 2 - 3 - 4

BF rack and mains filter BF-35 or 70, Conducted and radiated disturbances: EN 55011,

or SMTB.M 20 A single-axis rack and BF 35 filter. Group 1, class A

"360°" shields; equipotential according to the - Electrical standards for industrial machines:

wiring rules. EN 60204.1: - Insulator: 1500 VAC/1 min.

- Leakage current > 3 mA

(EMI filters)

Temperature range * storage - 20°C to + 70°C

* operation 5°C to +40°C

From 40°C on, the rated currents

must be reduced of 3 %/°C.

Max. temperature: 50°C

1.2 -CURRENT RATINGS FOR THE 400 VAC AMPLIFIER VERSION

Operating voltage DC bus 565 VDC (480 VDC < DC bus < 685 VDC

max.)

Auxiliary supply voltage 310 VDC (200 VDC < Uaux < 340 VDC max.)

Motor terminal to terminal output voltage 380Vrms for 565 VDC bus

Authorized output currents for current pulse mode operation (I2t protection in fusing mode)

AMPLIFIER

U rated

Imax (A rms)

Max. authorized rated current

(Arms) of the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

2*

SMT-BD2/m - 400/15 400 15.5 5 7.5

SMT-BD2/m - 400/30 400 30 8 15

SMT-BD2/m - 400/45 400 48 10 19

SMT-BD2/m - 400/60 400 60 not used 28

SMT-BD2/m - 400/100 400 100 not used 35

Authorized output currents for continuous current mode operation (I2t protection in limiting mode)

AMPLIFIER TYPE

U rated

Imax (A rms)

Max. authorized continuous

current (Arms) of the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

2*

SMT-BD2/m - 400/15 400 15.5 not used 5

SMT-BD2/m - 400/30 400 30 not used 10

SMT-BD2/m - 400/45 400 48 not used 15

SMT-BD2/m - 400/60 400 60 not used 23

SMT-BD2/m - 400/100 400 100 not used 28

* Maximum ambient temperature = + 40° C, fan 2 = 90 l/s.

Minimum inductance between phases 2 mH

Conformity with the standards: CE approval - EMC standards

with multiaxis power supply configuration Immunity: CEI standards 801- 2 - 3 - 4

BF-400 rack and mains filter F400-35 or 70. Conducted and radiated disturbances: EN 55011,

"360°" shields; equipotential according to the Group 1, class A

wiring rules. - Electrical standards for industrial machines:

EN 60204.1: - Insulator: 2500 VDC/1 min.

- Leakage current > 3 mA

(EMI filters without capacitors)

Temperature range * storage - 20°C to + 70°C

* operation 5°C to +40°C

From 40°C on, the rated currents

must be reduced of 3 %/°C.

Max. temperature: 50°C

11

CHAPTER 2 - Specifications

SMT-BD2/m

1.3 -OTHER SPECIFICATIONS

PWM switching frequency 10 kHz

Current regulator (PI) Adjusted to motor

Current loop bandwidth Cut-off frequency for 45° phase shift > 1 kHz

Internal current limitation Maximum current range : 20 % to 100 % of Imax

Rated current range : 20 % to 50 % of Imax

Imax = amplifier current rating

Analog torque limitation input 0 V to 10 V, resolution = 12 bits

100 % to 0 % of the torque set point value

No limitation for 0 Volt

Analog speed limitation input ±10 V, standard resolution = 12 bits

100 % to 0.1 % of the maximum speed value

Speed and position regulator Sampling period = 0,5 ms

Anti-wind-upsystem of the integrator

Adjustable digital gains

Antiresonance filter

Servo loop bandwidth Cut-off frequency for 45° phase shift

Selectable : 50 Hz, 75 Hz or 100 Hz

(see Note 1)

Max. motor speed Adjustable from 100 rpm to 25000 rpm

(see Note 2)

Encoder input Selectable by jumpers :

Quadrature and TTL A & B signals with Z marker

pulse

RS 422 line receiver

maximum pulses frequency: 500 kHz

Resolution:10

3to 106ppr

Incremental Sin/Cos encoder

Heidenhain 1Vcc Sin/Cos type or compatible

maximum signal frequency: 500 kHz

Resolution: 500 to 106ppr

Interpolation factor : 1024

Absolute single turn Sin/Cos encoder

Heidenhain ERN 1085 or compatible

maximum signal frequency: 200 kHz

resolution: 2048 ppr or 512 ppr

Interpolation factor : 1024

Note 1:

The maximum servo loop bandwidth value not only depends on the amplifier specification but also on the encoder resolution

and the mechanical motor load. The lower the encoder resolution, the lower the servo loop gains and the servo loop bandwidth,

to avoid any motor noise due to signal quantization effect. However when the “pulse interpolation” mode is activated with a

Sin/Cos encoder type, the servo loop bandwidth can be dramatically increased because the internal position resolution is equal

to the encoder resolution value multiplied by the interpolation factor (1024). The mechanical load backlashes and elasticity can

also limit the servo loop gains and bandwidth to avoid mechanical resonances. The optimal servo loop gain value for a given

application can be automatically calculated by using the amplifier Auto-tuning procedure.

Note 2:

The Max. motor speed value not only depends on the motor specification but also on the encoder specification. Both following

conditions must be answered for taking into account the maximum encoder pulse frequency value :

Max. motor speed (rpm) < 60 x 106 / Number of encoder pulses per revolution

Max. motor speed (rpm) < 60 x Encoder pulse frequency limit (Hz) / Number of encoder pulses per revolution

For example with the ROD426 (Heidenhain) series encoder, the pulse frequency limit value is 300 kHz. So, a motor equipped

with a ROD426 encoder having a resolution of 5000 ppr cannot exceed 3600 rpm.

12 CHAPTER 2 – Specifications

SMT-BD2/m

Hall sensors input Selectable by jumpers : 120° or 60° HES type

5 V or 15 V supply voltage

HES sequence error detection

Encoder output Quadrature and TTL A & B signals with Z marker

pulse

RS 422 line driver

Programmable encoder division ratio

output resolution / input resolution : 1, 1/2, 1/4, 1/8

Dedicated logic inputs Optoisolated, positive logic,

response time = 0.5 ms :

•Enable/Disable: ENABLE

•Servo On/Off: RUN

•Homingswitch:INDEX

•Limitswitch+:FC+

•Limitswitch-:FC-

•Sequence start: START

•Sequence stop: STOP

•Sequence wait: WAIT

•Sequence teach: TEACH

•Jog positive direction: JOG+

•Jog negative direction: JOG-

Amplifier fault reset: RESET

Programmable logic inputs Optoisolated, positive logic :

IN1toIN8

Dedicated logic outputs Relay contact Umax = 60 V,

Imax = 200 mA, Pmax = 10 W :

• "Power ready": closed if power OK

• "Amp ready": closed if amplifier OK

• "Phasing OK": closed if motor phasing OK

• "Brake": closed to desactivate the motor brake

Optoisolated:

•Sequence execution: SEQ

•Position reached: POS

•Speed reached: SPEED

•Motor enabled: OK

Programmable logic outputs Optoisolated :

OUT1 to OUT8

Monitor outputs 2 channels ANout1 & ANout2

+/-10 V full scale, 12 bit resolution

Programmable output signals on the

digitizing

oscilloscope Channel 1 and Channel 2 :

current ref (IDC), current mes (ID,IQ,IMES,I2t),

speed ref (CV), speed mes (GT)

Error display LEDs on front panel and diagnostic via serial link

Parameter setting Serial link RS232 in standard or RS422 optional

Automatic functions Motor parameters adjustment (Auto-phasing)

Regulator gains adjustment (Auto-tuning)

Altitude 1000 m

Moisture < 50 % at 40°C and < 90 % at 20°C

no condensation

(EN 60204.1 standard)

Cooling Natural convection or forced air, according to the

ratedcurrent(see current tables).

13

CHAPTER 2 – Specifications

SMT-BD2/m

2 - BLOCK DIAGRAM

The SMT-BD2/m servo module block diagram is presented below.

A

B

Z

A

B

Z

X1

X2

X6

X5

+5 V

+15 V

-15 V

U

V

W

PR

10

PR

8

310 V DC

X7

X4

Drive

protections

Encoder

input

Encoder

divider

Sequences

controller

Serial

link

Position Ref

Position

Supply

voltages

Position

Pulses

counter

Position

controller

Drive

parameters

Vector

control

Current Ref

Current

limitation

Current

loops

PWM

power stage

Current Mes

Motor phases

Power

supply

Aux. supply

OUTPUTS

INPUTS

SPEED LIMIT

TORQUE LIMIT

Current

Limit

The PR8 and PR10 connectors are not accessible for direct wiring; they are plugged on the BM20A single-axis

rack or on the multiaxis BF rack according to the SMT-BD2/m amplifier housing (see chapter 3).

14 CHAPTER 2 – Specifications

SMT-BD2/m

3 - MAIN PROTECTIONS

3.1 -DISPLAYED PROTECTIONS

PROTECTION ERROR DISPLAY LED*

Amplifier rated current overload I2t 5z

. blinking display = I2t warning threshold is reached (Idyn output) zz

. continuous display = I2t fault (amplifier inhibited in fusing mode)

Encoder cable interruption Encoder z5

zz

Encoder pulses counting error Counting 55

z5

Power stage failure: Power stage 55

. power supply overvoltage zz

. internal overcurrent protection

. short-circuit between phases

. amplifier overtemperature

(220/04 to 220/60 current ratings and 400 VAC amplifier range)

Amplifier overtemperature °C Amp 5z

(only 220/70 and 220/100 current rating amplifiers) 5z

Power supply undervoltage Undervolt. z5

5z

Motor overtemperature °C Motor 55

5z

Hall Effect Sensors or Sin/Cos commutation channels error HES zz

5z

Analog to Digital Conversion error ADC 5z

z5

Position following error Position zz

z5

Fault of the amplifier parameter or sequences storage EEPROM 5z

55

Amplifier automatic procedure: Busy 55

. blinking display = procedure operating 55

. continuous display = operating error

* z= LED is unlit 5= LED is lit.

All these faults are memory stored in the amplifier except for the "Undervolt." fault.

The reset of a stored fault can be made:

- by means of the RESET function in the Visual Drive Setup software

- via the fault RESET input (pin 13 of the X4 connector)

- by switching off the amplifier power supply.

15

CHAPTER 2 – Specifications

SMT-BD2/m

3.2 -FUSE PROTECTION

3.2.1 - Fuse protection for the 220 VAC amplifier version

F1 : Control of the average DC current of the power board supply (see Hardware adjustments in chapter 5).

F2 : Control of the average DC current of the logic board supply (see Hardware adjustments in chapter 5).

AMPLIFIER TYPE F1 F2

Power Logic

SMTBD2/m-220/04 to 12 10 AT 1 A

SMTBD2/m-220/17 and 30 15 AT 1 A

SMTBD2/m-220/45 20 AT 1 A

SMTBD2/m-220/60 20 AT 1 A

SMTBD2/m-220/70 - 1 A

SMTBD2/m-220/100 - 1 A

3.2.2 - Fuse protection for the 400 VAC amplifier version

F2 : Control of the average DC current of the logic board supply (see Hardware adjustments in chapter 5).

AMPLIFIER TYPE F2

Logic

SMT-BD2/m - 400/15 1 A

SMT-BD2/m - 400/30 1 A

SMT-BD2/m - 400/45 1 A

SMT-BD2/m - 400/60 1 A

SMT-BD2/m - 400/100 1 A

16 CHAPTER 3 – Inputs - Outputs

SMT-BD2/m

CHAPTER 3 - INPUTS - OUTPUTS

1 - CONNECTORS LOCATION

1.1 -RACK CONNECTORS

For the 400 VAC amplifier version, see BF-400 RACK manual.

For the 220 VAC amplifier version, see SMTB.M 20 A SINGLE-AXIS RACK manual or BF RACK manual.

1.2 -AMPLIFIER CONNECTORS

X1

X5

X2

X4

X6

X7

LED

B.P.

Faults display

Encoder sensor

Serial link

Command

Encoder output

Command

Analog inputs

Offset

Inputs

Outputs

2 - X5 SERIAL LINK CONNECTOR (Sub D 9 pins male)

PIN FUNCTION REMARKS

5 0 Volt GND (shield connection if no "360°" connection possible on the connector)

3 TXD Transmit data RS-232

2 RXD Receive data RS-232

6 TXH Transmit data RS-422

7 TXL Transmit data RS-422

8 RXL Receive data RS-422

9 RXH Receive data RS-422

17

CHAPTER 3 – Inputs - Outputs

SMT-BD2/m

3 - X1 ENCODER FEEDBACK CONNECTOR (Sub D 15 points female)

3.1 –X1 CONNECTOR FOR TTL INCREMENTAL ENCODER CONFIGURATION

The "TTL incremental encoder" configuration is selected according to the following COM and COD jumpers

setting (see chapter 5, section 1: Hardware adjustments).

The corresponding X1 connector pin function is described below.

PIN FUNCTION REMARKS

1 Marker Z/ Differential input of the encoder marker pulse Z/

9 Marker Z Differential input of the encoder marker pulse Z

2 Channel A/ Differential input of the encoder channel A/

10 Channel A Differential input of the encoder channel A

3 Channel B/ Differential input of the encoder channel B/

11 Channel B Differential input of the encoder channel B

5 +5V Encoder supply voltage (400 mA max. current)

4 GND Encoder supply GND

12 TC Motor thermal sensor input (10 mA max. load current)

13 GND Motor thermal sensor GND

6,7,8 reserved

14,15 reserved

Encoder input specification

Thermal sensor input specification

COM

COD

B2

B1

B5

B4

B3

X1-9,10,11

SMT-BD2/m

26LS32

X1-1,2,3

+5V

+5V

200R

200R

3.3K COD jumpers configuration

COD

B2

B1

ZM

ZM

Marker pulse enabled

Marker pulse disabled

ZM jumper configuration

X1-12

SMT-BD2/m

X1-13

+15V

+15V

100K

100nF

PSTH-A

MN OP

PTC thermal sensor

MN & OP jumpers configuration

MN OP NTC thermal sensor

PSTH-B

10K

+5V

A wrong jumper configuration may damage the

encoder and amplifier electronics.

!

Recommended driver:

26LS31

18 CHAPTER 3 – Inputs - Outputs

SMT-BD2/m

3.2 –X1 CONNECTOR FOR TTL INCREMENTAL ENCODER &HES CONFIGURATION

The “ TTL incremental encoder & HES” configuration is selected according to the following COM and COD

jumpers setting (see chapter 5, section 1: Hardware adjustments).

The corresponding X1 connector pin function is described below.

PIN FUNCTION REMARKS

1 Marker Z/ Differential input of the encoder marker pulse Z/

9 Marker Z Differential input of the encoder marker pulse Z

2 Channel A/ Differential input of the encoder channel A/

10 Channel A Differential input of the encoder channel A

3 Channel B/ Differential input of the encoder channel B/

11 Channel B Differential input of the encoder channel B

5 +5V Encoder supply voltage (400 mA max. current)

4 GND Encoder supply GND

14 HALL U Hall sensor input signal phase U

6 HALL V Hall sensor input signal phase V

7 HALL W Hall sensor input signal phase W

15 +15V Hall sensors supply voltage (50 mA max. current)

12 TC Motor thermal sensor input (10 mA max. load current)

13 GND Hall sensors/Thermal sensor GND

8 reserved

Encoder input specification

Specification of the Hall sensors input

60° type HES

COM

COD

B2

B1

B5

B4

B3 120° type HES

COM

COD

B2

B1

B5

B4

B3

X1-9,10,11

SMT-BD2/m

26LS32

X1-1,2,3

+5V

+5V

200R

200R

3.3K COD jumpers configuration

COD

B2

B1

ZM

ZM

Marker pulse enabled

Marker pulse disabled

ZM jumper configuration

X1-6,7,14

SMT-BD2/m

1K

X1-13

10K

1nF

+5V

74HC14

COM jumpers configuration

COM

COM

B5

B4

B3

60° HES

120° HES

B5

B4

B3

A wrong jumper configuration may damage the encoder and amplifier electronics.

!

Recommended driver:

26LS31

19

CHAPTER 3 – Inputs - Outputs

SMT-BD2/m

3.3 –X1 CONNECTOR FOR ABSOLUTE SINGLE TURN SIN/COS ENCODER CONFIGURATION

The “ Absolute single turn Sin/Cos encoder ” configuration (Heidenhain ERN 1085 or compatible) is selected

according to the following COM and COD jumpers setting (see chapter 5, section 1: Hardware adjustments).

The corresponding X1 connector pin function description is given below.

PIN FUNCTION REMARKS

1 Reference R/ Differential input of the Sin/Cos encoder reference pulse R/

9 Reference R Differential input of the Sin/Cos encoder reference pulse R

2 Channel A/ Differential input of the Sin/Cos encoder channel A/

10 Channel A Differential input of the Sin/Cos encoder channel A

3 Channel B/ Differential input of the Sin/Cos encoder channel B/

11 Channel B Differential input of the Sin/Cos encoder channel B

6 Channel C/ Differential input of the Sin/Cos encoder channel C/

14 Channel C Differential input of the Sin/Cos encoder channel C

8 Channel D/ Differential input of the Sin/Cos encoder channel D/

7 Channel D Differential input of the Sin/Cos encoder channel D

5 +5V Sin/Cos encoder supply voltage (400 mA max. current)

4 GND Sin/Cos encoder supply GND

12 TC Motor thermal sensor input (10 mA max. load current)

13 GND Motor thermal sensor GND

15 reserved

Specification of the Sin/Cos encoder channels

Specification of the Sin/Cos commutation channels

Remark: The Sin/cos encoder interpolation mode is activated by selecting the “pulse interpolation” configuration

during the amplifier parameter setting.

COM

B5

B4

B3

X1-14,7

SMT-BD2/m

X1-6,8

10K

1K 10K

50K

COM jumpers configuration

50K

X1-9,10,11

SMT-BD2/m

X1-1,2,3

10K

120R 10K

100K

COD jumpers configuration

COD

B2

B1

ZM

ZM

Marker pulse enabled

Marker pulse disabled

ZM jumper configuration

100K

COM

COD

B2

B1

B5

B4

B3

A wrong jumper configuration may damage the

encoder and amplifier electronics.

!

20 CHAPTER 3 – Inputs - Outputs

SMT-BD2/m

3.4 –X1 CONNECTOR FOR OTHER SIN/COS ENCODER CONFIGURATIONS

3.4.1) X1 connector for incremental Sin/Cos encoder configuration

The “ Incremental Sin/Cos encoder ” configuration (Heidenhain 1Vcc Sin/Cos encoder or compatible) is selected

according to the following COM and COD jumpers setting (see chapter 5, section 1: Hardware adjustments).

The corresponding X1 connector pin function description is given below.

PIN FUNCTION REMARKS

1 Reference R/ Differential input of the Sin/Cos encoder reference pulse R/

9 Reference R Differential input of the Sin/Cos encoder reference pulse R

2 Channel A/ Differential input of the Sin/Cos encoder channel A/

10 Channel A Differential input of the Sin/Cos encoder channel A

3 Channel B/ Differential input of the Sin/Cos encoder channel B/

11 Channel B Differential input of the Sin/Cos encoder channel B

5 +5V Sin/Cos encoder supply voltage (400 mA max. current)

4 GND Sin/Cos encoder supply GND

12 TC Motor thermal sensor input (10 mA max. load current)

13 GND Motor thermal sensor GND

6,7,8 reserved

14,15 reserved

The Sin/Cos channels specifications are given in section 3.3 of this chapter. The Sin/cos encoder interpolation

mode is activated by selecting the “pulse interpolation” configuration during the amplifier parameter setting.

3.4.2) X1 connector for incremental Sin/Cos encoder & HES configuration

The “ Incremental Sin/Cos encoder & HES” configuration (Heidenhain 1Vcc Sin/Cos encoder or compatible) is

selected according to the following COM and COD jumpers setting (see chapter 5, section 1: Hardware

adjustments).

The corresponding X1 connector pin function is described below.

PIN FUNCTION REMARKS

1 Reference R/ Differential input of the Sin/Cos encoder reference pulse R/

9 Reference R Differential input of the Sin/Cos encoder reference pulse R

2 Channel A/ Differential input of the Sin/Cos encoder channel A/

10 Channel A Differential input of the Sin/Cos encoder channel A

3 Channel B/ Differential input of the Sin/Cos encoder channel B/

11 Channel B Differential input of the Sin/Cos encoder channel B

5 +5V Sin/Cos encoder supply voltage (400 mA max. current)

4 GND Sin/Cos encoder supply GND

14 HALL U Hall sensor input signal phase U

6 HALL V Hall sensor input signal phase V

7 HALL W Hall sensor input signal phase W

15 +15V Hall sensors supply voltage (50 mA max. current)

12 TC Motor thermal sensor input (10 mA max. load current)

13 GND Motor thermal sensor GND

8 reserved

The Sin/Cos channels and Hall sensor inputs specifications are given in section 3.3 of this chapter. The Sin/cos

encoder interpolation mode is activated by selecting the “pulse interpolation” configuration during the amplifier

parameter setting.

COM

COD

B2

B1

B5

B4

B3

A wrong jumper configuration may damage the

encoder and amplifier electronics.

!

60° HES type

COM

COD

B2

B1

B5

B4

B3 120° HES type

COM

COD

B2

B1

B5

B4

B3

A wrong jumper configuration may damage the encoder and amplifier electronics.

!

Table of contents

Popular Valve Positioner manuals by other brands

Leuze electronic

Leuze electronic BPS 8 Original operating instructions

RTK

RTK SR-3300 Installation and operating instructions

Becker

Becker HPP-SB instruction manual

halstrup-walcher

halstrup-walcher PSD4 Series Assembly instruction and declaration

Parker

Parker 401XR Series product manual

Siemens

Siemens SIPART PS2 operating instructions

Seg

Seg SP760 Series instruction manual

Spirax Sarco

Spirax Sarco PP 5 Series Installation and maintenance instructions

halstrup-walcher

halstrup-walcher PS*3**C series instruction manual

Westlock

Westlock ICOT 5400 Technical manual

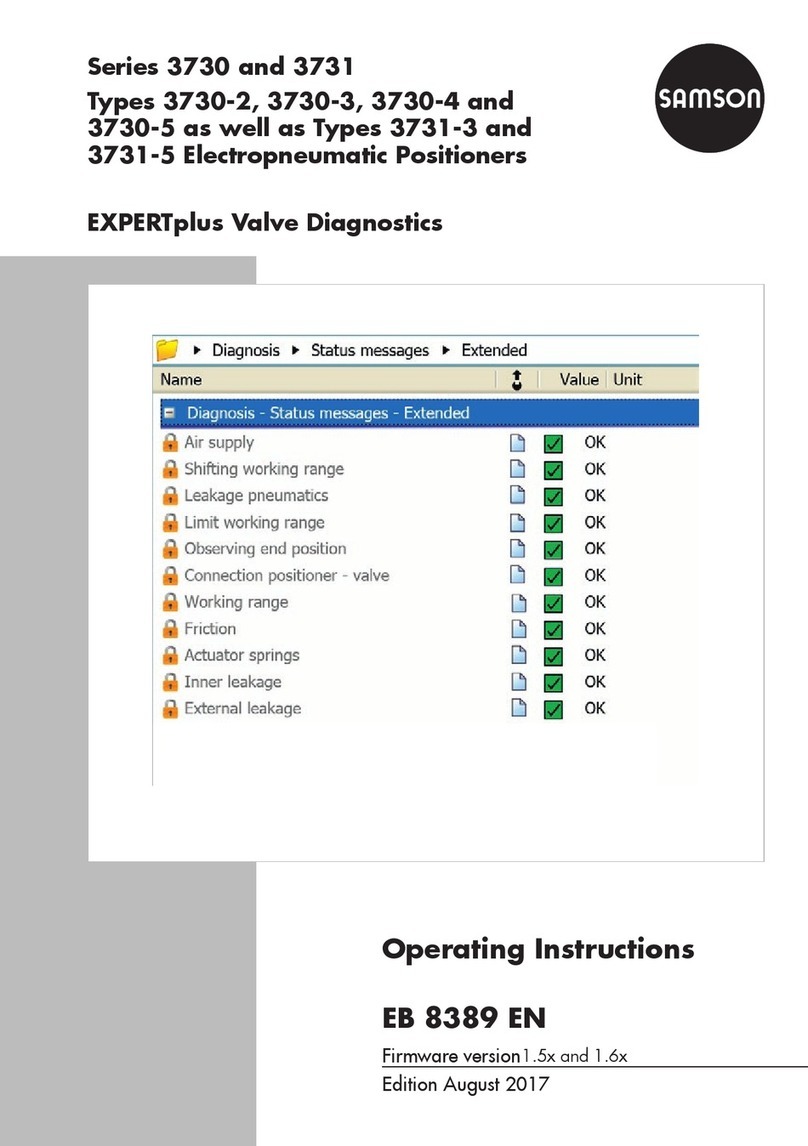

Samson

Samson TROVIS 3730-3 operating instructions

M-system

M-system MEXM instruction manual