1. Design and principle of oper-

ation

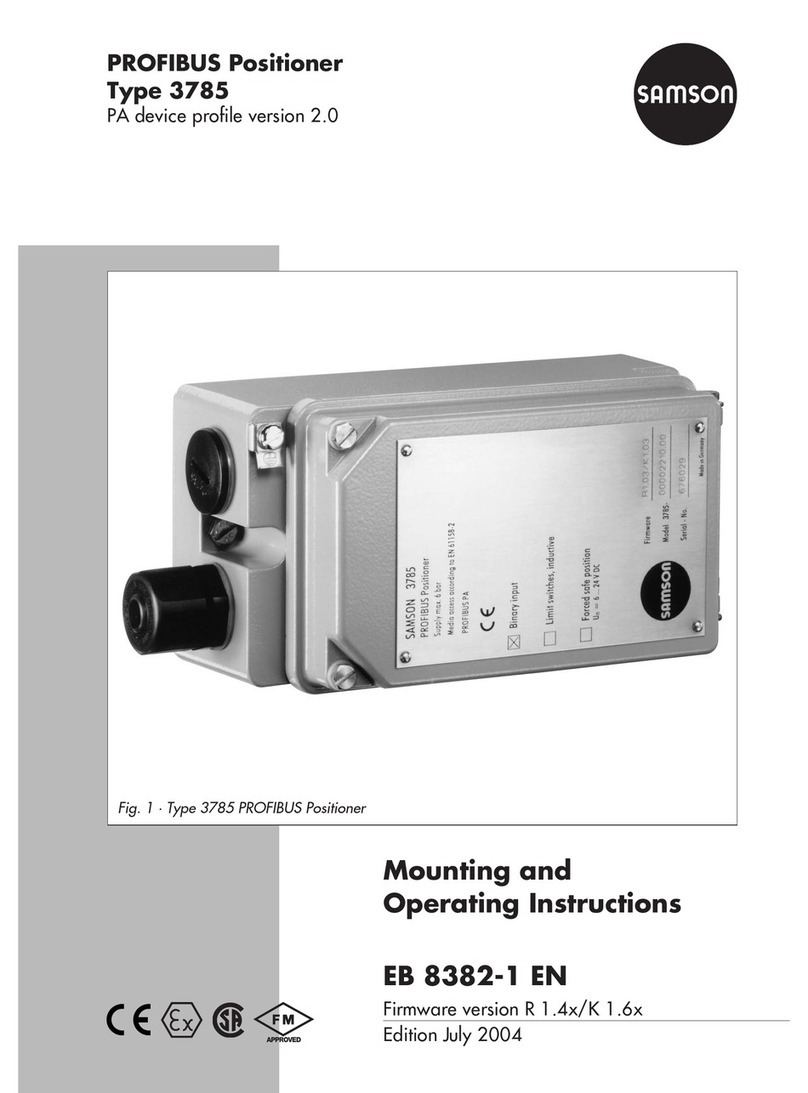

The digital PROFIBUS P positioner is at-

tached to pneumatic control valves. It as-

signs the valve position (controlled variable)

to the control signal (reference variable).

The positioner compares the digital control

signal transmitted from the control equip-

ment to the travel of the control valve and

issues a pneumatic signal pressure (output

variable). To do so, a supply air pressure of

1.4 to 6 bar is required. The electric power

is supplied by the bus connection of the

PROFIBUS P segment in accordance with

IEC 61158-2 regulations.

The positioner consists of an inductive, fric-

tionless displacement sensor system and an

electrically controlled valve block with two

on-off valves, as well as the electronics in-

cluding the two microcontrollers to edit the

control algorithm and manage PROFIBUS

communication.

When a system deviation occurs while com-

paring set point and actual value, the micro-

controller returns binary pulse-pause-modu-

lated signals which are used to control two

on-off valves with subsequent boosters. One

valve controls the exhaust air, the other the

supply air.

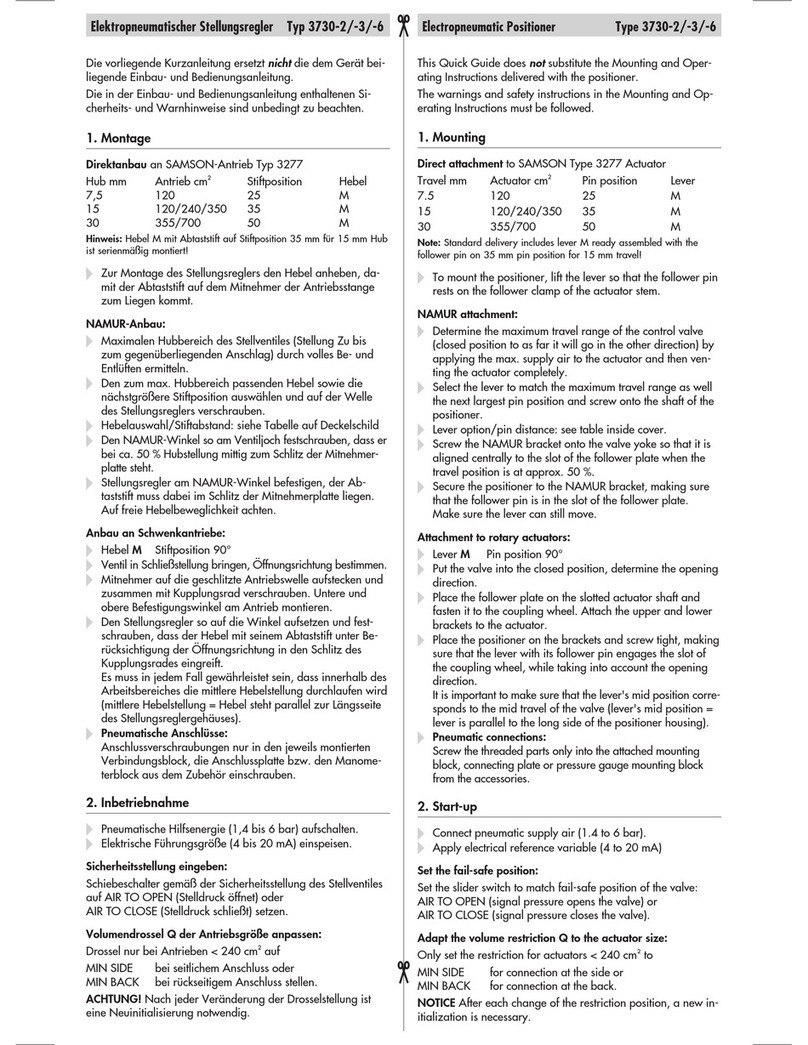

The supply air valve (3) connects the supply

air (7, supply air pressure 1.4 to 6 bar) and

the actuator (filling). The exhaust air

valve (4) connects the actuator and the at-

mosphere (venting). These on-off valves can

either have the switching states continuously

open or continuously closed, or they can

generate single pulses of variable width.

Controlling the two valves causes the actua-

tor of the control valve to move the plug

stem to a position corresponding to the ref-

erence variable. If there is no system devia-

tion, both the exhaust and supply air valves

are closed.

By default, the positioner is equipped with a

binary input for floating contacts, which

serves to signalize the switching state of an

additional field device via PROFIBUS.

The write protection switch in the hinged

cover (located near the bus address adjust-

ment) prevents that positioner settings are

overwritten via PROFIBUS communication

on activation.

Positioner with forced venting function:

The positioner is controlled by a 6 to 24 V

signal, causing the signal pressure to be ap-

plied to the actuator. When this voltage sig-

nal decreases, the signal pressure is shut off

and the actuator is vented. dditionally, the

control valve is moved to its fail-safe posi-

tion by the integrated springs.

ll positioners are equipped with the forced

venting function, which can be activated

and deactivated using a switch (also see sec-

tion 4.3).

1.1 Options

The standard positioner version can be sup-

plemented with limit switches. Two

proximity switches suitable for fail-safe cir-

cuits can be used to signalize the valves

final positions.

1.2 Communication

The positioner is completely controlled via

digital signal transmission according to

PROFIBUS P Profile Class B based on

DIN EN 50170 and DIN 19245 Part 4.

Data is transmitted as bit synchronous cur-

rent modulation with a transfer rate

10 EB 8382-2 EN

Design and principle of operation