Ingalls Engineering Co., Inc. 93048 User manual

© Ingalls Engineering Co., Inc. - 2011 Cherry Street, Suite 104 - Louisville, CO, 80027

(800) 641-9795 - (303) 665-7800 - Fax: (303) 665-7810 - www.IngallsEng.com

Installation Instructions for 93048

Ingalls Engineering Stiffy ™ Engine Torque Damper for 2000-08 Honda S2000

The Stiffy ™ Adjustable Engine Torque Damper is engineered to reduce deflection under hard acceleration and cornering for

improved performance and power to weight transfer. Deflection in the motor mounts, as with the chassis and suspension, is a

formidable enemy in power and weight transfer, robbing valuable horsepower and control. The innovative, built-in damper eliminates

the huge amounts of “torque shock” that result from wheel-hop and once installed; transfers more power to the road and improves

acceleration, shifting, and overall control and balance. The adjustable feature allows the assembly to be tuned and pre-loaded for

racing and street applications.

CAUTION: Observe proper safety and repair procedures for installation of all chassis parts. Some chassis parts require

specialized tools and experience and therefore MUST be installed by a qualified technician; otherwise and unsafe vehicle and/or

personal injury could result. Wear safety glasses and other protection.

WARNING: Before beginning, check for any damaged or loose suspension connections. Loose connections here indicate worn

or broken parts which MUST BE REPLACED. Failure to replace a damaged or worn spindle and/or link may cause the wheel to

separate from the vehicle, possibly resulting in serious personal injury. Installer MUST check for proper clearance. Modification(s)

may be required. Please proceed ONLY if the vehicle owner is completely aware of these potential suspension modifications.

Estimated Installation Time: One Hour Technical Rating: Easy

Included Parts List: Required Tools for Installation:

1 - Stiffy ™ Engine Torque Damper Metric Sockets

1 - Engine Bracket Metric Box Wrenches

1 - Chassis Bracket Crescent Wrench (up to 27mm)

1 - Cable Tie 3/8”Torque Wrench

1 - Hardware Kit 3/8” Socket Driver (Wrench)

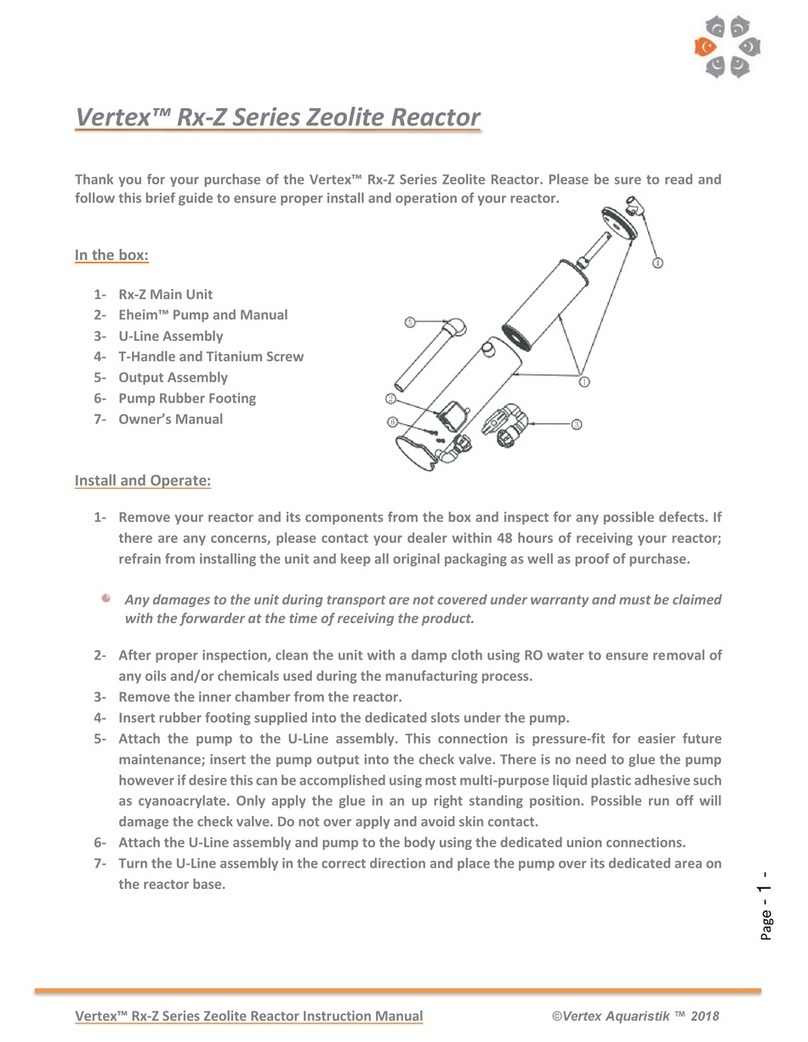

Step 1: Under the hood, locate the passenger’s side upper strut mount and remove the two M10 nuts (14mm HEX)

(Arrows “A”, Illustration 1) that secure the strut to the strut tower. Fit Chassis Mounting Bracket over the strut studs as

shown in Illustration 2, (ensure that the bent tab portion of the bracket is angling up). Secure Chassis Mounting

Bracket using the OEM M10 nuts.

Illustration 1 Illustration 2

© Ingalls Engineering Co., Inc. - 2011 Cherry Street, Suite 104 - Louisville, CO, 80027

(800) 641-9795 - (303) 665-7800 - Fax: (303) 665-7810 - www.IngallsEng.com

Step 2: On the front of the engine, locate the 10 mm bolt (Arrow “B”, Illustration 3) and remove. Next, locate the two

8 mm socket head cap screws (Arrows “C”, Illustration 3) and remove. Fit Engine Mounting Bracket onto the front of

the engine and secure using the provided M10 bolt, spacer and 8mm socket head cap screws (the spacer goes

between the bracket and engine with the 10 mm bolt). Tighten the 8mm bolts prior to fully tightening the 10mm bolt.

Illustration 3 Illustration 4

Step 3: The sensor on the front, passenger side of the motor (Arrow “E”, Illustration 5) will need to be moved to the

position shown (Arrow “G”, Illustration 6). Remove the 6mm bolt holding the sensor (Arrow “D”, Illustration 5) then

reinstall the bolt without the sensor in place. Move the sensor as shown using care not to damage any of the wiring

and retain with the OEM 6mm bolt (Arrow “F”, Illustration 6).

Illustration 5 Illustration 6

© Ingalls Engineering Co., Inc. - 2011 Cherry Street, Suite 104 - Louisville, CO, 80027

(800) 641-9795 - (303) 665-7800 - Fax: (303) 665-7810 - www.IngallsEng.com

Step 4: Install Stiffy™ onto the Chassis Mount Bracket and Engine Mount Bracket using the supplied hardware. Begin

with the Chassis bracket by placing the rod end underneath the bracket. The supplied 10 mm bolt should go down

through the bracket then rod end. The supplied rubber o-ring is placed between the Stiffy™ rod end and the bracket.

The Stiffy™ nuts (15mm HEX) are black in color. You may need to loosen the jam nut with an open-end wrench

(17mm) and adjustable wrench to increase the assembly length depending upon application. The supplied M10

(17mm HEX) bolt should go through the rod end and into the engine bracket, and the Stiffy ™ should mount forward

of the bracket. The supplied rubber o-ring is placed between the Stiffy™ rod end and the bracket. The Stiffy ™

adjustment dials should be facing toward the Chassis Mounting Bracket. Note: Refer to illustration 7 for proper

assembly of the mounting hardware. The nut and bolt can be swapped with the nut against the bracket or rod-end

depending upon application, but the washer and o-ring placement should not be changed.

Illustration 7

Notes:

Proper use and fitment of the rubber O-ring helps dampen additional road noise or “feel” that can be transferred through the damper

assembly. The O-ring should be used between the Stiffy ™ heim joint and bracket for optimal noise suppression. Dynamat or other

damping materials, as used in aftermarket audio and in-car electronics industries, can also be used to provide further noise and

vibration damping when used between the chassis bracket and the surface on which it mounts.

DO NOT attempt to adjust Stiffy ™ from its pre-set stiffness without consulting the Ingalls website. Large open-end wrenches are

required to adjust stiffness (27mm). Most standard and mechanics tool kits do not include these types of wrenches.

Limited Warranty

Subject to Disclaimer. All Ingalls Engineering Co., Inc. products are warranted against defects in materials and workmanship for ninety (90) days from date of

purchase. During the warranty period Ingalls will repair, or at its option replace, at no charge components that prove to be defective. The product must be returned,

shipping prepaid, to Ingalls facility. This limited warranty does not apply if the product is damaged by accident of misuse. The foregoing warranty is in lieu of all

other warranties expressed or implied; including but not limited to any implied warranty of merchantability, fitness, or adequacy for any other particular purpose or

use. Ingalls shall not be liable for any special, incidental, or consequential damages whether in contract, tort, or otherwise resulting from the use or the inability to

use the product. Warranty Disclaimer

Use of this product in competition, or use on vehicles altered from original manufacturer’s specifications or settings, EXPRESSLY VOIDS WARRANTY. The user is

urged to inspect for suspension binding or interference when the product is used in these manners. However, due to the varying conditions and manner of which

the product will be subjected to in such uses, Ingalls Engineering Co., Inc. makes no warranties, either express or implied, including any warranty of

merchantability or fitness for a particular purpose for use in competition or with specification or settings other than those specified by the original manufacturer’s

specifications.

This image shows how the Stiffy™ should look

after installation. The brackets should be

aligned so that the Stiffy™ is parallel to the front

of the valve cover. If need be, you can use

spacers or washers to ensure that the Stiffy™

will be properly aligned. Make sure however

that the rubber o-ring is against the heim joint

for noise su

pp

ression.

Table of contents

Popular Other manuals by other brands

Yongnuo

Yongnuo YN600EX-RT manual

Datalogic

Datalogic COBALT HF-CNTL-232-02 installation guide

resi-linx

resi-linx HD-4001 digi-mod User guide and installation manual

NEC

NEC Slot-In PC with Intel Celeron 2 x 1.6 GHz CPU STv2 (Sandy... installation instructions

Cress

Cress E1814 owner's manual

Thetford

Thetford C-200 CW D3 installation instructions

ATS

ATS Allison Transmission Pan kit installation manual

WELBA

WELBA WTS-200 Installation and operating instructions

Curt Manufacturing

Curt Manufacturing 11431 Installation instructions manual

Bazzaz

Bazzaz T143 installation instructions

Kodak

Kodak IM5 user guide

SMART DESIGN

SMART DESIGN C SANS SEUIL installation instructions