47109533_ed1 5

CAUTION

In the following step, take all precautions necessary to prevent

being burned by handling warm or hot parts.

14. Using an induction coil or oven, heat the Motor Housing (1)

until the motor opening is large enough to be placed over the

Cylinder. At that time, install the Housing over the Cylinder and

Front End Plate making sure the radial End Plate Alignment Pin in

the Rear End Plate enters the notch in the Motor Housing.

15. Allow the assembly to cool and install the Backcap Gasket (35)

and the assembled Backcap (23).

16. Secure the Backcap to the Housing by installing the three

Backcap Mounting Screws (36) and Lock Washers (37). Tighten

each Screw between 45 and 50 in–lb (5.1 and 5.6 Nm) torque.

17. Install the Exhaust Deector (22) in the bottom of the handle of

the Motor Housing and tighten it between 20 and 25 ft–lb (27

and 34 Nm) torque.

18. Thread the Inlet Bushing (2) into the bottom of the handle of the

Motor Housing (1) and tighten it between 30 and 35 ft–lb (40 and

47 Nm) torque.

19. Install theThrottle Rod Seal (9) in the groove on the large hub of

the Throttle Rod (8).

20. Install theThrottle Valve Seal (7) in the groove on the large hub of

the Throttle Valve (6).

21. Slide the Throttle Valve, Valve Seal end rst, onto the Throttle

Valve Rod.

22. Secure the ThrottleValve Assembly by installing the Valve

Retaining Ring (10) in the small groove on theThrottle Valve Rod.

23. Install the threeThrottle Bushing Seals (5) in the grooves on the

Throttle Bushing (4).

24. Slide the Throttle Bushing Assembly onto the shaft of theThrottle

Valve Rod and position the Trigger (11) on the same shaft. Install

the Trigger Pin (12).

25. Insert the assembled Trigger into the Housing. Make certain

the widest end of the Trigger is nearest the motor bore and

the narrowest portion of the Throttle Valve aligns with hole for

the Throttle Retaining Pin (13). Install the Pin making certain it

captures the Throttle Valve and secures the assembled Trigger.

26. Align the detent hole in the Reverse Valve (15) with the hole

inside the Reverse Valve Bushing (14) and slide the Valve into the

Bushing until almost reaching the detent hole. Insert the Reverse

Valve Detent Spring (16) and Reverse Valve Detent Ball (17) into

the hole and while compressing the Spring with the Ball, slide the

Valve completely into the Bushing.

27. Using snap ring pliers, install the Reverse Valve Retainer (18).

28. Slide the Reverse Lever (19) onto the Reverse Valve, making

certain the Reverse Lever Alignment Pin (21) enters the notch

on the face of the Reverse Valve Bushing. Secure the Lever to the

Valve by inserting the Reverse Lever Retaining Pin (20).

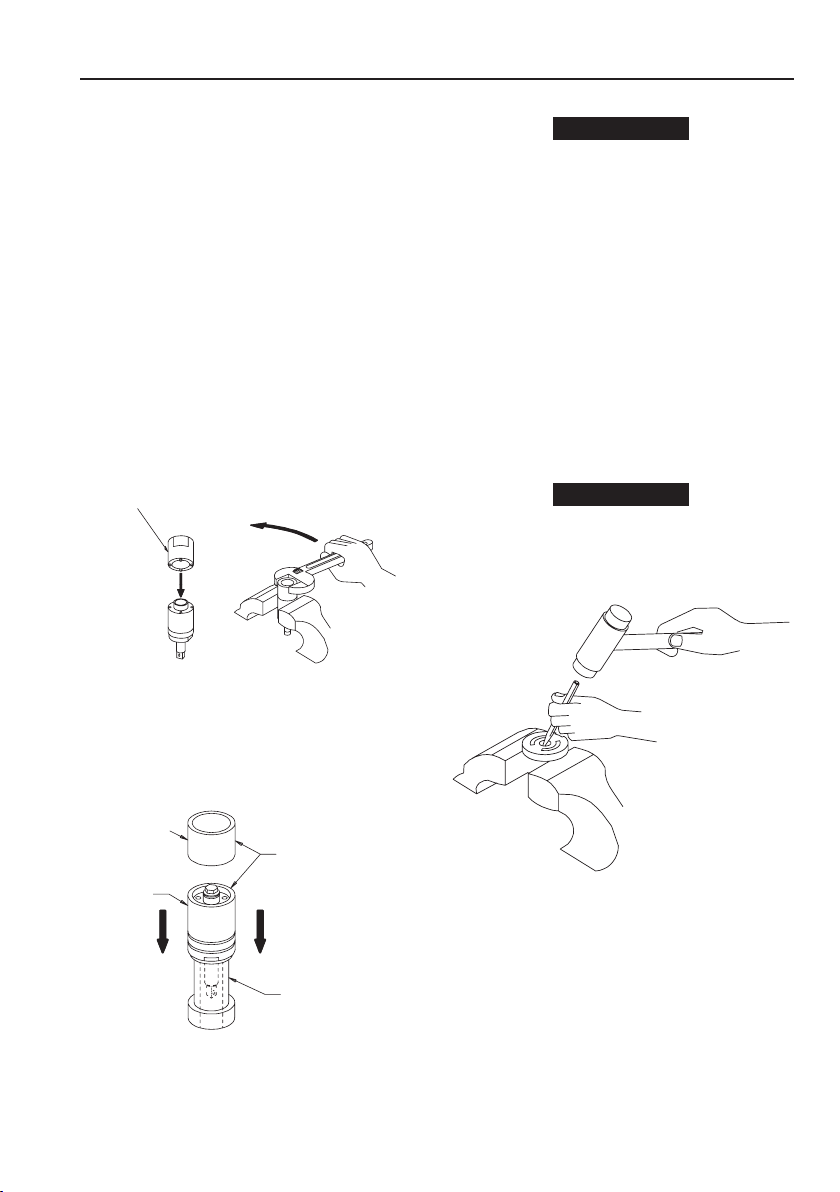

Assembly of the Impulse Mechanism

1. Insert the long shaft of the Piston Stop (58) into the central

opening of the O–ring Installer furnished with the Tool Kit (Part

No. 700A–99). Place the Piston Stop Seal (59) on the tapered end

of the Installer and roll the Seal up the taper and into the groove

on the large body of the Piston Stop. Install the Check Valve Front

Seal (61) and Check Valve Rear Seal (62) on the Check Valve (60).

2. When looking inside the central opening of the Liner Assembly

(55), the internal wall has three holes on one side which do not

extend through the wall. The opening on the end face of that wall

is for the Torque Valve Piston (57). Install theTorque Valve Piston,

large end trailing, into that opening.

3. Insert the Piston Spring (64) into hole in the end face of the

opposite wall. Insert the Check Valve Piston (63), large end

trailing, and the Check Valve Ball (65) into the same opening.

4. Thread the Threaded Tee Wrench furnished with the Tool Kit into

the end of the Check Valve Assembly and using the Wrench to

hold the Assembly, insert the Assembly into the opening against

the Ball.

5. Unscrew the Wrench and screw it into the Piston Stop Assembly

and using the Wrench to hold the Assembly, insert the Assembly

into the opening against the Piston. Mark this opening with a felt

marker to indicate that it contains the Torque Valve Piston.

6. Install the Sensor Seal Back–up O–ring (54) followed by the

Sensor Seal (53) on one end of the Sensor (62) and insert the

assembly, Seal end leading, into the central opening of the Rear

Liner Cover (50). Make certain the assembly slides freely in the

opening.

7. Install the Rear Liner Cover Seal (51) in the annular groove on the

face of the Rear Liner Cover.

8. Install the two Front Liner Cover Piston Seals (78) in the openings

on the face of the Front Liner Cover (71).

9. Install the Seal Back–Up Ring (77) followed by the Drive Shaft

O–ring (76) in the central opening in the face of the Front Liner

Cover.

10. Insert the short round hub of the Drive Shaft (66) into the central

opening of the Rear Liner Cover.

11. Insert a Blade (69) into one slot in the Drive Shaft. Install the Blade

Springs (70) through the Drive Shaft and into the holes in the

Blade. Place the remaining Blade on the Springs making certain

the Springs enter the holes in that Blade.

12. Using nger pressure, compress the Springs with the Blades

until the outer edges of the Blades are ush with the drive shaft

surface. Capture the Blades in this position by installing the

Liner Assembly, piston stop end trailing, over the Drive Shaft and

against the Rear Liner Cover.

NOTICE

This installation can be accomplished more easily by aligning the

compressed Blades with the webs at the narrowest portion of the

opening. Keeping the Blades on the web allows them to slide the

length of the Liner without interference.

13. Insert the hex end of the Rear Liner Cover into the Disassembly

Arbor from the Tool Kit and stand it on a workbench with the

Drive Shaft upward.

14. Install the Front Liner Cover Assembly over the Drive Shaft and

against the Liner. Make certain the Torque Adjustment Screw

(72) aligns with the proper piston stop opening that was marked

during assembly.

15. Install the two Liner Cover Seals (48) in the grooves inside the

Liner Housing (47) near the end with the external wrench ats.

16. Place the Liner Housing, Seal end trailing, over the assembled

Liner. Make certain the notch in the trailing end face of the

Housing aligns with the Oil Plug (73) in the Front Liner Cover.

Use the Pressing Sleeve from the Tool Kit to press the Housing

over the Seals and into position. Do not Damage the Seals during

installation.

17. Grasp the ats of the Liner Housing in vise jaws and using the

Spanner Plug furnished with the Tool Kit and a torque wrench,

install the Housing Cap, castellated end leading. This is a

left–hand thread; rotate the wrench counterclockwise to tighten

the Cap.Tighten the Cap on models 500PS3 and 700PS3 between

9.4 and 10.7 ft–lb (12.7 and 14.5 Nm) torque and on model

900PS4 between 10.7 and 12.1 ft–lb (12.7 and 16.4 Nm) torque.

18. Make certain the Drive Shaft rotates freely and then ll the

mechanism with uid and reassemble the tool as instructed in

the section, CHANGING THE MECHANISM FLUID.