5

47815111 A

Date: 05/23 SV205 Installation, Operating & Maintenance Manual

2General

2.1 Product general description

The SV205 is a light-weight, compact rotary vane compressor designed for the oil free

discharge of bulk liquids from general purpose tankers, e.g. liquid foodstuff, solvents, acids

alkalis, hot bitumen, resins and other chemicals.

The main advantage of using a compressor to discharge liquids is that the product does not

come into contact with machine. This eliminates any problems of material compatibility with

the liquid enabling a much wider variety of products to be discharged.

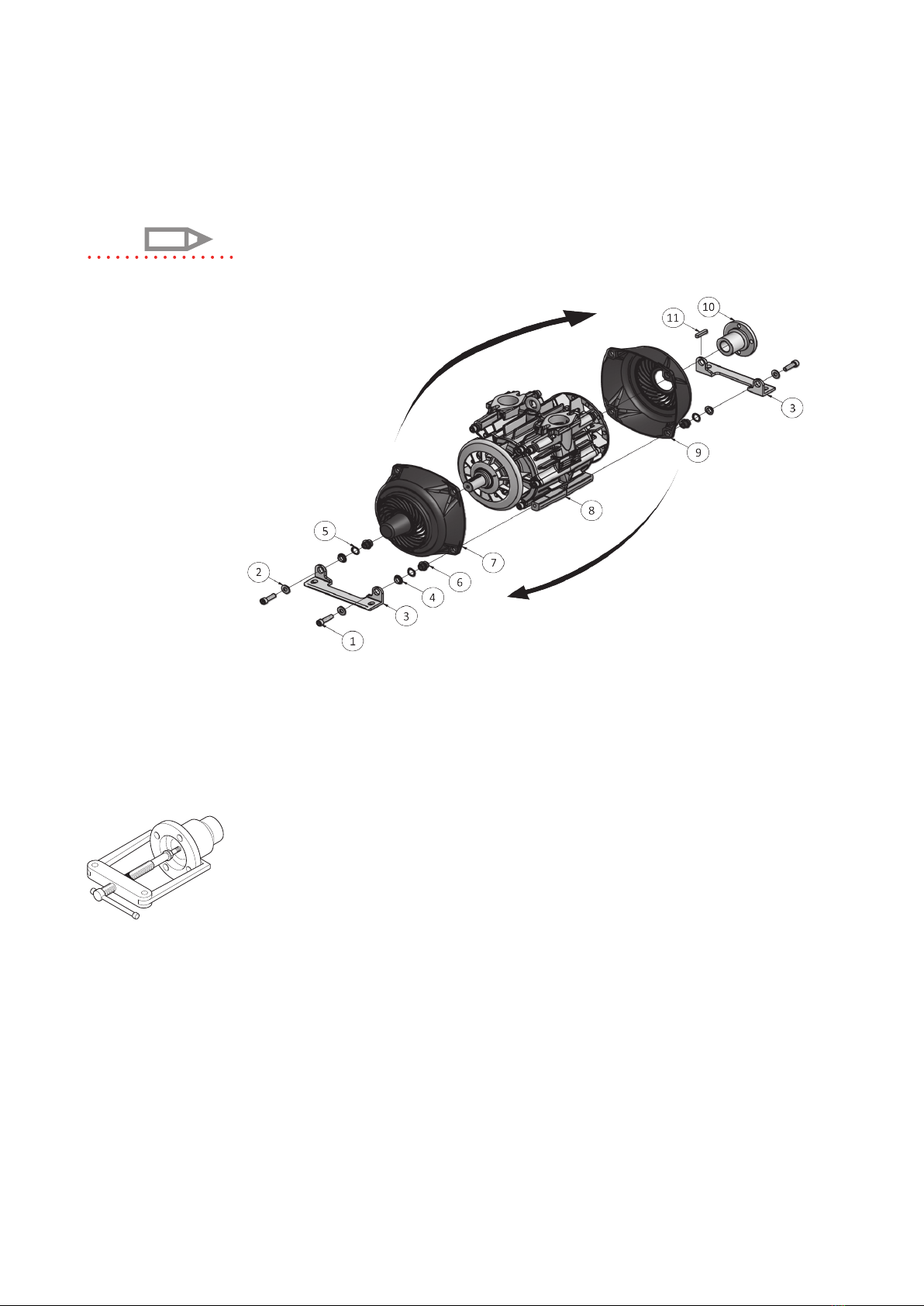

The machine is an oil free sliding vane design with the main stainless steel rotor being

supported by bearing arrangements at either end.

All the components in the main bore cavity are manufactured from corrosion resistant

materials to resist any possibility of atmospheric corrosion.

The very compact shape and size of the machine make it ideal for mounting inside the chassis

to enable direct low-cost prop. shaft driving or via other drive methods more suitable for

a particular application.

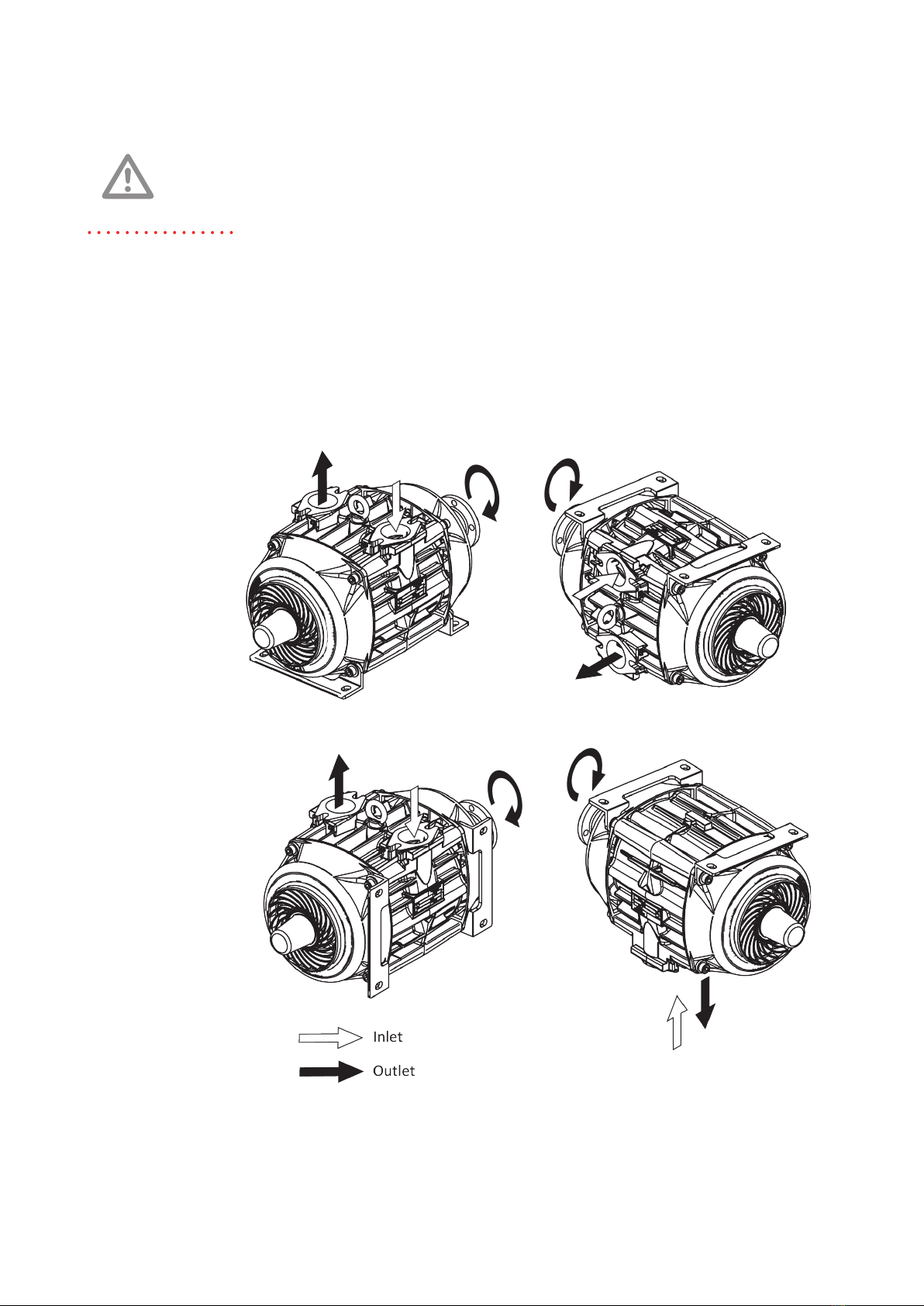

A through shaft allows CW or ACW input drive rotation and the compressor can be installed

on any face to provide the maximum mounting flexibility.

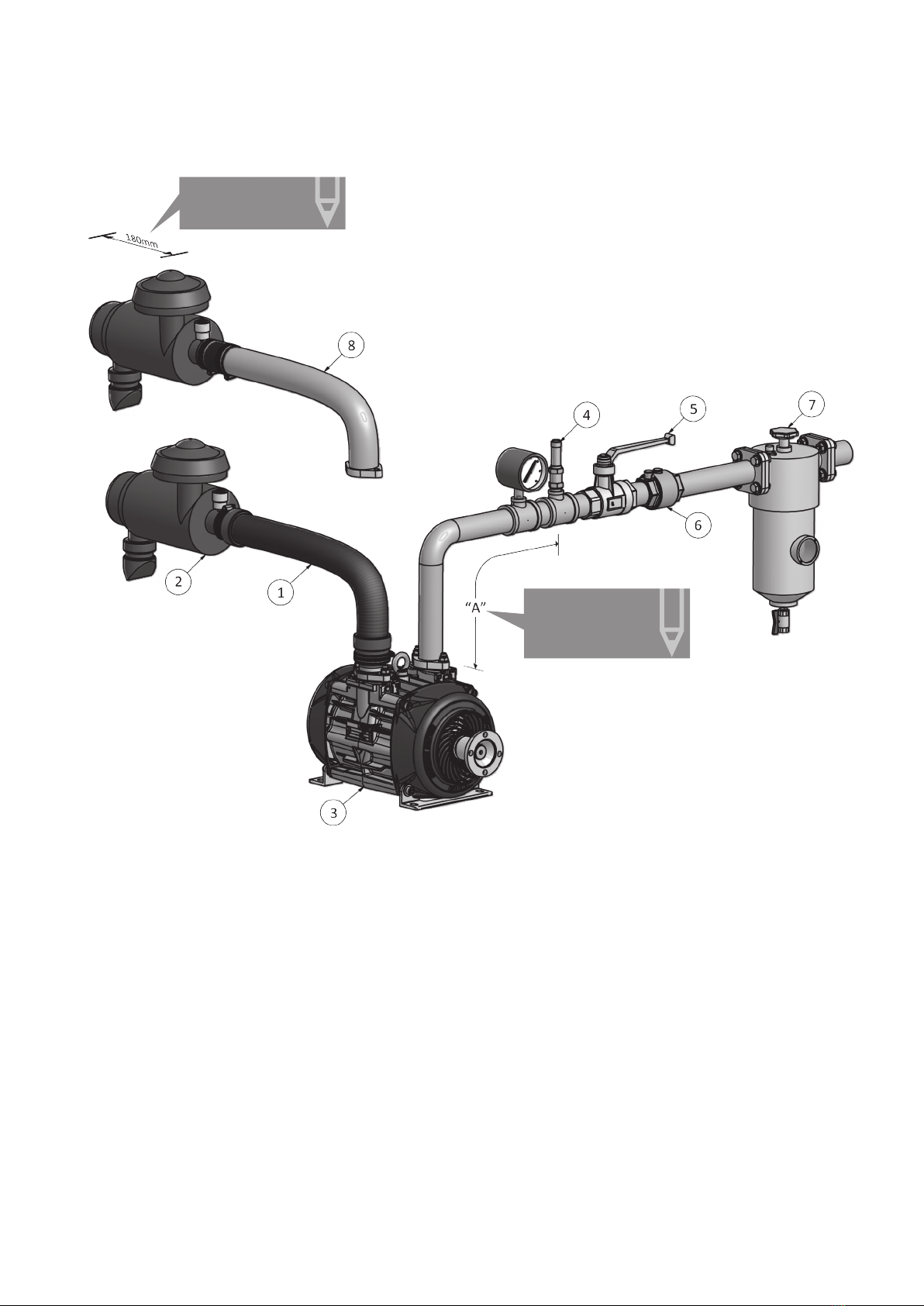

The standard package consists of:

SV205 cw basic machine

• Air Inlet Filter 5” Cyclonic

• Air Inlet Hose Kit

• Port Gaskets

• Non Return Valve - 1.5” BSP

2.2 Power Options

The SV205 can be driven using any of the following drive systems.

Prop. shaft Direct from a gearbox mounted PTO.

Hydraulically Several standard drives are available.

Electrically Motor drive packages on base frames/plates.

Engine Drive packages on base frames/plates.

2.3 Storage/Low use

Before the machine is installed or when it will not be used for long periods:

• Store the machine in a dry, heated building.

• Handle the machine with care and keep the suction and delivery ports covered.

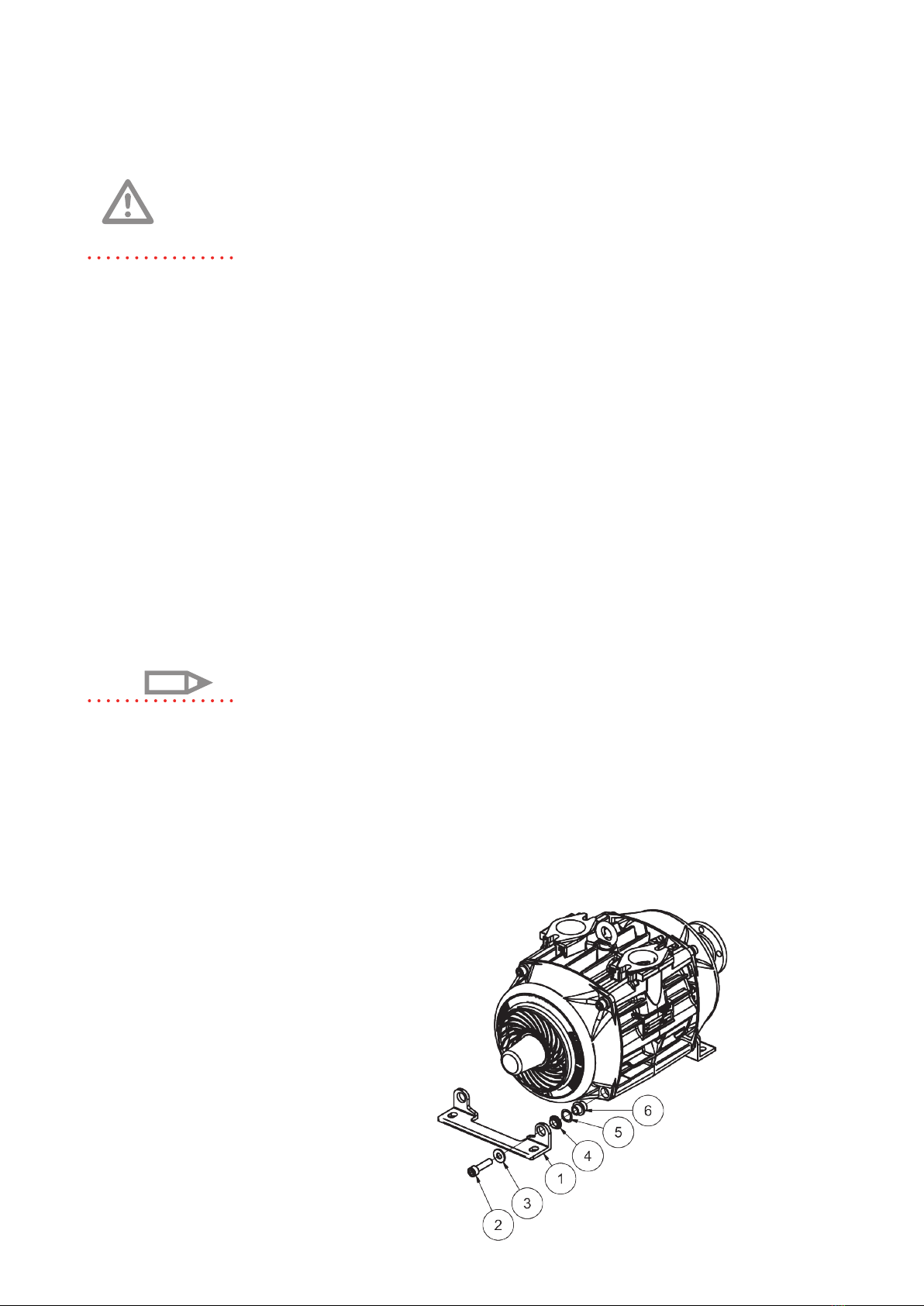

• Rotate the drive shaft of the machine each week, in the direction shown by the arrow

between the suction and delivery ports on the machine body. Where the compressor is

mounted on a vehicle and located outside, it should be operated for at least 15 minutes

Note

The shape and size of

the machine make it

particularly suitable

for PTO/prop.

shaft driving inside

the vehicle chassis.

Note

Do not allow dirt, oil

and grease to enter

the machine ports

as this could cause

severe damage.