Inkonova tilt User manual

TILT Assembly Manual

Code No.: MD03001-00-1107

1

TILT Assembly Manual

Code No.: MD03001-00-1107

2

Building the TILT drone

Process of building the TILT is common to all versions current versions: the parts may differ (it will be specified when 3DP and PRO

versions use different components) but assembly remains the same. Please follow the steps given below. You might find extra screws in

most steps than the ones strictly necessary OR very similar lengths than the ones stated in this manual but that should still be suitable.

NOTE: Please refer the Getting Started document for the detailed description of the part names and their functions.

Step 1

Insert the polymer

bearings on each arm

support part (4 pieces,

two left-hand and two

right-hand) and insert it

until it gets flushed on

the other side. Use a 9

or 10 mm drill bit or

similar to insert it as it

goes press fit.

PARTS

4x polymer bearings (large)

2x arms support RIGHT

2x arms support LEFT

HARDWARE

None

TILT Assembly Manual

Code No.: MD03001-00-1107

3

Step 2

Install both tensors, one

on a right-hand arm

support and the other

in a left-hand one. Do

not tighten them yet.

NOTE: you’ll find a

regular washer for M3

to use instead of the red

aluminium parts in the

picture

PARTS

Same as step 1

2x polymer bearings (small

ones)

HARDWARE

2x screw M3x30

2x lock nut M3

4x washer for M3

2x split washer for M3

2x 10mm Nylon cylinder

TILT Assembly Manual

Code No.: MD03001-00-1107

4

Step 3

Mount all four arm

supports with the

tensors on the base

plate. On each arm

support, use only the

inner screws now.

NOTE: pay attention to

the position of the

tensors. The base plate

has in its design a couple

of ‘arrows’ marking the

forward direction (in

picture top is front). In

that orientation the

tensors must both be on

the left.

PARTS

Same as step 2

1x base plate

4x 20 mm aluminum standoffs

HARDWARE

4x screw M3x20 (PRO version)

4x screw M3x25 (3DP version)

TILT Assembly Manual

Code No.: MD03001-00-1107

5

Step 4

Install the shafts with

the pulley in both front

and rear arms supports.

Do not tighten the

pulley set screws yet,

keep the pulleys

completely loose.

PARTS

Same as step 3

2x 8mm diametre shaft

2x pulley with 8mm bore *

HARDWARE

4x set screw M3 (long)

TILT Assembly Manual

Code No.: MD03001-00-1107

6

Step 5

Place the arm

connectors in the

shafts and tighten well

the screws.

PARTS

Same as step 4

4x arm connector

HARDWARE

4x screw M3x16

4x lock nut M3

TILT Assembly Manual

Code No.: MD03001-00-1107

7

Step 6

Mount the each motor

in a motor mount with

the M3x6 screws (4 on

each motor) and

thread lock

(medium/blue). Then

add the motor mount

clamps (the bottom

part of the motor

mount assembly) and

the carbon fiber tubes

inserting them until

the end of the mounts.

Do not tighten the

M3x20 screws yet,

keep them tight but

allowing the tube to

rotate

PARTS

4x motor mount

4x motor mount clamp

4x brushless motor

4x carbon fiber tube

HARDWARE

16x screw M3x6

8x screw M3x20 *

8x lock nut M3

* the mounts and tube have

extra bores that can be used

for positioning and even

keep them installed

TILT Assembly Manual

Code No.: MD03001-00-1107

8

Step 7

Mount the arms in

the arm connectors

and tighten the

screws.

PARTS

Same as steps 5 and 6

HARDWARE

4x screw M3x25

4x lock nut M3

TILT Assembly Manual

Code No.: MD03001-00-1107

9

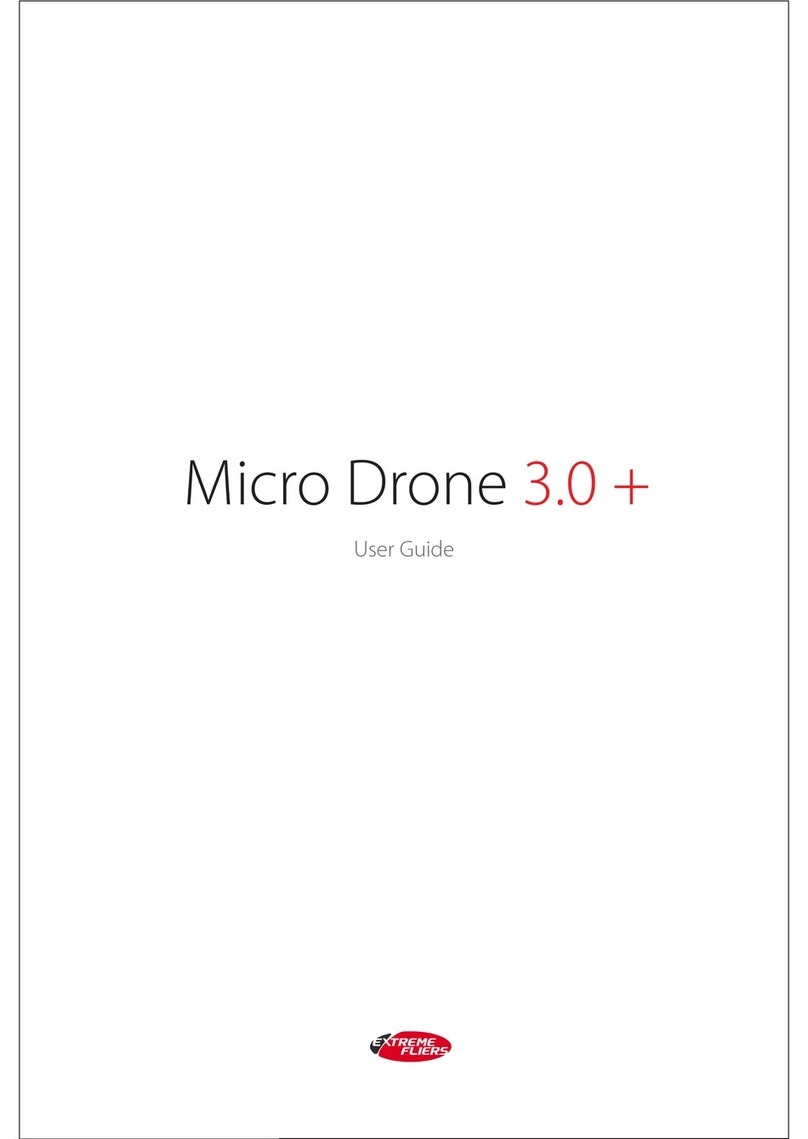

Step 8

If you have purchased

a PDB refer to the

PDB manual for

detailed description

on how to solder the

PDB components.

The picture shown

here is just orientative

of how it should look

like prior to mounting

the PDB to the frame

PARTS

Refer to the PDB manual

for detailed instructions

HARDWARE

Refer to the PDB manual

for detailed instructions

TILT Assembly Manual

Code No.: MD03001-00-1107

10

Step 9

Install the two Nylon

screws and nuts as

shown in the

pictures. The length

supplied is to be used

with landing legs. If

you do not want to

use landing legs you

can cut the Nylon

screws to a suitable

length. The nuts are

here important as

they serve as spacer

to avoid the exposed

bottom PDB pins to

touch the carbon

fiber base plate and

create dangerous

shorts. In the actual

design we do

recommend to use

Nylon screws if using

aluminium landing

legs.

PARTS

Same as step 8

HARDWARE

2x screw Nylon M3x12

2x nut Nylon M3

TILT Assembly Manual

Code No.: MD03001-00-1107

11

Step 10

Install the Nylon

screw and nut as

shown in the picture.

This screw will be

used to hold the PDB

and the nut as spacer

to avoid shorts. If not

using landing legs,

the screws in step 9

can also be installed

in this way.

PARTS

Same as step 7

HARDWARE

1x screw Nylon M3x12

1x nut Nylon M3

TILT Assembly Manual

Code No.: MD03001-00-1107

12

Step 11

Solder the pin headers

to the Naze flight

controller board as

shown in the pictures

with the black Naze32

board (headers

supplied). Cut the Nylon

screws to about 6 mm

long and install the

standoffs in the flight

controller.

If you want a low

profile headers setup,

you can use the red

Naze pictures as

example (rubber

dampeners not

included in the kit)

PARTS

1x Naze32 flight

controller board

HARDWARE

4x screw Nylon M3x12

(to be vut to about 6 mm

long)

4x standoff Nylon 10 mm

long Nylon

TILT Assembly Manual

Code No.: MD03001-00-1107

13

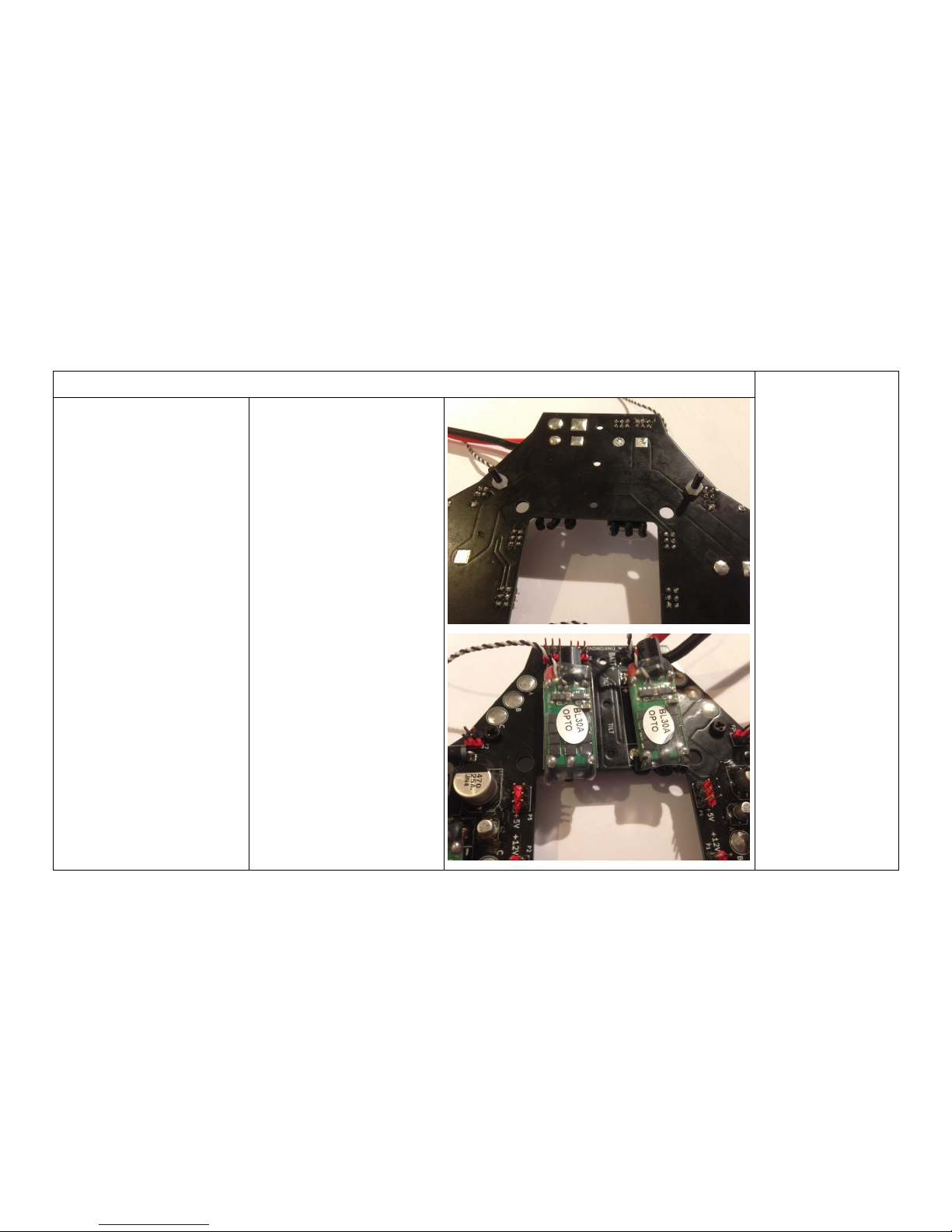

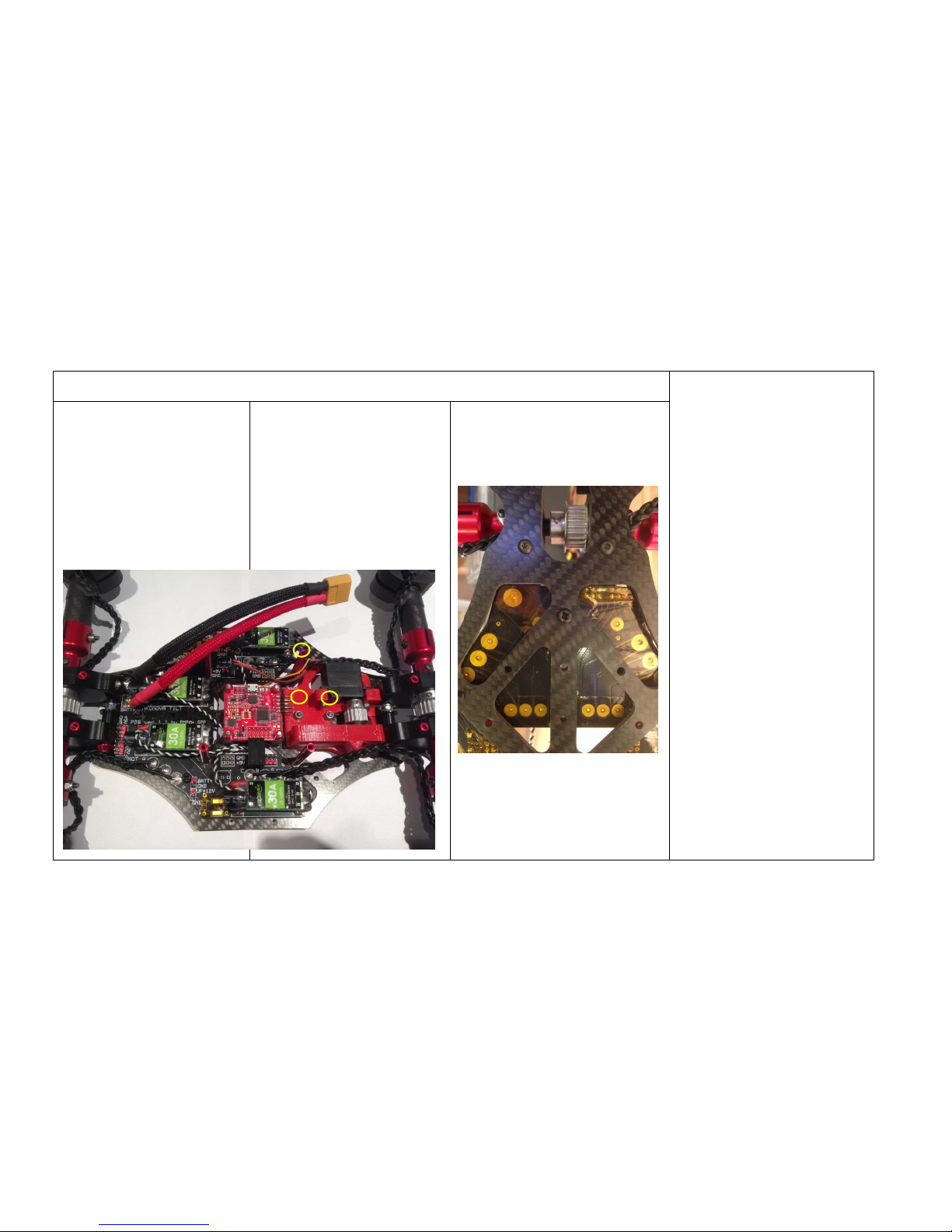

Step 12

Mount the flight controller with the

M3x6 on the base plate (the picture here

is just orientative) and the PDB or PDB

substitution with the Nylon nuts on the

already installed Nylon screws (for the

PDB substitution you do not need the

nylon nuts as separators as there is no

shortcircuit risk).

We recommend insulating the bottom

side of the PDB with electrical insulation

tape. It is not mandatory as the PDB and

solderings should not touch the frame

(CHECK!). We used Kapton (Polyimide)

tape to insulate the PDB from the carbon

fibre chassis.

NOTE: use tape with “low noise” glue

when possible. Some insulation tapes can

cause an increase in the noise in the

system. Using good quality tape with

suitable glue properties is good practice.

PARTS

Same as steps 9,

10 and 11

HARDWARE

4x screw M3x6

3x Nylon nuts

PDB substitution

(comes with all

frames)

TILT Assembly Manual

Code No.: MD03001-00-1107

14

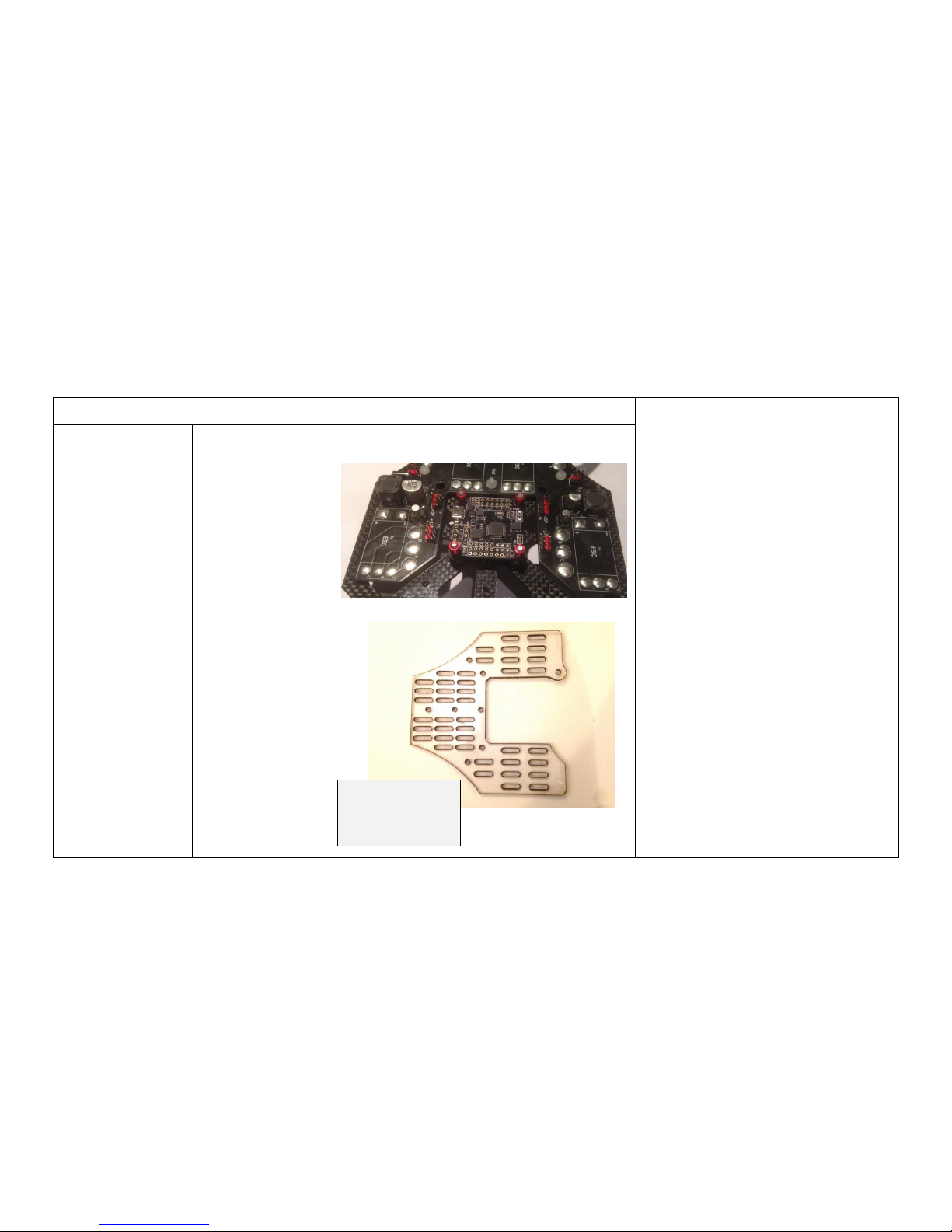

Step 13

Install the polymer

bearing in the IGUS

bearing housing. Then,

screw the servo bearing

housing into the servo

base with the M3x6

screws (keep the

middle bore empty).

Install the servo pulley

in the servo with the set

screws and then, the

servo in the base with

the M2 hardware.

Ensure the servo

pulley is aligned with

the polymer bearing.

Add the nylon cylinder

through the bearing and

screw the M3x20

screws to the pulley

through the Nylon

cylinder (use thread

lock here and do not

tighten excessively).

PARTS

Servo base

IGUS housing

Servo

1x polymer bearings (small)

1x Nylon cylinder 15 mm

HARDWARE

2x screw M3x6

1x screw M3x20

2x screw M2x12

2x washer M2

2x lock nut M2

2x set screw M3 (short)

TILT Assembly Manual

Code No.: MD03001-00-1107

15

Step 14

Install the tilt servo assembly

to the base plate with the

M3x10 and M3 nuts (yellow

circles) and the four stand-offs,

also with M3x10.

PARTS

Same as step 12

Servo asembly

4x stand-offs 35 mm

HARDWARE

7x screw M3x10

3x lock nut M3

TILT Assembly Manual

Code No.: MD03001-00-1107

16

Step 15

Mark 490 mm span in the belt with a

marker leaving similar belt length on

both sides. Pass the open belt

through the pulleys as shown in the

picture.

Check the arms support tensors are

loose and on the bottom of their

travel range.

Install the belt clamp ‘tightening’ the

belt until the 490 mm marks are

being nearly covered by the clamp

parts. Ensure the belt teeth match the

clamp cavities.

PARTS

Same as step 14

Belt

Clamp parts A and B

HARDWARE

4x screw M2x10

4x lock nut M2

8x washer M2

TILT Assembly Manual

Code No.: MD03001-00-1107

17

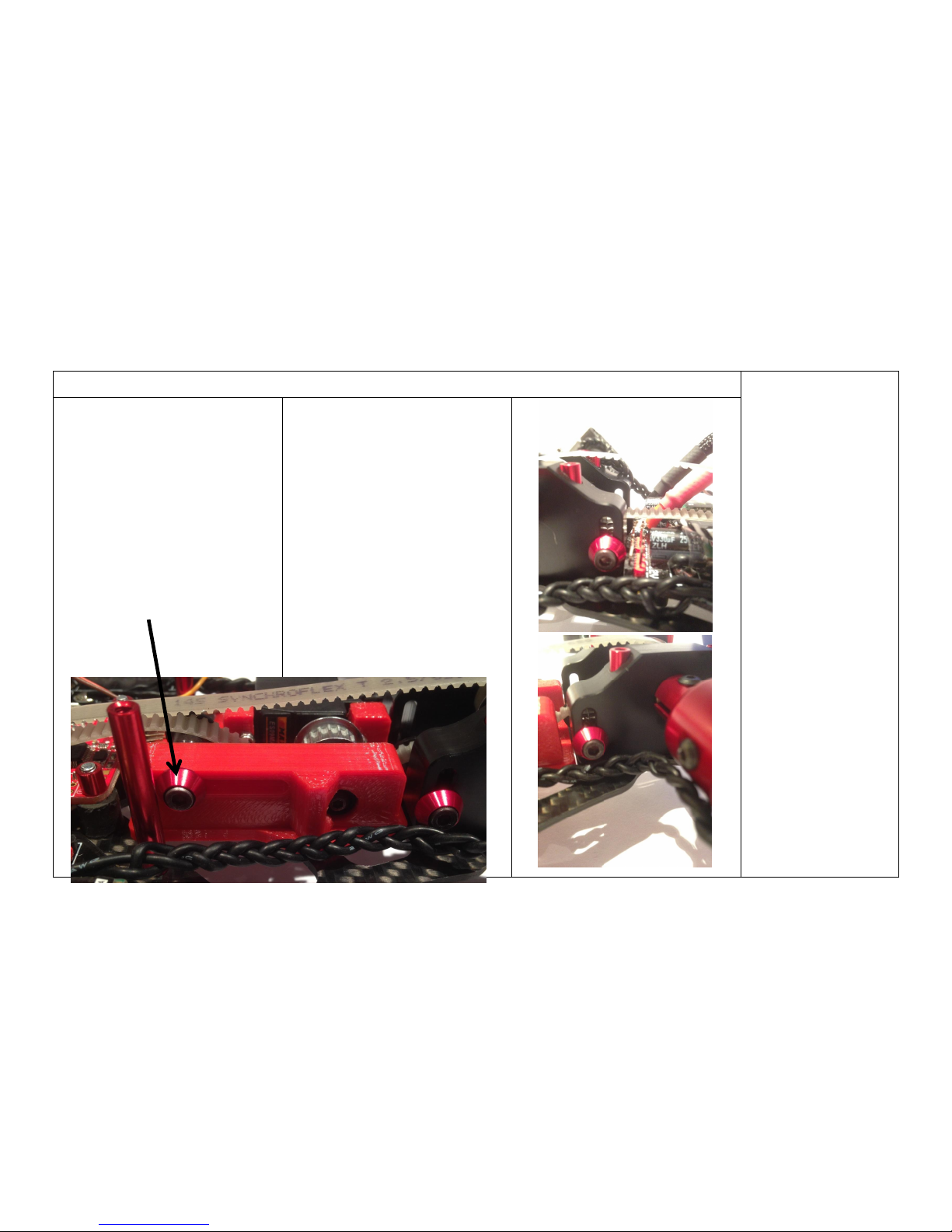

Step 16

Install the third belt

tensor in the servo

assembly with the

M3x25 screw and one

washer (instead of the

red aluminium part in

the picture: not

provided) and on the

other side of the 3D

printed red part, insert

first the split washer,

then the Nylon cylinder,

then the IGUS bearing,

the washer and finally

the M3 lock nut.

Lift the arm support

tensors to the middle

approx. and keep the

servo belt tensor loose

for now.

PARTS

Same as step 15

1x IGUS bearing (small)

1x Nylon cylinder 10 mm

HARDWARE

1x screw M3x25

1x lock nut M3

2x washer for M3

1x split washer for M3

Servo belt tensor

TILT Assembly Manual

Code No.: MD03001-00-1107

18

Step 17

Add the tip dummy

plates (acrylic) or

carbon fiber camera

plates in the front and

back at your

convenience: they are

placed in the gap below

the arm supports using

the two exterior screws.

PARTS

Same as step 16

Tip dummy plates or front

camera plate and/or rear tip

plate

HARDWARE

4x screw M3x20 (PRO version)

4x screw M3x25 (3DP version)

TILT Assembly Manual

Code No.: MD03001-00-1107

19

Step 18 (optional)

Add the gear platforms that you need

(two available). They just slide down

in the four central 35 mm stand-offs

and serve to place any gear you want

(receiver, video transmitter, etc).

PARTS

Same as step 17

HARDWARE

None

TILT Assembly Manual

Code No.: MD03001-00-1107

20

Step 19

Install the receiver and other gear.

PARTS

Same as step 18

HARDWARE

None or variable upon system