INNO Instrument VIEW600 User manual

1

Please read this user manual before using the device.

Please keep this manual together with the device.

User’s Manual

2018/09 Ver0.06

VIEW600

2

1

VIEW600

User’s Manual

2

3

Copyright 2018, INNO INSTRUMENT, INC.

All rights reserved.

This manual is only subject to the users who purchased this product (View600).

No part of this manual can be reproduced without any prior written permission

from the publisher.

INNO INSTRUMENT, INC

Address::E-22F,30,Songdomirae-ro,Yeonsu-gu,Incheon21990, Republic of

Korea

ⓒ

4

Contents

Preface

Chapter 1: Overview

Introduction

Basic function

OTDR test

VFL/LS module

Fiber microscope (Fiber Inspection Probe) module

OPM module

Basic conguration

Power supply

Size and weight

Environment condition

Chapter 2: Installation

Safety warning and precautionary measures

Operation warnings

Transportation and storage

Appearance overview

Front panel

The upper connection panel

Back panel

Charging method

Test port

Connection test

Connect the test ber

Connect VFL

Connect ber inspection probe (ber microscope)

Chapter 3: Basic Operation

Power on/off

8

11

11

11

11

12

13

13

13

13

14

14

15

15

15

16

16

17

17

17

18

18

19

19

19

20

21

21

Contents

Contents 5

Adjust the backlight brightness

Software upgrading

File copy

Chapter 4: OTDR Module

Move cursor key

Move trace key

Partial amplication key

“1:1” trace recovery key

Shortcut key for trace amplication

Shortcut key for trace shrink

Full screen display key

Parameter setting key

OTDR key

Event key

Measurement key

Loss

Attenuation

Reectance

Optical return loss

Trace information key

Start/Stop key

Save/Open key

OTDR setting key

Common Setting

Sample Setting

Analysis Set

Threshold Setting

Custom Setting

Create report key

Save as key

Next λ key

Return key

Main menu key

21

22

22

23

25

25

26

26

27

27

27

28

29

29

31

31

32

32

33

34

34

34

37

38

40

41

41

42

43

43

44

44

45

Contents

Contents6

Display screenshot key

Chapter 5: SOLA

“SOLA” operation

Start/ Stop

Save/Open

Management

Identication

Line denition (Link info)

Line pass

Element pass

Settings

Make report

Save as

Screenshot

Chapter 6: Optical Power Meter

Overview

OPM Operation

Chapter 7: VFL and Light Source

Overview

Visual light source operation

light source operation

Chapter 8: Fiber Microscope

Overview

Start ber end inspection

The function of ber microscope

Check the preserved image

Chapter 9: File management

Overview

Start le management

File manager function

“Operate” function

45

46

46

47

48

50

50

50

51

51

52

52

52

53

54

54

54

55

55

56

56

58

58

58

58

60

61

61

61

61

62

Contents

Contents 7

65

65

65

65

65

66

66

67

67

68

69

69

70

70

70

71

71

72

72

72

77

Chapter 10: System settings

Overview

System settings

Functions of system settings

Standby and brightness

Time

Language

WI-FI

Printer

System maintenance

Chapter 11: System Information

System information

Appendix

Structure requirement

Hardware interface requirement

Software interface requirement

Operating environment requirement

Performance requirement

Term list

Maintain and technical support

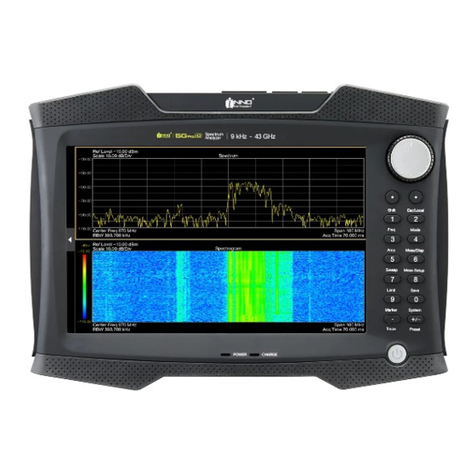

VIEW600 OTDR Module

Contents

Preface

8

Preface

Safety symbols

To prevent personal injury and property damage from the misuse of the device,

INNO Instrument uses the following safety symbols to show relevant information.

Before using the device, make sure that you understand the meaning of these

symbols. All symbols may not be found on this device. There could be safety

symbols not marked in this manual.

Safety symbols used in this manual:

Dangerous this symbol shows that this is a very dangerous operation and

improper operation can lead to serious injury, even death.

Warning this symbol shows that this is a relative dangerous operation and

improper operation can lead to serious injury, even death.

Caution This symbol shows that this a relatively dangerous operation, or has

a certain harm. Improper operation can result in mild or serious injury and property

loss.

Safety signs used in the manual and machine:

The following safety signs are marked on the device, near the operation position,

or in the manual to offer relevant safety. Before use, be sure that you have grasped

all the meanings and take necessary precautionary measures.

This sign shows a forbidden operation. This slash circle is labeled in the

operation position or around it.

This sign means that you must be careful when doing a certain operation. This

circle sign is labeled in the operation position or around it.

This sign means a warning and to be careful. Relevant content appears inside

the triangle or near it.

This sign shows an explanation. Relevant content is listed in the box.

These signs mean the labeled items should be recycled.

9

Preface

Laser Safety Label

COMPLIES WITH FDA RADIATION PERFORMANCE STANDARDS, 21

CFR SUBCHAPTER J.

Caution:

This device complies with Part 15 of the FCC Rules / Innovation, Science and

Economic Development Canada’s licence-exempt RSS(s). Operation is subject to

the following two conditions: (1) this device may not cause harmful interference. (2)

this device must accept any interference received, including interference that may

cause undesired operation.

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est con-

forme aux CNR d’Innovation, Sciences et Développement économique Canada

applicables aux appareils radio exempts de licence. L’exploitation est autorisée

aux deux conditions suivantes :

1. L’appareil ne doit pas produire de brouillage;

2. L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouil-

lage est susceptible d’en compromettre le fonctionnement.

Changes or modications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installa-

tion. This equipment generates uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interfer-

ence will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

Preface10

Electrical safety

In order to cut down the harmful effects to human and lower the damage to the

device, we put forward the following warning tips:

•Please don’t use it if the product or the charger is damaged or ruptured.

•Only the external adapter which is offered by our company can be used. For

other adapters, we can’t guarantee its safety and performance.

•Please don’t use the power adapter outdoors or in moisture place.

•Please be sure that the external input voltage conne to a permissible range.

Precautions! Be careful

Replace internal storage battery: Lithium battery is used as power source for this

product. If it exceeds the service life and needs to be replaced, please contact

with technical person for replacement.

External storage: The USB and SD card are used as external storage to preserve

data for this product.

INNO Instrument (China) Inc. is not responsible for the loss of data.

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

MPE Reminding

To satisfy FCC / IC RF exposure requirements, a separation distance of 20 cm or

more should be maintained between the antenna of this device and persons dur-

ing device operation.

To ensure compliance, operations at closer than this distance is not recom-

mended.

L’antenne installée doit être située de facon à ce que la population ne puissey être

exposée à une distance de moin de 20 cm. Installer l’antenne de facon à ce que

le personnel ne puisse approcher à 20 cm ou moins de la position centrale de l’

antenne.

La FCC des éltats-unis stipule que cet appareil doit être en tout temps éloigné

d’au moins 20 cm des personnes pendant son functionnement.

11

Overview

Introduction

High-performance hardware and wieldy software used in View600 can shorten the

process of installation, debugging and ber distance maintenance.

This chapter will describe the features and basic operations of VIEW600 OTDR

test unit.

Basic function

View600 is mainly used for ber fault diagnosis, especially in FTTH application.

Besides the basic OTDR function, optical power meter and light source function

for ber discriminating are also internally installed. In addition, View600 also owns

visual light source(VLS/VFL)option function. With visual light source, it can carry

out the visualization inspection to nd ber bending and ber rupture in dead zone.

OTDR test

Based on Rayleigh scattering and Fresnel Reection principle, OTDR can real-

ize the relevant measurement on optical ber link. It can also carry out distance

measurement to ber connection loss and fault location, thus it can determine the

any point loss on the optical ber. OTDR auto analysis function can automatically

analyze measured traces to nd the events on ber, such as the reection loss or

the splicing point over loss threshold limit. Besides, the detected data can be also

displayed in the event table on OTDR.

1

Chapter 1 Overview

Chapter 1 Overview12

Light source

Chapter 1 Overview

VFL/LS module

Visual fault locator which adopts 650±20nm light source or visual light source

can offer visualization method for ber fault location. The red light from visual light

source can be captured by human eyes, being able to directly locate fault location

in ber test dead zone or make ber core calibration in multi-ber cable.

LS (Stable light source)

Light source with different wavelengths (i.e. 1310/1550/1625nm) and multiple

signal modulation modes in-built in View600 are able to satisfy demands in actual

applications, as shown in the following picture.

Chapter 1 Overview 13

Fiber microscope (Fiber Inspection Probe) module

The grind quality and cleanliness of optical connector can be detected by being

connected external ber inspection device to USB port.

OPM module

The optical power meter is used to measure absolute optical power meter or rela-

tive optical power loss through a span of optical ber. This module can measure

optical power of multi-wavelength.

Basic conguration

•Color TFT LCD

•AC adapter / charger, power cord

•Chargeable lithium battery

•Basic menu operation

•Shoulder belt

•Operation manual

Power supply

•External DC power supply: 19V input voltage; input current ≥3.42A;

•Lithium battery supply: 11.1V, 6.7Ah, about 3h of fully charging time

Chapter 1 Overview

Chapter 1 Overview14

Size and weight

•Size: 218 x 159 x 70 mm

•Weight: 1.84Kg (without battery) / 0.36kg (with battery)

Environment condition

•Operating environment: Altitude: 0 to 5000m, Temperature: -20℃to 60℃,

Relative humidity: 0% to 95%, Max. wind velocity: 15m/s

•Storage environment: temperature: -10℃to 50℃, Relative humidity: 0% to 95%,

temperature of battery storage for a long time: -20℃to 30℃

Chapter 1 Overview

15

Installation

Safety warning and precautionary measures

It is very important that VIEW600 is designed for ber optical testing, not applied

for any other purpose. Since OTDR is high precision machine, it should be seri-

ously carried. Please strictly comply with the following safety rules and general

specications when you use and carry it. Any violation to the warnings and cau-

tions in this manual will cause deviation from the standard requirement for OTDR

design, manufacture and use. Consequences caused by users’ violation to the

requirements should be borne by the users themselves.

Operation warnings

•DO NOT operate OTDR in a ammable or explosive environment.

•DO NOT disassemble or modify any component of the OTDR without approval.

Component replacement and internal adjustments must be implemented by

its authorized technicians or engineers.

•Please be careful when connecting battery adapter cable. Do not pull the cable

when you take it down from the socket, but just hold the plug. Please make sure

the cables are in good condition to avoid risk of re or electric shock accidents.

•Please not expose OTDR to re, electric shock, rain, or rain and other humidity

environment.

•When the following cases occurred, please turn off OTDR and pull out the

adapter immediately, otherwise it will lead to serious consequences, such as

abnormal operation or fault beyond repair.

•Fumes, peculiar smell or abnormal sound.

•Liquid or foreign matters fall into the inner of OTDR.

•OTDR suffers from strong vibration or impact.

Note: Please contact with maintenance center once you encounter the above

cases. If timely measures are not taken, it will result in electric shock, re ac-

cident, body hurt, machine scrap, even death.

•Please only use exclusive VIEW600 AC adapter. Inappropriate alternating current

2

Chapter 2 Installation

Chapter 2 Installation16

power supply will lead to fumes, electric shock or facility damage; even it will result

in re accident, body hurt and death.

•Please only use exclusive AC power cord. Weighty items should not be placed

on the power line, please not let power line heated or change the power line.

Inappropriate or damaged power line will lead to fumes, electric shock and facility

damage; even it will result in re accident, body hurt or death.

Transportation and storage

•When moving OTDR to warm place from cold environment, try to move it in a

gradual warming way, otherwise condensation will be produced in the inner of the

device, resulting in adverse effects to the device.

•Please pack it when you don’t use it.

•Please keep OTDR clean and dry.

•OTDR has been precisely calibrated and adjusted, please place it in carrying

case for fear it will be damaged or polluted. Proper buffer box shook should be

needed during long-distance transportation.

•Please don’t expose the device in direct sunlight or in overheated environment.

•Keep the minimum humidity when preservation. Relative humidity should be less

than 95%.

Appearance overview

OPM

VFL DC

USB

On / Off keyMenu

Chapter 2 Installation

RJ45

Chapter 2 Installation 17

Front panel

The upper connect panel

Back panel

Keys and denitions

Power Switch (on / off)

MENU Home menu

Chapter 2 Installation

Port description

DC power connector Connect the adapter.

SMF port(Testing

port)

VIEW600 testing interface, applied in OTDR and light source modules of

VIEW600.

VFL port Visual light source port.

USB port Connect USB storage device / ber end probe.

OPM port Optical power meter port

RJ45 Network Interface

Chapter 2 Installation18

Charging method

Remaining electric capacity can be represented as the following battery status

when View600 is power-on.

Test port

The test port lies on the upper panel of the main body. There are two or three test

ports on view600. The type of the test port connected by optical ber depends

on the testing application, while the number of the test port depends on the mea-

sured wavelength.

Follows are some universal connecters (FC/SC) in use for VIEW600:

Procedures for cleaning universal connector:

•Open the lid of the measurement port which needs to be cleaned.

•Take off the universal connector.

•Blow compressed air toward the top of connecting bar.

•Use a special cleaning belt or dust-free belt dipped in alcohol to clean the top of

Chapter 2 InstallationChapter 2 Installation

Table of contents

Other INNO Instrument Measuring Instrument manuals