EN

Operating instructions capsule pressure gauge, model 63x.50 per ATEX 3

40433177.01 11/2020 EN/DE

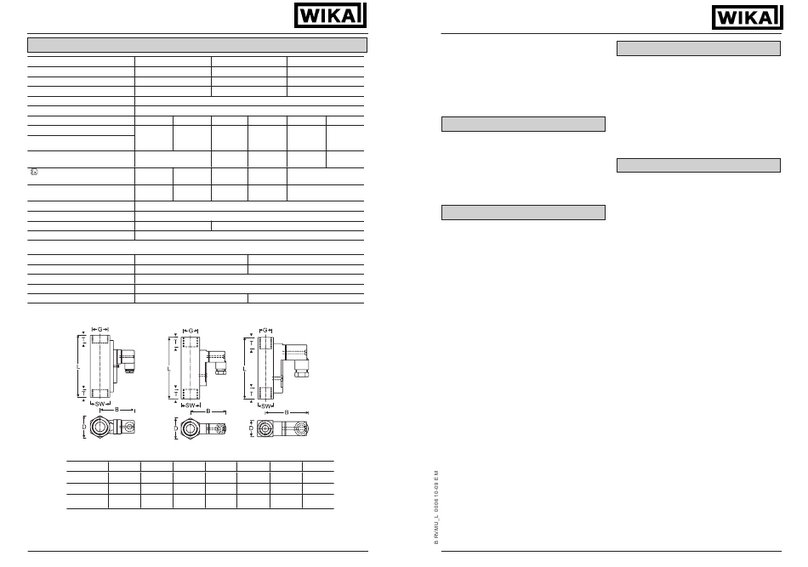

Contents

Declarations of conformity can be found online at www.wika.com.

1. General information 4

1.1 Explanation of symbols ................................................................. 5

2. Safety 6

2.1 Intended use ................................................................................. 6

2.2 Responsibility of the operator........................................................ 7

2.3 Personnel qualification .................................................................. 9

2.4 Safety instructions for hazardous locations ................................. 10

2.5 Labelling / Safety marks .............................................................. 15

2.6 Ignition hazard analysis............................................................... 16

3. Specications 17

4. Design and function 18

5. Transport, packaging and storage 18

5.1 Transport ..................................................................................... 18

5.2 Packaging and storage................................................................ 19

6. Commissioning, operation 19

6.1 Mechanical connection ............................................................... 19

6.2 Requirements for the installation point ........................................ 20

6.3 Installation................................................................................... 21

6.4 External zero point setting (if available)....................................... 22

6.5 Permissible ambient and operating temperatures ....................... 22

6.6 Permissible vibration load at the installation site ......................... 23

6.7 Level check ................................................................................. 23

6.8 Commissioning ........................................................................... 23

7. Faults 24

8. Maintenance and cleaning 26

8.1 Maintenance ............................................................................... 26

8.2 Cleaning...................................................................................... 26

9. Dismounting,returnanddisposal 27

9.1 Dismounting................................................................................ 27

9.2 Return ......................................................................................... 27

9.3 Disposal ...................................................................................... 27

Annex: EU Declaration of conformity 54