Innolas Laser nanio Series Operating manual

nanio Industrial DPSS Laser

User and Installation Manual

Innolas Laser GmbH

Justus-von-Liebig-Ring 8

D-82152 Krailling

Germany

© 2009 InnoLas Laser GmbH. All rights reserved.

Revision History

1.0 First release

Release date: 15 July 2009

Customer Support Contact Addresses

InnoLas Laser GmbH

Justus-von-Liebig Ring 8

D-82152 Krailling

Germany

Tel: +49 89 899 36 0 - 0

Fax: +49 89 899 36 0 - 16

E-mail: [email protected]

InnoLas (UK) Ltd.

67 Somers Road

Rugby

Warwickshire CV22 7DG

United Kingdom

Tel: +44 1788 550 777

Fax: +44 1788 550 888

E-mail: [email protected]

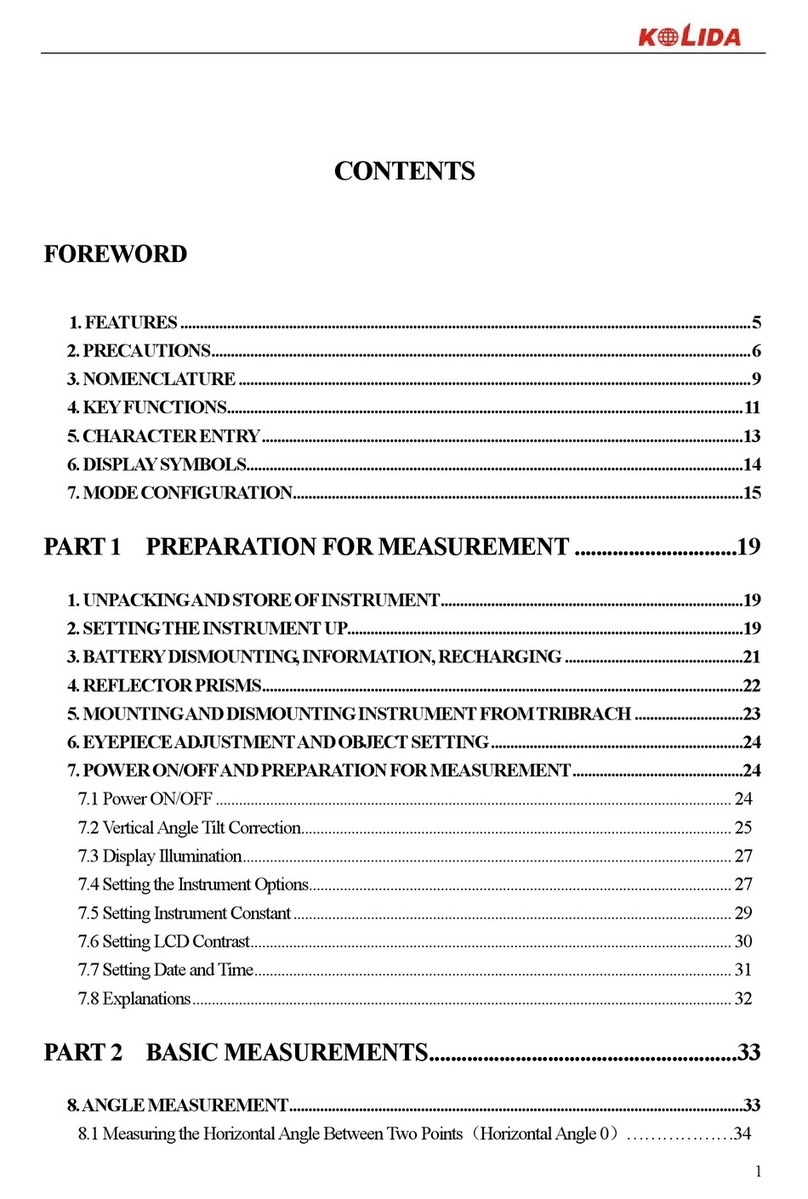

Table of Contents

Preface

Audience

Other Publications

How to Use this Manual

1. Safety...........................................................................................................................................1

1.1. Qualification and training of personnel........................................................................1

1.2. Electrical.............................................................................................................................2

1.3. Laser radiation...................................................................................................................2

1.4. Location of safety labels...................................................................................................3

1.5. Refrigerant medium.........................................................................................................4

1.6. Hazardous materials........................................................................................................5

1.7. Decommissioning and disposal......................................................................................5

2. General Description.................................................................................................................7

2.1. Intended use......................................................................................................................7

2.2. Laser Head.........................................................................................................................7

2.3. Power Supply....................................................................................................................8

2.4. Chiller options...................................................................................................................8

2.4.1. Water/air....................................................................................................................8

2.4.2. Water/water..............................................................................................................9

2.5. Beam Delivery Options....................................................................................................9

2.6. Specifications.....................................................................................................................9

2.6.1. Electrical supply.......................................................................................................9

2.6.2. Dimensions.............................................................................................................10

2.6.3. Nominal weights....................................................................................................13

2.6.4. Customer connections...........................................................................................13

2.6.5. Performance............................................................................................................13

2.6.6. Environmental........................................................................................................13

2.6.7. Design lifetime of the equipment........................................................................13

3. Operation..................................................................................................................................15

3.1. Direct start up..................................................................................................................15

3.2. Direct shut down.............................................................................................................15

3.3. Remote start up...............................................................................................................15

3.4. Remote shut down..........................................................................................................16

3.5. Emergency shut down...................................................................................................16

3.6. Restart after an emergency shut down........................................................................16

4. Software....................................................................................................................................17

4.1. Default software .............................................................................................................17

4.2. RS232 control protocols..................................................................................................17

5. Routine maintenance.............................................................................................................21

5.1. Safety compliance checks...............................................................................................21

5.2. Chiller...............................................................................................................................21

5.2.1. General checks........................................................................................................21

5.2.2. Water/water............................................................................................................21

5.2.3. Water/air..................................................................................................................23

5.3. Power supply...................................................................................................................23

5.4. Laser head........................................................................................................................24

6. Troubleshooting......................................................................................................................25

7. Installation...............................................................................................................................27

7.1. Unpacking........................................................................................................................27

7.2. Positioning and mechanical mounting........................................................................27

7.2.1. Laser head...............................................................................................................28

7.2.2. Power supply..........................................................................................................28

7.2.3. Chiller......................................................................................................................28

7.3. Electrical connections.....................................................................................................29

7.4. Coolant connections.......................................................................................................30

7.5. Safety and interlock connections..................................................................................30

7.5.1. Emergency stop interlock.....................................................................................30

7.5.2. Shutter safety interlock.........................................................................................30

7.5.3. External laser emission warning lamp................................................................30

7.6. Control connections........................................................................................................30

7.7. External beam delivery components............................................................................30

7.8. Initial operation...............................................................................................................31

8. Transport and re-commissioning.........................................................................................33

8.1. Transport..........................................................................................................................33

8.2. Recommissioning............................................................................................................33

9. Interfacing................................................................................................................................35

9.1. Interlocks..........................................................................................................................35

9.1.1. Emergency stop......................................................................................................35

9.1.2. Shutter.....................................................................................................................35

9.1.3. System reset............................................................................................................35

9.2. Emission warning lamp.................................................................................................36

9.3. Q-switch control inputs..................................................................................................36

9.4. User interface...................................................................................................................36

10. Parts list...................................................................................................................................39

Preface

Audience

This manual should be read by all personnel who install or operate the nanio laser.

Important!

Read this manual carefully before operating the laser for the first time. Pay

special attention to the Safety chapter.

The nanio laser is designed and sold for use in OEM systems and is not to be used as a

stand-alone laser. The OEM is responsible for compliance with all applicable safety

regulations.

Other Publications

•EN60825–1 Radiation Safety of Laser Products, Equipment Classification, Requirements

and User's Guide

http://www.cenelec.org

•IEC 60204–1 Safety of Machinery, Electrical Equipment of Machines

•IEC 61010–1 Safety Requirements for Electrical Equipment for Measurements, Control and

Laboratory Use

•Laser Safety Guide

Laser Institute of America, 13501 Ingenuity Drive, Suite 128, Orlando, Florida

32826, USA

http://www.laserinstitute.org

•ANSI Z136.1–2000 — Safe Use of Lasers, American National Standards Institute

http://www.ansi.org/

http://www.z136.org/

•H.I.B. Systemtechnik GmbH Industrial Cooling Systems, Operating Instructions

Withdrawable Units (19 inch)

How to Use this Manual

The manual contains information required for safe operation, installation and routine

maintenance of the equipment.

nanio Industrial DPSS Laser User and Installation Manual

iPreface

InnoLas Laser GmbH

Preface ii

1. Safety

Only authorised personnel, familiar with the potential dangers presented by laser

equipment during operation or installation, are allowed to work with the laser system.

It is of utmost importance that personnel working with the system read, understand

and observe the information and instructions in this manual.

WARNING

Risk of exposure to laser radiation

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

The nanio is a Class IV laser intended to be used as part of an integrated laser-based

processing system.

Safe use of this equipment is reinforced by safety labels fixed to the equipment in a

visible manner. The type of safety labels used and their location is detailed in section

1.4.

The use of controls, replacement parts, adjustments, or procedures other than those

specified within this manual may result in exposure to any of these hazards.

• Laser hazards

• Electrical hazards

• Environmental hazards

• Mechanical hazards.

The degree of seriousness of the hazard is indicated by the use of the following signal

words:

DANGER

Indicates an imminent hazard which, if not avoided, is extremely likely to result in

death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It is also used to alert the user against unsafe working

practices and potential damage to the equipment.

1.1. Qualification and training of personnel

Personnel who install and/or operate the laser must be adequately qualified for the

work concerned and should have read this manual. the user must clearly specify the

sphere of responsibility, competence and

nanio Industrial DPSS Laser User and Installation Manual

11. Safety

1.2. Electrical

DANGER

Risk of electrocution

Switch off and disconnect the equipment from the mains electrical supply before

exposing electrical terminals. Only trained and authorised personnel should

remove covers from the power supply or water to air chiller.

DANGER

Risk of electrocution

Electrical connections must only be made by trained and authorised personnel.

Before working on the system:

• Remove the key from the key switch on the power supply.

• Turn off the mains electrical supply and, if possible, disconnect the equipment from

the supply.

• Restrict access to the area to trained people who are aware of the hazards.

• Refer to the system manual and circuit diagrams for wiring connections and

polarities. Never guess or use trial and error techniques.

• Fit only InnoLas approved parts.

• Do not operate the equipment with safety panels removed or with interlock

switches overridden (unless a key operated override facility has been included).

• Never attempt to work on electrical circuits when alone; always have a colleague

nearby.

• Observe the requirement of the electrical safety codes for the establishment where

the laser is installed.

• External equipment connected to the system must comply with EN61010–1 and

appropriate local standards.

1.3. Laser radiation

WARNING

Risk of exposure to laser radiation

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

During installation or in a maintenance situation, the operating area of the laser system

must be clearly marked to warn unauthorised personnel not to enter the area. All

entrances and exits must be marked with appropriate warning signs.

OEM system integrators are obliged to provide training to their customers and to make

them familiar with the potential dangers of Class IV laser in general and the nanio laser

in particular.

InnoLas Laser GmbH

1. Safety 2

When working on the system during installation or in a maintenance situation, observe

the following rules:

• Avoid eye or skin contact to direct or scattered radiation.

• Always wear protective eye wear matched to the emission wavelength of the laser.

Instruct all personnel in the vicinity to wear identical protective eye wear.

• Never look into the laser beam!

• Make sure there are no reflective materials in the beam path that could deflect the

beam toward the operator or another person in the vicinity.

• Use only non-flammable, absorbing or non-reflective materials as beam dumps.

• Never operate the laser in the vicinity of explosive liquids or gases.

• Be aware that laser processing certain materials (e.g. plastics) may create poisonous

fumes and by-products.

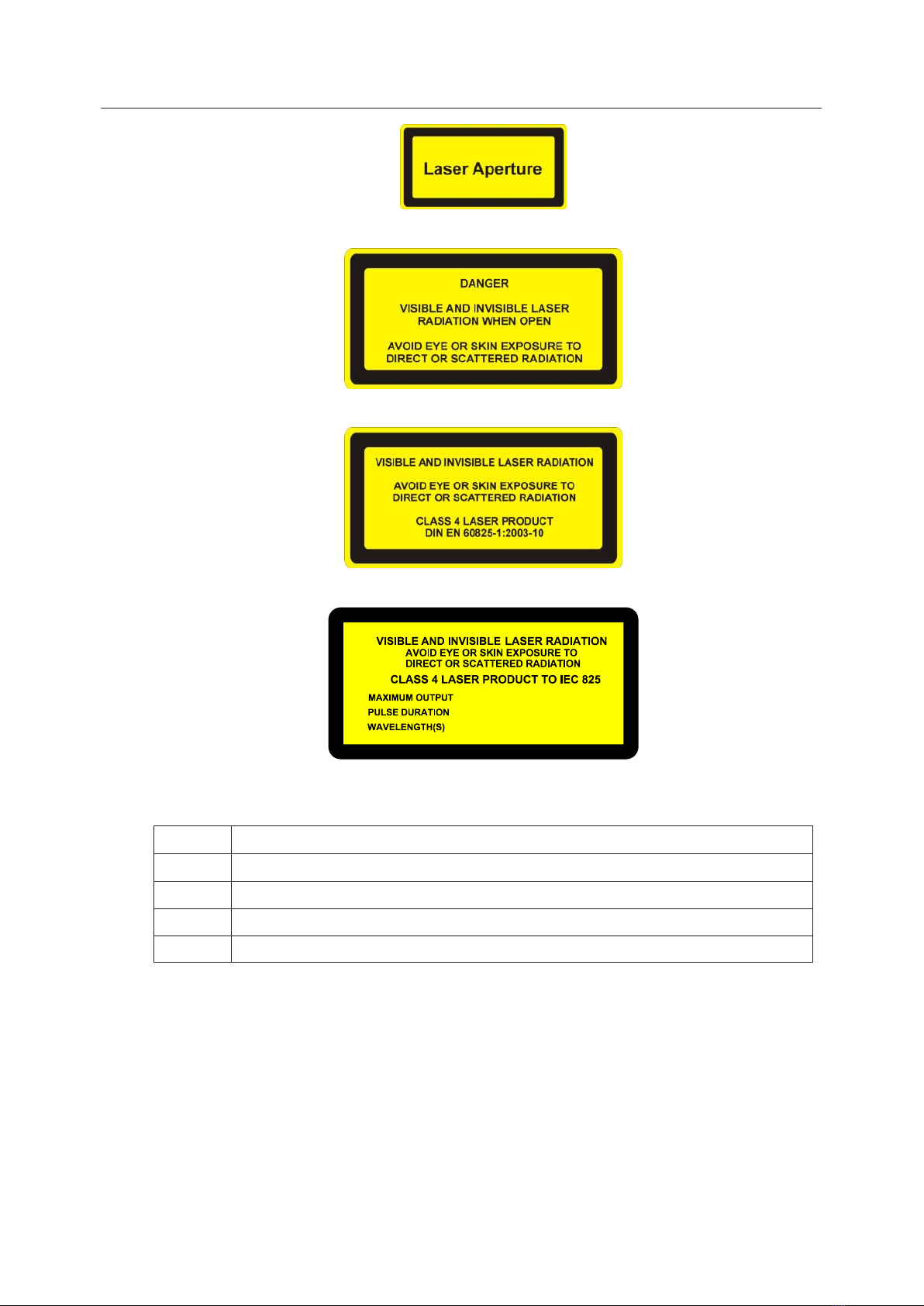

1.4. Location of safety labels

The labels shown on the following drawing are fitted to the equipment in the locations

specified and must not be removed or defaced. Immediately replace any missing

labels. Replacement labels can be obtained from InnoLas.

Labels on the side of the laser head are repeated on both side faces.

Figure 1 - Safety label locations

Figure 2 - Label A

nanio Industrial DPSS Laser User and Installation Manual

31. Safety

Figure 3 - Label B

Figure 4 - Label C

Figure 5 - Label D

Figure 6 - Label E

The following information appears on Label E:

Po40 W

Pp100 kW

t 20–500 ns

F Single shot to 500 kHz

λ 1064/532/355 nm

DONT FORGET THE TYPE LABEL!!

1.5. Refrigerant medium

The water/air chiller contains a refrigerant medium. Avoid direct contact with the

refrigerant.

InnoLas Laser GmbH

1. Safety 4

DANGER

Risk of explosion

Do not use a water/air chiller in an explosive atmosphere or for cooling

flammable of explosive substances.

WARNING

Risk of lung damage

Never smoke in the vicinity of a water/air chiller. If refrigerant escapes it

decomposes to form cauterising acids that can severely damage your lungs.

If the refrigerant has to be drained or replaced, the procedure must be performed by a

specialised and trained person. Discarded refrigerant must be disposed of in

accordance with ISO/DIS 11650 or an equivalent local rules and regulations.

1.6. Hazardous materials

The laser head contains indium used as a heat conductor in the diode module and all

crystal mounts. Indium is toxic. Do not open the diode modules or crystal assemblies.

1.7. Decommissioning and disposal

If the laser will be definitively taken out of service and decommissioned, disconnect

and remove all signal and power cables, disconnect the external cooling water pipes

and drain the chiller.

Dispose of a water/air chiller in accordance with EN 378–4.

Dispose of the system according to appropriate local regulations, paying particular

attention to disposal of indium components in the laser head.

nanio Industrial DPSS Laser User and Installation Manual

51. Safety

InnoLas Laser GmbH

1. Safety 6

2. General Description

2.1. Intended use

The nanio is a diode-pumped solid-state laser system designed for OEM applications

as part of an integrated laser-based materials processing system. It offers a choice of

output wavelengths and powers with repetition rates up to 500 kHz and excellent

beam quality and stability.

The laser fails safe with no beam output and therefore must not be used where the

beam is part of a safety system; for example, as a light barrier.

2.2. Laser Head

Figure 7 - Laser head

The laser head consists of a diode module and a resonator module. The resonator

module is supplied in several lengths depending on the output specification. All

electrical and cooling connections are on the end face of the diode module. Laser

ouptut is emitted from the end face of the resonator module and can be configured so

that the beam axis is to the left or right of the centre line. The laser head can be

mounted using the bottom surface (preferred) or either side face. In each case, a three-

point fixing is provided with precise and repeatable location assured by means of

precision reference holes and slots for dowel pins.

The complete assembly is sealed to prevent the ingress of dust and humidity and is

fitted with a desiccant cartridge. It is temperature stabilised by means of stainless steel

cooling pipes embedded under the base of the resonator module and into a Peltier

cooler in the diode module.

Important!

Never open the laser head unless. No user serviceable parts inside.

The laser head contains the following key components:

• One or two laser diode modules with collimating optics

• Control electronics

nanio Industrial DPSS Laser User and Installation Manual

72. General Description

• Laser crystal and resonator mirrors

• Intra-cavity accousto-optic Q-switch

Note: The Q-switch driver can be mounted on the left or right-hand side of the resonator

module, depending on the mounting method chosen for the laser head.

• Intra-cavity safety shutter with dual-redundant closure detector

In addition, it can be fitted with harmonic generation and separation modules and an

external accousto-optic modulator.

All connectors can be supplied in either inline or 90° configurations.

2.3. Power Supply

Figure 8 - Power supply

The power supply is common to all nanio lasers. This provides maximum flexibility

and minimises spare part holdings. An output is provided for the chiller. Water/water

chillers are both powered and controlled from the power supply. Water/air chillers use

an independent mains electrical connection but are controlled from the power supply.

The power supply is designed to fit into a 19–inch rack and is 2RU high.

2.4. Chiller options

2.4.1. Water/air

Figure 9 - Water/air chiller

The water/air chiller is recommended for low average power or low duty cycle

applications. It is designed to fit into a 19–inch rack and is available in low power (5RU

high) or medium power (6RU high) versions.

Water/air chillers require an unrestricted flow of air at less than 40°C.

InnoLas Laser GmbH

2. General Description 8

2.4.2. Water/water

Figure 10 - Water/water chiller

Water/water chillers are available in standard and clean-room versions. They are

designed for high average power or high duty cycle applications. Both versions fit into

a 19–inch rack and are 4RU high. External water pipe connections are xx flow and xx

return.

Water/water chillers require an external water supply with minimum flow rate of

8 l/min and pressure differential of 100 kPa

2.5. Beam Delivery Options

• Beam expander

• Scan head mounting option

2.6. Specifications

2.6.1. Electrical supply

Maximum power consumption 1.5 kVA

Maximum current demand 16 A

Supply voltage Single phase 115–230 VAC ± 10%

Supply frequency 50/60 Hz

nanio Industrial DPSS Laser User and Installation Manual

92. General Description

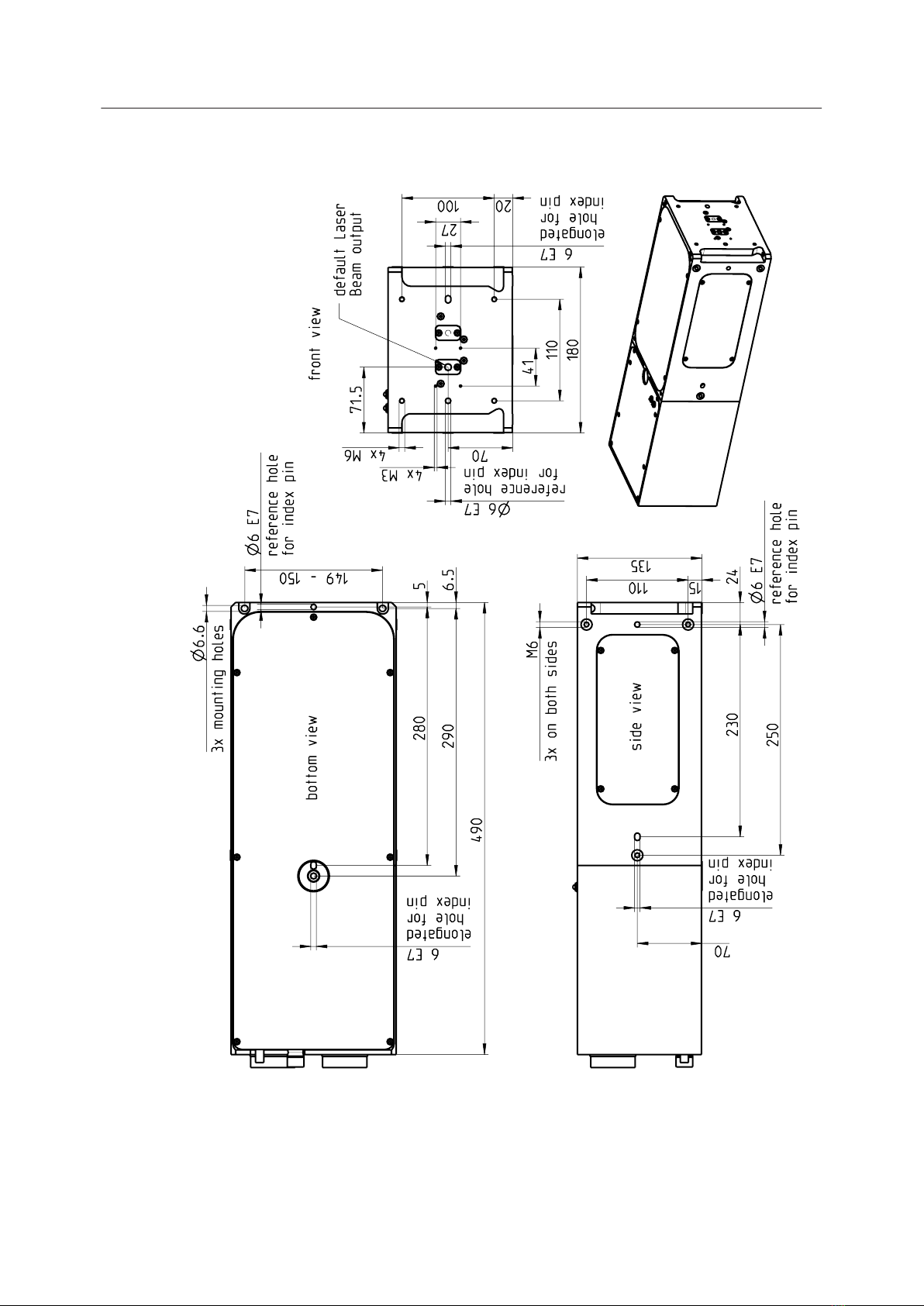

2.6.2. Dimensions

Figure 11 - 490 mm head

InnoLas Laser GmbH

2. General Description 10

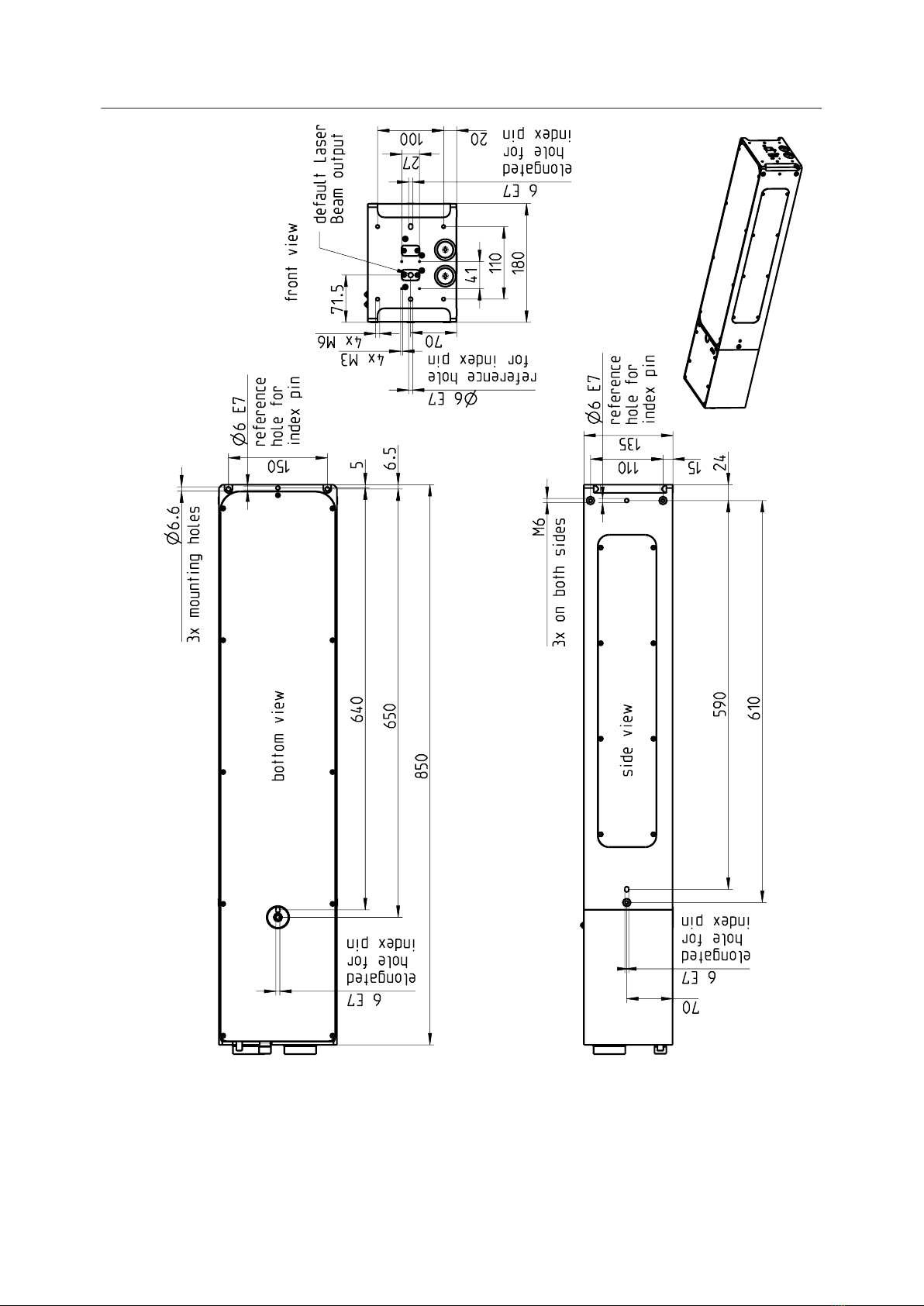

Figure 12 - 590 mm head

nanio Industrial DPSS Laser User and Installation Manual

11 2. General Description

Figure 13 - 850 mm head

Umbilical cables and cooling water pipes linking laser head, power supply and chiller

have a standard length of 3 m but can be supplied in lengths from 1 m to 20 m on request.

InnoLas Laser GmbH

2. General Description 12

Table of contents