Starr Instruments TGD-100 User manual

TGD-100

Ultrasonic Thickness Gauge

Instruction Manual

VER:3.1

1

Contents

1 INTRODUCTION ....................................................................................3

1.1 SCOPE OF APPLICATIONS........................................................................... 3

1.2 PRIMARY THEORY ................................................................................... 3

1.3 MEASURING PRINCIPLE ............................................................................ 3

1.4 APPEARANCE ......................................................................................... 4

1.5 KEYBOARD ............................................................................................ 4

1.6 DISPLAY SYMBOLS ................................................................................... 4

2 PRODUCT SPECIFICATIONS ................................................................... 5

2.1 TECHNOLOGY PARAMETER ........................................................................ 5

2.2 MAIN FUNCTIONS................................................................................... 5

3 OPERATION ..........................................................................................6

3.1 PREPARATION FOR MEASUREMENT ............................................................. 6

3.2 ADJUSTING SOUND VELOCITY..................................................................... 6

3.3 SETTING PROBE FREQUENCY ...................................................................... 7

3.4 MEASUREMENT OF THICKNESS................................................................... 8

3.5 ZERO CALIBRATION.................................................................................. 8

3.6 MEASUREMENT OF SOUND VELOCITY .......................................................... 9

3.7 SETTING ALARM THICKNESS LIMITS............................................................ 10

3.8 MENU OPTION ..................................................................................... 10

3.8.1 SYSTEM SETUP .................................................................................. 10

3.8.2 PRINT FUNCTION ............................................................................... 12

3.8.3 MEMORY MANAGE............................................................................ 14

4 DATA LOGGER OPERATION................................................................. 14

4.1 LOGGING READINGS INTO MEMORY .......................................................... 14

4.2 REVIEWING STORED THICKNESS READINGS .................................................. 15

4.3 CLEARING CURRENT THICKNESS VALUE ...................................................... 15

5. MEASURING TECHNOLOGY ............................................................... 15

5.1 CLEANING SURFACE............................................................................... 15

5.2 IMPROVING REQUIREMENT ON ROUGHNESS................................................ 15

5.3 ROUGH MACHINED SURFACE ................................................................... 15

5.4 MEASURING CYLINDRICAL SURFACE........................................................... 16

5.5 COMPOUND PROFILE ............................................................................. 16

2

5.6 UN-PARALLEL SURFACE .......................................................................... 16

5.7 INFLUENCE OF MATERIAL’S TEMPERATURE .................................................. 16

5.8 MATERIAL WITH LARGE ATTENUATION....................................................... 16

5.9 REFERENCE TEST PIECE ........................................................................... 17

5.10 SEVERAL MEASURING METHODS............................................................. 18

5.12 CHANGING PROBE............................................................................... 19

5.13 MEASURING CASTING .......................................................................... 19

6 PREVENTING ERRORS IN MEASUREMENT........................................... 20

6.1 ULTRA-THIN MATERIAL.......................................................................... 20

6.2 RUST,CORROSION AND PIT .................................................................... 21

6.3 ERROR IN IDENTIFYING MATERIAL ............................................................ 21

6.4 WEARNESS OF PROBE............................................................................ 21

6.5 OVERLAPPED MATERIAL AND COMPOUND MATERIAL................................... 21

6.6 INFLUENCE OF OXIDATION LAYER AT METAL’S SURFACE ................................ 21

6.7 ABNORMAL READOUT OF THICKNESS ........................................................ 22

6.8 UTILIZATION AND SELECTION OF COUPLING AGENT ...................................... 22

7. ATTENTION ....................................................................................... 22

7.1 CLEANING THE TEST PIECE ...................................................................... 22

7.2 CLEANING THE INSTRUMENT’S CASE ......................................................... 23

7.3 PROTECTING THE PROBE ........................................................................ 23

7.4 REPLACING BATTERIES ........................................................................... 23

7.5 ABSOLUTELY AVOID COLLISION AND MOISTURE............................................ 23

8. MAINTENANCE.................................................................................. 23

9. OPERATION TO RESTORE THE FACTORY PARAMETERS...................... 25

10.CONFIGURATION.............................................................................. 26

3

1 Introduction

1.1 Scope of applications

Ultrasonic Thickness Gauge measuring with ultrasonic wave is

applicable for measuring the thickness of any material in which ultrasonic

wave can be transmitted and reflected back from the other face.

The gauge can provide quick and accurate measurement to various

work pieces such as sheets of board and processing parts. Another

important application of the gauge is to monitor various pipes and

pressure vessels in production equipment, and monitor the thinning

degree during using. It can be widely used in petroleum, chemical,

metallurgy, shipping, aerospace, aviation and other fields.

1.2 Primary Theory

The primary theory of measuring thickness with ultrasonic wave is

similar to that of measuring thickness with optical wave. The ultrasonic

wave emitted from the probe reaches the object and transmits in it.

When the ultrasonic wave reaches the bounding surface of the material, it

is reflected back to the probe. The thickness of the material can be

determined by accurately measuring the time of the ultrasonic wave

transmitting in it.

1.3 Measuring Principle

The digital ultrasonic thickness gauge determines the thickness of a part

or structure by accurately measuring the time required for a short

ultrasonic pulse generated by a transducer to travel through the thickness

of the material, reflect from the back or inside surface, and be returned to

the transducer. The measured two-way transit time is divided by two to

account for the down-and-back travel path, and then multiplied by the

velocity of sound in the material.

The result is expressed in the well-known relationship:

Where: H- Thickness of the test piece.

v- Sound Velocity in the material.

t- The measured round trip transit time.

v ×t

H =

2

4

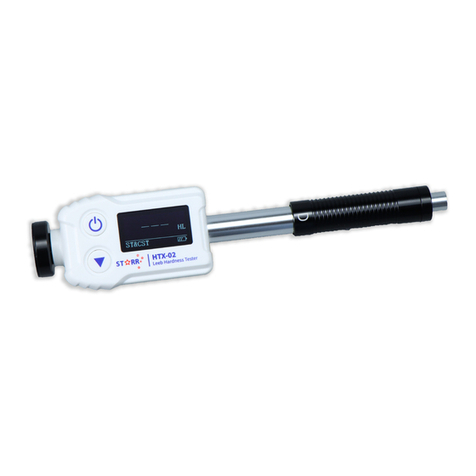

1.4 Appearance

1.5 Keyboard

Power ON/OFF ☼LCD backlight on/off

Sound velocity Save data / Browse data

Calibration standard block of 4.00mm Function selector

Adjusting sound velocity and thickness; key for moving menu cursor

Adjusting sound velocity and thickness; key for moving menu cursor

2-point calibration; to be used together with function keys.

1.6 Display symbols

THICKNESSGUAGE

Ultrasonic

5

2 Product Specifications

2.1 Technology parameter

Display: 128×64 LCD with LED backlight.

Measuring range: 0.75mm~300.0mm (0.03inch~11.8 inch)

Sound Velocity Range: 1000m/s~9999m/s (0.039~0.394in/µs

Display resolution: 0.01mm or 0.1mm (lower than 100.0mm)

0.1mm (more than 99.99mm)

Accuracy: ±(0.5%Thickness +0.02)mm, depends on Materials and

conditions

Units: Metric/Imperial unit selectable.

Lower limit for steel pipes:

5MHz probe: 20mm3.0mm (0.80.12 inch)

10MHz probe: 20mm3.0mm (0.60.08 inch)

Power Source: 2pcs 1.5V AA size, batteries.100 hours typical operating

time (LED backlight off).

Communication: RS232 serial port

Outline Dimensions: 150mm×74mm×32mm

Weight: 238 g

Four measurements readings per second for single point measurement,

Memory for up to 5 files(up to 100 values for each file) of stored values

2.2 Main Functions

1) Capable of performing measurements on a wide range of material,

including metals, plastic, ceramics, composites, epoxies, glass and other

ultrasonic wave well-conductive materials.

2) Transducer models are available for special application, including for

coarse grain material and high temperature applications.

3) Probe-Zero function, Sound-Velocity, Calibration function.

4) Two-Point Calibration function.

5) Coupling status Indicator showing the coupling status.

6) Battery information indicates the rest capacity of the battery.

7) Auto sleep and auto power off function to conserve battery life.

8) Optional software to process the memory data on the PC.

9) Optional thermal mini-printer to print the measured data via RS232

port.

6

3 Operation

3.1 Preparation for measurement

3.1.1 Insert the probe plug into the socket for the probe on the main

unit,

3.1.2 Press to turn on the instrument.

3.1.3 LCD will Display software editions information about the

instrument. And then display Latest sound velocity.

3.2 Adjusting sound velocity

If the current display is thickness, by pressing , you can come into

speed-of-sound state, and it will display content in current sound velocity

memory unit. The sound velocity memory unit will change once every time

when you press the VEL key, it can display 5 sound velocities alternatively. If

you hope to change the contents in the current sound velocity unit, you can

adjust that with or till reach the desired value, and then the value be

saved to memory.

7

3.3 Setting probe frequency

Press key to move the cursor to the position as that shown in the

following figure. Press to change the frequency setting. LCD will display in

sequence the probe frequency to be set 5M, 7M or ZW.

8

3.4 Measurement of thickness

First, set the sound velocity and then coat the coupling agent at the place

to be measured, couple the probe with the material to be measured, now

you can begin the measurement. The screen will display the thickness of

material to be measured. After you remove the probe, the thickness value

will be maintained, while the coupling indicator will disappear.

Note: when the probe is coupled with the material to be measured, the

instrument will display the coupling indicator; if the indicator flashes or

doesn't appear, it means that the coupling is not so good.

3.5 Zero calibration

Select the correct transducer frequency,The sound velocity adjusted to

5900m / s,While the gain is set to use when measuring the gain,Then the

probe with the case on 4mm standard test block and displayed good

coupling signs,Zero point calibration by the key. Instruments buzzer

about the same time, the screen instructions to complete the

calibration: calibrate zero done, That the calibration is complete, while

calibration data is stored in the instrument, If want to erase the

calibration data, please operate according to memory manage,

If the instrument before the keys are not well coupled with the

standard test block completion instructions or display calibration is not

succeed, the calibration instrument will retain the original value, the

screen display process as shown below:

9

Note: After every change of the probe, probe temperature, ambient

temperature changes, etc. After the work environment, or working for

some time after the discovery measurement errors should see the

standard test block measured value is accurate, if the difference would be

larger school Zero operation.

Calibrated display thickness may be bias 4.00 ± 0.02, now only shows the

calibration is complete instructions, without further calibration.

3.6 Measurement of sound velocity

The sound velocity of a material can be measured using a test piece with

given thickness. First, measure the test piece with caliper or micron

micrometer and read the thickness accurately. Couple the probe with the

test piece with given thickness till it displays a value, remove the probe,

then adjust the display to the actual thickness with or , press ,

now it will display the sound velocity to be measured. Save the value into

current sound velocity memory unit. For measuring sound velocity, one

must select a test piece with adequate thickness, and the recommended

min. wall thickness is 20.0mm. When measuring the sound velocity,

please turn off the min. capturing function.

For example: To measure the sound velocity of a material with a thickness

of 25.0mm, the procedure is:

10

3.7 Setting alarm thickness limits

The instrument will alarm if the measurement is out of limits. When the

measurement is lower than the low limit or higher than the high limit, the

buzzer will alarm. The alarming limit is set as follows:

1) Press , move cursor to ALARM.

2) Press display the low and high limit of previous setting, useor

to set the new low or high limit.

3) To exit the Limit Setting, press , , or start to measure.

3.8 Menu option

The setting and function of the instrument be handle in Menu option.

Press ,, move cursor to MENU then Press display main menu.

3.8.1 System Setup

1)

11

Measurement units: metric and Imperial

2) Receiving gain: LOW and HIGH

1. The LOW is mainly used for measuring coarse material

with high scatter and small sound absorption, such as cast

aluminum, cast copper and other metallic parts.

3) Display resolution: 0.1mm(LOW) and 0.01mm(HIGH)

4) Minimum capture measurement OFF and ON

1. To capture min.

measurement is to trap the

minimum value in a group of

measured values. When the

probe couples with the work

piece, it will display actual

measurement, when the

probe is taken away, it will

display the min. value of

measurement carried out a moment ago, and the MIN indicator

for the minimum value will flash several seconds. If you continue

the measurement when the MIN is flashing, the former

measurements will continue to take part in the min. value

capturing. If you carry out measurement after MIN indicator stops

flashing, the min. value capturing will begin from then on.

2. When the Min. capture function is ON, LCD will have MIN

indication

5) 2-Point Calibration: OFF and ON

1. Select two standard samples of the same material with

workpiece to be measured, among which, one has a thickness

equal to or slightly higher than the tested piece, and the thickness

of another test piece is slightly lower than the tested piece.

2. Before carrying out 2-point calibration, please turn off Min.

Capture function, perform the Erase CAL Data function in the

Memory Manager, and erase the former calibration record.

3. Set the 2-point calibration is ON.

4. Press , key return main display.

5. One can carry out 2-point calibration at any time during

measurement.

12

6. Press under thickness-measuring state to enter into 2-Point

CAL, the screen will prompt to

calibrate the thinner piece.

7. Measure the thinner standard test piece, use or to

adjust the measurement to standard value. Press ENTER, the

screen prompts to measure the thicker piece.

8. Measure the thicker standard test piece, useor to adjust

the measurement to standard value.

9. Press , the calibration operation is finished.

6) Auto Down : Power-saving mode ON(default)

7) Baud Rate: 1200;2400;4800;9600

8) Adjusting Display Brightness

1. Press select “Set brightness”:

2. Use or to adjust the display brightness.

3. Press exit setup.

3.8.2 Print function

Connect main unit with micro printer from by the communication

cable, print measured results through menu selection.

When the printing is completed, the buzzer will give out sound, the

display will return to MENU state.

Send data to PC:

Connect main unit with PC by using the communication cable, one can

13

send measured results through menu selection.

14

3.8.3 Memory Manage

Erase file: Clearing selected files

Erase all data: Clearing entire memory

Erase CAL data: Clearing calibrating data

4 Data logger operation

4.1 Logging readings into memory

The instrument divides the memory unit into 5 files. Each can save 100

measurement values. Before saving data, Please set file number first. If

you select the current file No., you can save the measurement directly by

pressing . The procedures for setting file No. are:

1) Use to move the cursor to the position shown in the following

figure:

2) Press , by pressing F1~F5 to display file No.s cyclically. You can exit by

pressing or conducting one measurement.

15

4.2 Reviewing stored thickness readings

1) Use to move cursor to the position shown in the following figure:

2) Pressing to brown the contents of memory. Press , erase current

data.

3) Pressing or review stored thickness.

4.3 Clearing current thickness Value

Under the state of Reviewing stored readings, press to erase a

saved value currently displayed.

5. Measuring technology

5.1 Cleaning surface

Before measuring, please clean any dust, dirt and rust on the object, and

remove any cover such as paint, etc. on it.

5.2 Improving requirement on roughness

Too rough surface will cause error in measurement. Before measuring,

please smooth the surface of object by grinding, polishing or filing, etc. or

use coupling agent with high viscosity for that.

5.3 Rough machined surface

The regular fine slots on rough machined (by such machines as lathe or

planer) surface will also cause error in measurement. The way for

compensating that is the same as that in 5.2. In addition, by so adjusting

the included angle between the probe’s crosstalk interlayer plate (the

metallic layer passing through the center of probe bottom) and the fine

slots of the object that the interlayer plate is perpendicular or parallel to

the fine slots, and by taking the min. value of the readouts as the

measured thickness, one can also get better results.

16

5.4 Measuring cylindrical surface

When measuring cylindrical material, such as pipes, oil tubes, etc., it is

very important to select properly the included angle between the probe’s

crosstalk interlayer plate and the axial line of the material to be measured.

Briefly to say, first couple the probe with the material to be measured,

make the probe’s crosstalk interlayer plate be perpendicular or parallel to

the axial line of the object, shake the probe vertically along the axial line

of the object, the readouts displayed on screen will change regularly.

Select the min. readout from displayed ones as the accurate thickness of

the object.

The standard for selecting the included angle between the probe’s

crosstalk interlayer plate and the axial line of the object is depending on

the curvature of it. For a pipe with large diameter, the probe’s crosstalk

interlayer plate should be perpendicular to the axial line of the object; for

a pipe with small diameter, one can measure with the probe’s crosstalk

interlayer plate being both parallel and perpendicular to the axial line of

the object, and take the min. readout as the thickness.

5.5 Compound profile

When the material to be measured has a compound profile (such as bend

of a pipe), one can use the way described in 5.4 to measure. The

exception is that one should have two analyses, get two results when the

probe’s crosstalk interlayer plate being both parallel and perpendicular to

the axial line of the object, and take the min. readout as the thickness.

5.6 Non-parallel surface

To get a satisfactory ultrasonic response, the other surface of the object

must be parallel to or co-axial with the surface to be measured, otherwise,

it will cause measuring error or even no display.

5.7 Influence of material’s temperature

Both the thickness and transmitting speed of ultrasonic wave are

influenced by temperature. If it has a high requirement on the measuring

accuracy, one can use comparison method by test pieces, i.e., use a test

piece with same material to measure under same temperature, and get

temperature compensation coefficient, and use this coefficient to correct

the actual measurement of the object.

5.8 Material with large attenuation

For some material such as fiber, with porous and coarse particles, they

will cause large scatter and energy attenuation in ultrasonic wave, which

17

will cause abnormal readouts even no display (generally, the abnormal

readout is less than actual thickness). In this situation, this kind of

material doesn't apply to be measured with this instrument.

5.9 Reference test piece

When making accurate measuring for different materials under different

conditions, the more the standard test piece is near to the material to be

measured, the more accurate the measurement is. The ideal reference

test pieces should be a group of test pieces with different thickness made

of materials to be measured, the test pieces can provide calibrating

factors for the instrument (such as the microstructure of the material,

heat-treating condition, direction of particles, surface roughness, etc.). To

meet the highest requirement on measuring accuracy, a set of reference

test pieces will be critical.

Under most situations, one can get satisfactory measuring accuracy with

only one reference test piece, which should have same material and

similar thickness with the object. Take an even object, measure it by using

a micron micrometer, then it can be used as a test piece.

For thin material, when its thickness is near to the low limit of the probe’s

measuring range, one can use test piece to determine the accurate low

limit. Never measure a material with a thickness lower than the low limit.

If the thickness range can be estimated, the thickness for the test piece

should select the high limit.

When the object is thick, especially for alloy with complex internal

structure, please select a test piece similar to the object from a group of

test pieces, thus to can have idea of calibration.

For most casting and forging, their internal structures have some direction.

In different direction, the sound velocity will have some change. To solve

the problem, the test piece should have an internal structure with same

direction as that of the object, and the transmitting direction of sound

wave in it should also be same as that for the object.

Under certain circumstances, look up the speed-of-sound table for given

materials can replace reference test pieces. But this is approximately to

substitute some test pieces. Under some situations, the value in the

speed-of-sound table will have some difference from the actual measured

values, this is due to difference in the material’s physical and chemical

characteristics. This way is usually used for measuring low-carbon steel,

and can only be taken as a rough measurement.

Thickness Gauge can measure sound velocity. Measure the sound velocity

18

first, and then measure the work piece with the measured speed.

5.10 Several measuring methods

a) Single measuring way: measurement at one point.

b) Double measuring way: measure with probe at one point twice. During

the two measurements, the probe’s crosstalk interlayer plate should be

placed in perpendicular direction, and take the min. readout as the

accurate thickness of the material.

c)Multi-point measuring way: make several measurements in a range, and

take the min. readout as the thickness of the material.

19

5.11 Selecting probes

Probe

Frequenc

y

Measuring range

Min. area

Application

5P 10

5MHz

1.0mm~300.0mm

(steel)

20×3mm

General

Straight probe

5P10/90

General bent probe

7P6 300

7 MHz

0.75mm~25.0mm

(steel)

15×2mm

thin work piece

ZW5P10

5 MHz

0.75mm~25.0mm

(steel)

30mm

high temperature

2P 14

2 MHz

3.0mm~300.0mm

(steel)

20mm

casting work piece

5.12 Changing probe

The wear of the probe’s interlayer plate will influence the measurement.

Please replace probe when the following situation happens.

1. When measuring different thickness, it always displays the same

value.

2. When plugging the probe, it has echo indication or measured value

display without measuring.

5.13 Measuring casting

It has specialty for measuring casting. The crystal particles for castings are

coarse, the structures are not dense enough, plus that they are in gross

state, which makes difficulty in measuring their thickness.

First of all, due to coarse crystal particles and not-so-dense structure, it

will cause large attenuation in sound energy. The attenuation is due to

material’s scatter and absorption of sound energy. The attenuation

degree is closely relative with the size of crystal particle and ultrasonic

frequency. Under the same frequency, the attenuation will increase with

the crystal diameter, but it has a high limit, when it reaches to this limit, if

the crystal diameter increases, the attenuation will tend to be a fixed

Table of contents

Other Starr Instruments Measuring Instrument manuals