Innotech MT01 User manual

© MASS ELECTRONICS Pty Ltd 2008

Models:

MT01 240V 4 Channel Time Switch with Optimum Start

DS 11.01

August 2013

MT01

MAXTime

Application

The MAXTime can be used in a variety of situations that require

automatic on/o scheduling. Its optimum start functionality make it

particularly useful for Air Conditioning applications.

• Air Conditioning scheduling

• Optimum Start Function reduces power consumption

• Automatic Security Light activation

• Timed control of Plant and Equipment

• Internal Aer Hours Timers

Overview

The Innotech MAXTime is a 4 Channel programmable 365 day

time switch with optimum start capabilities. Its applications

include air conditioner plant scheduling and usage

optimising, lighting, security and virtually any application that

requires events to occur at a scheduled time.

Features

• 4 Independently programmable Relay channels with 10Amp

@ 240VAC Capability

• Aer Hours capability on all channels

• 4 line, 80 character backlit Liquid Crystal Display

• Optimum Start on All Channels with Thermistor inputs

• 32 On/O Weekly Events per Channel

• 20 On/O Yearly Events per Channel

• 20 On/O Master Yearly Events (All Channels)

• User Programmable Aer Hours Timer

• Current Time and Date (Battery Backed)

• Aer Hours Usage Log (Battery Backed)

• Automatic Daylight Savings Adjustment

• All Configuration and Schedule Data is stored to non-volatile

memory

• Calibration function for Thermistor inputs

• Operates on 24 or 240VAC

• DIN Rail mountable

Approvals

The Innotech MT01 conforms to:

• Electromagnetic emission and immunity requirements

according to standards EN55011 (CISPR11) and EN50822 for

RCM Labelling

• Designed and tested in accordance with IEC61010-1, Edition

3.0:2010 Safety Standard

© MASS ELECTRONICS Pty Ltd 2008

Page 2

DS 11.01 - MT01 - MAXTime

August 2013

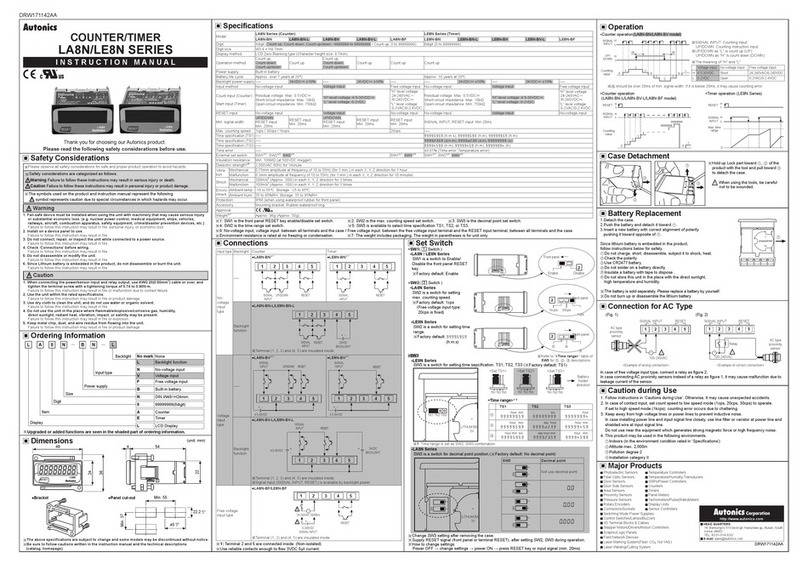

Specifications

Power Supply

• 240VAC + 10% @ 50/60Hz OR

• 24VAC + 10% @ 50/60Hz

• Power Consumption: 7VA Max

When powered by 24 VAC, the operating voltage must meet the

requirements of safety extra low voltage (SELV) to EN 60730

terminals.

Sensor Wiring

1. Do Not connect 24V or 240VAC to “IN+ or IN-” terminals.

2. Screened cable should be used between the sensor and the

MT01. The screen is terminated to the IN- terminal.

3. The temperature sensor is connected between the “IN+ and

IN-” terminals.

Temperature Ratings

• Storage: 0 to 50°C non-condensing

• Operating: 0 to 40°C non-condensing

Enclosure & Mounting

The Innotech MAXTime is housed in a rectangular case suitable for

DIN Rail mounting. The housing is moulded from flame retardant

plastics recognised by UL as UL 94-V0.

Colour: Grey

Dimensions (max): 89mm (l) x 107mm (w) x 69mm (d)

Installation

• The MAXTime should be mounted on DIN rail in cabinets

approved for switchgear or industrial control equipment. It

should be mounted in a dry and clean location, free of excess

vibration. Maximum terminal cable entry is 1.5mm wire.

• Wire in accordance with Innotech connection diagrams and local

bylaws or refer to your local distributor.

Both a 240VAC supply and a 24VAC supply should NEVER be

connected at the same time.

Outputs

• 4 x 10A @ 240 VAC Relays, Normally Open.

Inputs

• 4 x 10K NTC Thermistor / Dry Contact Digital Inputs Thermistor

Input Range: 0°C to 50°C

• The Controller can be configured for use in any one of the four

options shown in the table below:

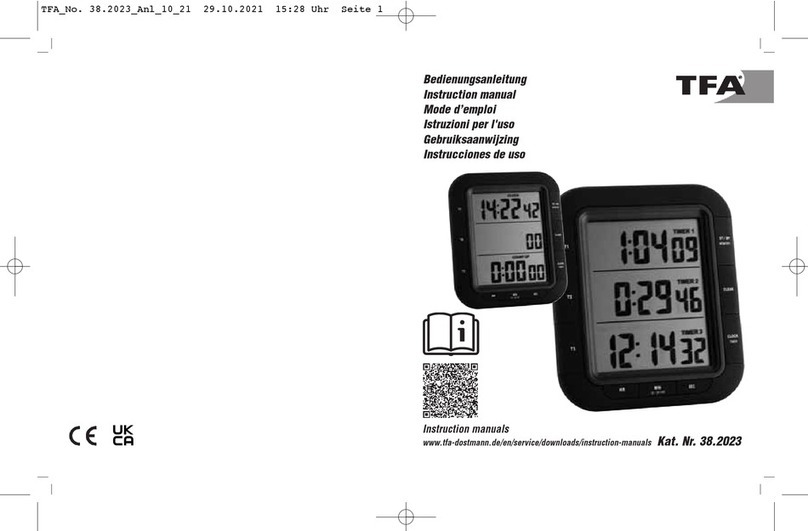

Interface

The interface of the MAXTime comprises of a 4 line, 80 character

backlit Liquid Crystal Display (LCD) with Directional Cursor Keys,

Escape (#) and Enter keys. A menu system with on-screen user

instructions ensures ease-of-use.

The Default screen of the display shows the current time and status

of all relay channels. Pressing Enter on the keypad will take the user

to the menu system where schedule and configuration changes can

be made. The display always returns to the default screen if no keys

are pressed within two minutes.

The Schedule Menu allows the user to Add, Edit or Delete Weekly

and Yearly Schedules. Weekly Schedules require a Start and Stop

time in Hours, Minutes and Day of Week. Yearly Schedules require a

Date, Month and Year. The Yearly schedule will override all weekly

schedules from 0:00 of the Start Date to 24:00 of the Stop Date. i.e. A

Weekly Schedule for Monday 9:00 to Monday 17:00 on Relay Channel

1 will activate that relay every Monday between 9:00 and 17:00. If

however, a yearly exception schedule set to Start on 2nd September

2002 and Stop on the Same day, will override the Weekly Schedule to

o, since 2nd September 2002 is a Monday.

In addition to the Individual Yearly Schedules for each channel,

Schedules entered into the Master Yearly Schedule will override all

weekly schedules on all channels. This is a convenient way to add

holiday periods to all channels instantly.

Input Configuration

MT01

Option Optimum Start Sensor Aer Hours Push Button

1

2

3

4

This product should only be installed by qualified personnel.

© MASS ELECTRONICS Pty Ltd 2008

Page 3

DS 11.01 - MT01 - MAXTime

August 2013

Aer Hours

The Aer Hours features can also be accessed from the

Schedules menu. This screen will display the Time remaining for

any channels where the aer hours function has been activated.

The Total accumulated hours of Aer hours usage for each

channel (battery backed log) and the Aer Hours delay can be

adjusted by the user in 15 minute intervals from 15 minutes to 8

hours.

The Aer hours timer cannot be activated if that channel is

currently activated from a schedule. Also, if the Aer hours

timer is triggered prior to the start of a scheduled event, the

Aer hours log will accumulate only for the time used outside

the schedule.

To reset the accumulated Aer hours log for a particular

channel, press and hold the ENTER Key for 5 seconds while

the accumulated time is displayed. The Aer hours log for that

channel will then be reset back to zero.

The Clock Menu allows Setting of the System time and the

Daylight Saving Parameters. When the System time reaches

the calculated Daylight Saving Start Date, the System time will

advance by one hour. When the System time reaches calculated

Daylight Saving Stop Date, the System time will retard by one

hour. Both the System time and Daylight Saving Parameters are

battery backed and will be retained in the absence of a supply

voltage.

The Calibrate menu can be used to view the measured

temperature when a thermistor is connected to any of the input

terminals. The measured value can then be adjusted by an oset

value which will change the measured temperature as seen by

the optimum start algorithm.

Optimum Start

The Optimum start (OptStart) menu is used to configure parameters and

enable/disable the optimum start control algorithm. When enabled, the

optimum start will aect all schedules for that channel. The optimum

start parameters are:

1. Setpoint

Desired temperature to be achieved at occupied time (scheduled

start time).

2. Alpha

A smoothing filter applied to changes to the optimum start output.

3. Deadband

This defines the total temperature deadband.

4. Heat Value

This is a parameter of the building the optimum start is used in.

The optimum start uses this value to estimate the time required to

start heating before scheduled time. Each time the optimum start

runs, it will recalculate this value and apply the alpha value from

parameter 2. This parameter is in °C/Hour since it is the number

of degrees Celsius that the air conditioning plant can heat the

building within one hour.

5. Cool Value

As per Initial Heat except applies to cooling.

6. Maximum Prestart

In minutes - This is the maximum number of minutes the optimum

start is allowed to start before the scheduled time.

© MASS ELECTRONICS Pty Ltd 2008

Page 4

DS 11.01 - MT01 - MAXTime

August 2013

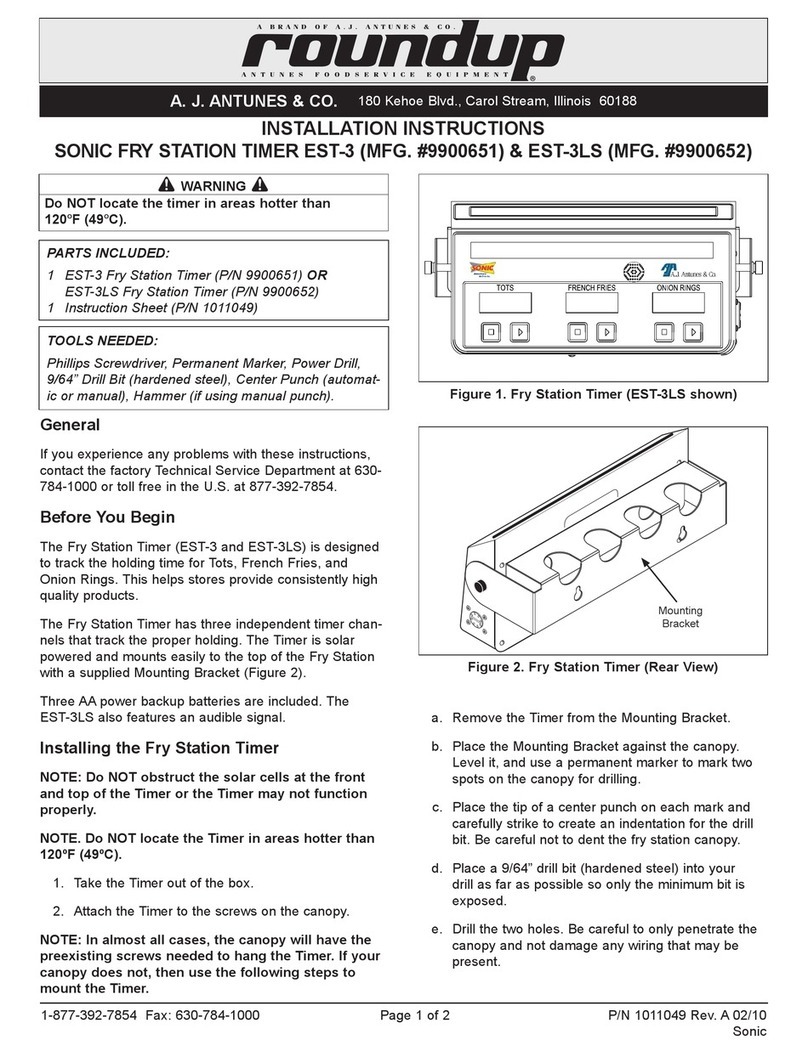

1. Never touch the I/O terminals while power is being supplied.

2. Never attempt to disassemble the unit while power is being supplied.

3. Emergency stop circuits, limit circuits, interlock circuits and similar safety measures must be provided.

4. The TIMESWITCH outputs may remain On or O due to burning or deposition of the output relays.

External safety measures must be provided for such problems to ensure safety in the system.

5. Follow Innotech wiring diagrams and the installation / wiring instructions contained in this Datasheet.

The following describes potentially hazardous situations which, if not avoided,

could result in death, serious or minor injury, or property damage.

CAUTION

24VAC Supply

*

Relay Output 1

Relay Output 2

Relay Output 3

Relay Output 4

Thermistor/Digital Input

*

Use only 240VAC OR 24VAC, NOT BOTH!

Thermistor/Digital Input

Thermistor/Digital Input

Thermistor/Digital Input

INPUT WIRING

SENX

SERIES SENSOR

FOR OPTIMUM

START (IF USED)

IN1 - IN4

+

-

VOLTAGE FREE

NORMALLY OPEN

MOMENTARY PUSH BUTTON

FOR AFTER HOURS (IF USED)

YOUR DISTRIBUTOR

Australian Owned, Designed & Manufactured

by Mass Electronics Brisbane

Phone: +61 7 3421 9100 Fax: +61 7 3421 9101

Email:

[email protected] www.innotech.com.au

The INNOTECH device and the word INNOTECH are registered or unregistered trademarks of Mass Electronics Pty Ltd in Australia, USA and other countries

This manual suits for next models

1

Popular Timer manuals by other brands

Delta

Delta DE212 GLOBAL installation manual

GardenMate

GardenMate Easy Dial operating instructions

Green Brook

Green Brook T17B Installation & operating instructions

Timeguard

Timeguard ETU17 Installation & operating instructions

Silvercrest

Silvercrest TE-10 Operation and safety notes

Skytech

Skytech TM-R-AF1 Installation and operating instructions

Aqua Control

Aqua Control Clicker quick start guide

Delta

Delta GT-ZSm-01 Essantials user guide

Danfoss

Danfoss 811 User instructions

Interspace Industries

Interspace Industries CountDown Touch user manual

Intermatic

Intermatic Grasslin Talento Smart B10 mini operating manual

Intermatic

Intermatic DT620 Series Installation and user instructions