Inomatic AMTEK Series User manual

AMTEK

150/250/350/450/750

Operation Manual

58kHz Acousto-Magnetic EAS System

valid for

AM Pro-Line electronics TX/RX/Mono

Hardware Version AMPRO 700 V7.4, Firmware Version AMP 3.1

AMTEK Version 7.4 2019-01 Page 2 ©Inomatic 2017-2019

SAFETY GUIDELINES

Any manipulation of the system should be done by qualified and

trained personnel only.

Do not open the AMTEK system’s power supply when connected to

power! High voltage!

Make sure the power supply is properly connected to mains PE

Do not touch the antenna wire or matching circuit when connected to

power! High voltage!

Before changing blown fuses or manipulating the antennas, always

disconnect from 230V power source first!

Do not plug in or out the power supply cables to or from the processor

board unless the power supply is switched off!

Do not insert or take-out any jumpers unless the power supply is

switched off!

Route the RX-TX cable and power supply cables through places where

they cannot be easily damaged!

Do not use the system in water condensing conditions!

Do not use the system in explosive environmental conditions!

AMTEK Version 7.4 2019-01 Page 3 ©Inomatic 2017-2019

F40 tag

Mini Pencil

Super tag II

APX (DR) label

1. INTRODUCTION

1.1. System Description

The “AMTEK”range of Acoustomagnetic EAS Systems is fully compatible with all

58 kHz tags and Acustomagnetic labels on the market. The systems are designed to get

optimum detection performance and to avoid false alarms at the same time, by using

digital signal processing and anti-noise algorithm.

The AMTEK Pro-Line antennas with AMPRO V 7.4 electronics can be operated as

“Mono”or “TX”antenna (setting via infoNet V5 onwards)

1.) Single Mono antenna

2.) Multi Mono antennas

3.) Dual system 1 Processor TX and 1 Receiver antenna

4.) Split system 1 Processor TX and 2 Receiver antennas

Working principle “Mono”:A 58 kHz pulsed magnetic field is generated by the

Processor antenna. The Processor antenna is using the same loops for transmitting the

58KHz TX pulses and for receiving the tag/label signal. Any 58 kHz AM label or hard tag

brought into the magnetic field will generate a signal which can be detected in the receiver

mode and subsequently trigger an alarm signal.

Working principle “TX”: A 58 kHz pulsed magnetic field is generated between the

Transmitter (TX) antenna and one or two Receiver (RX) antennas. Any 58 kHz AM label

or hard tag brought into the magnetic field will generate a signal which can be detected

by the Receiver antennas and subsequently trigger an alarm signal.

AM Hard Tags and Labels

AMTEK Version 7.4 2019-01 Page 4 ©Inomatic 2017-2019

Typical System Performance

Depending on the AM tags used and the installation environment, the detection distance

can vary. The following table gives an overview of typical detection ranges with the

different AMTEK systems and security elements.

Distances(m)

AMTEK 350 Mono

AMTEK 350TX/RX

F40 tag

1.40

2.70

Mini Pencil

1.20

2.20

Super tag II

1.10

2.00

DR label

1.10

2.00

1.2. Additional Features

All Version AMTEK V7.4 Processor antennas are equipped with 2 additional alarms that

allow an easier handling of certain situations.

The Jammer alarm indicated that the system is compromised by a jammer signal.

The alarm light and buzzer sequence for Jammer alarm can be set via InfoNet software.

In this case the detection of the system is disabled to avoid false alarm.

The Near Tag alarm is triggered by a continuous detection of a stationary security

element in the detection zone. The alarm light and buzzer sequence for Jammer alarm

can be set via InfoNet software. By enabling the Near Tag alarm, one can easily detect

tags that have accidentally been placed inside the system’s detection area.

Both of the above described alarm features can easily be enabled/disabled by activating

the respective checkbox inside the InfoNet software.

Programmable on/off time:

The system can be automatically switched on/off at certain times. The time for ON and

OFF can be set via the InfoNet software. The system will consume much lesspower during

OFF time (Energy saving)

AMTEK Version 7.4 2019-01 Page 5 ©Inomatic 2017-2019

Incoming/outgoing alarm (only with integrated visitor counter):

The system is able to distinguish between incoming and outgoing alarm if equipped with

the optional integrated visitor counter. The alarm indication is different for the two types

of alarms allowing easy identification of incoming and outgoing alarm.

Firmware update:

If a new firmware becomes available, the processor’s firmware can be updated via the

InfoNet software allowing update of new system features without replacing the

electronics.

Selection of light/sound sequence:

The system alarm light and sound can be programmed in different sequences. Different

aisle could have different sound sequence enabling the identification of where the alarm

came from. It is also possible to have the alarm light on longer than the alarm sound to

easily identify the alarm position. For multi aisle installation this feature is especially

useful.

Remote Tuning/Service/Monitoring

In order to reduce the need for service calls, especially for remote places, our PRO-

LINE systems can be accessed via Internet. The system service provider can log-in

from their office into the system via infoNet Cloud (provided they are authorized) and

diagnose/solve potential problems.

Integrated bidirectional visitor counter

Possibility to count customers per aisle and to determine the direction of

movement (in or out of the shop)

Showing the importance of the alarm (is a customer moving in or out during the

alarm)

Detecting undefined alarms

Pinpoint the exact aisle where the alarm occurred

Generate reports on visitor counts and alarm counts

AMTEK Version 7.4 2019-01 Page 6 ©Inomatic 2017-2019

2. AMTEK SYSTEM

2.1. Component Overview

The standard Mono system comprises the following components:

a.) Processor Board AMPRO 700V7.4

b.) Power Supply AMPSS 700V6 or higher

c.) Antenna AMTEK 150/250/350/450 or AMTEK 750

d.) Computer Cable LAN Cable AMCOM 710

e.) infoNet Software infoNet V5.0 or higher

2.1.1 Specifications:

Transmitter Operating Frequency 58 kHz (±200Hz)

Transmit Burst Duration 1.5ms or 1.6ms (can be set in InfoNet)

Max. Transmit Current 16A peak

Transmitter Coil Resistance 2 ohm (±5%)

Burst Repetition Rate 50Hz (60Hz)

Receiver Center Frequency 58 kHz

Alarm Audio level 97dBA

Environmental Ambient Temperature 0°C to 50°C

Relative Humidity 0 to 90% (Non-condensing)

Please note that the Version 7.4 processor board hardware can come with

different Firmware Versions. Please check the label on the processor if you are

not aware of your board’s firmware version.

AMTEK Version 7.4 2019-01 Page 7 ©Inomatic 2017-2019

2.2. AM Processor Board AMPR 700V7.4

The picture below shows a top view of the Processor board. Table 2.2 lists the board’s

relevant connectors and tuning components together with their functions.

J17

Reset

S1

X3

X5

Matching upper coil

Matching lower coil

X6

X7

X1

X2

BT1

J14

J15

J16

X4

P1

R82

LAN

1

H19

H20

H21

H17

H18

H14

H15

H16

H11

H12

H13

H1

to

H5

H6

to

H10

LAN

2

Picture 2.1 - Processor board V7.4 top view

J1 to J6

J7 toJ12

TX1 TX2

AMTEK Version 7.4 2019-01 Page 8 ©Inomatic 2017-2019

Table 2.2 Processor board's relevant components for connection and tuning

Component

Function

Component

Function

X1 & X2

Powers supply

RC1

Receiver channel 1

X3

Upper TX loop connection

RC2

Receiver channel 2

X4

Lower TX loop connection

TX1

LED bar for upper TX loop

X5

LED Alarm Lights

TX2

LED bar for lower TX loop

X6

Relay output NO contact

LAN1

Switch port 1

X7

Buzzer connector

LAN2

Switch port2

Reset

Reset of the processor

S1

Not in use

J14

Download Firmware

H19

12V power supply

J15

Master/Slave selection

H20

5V power supply

J16

Factory use

H21

3.3V power supply

J17

Sync bus termination

H14

Indicator for Internet

BT1

Real Time Clock battery 3V

H15

Flashing Normal Operation

R82

Buzzer Volume

H16

Indicator for Master/Slave

H17

H11 –H13

LAN switch indicators

H18

H14 –H16

LAN Data indicators

Jumpers 14 (Download Firmware)

The firmware of the AM Processor

board V7.4 can be updated via the

infoNet V5 software.

For more details see Software Manual

LED Light connector X5

The AM Pro-line V7.4 board allows the connection of a two color LED top-light.

GND

12V

LED1 (ON LED, active low)

LED 2 (Alarm LED, active low)

Maximum current for LED1 and LED 2 is 200mA

1

2

Normal Operation

Download Firmware

J14

AMTEK Version 7.4 2019-01 Page 9 ©Inomatic 2017-2019

Indicator LED’s

LAN/SYNC LEDs

H11 LAN port ready LED ON

H12 if LAN 2 is connected LED ON

H13 If LAN 1 is connected LED ON

H14 If the board has Internet access LED ON

H15 If sync pulse from power supply/ hardware sync LED blinking

H16 If the board is set as Master LED ON. If Salve LED OFF

H17 LAN ok LED blinking

H18 LAN ok LED ON

Power LEDs

H19 12VDC power LED ON

H20 5VDC power LED ON

H21 3.3VDC power LED ON

H11

H12

H13

H14

H15

H16

H19

H20

H21

H17 H18

AMTEK Version 7.4 2019-01 Page 10 ©Inomatic 2017-2019

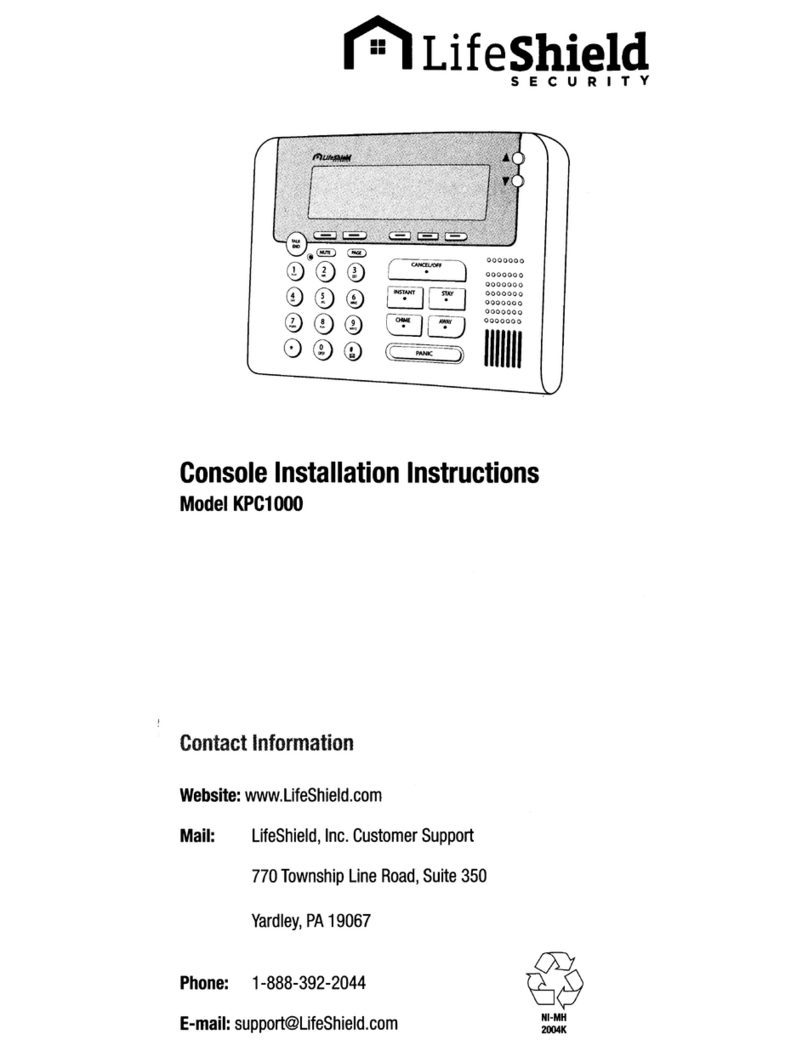

2.3. Receiver Board AMRB 700V5.3

Picture 2.3 below shows the RX board and the relevant components:

Each RX board controls the resonance of two loops in the RX antenna. The matching for

the upper and lower receiver loop can be adjusted through the 2 rotary switchesTW1 and

TW2. TW1 adjusts the matching for the upper loop and TW2 adjusts the matching of the

lower loop.

In this case, the RX matching can be modified for the upper and lower loop using the

rotary switches TW1 and TW2.

X2 - Lower receiver

loop connector

X1 - Upper receiver

loop connector

X4 - Alarm Lights

X3 –Integrated

Visitor counter&

Alarm light

X6 - Connector to

Processor board

TW2

TW1

CS1

All our antennas are pre-tuned in the factory and RX antenna matching WILL NOT

HAVE TO BE ADJUSTED in almost any case. When installing the system near

metallic frames or metallic doors, resonance value may be affected.

X5 –Buzzer

connector

R28–Buzzer Vol.

AMTEK Version 7.4 2019-01 Page 11 ©Inomatic 2017-2019

LED Light connector X4

The AM Pro-line V5 Receiver board allows the connection of a two color LED top-light.

GND

+12V

LED1 (ON-LED, active low)

LED2 (Alarm, active low)

Maximum current for LED1 and LED 2 is 200mA

2.4. RX-TX-Connection Cable AMCTR 710

The AMCTR 700 connection cable is supplied together with

the RX antenna. It connects the receiver board with the

processor board of the TX pedestal. Connect one end of the

cable to the RX board (X6) and the other end to the TX board

(RC1 or RC2).

To avoid noise capturing, the connection between the RX

and TX antenna should be as short as possible.

AMCTR 710 Connection Cable

AMTEK Version 7.4 2019-01 Page 12 ©Inomatic 2017-2019

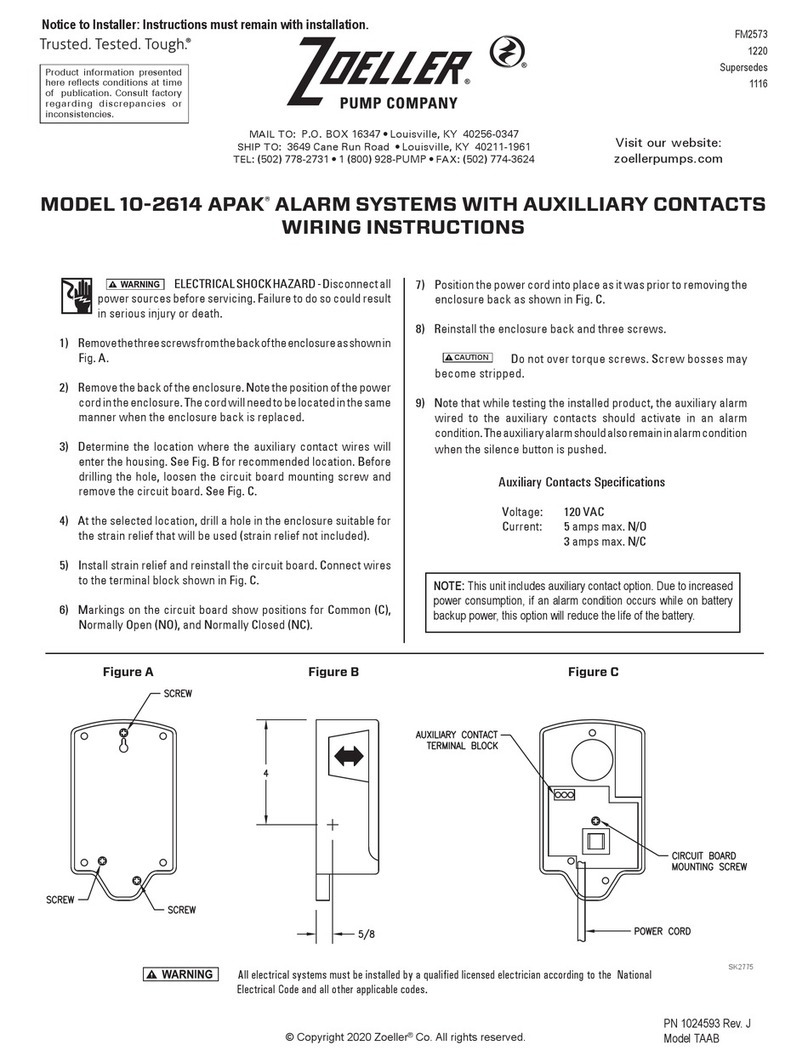

2.5. Dual Power Supply AMPSS 700V6 (50VDC, 43VAC)

The Dual power supply AMPSS700V6 is used for all our AM systems using V4, V6 or

V7 processor boards. It provides the power and the Synchronization signal to the

system electronics for maximum 2 TX antennas.

Technical specifications for AMPSS 700

Dimensions (L x W x H)

210 x 150 x 70 mm

Weight

3.0 kg

Input voltage / frequency / current

230VAC / 50/60Hz / 500mA

(on request 110VAC / 50/60Hz)

Mains inlet type

AC IEA with ON/OFF switch

Output voltage

50 VDC and 18VDC

Output cable

5x1mm2, 8m length. This cable can be

extended to 15m using a 3x1mm2cable or

thicker.

Temperature range

0 –50C

Primary fuse (FP)

230VAC –1A slow , 110VAC –2A slow

Secondary fuses:

(Inside the housing)

F1 (50V, 3A), F2 (18V, 2A), F3 (18V, 2A)

F4 (50V, 2A), F5 (18V, 2A), F6 (50V, 2A)

X1

Power Processor board 1

L1

50VDC (LED red/blue)

L2

18VDC (LED red/blue)

X2

Power Processor board 2

L3

50VDC (LED red/blue)

L4

18VDC (LED red/blue)

If any LED lights “red” means the respective voltage is missing

AMPSS 700 V6 power supply

L1 L2 X1 X2 L3 L4

AMTEK Version 7.4 2019-01 Page 13 ©Inomatic 2017-2019

To operate the power supply, connect the power

supply via the main power cable to a 220V (110V)

power outlet and switch on the main switch SM.

Make sure the “Earth” of the power plug is connected

to the power socket.

The AMPSS700V6 has 2 system power outlets (X1 and X2)

The output cable of the power supply is connected to the processor board through

1 x 3 pin and 1 x 2 pin connectors.

If the connector needs to be removed for some reason, the color code of the cables

must be observed. To avoid damages to the power supply and to the system electronics

replace the fuse with the same kind of fuse if necessary.

If any fuse needs to be changed always unplug the power supply

from the AC source first.

Always connect the power supply to the system first before switching on

the power supply.

Always switch off the power supply first before disconnecting the power

supply to the system.

Local laws and regulations must be respected when installing and

servicing this device

FP

AMTEK Version 7.4 2019-01 Page 14 ©Inomatic 2017-2019

2.5.1 Power supply cable/connector

V7.4 Processor board Power supply V6 (X1 or X2)

Please note that the power supply cable between the power supply and the

processor board should not exceed 15 meter.

The AMPSS 700V6 was designed to power our new AM antenna generation

whit AWG 20 antenna wires which require reduced loop voltage.

Operating the TX antennawith a higher voltage (> 50VDC) may result in higher

matching voltage which can damage the board.

RED 50VDC

BLACK GND

BLUE 18VDC

YELLOW GND

BROWN Sync

RED 50VDC

BLACK GND

YELLOW GND

BROWN Sync

BLUE 18VDC

AMTEK Version 7.4 2019-01 Page 15 ©Inomatic 2017-2019

2.6. System Configurations

2.6.1 Single Mono Antenna (AMPRO 700V7.4 configured as “Mono”)

Single Mono Configuration

LED light

LAN Cable

To X1 &2

Buzzer output

Relay Output

AMPSS 700

AMTEK Version 7.4 2019-01 Page 16 ©Inomatic 2017-2019

2.6.2 Multiple Mono Antennas (AMPRO 700V7.4 configured as “Mono”)

The AM power supply V6 allows the connection of up to two AM Processor antennas.

Hardware synchronization might be necessary, if 2 or more AM Processor antennas are

used.

Multi Mono antenna Configuration

LED light

LED light

LED light

AMPSS 700

AMPSS 700

Hardware sync

To X1 & X2

To X1 & X2

To X1 & X2

AMTEK Version 7.4 2019-01 Page 17 ©Inomatic 2017-2019

2.6.3 Single TX Antenna ((AMPRO 700V7.4 configured as “TX” Dual system)

One processor board (TX) can drive one or two RX antenna(s), thus resulting in two

configuration modes: “Dual and Split system. The following gives a schematic overview

about the necessary components and connections for both configurations.

LED light

LED light

TX antenna

RX antenna

AMPSS 700

AMCTR 710

To X1 & X2

Shop -LAN

LAN Port

AMTEK Version 7.4 2019-01 Page 18 ©Inomatic 2017-2019

2.6.4 Single TX Antenna ((AMPRO 700V7.4 configured as “TX” Split system)

To reduce any noise influence, make sure:

1.) To place the power supply as close as possible to the TX antenna.

2.) To have the connection between the RX and the TX antenna (AMCTR 710

Connection Cable) as short as possible.

Hardware synchronization might only be necessary, if 2 or more TX antennas are used.

RX antenna

RX antenna

LED light

LED light

LED light

TX antenna

To X1 & X2

AMPSS 700

AMCTR 710

AMCTR 710

Shop -LAN

LAN Port

AMTEK Version 7.4 2019-01 Page 19 ©Inomatic 2017-2019

3. SYSTEM INSTALLATION

This chapter covers the various issues related to Acoustic Magnetic systems and

Electronic Article Surveillance systems in general, like:

Noise sources

Installation guidelines

3.1. Noise sources

Below there are various noise sources listed that might affect the performance of any

EAS system. It is strongly recommended to either eliminate these noise sources (as far

as possible) or maintain the largest possible distance to these noise sources.

The following devices can create or absorb AM noise signals which can reduce the

performance of an EAS system:

AM systems installed in other shops (even if they are installed up to 100m or

more away from your store).

Any electronic device that operates around 58kHz or produces harmonic

frequencies around 58kHz.

An active laptop. The back light in the screen can create a lot of noise which is

detected by the EAS system and can reduce the performance dramatically. Make

sure to keep laptop computers at least 3 meters away from the antennas.

(Moving) Objects containing metal, like sliding and revolving doors, elevators,

escalators, roller shutters, frames, etc.

Electronic devices, like computers, laptop screens, LCD screens, cash registers,

engines, transformers, etc.

Vertically positioned power cables, both low voltage and high voltage.

Lights (flashing, fluorescent, halogen, gas-de-charge, etc.)

Metal scan systems installed in close vicinity.

AMTEK Version 7.4 2019-01 Page 20 ©Inomatic 2017-2019

3.2. Installation Requirements

Make sure all parts have arrived. Make sure there are no damaged parts. If there

is any damaged part, notify the transport company.

Installation shall be performed by a qualified installer with all necessary

national/local electrical/fire codes training.

If possible, connect the Processor / RX antenna and put them in the required

position in the entrance/exit without drilling holes in the floor and bolting the

antennas down. Switch on the system and test the performance. In this way the

noise level and system sensitivity can be determined and if necessary (in case of

high noise or poor sensitivity) the system can be moved to find a better position

The pedestals shall be placed at a distance equal to or smaller than the maximum

value depending on the kind of tag.

Avoid placing the Processor / RX pedestals near metallic structures (doors, frames,

etc...) or neon/discharge lamps.

Always install the TX antenna on that side where the highest noise is or where

the highest noise can be expected.

Metal framed doors may never swing between the EAS antennas, as this will

distort the energy field of the system in such a way that it might result in high

noise, poor detection and potential false alarms

Not connected RX antennas nearby a running system are to be avoided. They act

as a big hard tag.

Avoid unnecessary long cables. Run the power supply cables in a direct line to

the EAS antennas. Never run power supply cables vertically up the wall within

one meter distance of the antennas (never around the entrance/exit doorframe).

The AC source should be a clean AC source. If possible do not share the AC

source with computers, neon lights/discharge lamps, or equipment with switching

power supplies, make sure the “Earth” of the power supply plug is connected to

the power supply socket.

Blown fuses shall be replaced with fuses of the same kind.

ALWAYS UNPLUG power supply BEFORE CHANGING blown fuses!

This manual suits for next models

5

Table of contents