Inorea PB6014 User manual

12.09.2019 http://www.inorea.com

2

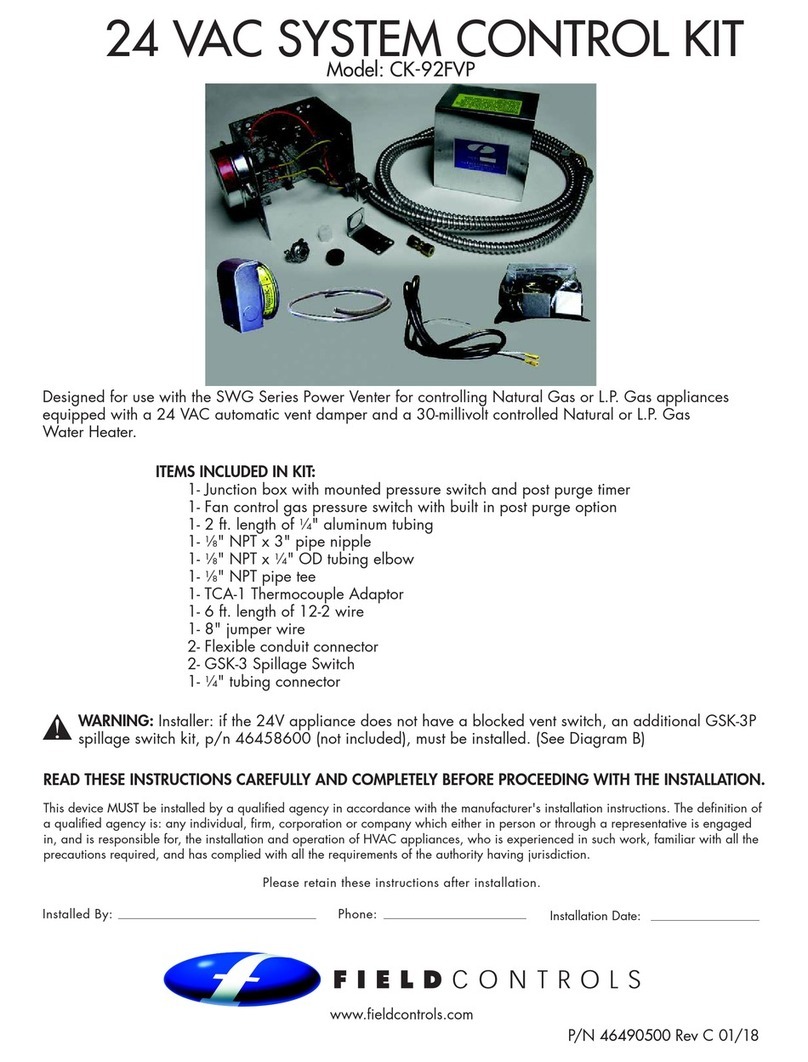

QUICK START GUIDE : Brakeunit extern

SUMMARY

1. FOREWORD...................................................................................................................................... 3

2. PRECAUTION.................................................................................................................................... 4

3. INSTALLATION ................................................................................................................................. 6

3.1. Conditions for use ................................................................................................................... 6

3.2. Sharp size................................................................................................................................. 6

3.3. Main Circuit specification........................................................................................................ 8

4. FUNCTION PARAMETER DESCRIPTION............................................................................................ 9

5. SINGLE UNIT RUNNING.................................................................................................................. 10

6. PARALLELED RUNNING.................................................................................................................. 10

6.1. Host and slage select of function setting .............................................................................. 11

6.2. Host and slave control connection........................................................................................ 11

7. VOLTAGE SET AND CALCULATION................................................................................................. 11

7.1. Why brake voltage 670V ?..................................................................................................... 11

7.2. PB60 brake unit characteristic :............................................................................................. 12

7.3. Brake unit function :.............................................................................................................. 12

7.4. Brake current calculation : .................................................................................................... 12

7.5. Brake resistor calculation and selection :.............................................................................. 13

7.6. Brake unit safty limit ............................................................................................................. 13

8. FAULT DIAGNOSIS AND SOLUTIONS.............................................................................................. 14

9. STANDARD SPECIFICATION............................................................................................................ 14

9.1. Model specification............................................................................................................... 14

9.2. Model designation................................................................................................................. 15

9.3. 400V specification and selection reference .......................................................................... 15

9.4. Brake resistor selection......................................................................................................... 15

12.09.2019 http://www.inorea.com

3

QUICK START GUIDE : Brakeunit extern

1. FOREWORD

Thank you very much for purchasing Inoréa Brake Unit.

Please read the manual carefully before the installation of the product in order to ensure that it can

be correctly installed and operated.

The function of brake unit and brake resistor is to feed back the regenerative consumption of motor

to the brake resistor when the motor decelerates, enhances the brake capability of the inverter,

ensures the motor to stop in a short time in the setting time. This product is not only suitable for Inoréa

inverter but also to all other brand inverters.

User could select the right capacity brake unit according to the inverter’s capacity and brake capability.

Please keep this user’s manual in good condition, for it will be helpful to the repair, maintenance, and

applications in the future.

12.09.2019 http://www.inorea.com

4

QUICK START GUIDE : Brake unit extern

2. PRECAUTION

Please read the manual before the installation, operation and inspection of the product. For the safe

operation, remind you to pay special attention to the “Warning” and “ could lead to life harm or

private loss !

*Attention : Attention” in the manual.

*Attention : The potential danger will lead to slight or medium life harm or equipment damage. It

could also warn the violate operation.

WARNING

The potential danger

●Do not use any brake unit and brake resistor lack of or with damaged spares.

●Do not touch the internal spares for there are CMOS spares on the control card of the brake

unit. Otherwise it will damage the spares.

●Please add the fan or other cooling equipment when multiple brake units installed parallel in

the onecabinet.

●Ensure the right setting of brake unit and brake resistor.

●Do not make voltage resistance test on the brake unit, or it will lead semiconductor spares

damaged in the main circuit of the brake unit.

●Fix the srew when connecting, or the loose connection will lead fire or creepage.

●Do not touch the brake unit, the internal spares and printing board after the brake unit is

connected, otherwise it will lead to electric shock. There is high voltage direct current inside.

●Do not touch the heat sink of the brake unit and the brake resistors, otherwise it will lead to

scald or electric shock. There is high temperature and heated spares inside after the brake unit

is connected.

●The brake resistor should be with temperature and other protection. Because the brake unit

is defective when the brake resistor keeps heated, it should have been isolated itself. Inoréa

will not take the responsibility of such accident caused by no automatic isolation.

●The unit and brake resistor should be installed on the medium with flame retardancy.

●Connection is allowed only when the power is switched off and completely out of power.

12.09.2019 http://www.inorea.com

5

QUICK START GUIDE : Brake unit extern

●Only well-trained personnel are allowed to use this unit.

●Ensure the correct connection before running.

●Ensure the right host and slave selection and voltage class before running.

●Only when the charge light is off and ensure the charge voltage is 0 with the multimeter, the

brake unit could be adjusted and repaired.

●During the running, do not touch any spares inside.

●Please refer to the content in the manual when analyze and manage the fault of the brake unit.

Any modification to the brake unit is not allowed otherwise the life harm and property loses

will not be burdened by Inoréa.

●This product is the accessories of the inverter, if it is used improperly which would not only do

damage to itself but also to the inverter. Please pay much attention to this.

12.09.2019 http://www.inorea.com

6

QUICK START GUIDE : brake unit extern

3. INSTALLATION

3.1. Conditions for use

Hangging Brake unit should be installed inside the house where is ventilative.

Ambient condition should accord with the followings: (1).Ambient temperature -10℃~40℃.0℃~40

℃

(2).Prevent dropping dust, powder, cotton fiber or fine metal powder from entering it.

(3).Prevent oil, salt and corrosive gas from entering it. (4).Avoid vibration.

(5).Avoid high temperature and moisture and avoid being wetted due to raining, with the humidity

below 90%RH (not dewing). (6).Prohibit the use in the dangerous environment where inflammable or

combustible or explosive gas, liquid or solid exists.

3.2. Sharp size

12.09.2019 http://www.inorea.com

8

QUICK START GUIDE : brake unit extern

3.3. Main Circuit specification

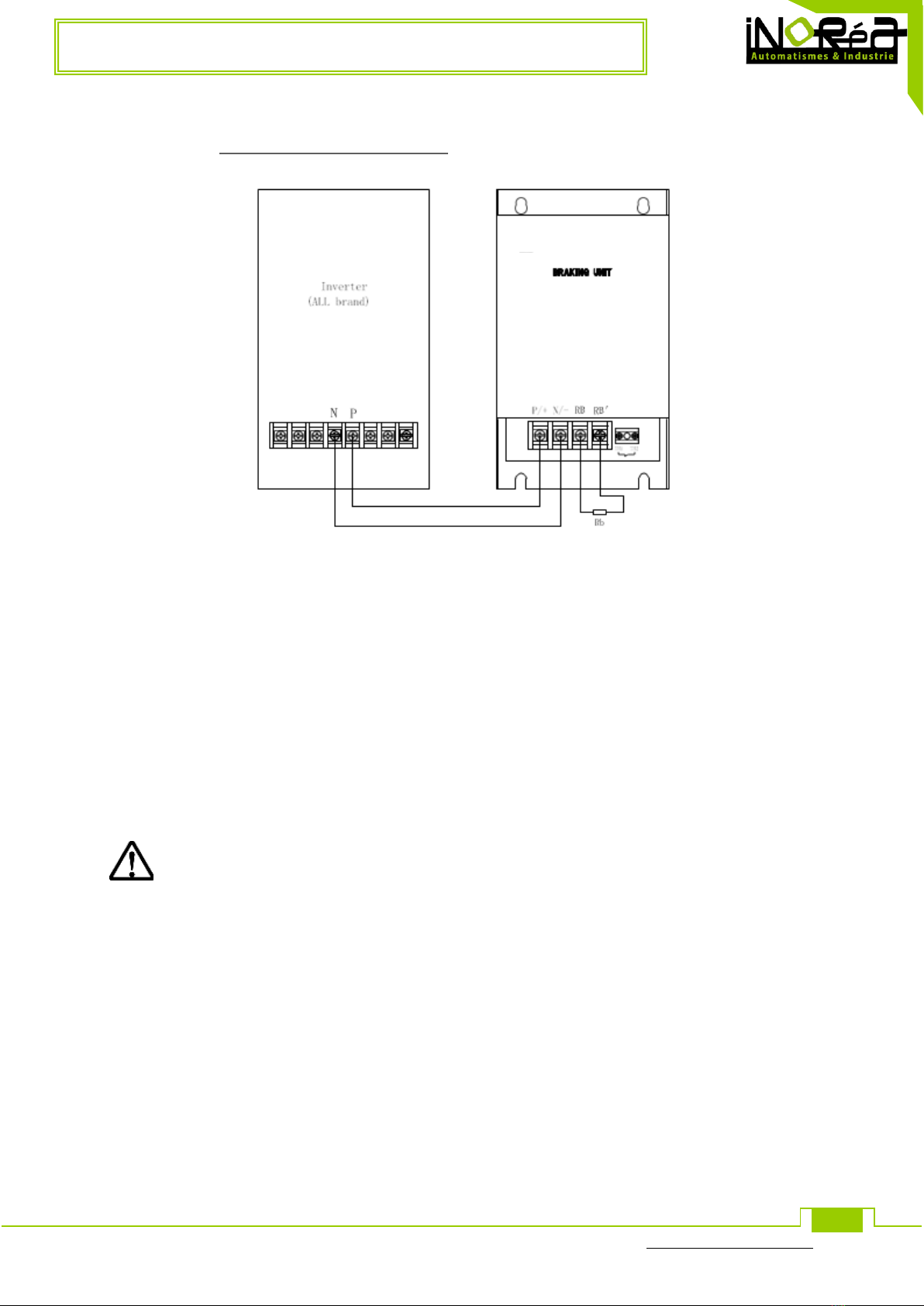

Connection diagram of Brake unit and Inverter

Note : The distance of the connection between the inverter and brake unit should as short as possible

less than 2cm.

No limitation to the distance between the brake resistor (Rb) and brake unit, but the shorter distance

may cause less faults because of the broken cable.

P,N is the “+”“-”of the DC bus in the inverter, P is positive, N is negative.

The DC cables should be winded to reduce the radiation and inductance.

Warning:Incorrect connection of the main circuit will lead the damage to the brake unit and

inverter.

12.09.2019 http://www.inorea.com

9

QUICK START GUIDE : brake unit extern

4. FUNCTION PARAMETER DESCRIPTION

Parameter setting switch and control terminal

Note:Only PB6034 have M,S slave and host selection,but other type no. The voltage class is set

OK during the factory setting.

Warning:Incorrect selection of the slave and host will lead abnormal running and

damage!

Description of control circuit terminal of the brake unit

Terminal

Specification

Note

Parameter

Setting

switch

1

Slave and host selection switch, when

M is ON, the brake unit is set to be

host brake unit

Factory

setting:

ON

2

Slave and host selection switch, when

S is ON, the brake unit is set to be

slave brake unit.

Factory

setting:

OFF

Control

M1/M

2

Slave and host control terminal

S1/S2

Slave and host control terminal

TH1/

TH2

OH protection switch(always close)

12.09.2019 http://www.inorea.com

11

QUICK START GUIDE : brake unit extern

Diagram of the connection of paralleled running brake unit and inverter (Only PB6034 with this

function). If 2 or more over brake units are paralleled, please refer to the above diagram and connect

the inverters, multiple brake units and brake resistors.

6.1. Host and slage select of function setting

(1) The factory setting of the brake unit is set to be the host (M), do not modify the factory setting

if only one brake unit is used.

(2) When 2 or more over brake units are paralleled, the control terminal (S) is used. Please refer

to the “Host and slave control connection”.

6.2. Host and slave control connection

(1) The brake unit has host/slave switch. Set the brake unit 1 to be “M”, the brake unit 2 and 3

to be “S”

(2) Connect separately M1, M2 of the brake unit 1 with S1, S2 of the brake unit 2; Connect

separately M1, M2 of the brake unit 2 with S1, S2 of the brake unit 3. Etc.

Note :Double wind the M1, M2 and S1, S2, and please make it as short as you can; the maximum

paralleled brake units is only 10.

7. VOLTAGE SET AND CALCULATION

Voltage

Input power voltage of inverter

Brake start voltage(PN

380V

370VAC~450VAC

670VDC±3

7.1. Why brake voltage 670V ?

Brake unit voltage is from 630V to 700V, how to select the right voltage? In China, it should select

according to Chinese electric net. Brake voltage should be on the following 2 standards:

•Brake voltage should be large enough and not lead the brake unit misact because of

the raised voltage of the electric net.

The electric net fluctuates in China. Some places the voltage will be over AC 450V, the inverter DC

voltage is 640V, the safe voltage should be larger than that. If the brake voltage is set low, the brake

resistors may be burned. The actual fluctuation is ±20%.

•Brake unit voltage should be low enough, make the inverter run at about the rated

voltage, ensure the safe running of the equipments.

12.09.2019 http://www.inorea.com

12

QUICK START GUIDE : brake unit extern

High brake voltage could ensure that the brake unit would not misact but too high voltage will do

damage to the long running equipments, especially to the inverter with spares of low voltage. At the

same time, high voltage will also make the motor voltage saturated, motor waste and decline control

precision.

7.2. PB60 brake unit characteristic :

•Special circuit design for any resistor in the market, no need for senseless resistor.

•When abnormalworking, no damage to theinverter. P-Nwill not be short circuited if the cable

connection is good.

•Suitable for domestic electric net, normal running in 300V to 460V.

•Profession manufacture, keeps improving.

7.3. Brake unit function :

In the system of frequency conversion, motor decelerates and stops by reducing the frequency. At the

moment of frequency reduction, motor’s synchronization rotate speed declines, and because of

machinery inertia, motor rotor rotate speed remains. When synchronization rotate speed is smaller

than rotor rotate speed, the phase of rotor current almost becomes 180,motor turns from

electromotion to electricity generation. Meanwhile torque of motor axis changes to brake torque and

decelerate the motor speed quickly, motor is during regeneration brake, motor regeneration energy

feedback to DC bus via fly-wheel diode. Because the energy in the DC circuit could not feedback to

electric net by diode bridge but only absorbed by inverter, although other section could waste some

energy but capacitor could accumulate electric charge for a short time and forms “ pumps raise

voltage” to enlarge the DC bus voltage. Too high DC voltage will damage the spares. So to manage such

regeneration energy, brake unit (resistor) should be used to waste them, otherwise the inverter will be

OU or faulted.

7.4. Brake current calculation :

Brake current is the DC current in the brake unit and brake resistor.

380V Standard AC motor:P Motor power。

K---------- Conversion efficiency of the machine energy when feedback comes. Usually 0.7 (applicable

for most occasion)

V DC working voltage. 670V

I Brake current.

Calculation norm:Motor electricity regeneration should be absorbed completely by resistor.

Motor electricity regeneration=1000*P*K=Resistor absorbing power.

12.09.2019 http://www.inorea.com

13

QUICK START GUIDE : brake unit extern

7.5. Brake resistor calculation and selection :

Resistor value indirectly decides the system control moment. Too small brake moment will lead

inverter OU.

380V Standard DC motor:P Motor power

K---------- Conversion efficiency of the machine energy when feedback comes. Usually 0.7 (applicable

for most occasion)

V DC working voltage. 670V

R Brake resistor equivalent value

Q Brake resistor rated waste power

S Brake resistor waste power safety coefficient 1.4

Kc--------- The proportion of regeneration in the motor working procession (evaluate according to the

load)

Normal Kc Value as below:

Centrifuge Kc=5%——20%

Elevator Kc=10%——15%

Oil field 油田磕头机 Kc=10%——20% Crane lower than 100m

Kc=20%——40% Occasional brake load Kc=5%

Others Kc=10%

Calculation norm:Motor electricity regeneration should be absorbed completely by resistor.

Motor regeneration energy=1000*P*K=resistor absorptivity V*V/R)

Resistor power calculation norm:

otor electricity regeneration should be absorbed completely by resistor and transfer to heat energy.

Q=P*K*Kc*S=P*0.7*Kc*1.4 Approximately Q=P*Kc

And : resistor power=motor power* Kc

7.6. Brake unit safty limit

Current in brake unit is 670/R. Such current should not be larger than that the allowable maximum

current.

12.09.2019 http://www.inorea.com

14

QUICK START GUIDE : brake unit extern

8. FAULT DIAGNOSIS AND SOLUTIONS

No.

Fault

Possible cause

1

The brake

resistor

heated

badly when

it brakes.

Main circuit power IGBT

of the unit short circuit

Incorrect selection of the

brake unit voltage

Brake unit faulted

2

Inverter

OU

Lack of braking of the

brake resistor

Not suited brake unit

voltage

Brake unit faulted

3

No brake

sound

Brake resistor short or

open circuit

Cable connection not good

Brake unit fault

4

relay action

over heat

protection

Heat sink temperature over

80℃

The electric net voltage is too high, please select the high voltage setting.

Warning : Open the P and N, ensure there is no voltage between PN when use and inspect the

unit! This unit control circuit is not isolated circuit.

9. STANDARD SPECIFICATION

9.1. Model specification

The allowed maximum current of the power spares IGBT inside the brake unit with the certain

temperature.

12.09.2019 http://www.inorea.com

15

QUICK START GUIDE : brake unit extern

9.2. Model designation

9.3. 400V specification and selection reference

KW

Brake Unit

Brake resistor(150% brake

torque)

Type

Qty(pc)

Type

Qty(pc)

5.5

PB0614

1

75Ω/780W

1

7.5

1

50Ω/1040W

1

9.4.Brake resistor selection

(1) PB6014 and 30KW inverter, the brake resistor should be with 130% brake torque.

(2) Not any earthing accident allowed to the brake resistor, otherwise it will lead the serious

damage to the unit and inverter.

(3) Selection of the brake resistor capacity is for reference, it depends on the load intertia, brake

frequency, etc characteristic. Please inquire Powtran when you have questions.

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

Leviton

Leviton SGAMP install guide

Toledo Transducers

Toledo Transducers Press Pilot 150 Manual and installation guide

Tube-Town

Tube-Town PoS150 manual

Roger Technology

Roger Technology B70/1DC Instruction and warnings for the installer

Gascat

Gascat ARES N Installation, operation & maintenance manual

Aqua Environment Inc

Aqua Environment Inc 504 Owner's operation and maintenance manual