Econex MPV Series Instruction Manual

1 of 11

MODULATING CONTROL VALVE

SERIES MPV

INSTRUCTIONS FOR THE

INSTALLATION AND MAINTENANCE

1. MAIN FEATURES 2

2. TECHNICAL FEATURES 2

3. INSTALLATION 3

4. ELECTRIC CONNECTIONS 4

5. WIRING 5

5.1 WITHOUT MANUAL/AUTOMATIC CONTROL STATION 5

5.2 WITH MANUAL/AUTOMATIC CONTROL STATION 6

6. AUXILIARY MICROSWITCHES 7

7. POTENTIOMETER/S 7

8. CONTROL STATION 7

9. CALIBRATIONS 8

9.1 LIMIT SWITCH 8

9.2 POTENTIOMETER/S9

9.3 ELECTRONIC CARD 10

9.4 MAX.CAPACITY ADJUSTMENT 11

10. START-UP 11

11. MAINTENANCE AND CHECKS 11

12. REPLACEMENT 11

2 of 11

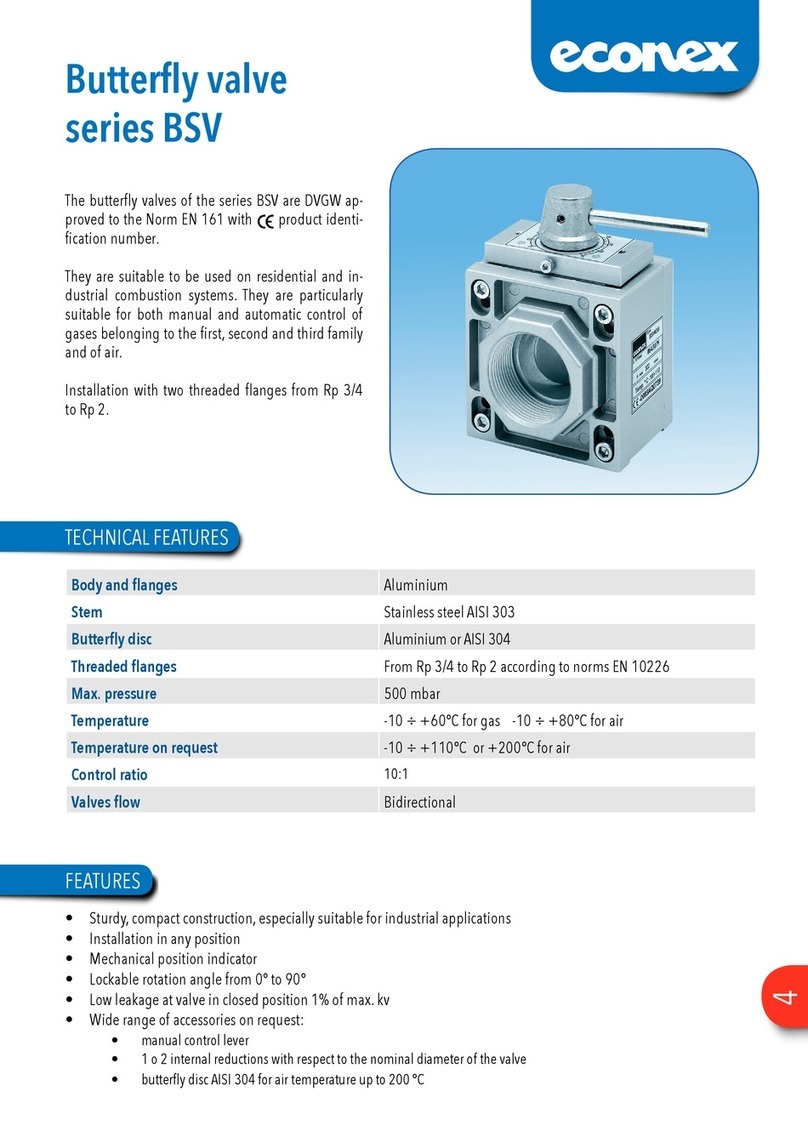

1. MAIN FEATURES

The modulating valves in the MPV [Modulating Plug Valve] series have been designed

with a modern concept and they are DVGW approved, with CE identification number.

They are suitable to be used in commercial and industrial combustion systems.

They are especially suitable for the proportional adjustment of non corrosive fuel gases

from the first, second and third family and air. The MPV valve is an adjustment device

without zero closing. The actuator is equipped with a single-pole bi-directional motor

with high static torque and holding torque for 3-positional control or electronic

modulation with analogic signal current [4 ÷ 20 mA] or tension [0 ÷ 10 Vdc] variation

at. The adjustment of flow volume in the valve operates by a delivery adjusting

cylinder with linear characteristics. The cylinder rotation changes the passage opening

and the flow volume is adjusted according to a linear trend.

Three different orifice sizes are available according to the operating conditions,

interchangeable without removing he valve from the plant.

W

ARNING

Installation, wirin

g

, ad

j

ustment and maintenance of

g

ear motors must be carried out

e

xclusively by skilled and authorized service technicians. Non-proper installation,

a

d

j

ustment, modifications, use and maintenance may cause in

j

uries to the staff or

material dama

g

es. It is therefore necessary to respect strictly the followin

g

instructions and local prescriptions for the installation of electric and gas devices.

2. TECHNICAL FEATURES

Operating pressure : max. 500 mbar

Valve group : 2

Ambient temperature : from -10 to +60°C

Adjusting ratio : 25:1

Fittings : Rp 1, according to ISO 7-1

Delivery feature : linear

Valve : without zero closing

Available voltage : 230 Vac / 50 - 60 Hz

115 Vac / 50 - 60 Hz

24 Vac / 50 - 60 Hz

Nominal load : 7 VA

Electric protection : IP 54 according to EN60529

Duty cycle : continuous 100%

Cable fasteners : 2 x Pg 13.5

Opening/closing times : 30 ÷ 60 seconds at 50 Hz

Limit - Aux. switches rating : 5 [1] A 250 Vac

Available potentiometers : 150, 1000 [standard], 2500 ohm

Control signal : 4 ÷ 20 mA [only with supply voltage 24 Vac]

[for electronic version] : 0 ÷ 10 Vdc [only with supply voltage 24 Vac]

Accessories : adjustable manual by-pass

3 of 11

3. INSTALLATION

3.1 Make sure that all the operating data shown on the valve label comply with the

system operating data.

3.2 When installing the valve be sure that there is sufficient clearance above the

gear cover and that it can be easily accessible in order to perform the electrical

connections and the calibration of the electric limit switches.

3.3 Install a filter before the MPV valve.

3.4 Before installing the valve, make sure the piping is clean and free of every

impurity, and it is perfectly aligned with the valve body and not subject to

vibrations.

3.5 Remove the protection plugs installed on the valve body.

3.6 The sealant must be applied only on the piping outer threading and not on the

valve inner threading. Use gas suitable sealants only.

3.7 Comply with the gas flow direction marked by the arrows on the valve body.

3.8 The MPV valve installation can be carried out in every position.

3.9 The MPV valve can be installed in every premise included in the range of the

electric protection IP 54, except for premises with presence of acid fumes or

other vapours that can etch the metal parts, in atmosphere with gas or

explosive vapour leaks.

3.10 For the installation of the MPV valve on the piping do not use the actuator as

lever, rather use the suitable wrench.

3.11 Install the MPV valve without voltage.

4 of 11

4. ELECTRIC CONNECTIONS

4.1 Arrange the wiring and the grounding according to the local norms in force.

4.2 To access the inner terminal board and for the electric connections, remove the

cover loosening the 4 fastening screws.

4.3 Two threaded holes for cable pressers Pg 13.5 are already arranged on the

base of the electric actuator.

4.4 Before servicing make sure, that power supply is disconnected by means of the

two-pole-switch [phase and neutral]; in case of non-observance, damages to

people and equipments may occur.

4.5 All wires must comply with local prescriptions and, in any case, their section

must be ranging between 1 and 1.5 mm2. Connection piping recommended

H07V-U…G1.5 mm2.

4.6 Wiring diagrams are reported in the attached technical bulletin and on the plate

inside the cover.

4.7 Auxiliary microswitches are single-pole double through and voltage-free.

4.8 If a potentiometer is installed, its resistance value is indicated on the

nameplate.

4.9 Make sure the supply voltage and the system frequency correspond to those

indicated on the valve plate.

4.10 Low-tension signalling cable [tension lower than 48V] must be laid separately

from the higher-tension conduits [tension higher than 48V]. In case they are

laid in a single channel, screened cables must be used.

5 of 11

5. WIRING

The wiring schemes refer to the valve in “closed” [0°] position.

5.1 WITHOUT MANUAL/AUTOMATIC CONTROL STATION

TERMINAL BOARD

Terminal earthing

Terminal N1 N = neutral

Terminal L2 by tension the valve closes

Terminal 3 by tension the valve opens

Terminal 4 for manual electric operation

Terminal 16 answer signal when the valve reaches the “open” position

Terminal 17 answer signal when the valve reaches the “closed” position

6 of 11

5.2 WITH MANUAL/AUTOMATIC CONTROL STATION

Terminal earthing

Terminal 1 N = neutral

Terminal 2 by tension the valve closes

Terminal 3 by tension the valve opens

Terminal 4 for manual electric control

Terminal 16 answer signal when the valve reaches the “open” position

Terminal 17 answer signal when the valve reaches the “closed” position

6.3 Auxiliary microswitches

Terminal 20 common contact from the auxiliary microswitch S3

Terminal 21 normally open contact of the auxiliary microswitch S3

Terminal 22 normally closed contact of the auxiliary microswitch S3

Terminal 23 common contact from the auxiliary microswitch S4

Terminal 24 normally open contact of the auxiliary microswitch S4

Terminal 25 normally closed contact of the auxiliary microswitch S4

6.4 Potentiometer/s for answer signal of the position Pot. A and/or Pot. B

Terminal 30 max. value

Terminal 31 cursor

Terminal 32 min. value

Terminal 33 max. value

Terminal 34 cursor

Terminal 35 min. value

7 of 11

6. AUXILIARY MICROSWITCHES

On request, the valve can be equipped with 2 auxiliary microswitches that can be

adjusted in any position.

Microswitches are voltage-free.

The contact capacity is 5 A/250 Vac with ohmic load and 1 A/250 Vac with inductive

load.

Contact rating is about 5 A/250 with Ohm load and about 1 A/250 with inductive load.

For adjusting the cams of auxiliary microswitches, proceed as for cams of endswitches

as indicated in paragraph 9.1 chapter 9 “CALIBRATIONS”.

7. POTENTIOMETER/S

On request, the valve can be equipped with 1 or 2 independent potentiometers [pot. A

and/or Pot. B] for the answer signal of the valve position.

Resistance value of the potentiometer is indicated on the identification label.

If the resistance value does not correspond to the wished one, proceed as indicated in

paragraph 9.2 of chapter 9 «CALIBRATIONS».

Absorbed power is 2 W for each potentiometer.

8. CONTROL STATION

8.1 The control station enables the manual electric activation of the valve.

8.2 Phase L must be connected to the terminal no. 4.

8.3 The AUTO/MAN switch is delivered by the factory in AUTO position .

8.4 Set the AUTO/MAN switch in the manual position indicated by stylized hand

8.5 Activate the Open/Stopped/Closed switch as follows:

8.5.1 Keeping the lever pushed towards the symbol ◄the valve opens [the cam S2

adjusts the desired final opening position].

8.5.2 Keeping the lever pushed towards the symbol ►the valve closes [the cam S1

adjusts the desired final closing position].

8.5.3 Positioning the lever to the centre, the valve motor is not activated.

8.5.4 ATTENTION: after the operations for manual electric activation of the valve,

reset the AUTO/MAN switch onto AUTO position .

8 of 11

9. CALIBRATIONS

9.1 LIMIT SWITCH

9.1.1 The MPV valve is delivered by the factory in closed position. The limit switches

are adjusted to reach the positions of closed valve and completely open valve.

9.1.2 For “OPEN” position adjustment, it is necessary to operate on cam “S2”.

9.1.3 For cam adjustment, use the proper “half-moon” key, supplied with the

actuator and installed inside it.

9.1.4 Use the key from the right side, introducing the pin into one of the holes on

the sides of the blue cam of the cam involved and lever it to required position.

9.1.5 If the blue cam is in a behind position, use at first the lever on its curved side

to move the blue cam to a more suitable position to perform adjustment

[picture 1].

Picture 1

9.1.6 To calibrate, refer to the mechanical position indicator disc; the valve is closed

when the mechanical pointer is in the 0 position, the valve is completely open

when the mechanical pointer is in the 90° position.

9.1.7 The cam adjustment is possible in both directions.

9.1.8 The lever roller operates the microswitch when it is on the bottom of the cam

groove, stopping the motor rotation.

9.1.9 Remove the wrench before starting the actuator.

9.1.10 The movable crown can be driven also by a small screwdriver, acting on the

suitable notches.

9.1.11 Avoid valve rotation over 90°, in order to prevent damage on the adjusting

cylinder, and/or force the potentiometer shaft rotation.

9 of 11

9.2 POTENTIOMETER/S

9.2.1 The potentiometer shaft is frictioned and is accessible from the upper side

inside the gear motor.

9.2.2 Disconnect the cables connected with the regulation system from the

respective terminals n. 30, 31 and 32 [Pot. A] and, if necessary, n. 33, 34 and

35 [Pot. B].

9.2.3 By means of a suitable screwdriver with 5 mm cut rotate the potentiometer

shaft and measure the resistance value of 0 Ohm between terminals n. 31 and

32 and, if necessary, also between terminals n. 34 and 35 when the valve is

closed [picture 2].

Picture 2

9.2.4 By rotating the potentiometer:

●clockwise 3the resistance value increases

●counter dock wise 4the resistance value decreases

9.2.5 The gearbox between the gear motor shaft and the potentiometer shaft is

foreseen for a 90° rotation angle between closed valve and totally open valve.

Hence should the gear motor opening be reduced with a rotation angle lower

than 90°, the variation of the potentiometer resistance value will be

proportionally reduced.

If, vice versa, the rotation angle had been wrongly adjusted over 90° there

will be no increase in the resistance value beyond the plate maximum value.

10 of 11

9.3 ELECTRONIC CARD

9.3.1 Supply the servocontrol as per schema SE.

9.3.2 Select the MAN function

9.3.3 Position the adjustment instrument on 4 mA [or on 0 Vdc].

9.3.4 Turn the servocontrol manually till reaching the mechanical zero.

9.3.5 Adjust the closing cam «S1» at few degrees before microswitch involvement.

9.3.6 Turn the potentiometer shaft clockwise 3till it stops mechanically.

9.3.7 Select the AUTO position

9.3.8 Set the adjustment device on 6 mA [or on 2 Vdc] and wait up the servocontrol

moves, then take it back to 4 mA [or on 0 Vdc] and check it reaches 0 degrees.

9.3.9 If it does not exactly come back to 0 degrees, turn the potentiometer shaft

counterclockwise 4till 0 degrees.

9.3.10 Set the adjustment device at 20 mA [or on 10 Vdc] and check the max.

opening, then calibrate the opening cam «S2» at few degrees before the

microswitch involvement.

9.3.11 Set the adjustment device on 4 mA [or on 0 Vdc] regulating the servocontrol

back to 0 degrees.

11 of 11

9.4 MAX.CAPACITY ADJUSTMENT

9.4.1 To reduce the max. capacity fit a 3 mm hexagon socket screw in the suitable

seat on the lower part of the valve body and rotate it counterclockwise 4.

9.4.2 The MPV valves are supplied by the factory adjusted for the max. capacity.

10. START-UP

10.1 Before starting the system up, carefully check the following points of the MPV

valve:

- correct installation according to the flow direction

- gas outer seals

- correct electric connections and grounding

- perfect electric and mechanical operation by opening and closing with closed

gas main cock.

Once preliminary conditions compliance, the gas main cock can be opened and

the operating test can be carried out.

11. MAINTENANCE AND CHECKS

11.1 The MPV valve does not require any special maintenance.

Both the valve body and the actuator do not need any lubrication.

11.2 At least once a year, and above all for systems subject to vibrations, it is

recommended to check the harness for faulty contacts of the terminal board

and to tighten the screws.

12. REPLACEMENT

For replacement of MPV valve, operate as follows:

12.1 Close the gas main cock.

12.2 Cut off the supply voltage to the valve.

12.3 Remove the actuator cover.

12.4 Disconnect all the electric connections, noting the cable numbers.

12.5 Remove the valve body from the piping.

12.6 Install the new valve according to the instructions of the previous chapters.

These instructions can be subject to possible variations without notice.

Table of contents

Other Econex Control Unit manuals

Popular Control Unit manuals by other brands

Agilent Technologies

Agilent Technologies Turbo-V user manual

Clack

Clack Water Specialist WS1TC Operation and instruction manual

Flotrol

Flotrol F20 SVE Installation and service manual

Elesa

Elesa UC-RF operating instructions

Bailey

Bailey infi 90 IMASI02 Instruction

Siemens

Siemens TMM-1 installation instructions