INOXPA LR Series Manual

INSTALLATION, SERVICE AND MAINTENANCE INSTRUCTIONS

SIDE-ENTRY AGITATOR

LR / LM

Manual Original

20.025.30.01EN

(0) 2019/04

20.025.32.0001

20.025.30.02EN

(0) 2019/02

(1) The serial number may be preceded by a slash and by one or two alphanumeric characters

20.025.30.02EN

(0) 2019/02

EC Declaration of Conformity

We,

INOXPA, S.A.U.

Telers, 60

17820 –Banyoles (Girona)

Hereby declare under our sole responsibility that the machine

LR/LM side entry agitator

From serial number IXXXXXX to IXXXXXX (1) / XXXXXXXXXIIN to XXXXXXXXXIIN (1)

Fulfills all the relevant provisions of the following directive:

Machinery Directive 2006/42/EC

Low Voltage Directive 2014/35/EU

Electromagnetic Compatibility Directive 2014/30/EU

Applicable harmonized standards:

UNE-EN ISO 12100:2012

UNE-EN 14120:2016

The technical file has been prepared by the signer of this document in INOXPA.

David Reyero Brunet

Technical Office Manager

Banyoles, 7th February, 2019

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 3

1. Table of Contents

1. Índex

2. Generalities

2.1.Instructions manual.......................................................................................................................................4

2.2.Compliance with the instructions ..................................................................................................................4

2.3.Warranty........................................................................................................................................................4

3. Safety

3.1.Warning symbols...........................................................................................................................................5

3.2.General safety instructions ...........................................................................................................................5

4. General Information

4.1.Description....................................................................................................................................................7

4.2.Operating principle........................................................................................................................................7

4.3.Application.....................................................................................................................................................7

5. Installation

5.1.Reception of the agitator...............................................................................................................................8

5.2.Identification of the agitator...........................................................................................................................8

5.3.Transport and storage.................................................................................................................................11

5.4.Location.......................................................................................................................................................11

5.5.Electrical installation ...................................................................................................................................12

5.6.Assembly.....................................................................................................................................................12

6. Start-up

7. Troubleshooting

8. Maintenance

8.1.General considerations...............................................................................................................................16

8.2.Maintenance................................................................................................................................................16

8.3.Lubrication...................................................................................................................................................16

8.4.Spare parts..................................................................................................................................................16

8.5.Conservation...............................................................................................................................................16

8.6.Disassembly and assembly of the agitator .................................................................................................17

9. Technical Specifications

9.1.Materials......................................................................................................................................................19

9.2.Other features.............................................................................................................................................19

9.3.Weights.......................................................................................................................................................19

9.4.Dimensions of LR side-entry agitator..........................................................................................................20

9.5.Dimensions of LM side-entry agitator .........................................................................................................21

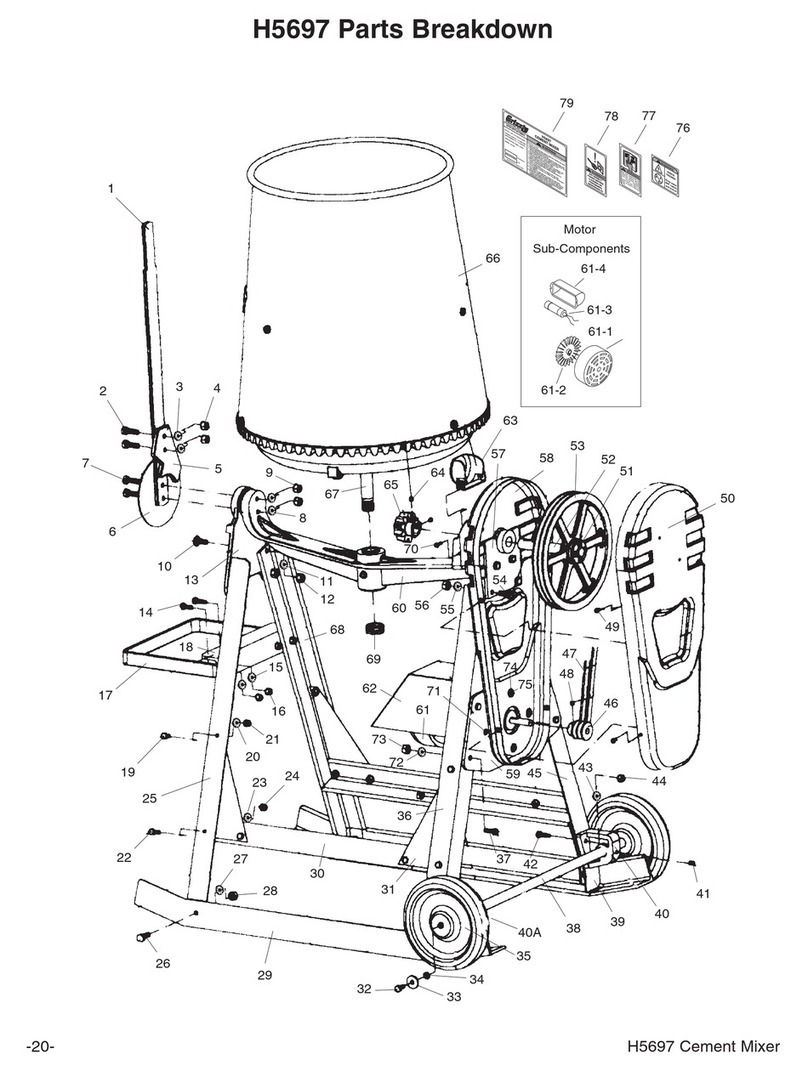

9.6.Exploded drawing and parts list of LR side-entry agitator ..........................................................................22

9.7.Exploded drawing and parts list of LM side-entry agitator..........................................................................23

Generalities

4 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

2. Generalities

2.1. INSTRUCTIONS MANUAL

This manual contains information about the reception, installation, operation, assembly, disassembly and

maintenance of the LR/LM side-entry agitator.

Carefully read the instruction prior to starting the agitator, familiarize yourself with the installation, operation and

correct use of the agitator and strictly follow the instructions. These instructions should be kept in a safe location

near the installation area.

The information published in the instruction manual is based on updated data.

INOXPA reserves the right to modify this instruction manual without prior notice.

2.2. COMPLIANCE WITH THE INSTRUCTIONS

Not following the instructions may impose a risk for the operators, the environment and the machine, and may

result in the loss of the right to claim damages.

This non-compliance may result in the following risks:

failure of important machine/plant functions,

failure of specific maintenance and repair procedures,

possible electrical, mechanical and chemical hazards,

risk to the environment due to the type of substances released.

2.3. WARRANTY

Any warranty will be void immediately and lawfully and, additionally, INOXPA will be compensated for any civil

liability claims submitted by third parties, in the following cases:

the service and maintenance work have not been carried out in accordance with the service instructions,

the repairs have not been carried out by our personnel or have been carried out without our written

authorisation,

modifications have been carried out on our material or equipment without written authorisation,

the parts or lubricants used are not original INOXPA parts and products,

the material or equipment has been improperly used, has been used negligently, or has not been used

according to the instructions and their intended.

The General Conditions of Delivery already in your possession are also applicable:

The machine may not undergo any modification without prior approval from the manufacturer.

For your safety, only use original spare parts and accessories.

The usage of other parts will relieve the manufacturer of any liability.

Changing the service conditions can only be carried out with prior written authorization from

INOXPA.

Please do not hesitate to contact us in case of doubts or if further explanations are required regarding

specific data (adjustments, assembly, disassembly, etc.).

Safety

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 5

3. Safety

3.1. WARNING SYMBOLS

Safety hazard for people in general and/or for equipment

Electric hazard

Important instruction for the protection of the equipment and its functions

3.2. GENERAL SAFETY INSTRUCTIONS

Read the instruction manual carefully before installing and starting the agitator. Contact INOXPA in

case of doubt.

3.2.1. During the installation

The Technical Specifications of chapter 9.

The installation and use of the agitator should always be in accordance with applicable regulations

in regard to health and safety.

Before starting up the agitator, check that it is properly anchored and its shaft is perfectly aligned.

Incorrect alignment and/or excessive stress during coupling can cause serious mechanical

problems in the agitator.

Take all possible precautions when lifting the agitator. Always use properly attached slings when

moving the agitator with a crane or other lifting device.

Keep the motor and the switchboard under control, particularly in areas where there is a risk of fire

or explosion.

When cleaning, do not spray directly on the engine.

Do not disassemble the agitator until the switchboard has been disconnected. Remove the fuses

and disconnect the power cable supplying the motor.

All electric work should be carried out by specialised personnel.

3.2.2. During operation

The Technical Specifications of chapter 9 should always be observed. Under no circumstances can

the specified limit values be exceeded.

Before starting up the agitator, remove all the tools used during the assembly.

Do not operate the agitator when the rotating parts are not equipped with their guards or are not

properly assembled.

The agitator has rotating parts. Do not place hands or fingers in the agitator while it is operating.

This may cause serious injuries.

Do not touch the parts of the agitator that are in contact with the fluid when in operation. When the

agitator operates with hot fluids (temperatures above 50ºC), there is a risk of skin burning. In such

cases, collective-protection means (in this order or priority: separation, protective screen, heat-

insulating material) or, in the absence of this, individual protection gear (gloves) must be used.

ATTENTION

Safety

6 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

The agitator and its installation can generate sound levels above 85 dB(A) under unfavourable

operating conditions. In such cases, the operators must use devices for protection against noise.

3.2.3. During maintenance

The Technical Specifications of chapter 9 shall always be observed.

The agitator cannot operate without fluid. Standard agitators are not designed to work during the

filling or emptying of tanks.

The maximum operating conditions of the agitator should not be exceeded. Nor should the

operating parameters for which the agitator was initially designed be modified without written

authorisations from INOXPA.

Do not leave loose parts on the floor.

Do not disassemble the agitator until the switchboard has been disconnected. Remove the fuses

and disconnect the power cable supplying the motor.

All the electric work should be carried out by specialised personnel.

General Information

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 7

4. General Information

4.1. DESCRIPTION

The LM agitator range includes the side-entry agitators with the agitator shaft fixed directly onto the motor and

the LR agitator range includes side-entry agitators with the agitator shaft fixed directly onto the gear motor. The

lantern connected to the tank has a base plate made of stainless steel. The agitator shaft is guided by a

bearing. The sealing of the shaft is carried out mechanically and is standardized according to DIN 24960.

The standard mixing element is the marine propeller type 10.

4.2. OPERATING PRINCIPLE

The LR agitators are driven by geared motors and the LM agitators are provided with direct motors.

These agitators are installed in a slanted position.

The rotation of the propeller creates a flow that impells the product to the bottom of the tank and then raises up

to the surface along the wall apposite to the agitator. The effect is promoted if the bottom is curved.

The agitator is installed decentralized to enhance the circular flow. Thus a complete homogenization of the

product is achieved.

4.3. APPLICATION

This lightweight range allows mixing and blending processes to be carried out in open and closed tanks with a

variable viscosity between 1 and 1000 cPs.

The main application is agitation of low viscosity products like wine, oil, milk, beer, alcohol, etc. in large volume

tanks.

Each agitator has performance limits. The agitator was selected for a given set of mixing conditions

when the order was placed. INOXPA shall not be held responsible for any damage that might be

suffered or malfunctioning of the equipment of the information provided by the buyer is incomplete

or incorrect (e. g. nature of the fluids or installation details).

Installation

8 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

5. Installation

5.1. RECEPTION OF THE AGITATOR

INOXPA is not liable for any deterioration of the material caused by its transport or unpacking.

Visually check that the packaging has not been damaged.

If the agitator is supplied without a drive or other element, the purchaser shall be responsible for its

assembly, installation, start-up and operation.

When receiving the agitator, check the packaging and its content to ensure that it matches the delivery note.

INOXPA packs the agitator in their fully assembled form or disassembled on a case-by-case basis. Ensure that

the agitator has not been damaged in any way. If it is not in good conditions and/or any parts are missing, the

carrier must submit a report as soon as possible.

The following documentation is included with the agitator:

shipping documents,

instructions and Servicing manual for the agitator,

instructions and Servicing manual for the gear-motor when the agitator is supplied by INOXPA.

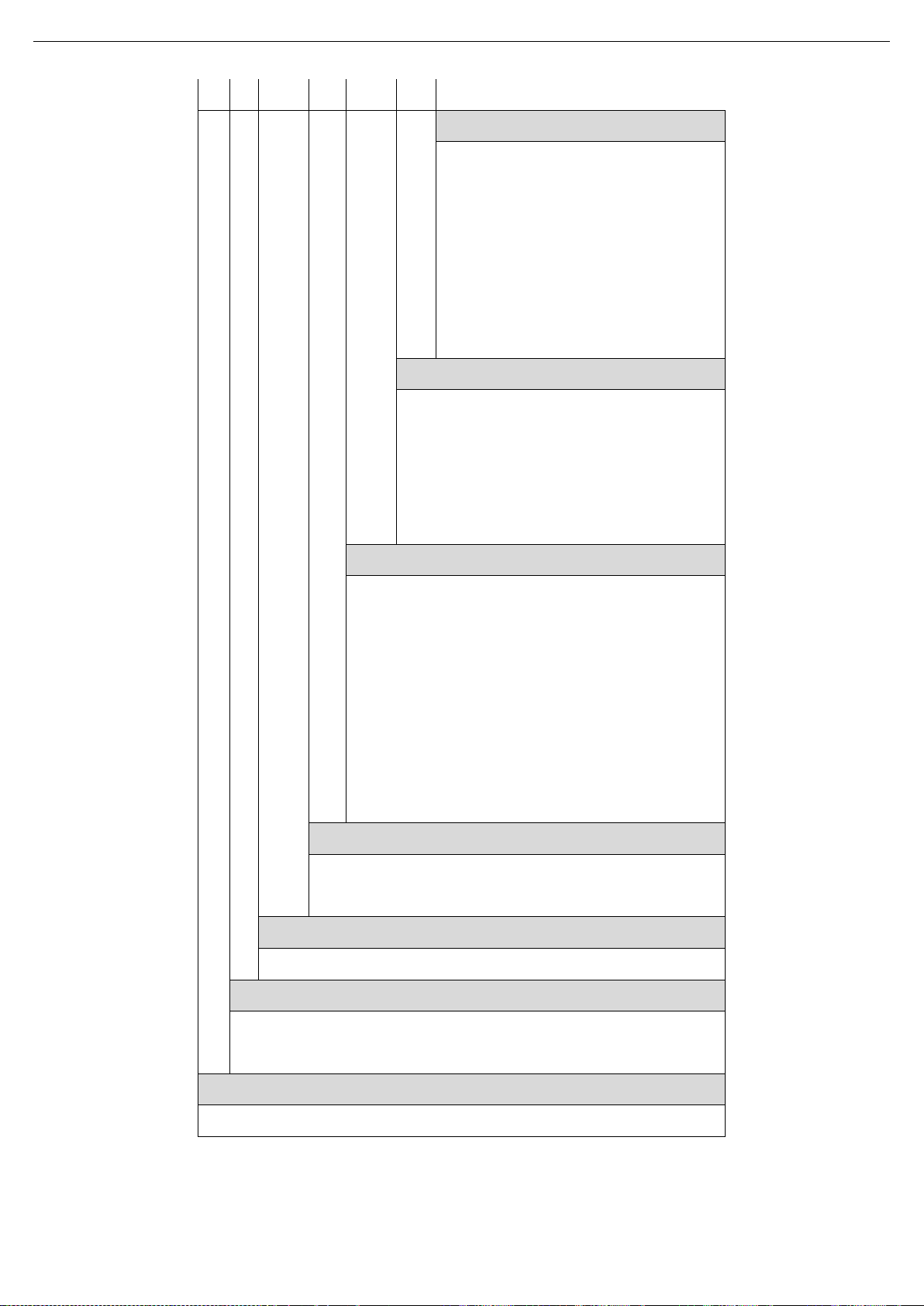

5.2. IDENTIFICATION OF THE AGITATOR

The agitator is identified using a rating plate fixed onto the motor. The type of agitator and the serial number

appear on the nameplate.

Serial number

20.003.32.0009

Installation

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 9

LR

1.

10

-

200

05

-

1

-

325

Diameter of agitation element

325

325 mm

400

400 mm

500

500 mm

600

600 mm

650

650 mm

Motor

1

IP-55

2

IP-65

3

Flameproof

6

Explosion-proof

7

Single phased

Motor power

05

0,55 kW

07

0,75 kW

15

1,5 kW

30

3 kW

40

4 kW

Motor speed

200

200 rpm

Type of agitation elements

10

marine propeller

Number of agitation elements

1

one agitation element

2

two agitation elements

Name of the agitator

LR

side-entry agitator with gear motor

Installation

10 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

LM

1.

10

-

4

015

-

1

-

175

Diameter of agitation element

175

175 mm

200

200 mm

225

225 mm

250

250 mm

275

275 mm

300

300 mm

350

350 mm

Motor

1

IP-55

2

IP-65

3

Flameproof

4

Explosion-proof

5

Single phased

Motor power

011

1,1 kW

015

1,5 kW

022

2,2 kW

030

3 kW

055

5,5 kW

075

7,5 kW

092

9,2 kW

110

11 kW

Motor speed

4

1500 rpm

6

1000 rpm

Type of agitation elements

10

marine propeller

Number of agitation elements

1

one agitation element

2

two agitation elements

Name of the agitator

LM

Side-entry agitator with motor

Installation

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 11

5.3. TRANSPORT AND STORAGE

According to the model, the agitators are too heavy to be stored or installed manually. Use an

appropriate mode of transport. Do not handle the agitator by the shaft as this may become

deformed.

Take all possible precautions when lifting the agitator. Always use properly attached slings when

moving the agitator with a crane or other lifting device.

If the agitator is not to be installed immediately, it must be stored in an appropriate place. The shaft must be

stored in a horizontal position and placed on wooden supports or for a similar material. In this position, the shaft

will not becoming deformed but it must not be subject to any type of load.

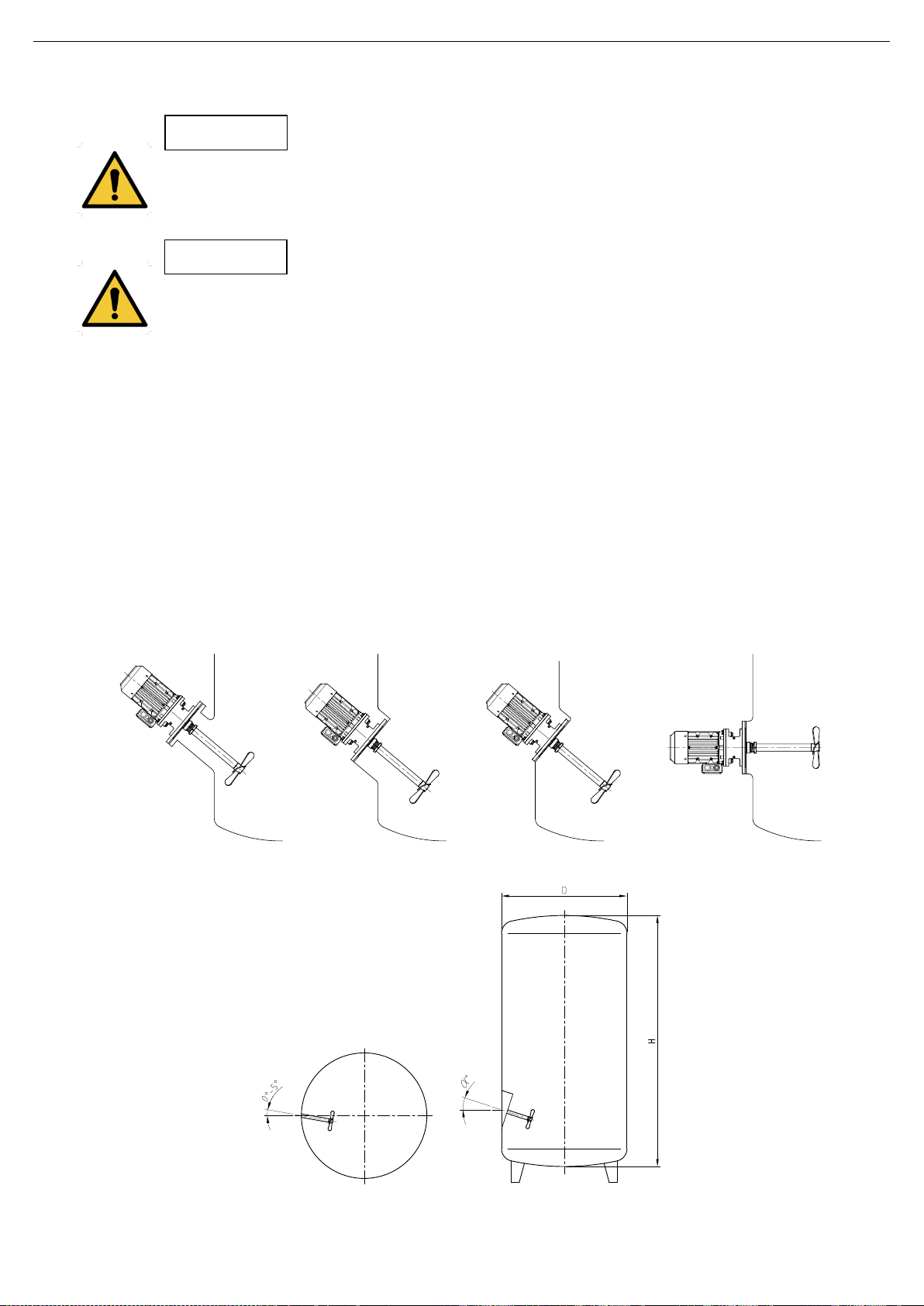

5.4. LOCATION

Place the agitator in such a way as to facilitate inspections and checks. Leave enough room around the agitator

for service, disassembly and maintenance operations. It is very important to be able to access the electric

connection device of the agitator, even when in operation.

For a good agitation process, it may be necessary to place a deflector in the tank. Ask our Technical

Department for information on any particular application. If required, the approximate dimensions for the

deflector for different tank diameter are shown in the next figures and the next table:

VERTICALS: HORIZONTAL:

ATTENTION

ATTENTION

Salient

Outside

Built-in

20.025.32.0002

20.025.32.0003

Installation

12 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

ANGULOS DE ATAQUE

Relación H/D

0,5

1

1,5

2

2,5

3

4

5

αº

0º

8º

14º

18º

25º

30º

40º

50º

Visc. máx cPS

3000

3000

1500

1500

500

300

150

100

FONDOS

º

º

º

º

-

-

-

-

º

º

º

º

º

º

º

º

º

º

º

º

º

º

º

º

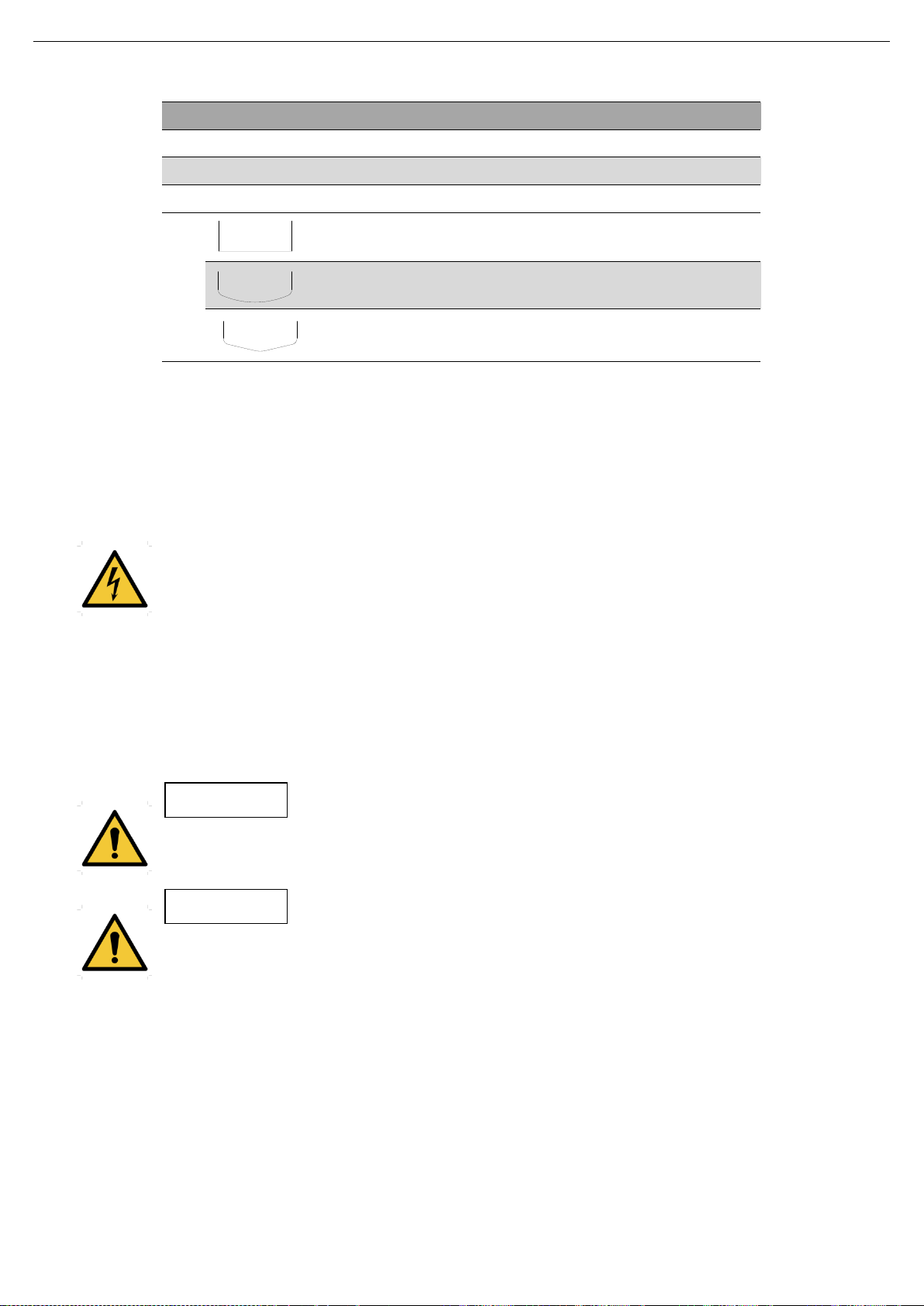

5.5. ELECTRICAL INSTALLATION

Before connecting the electrical motor to the mains, check local regulations on electrical safety as well as the

applicable standards.

Check the instructions manual of the manufacturer of the motor for information on how to connect it to the

mains.

Take the connection of the electrical motors must be performed by qualified personnel.

Take the appropriate measures to prevent any fault.

The motor must be provided with devices for protection against power overload and short-circuits.

The agitator cannot be used in areas where there is a risk of fire or explosion when this has not

been specified in the order.

5.6. ASSEMBLY

To situate and fit the agitator in the flange support of the tank, you should disassemble the propeller from the

shaft. Then, the agitator flange should be fitted on to the one of the tank screws placed in position in their

corresponding drilled holes, and the fit the nuts. When they are fully tightened, fit the propeller to the end of the

agitator shaft. Be careful, when assembling the agitator element not to knock the agitator shaft, to avoid any

distortion.

Force should never be applied to the end of the agitator shaft, as it can easily suffer permanent

damage.

Check the alignment of the agitator shaft with the half shaft once its assembly is completed.

ATTENTION

ATTENTION

Start-up

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 13

6. Start-up

The start-up of the agitator can be carried out provide the instructions indicated in the chapter 5.

Installation have been followed.

Check that the power supply matches the rating indicated on the motor plate.

Check the alignment of the agitator shaft.

Check the level of fluid in the tank. When not specified in the order, the agitator cannot be operated

during the filling or emptying of the tank.

The agitator can NEVER operate without fluid. The agitation elements may only be submerged to a

height equal to 1,5 times its diameter.

All the guards must be in place.

Start up the agitator.

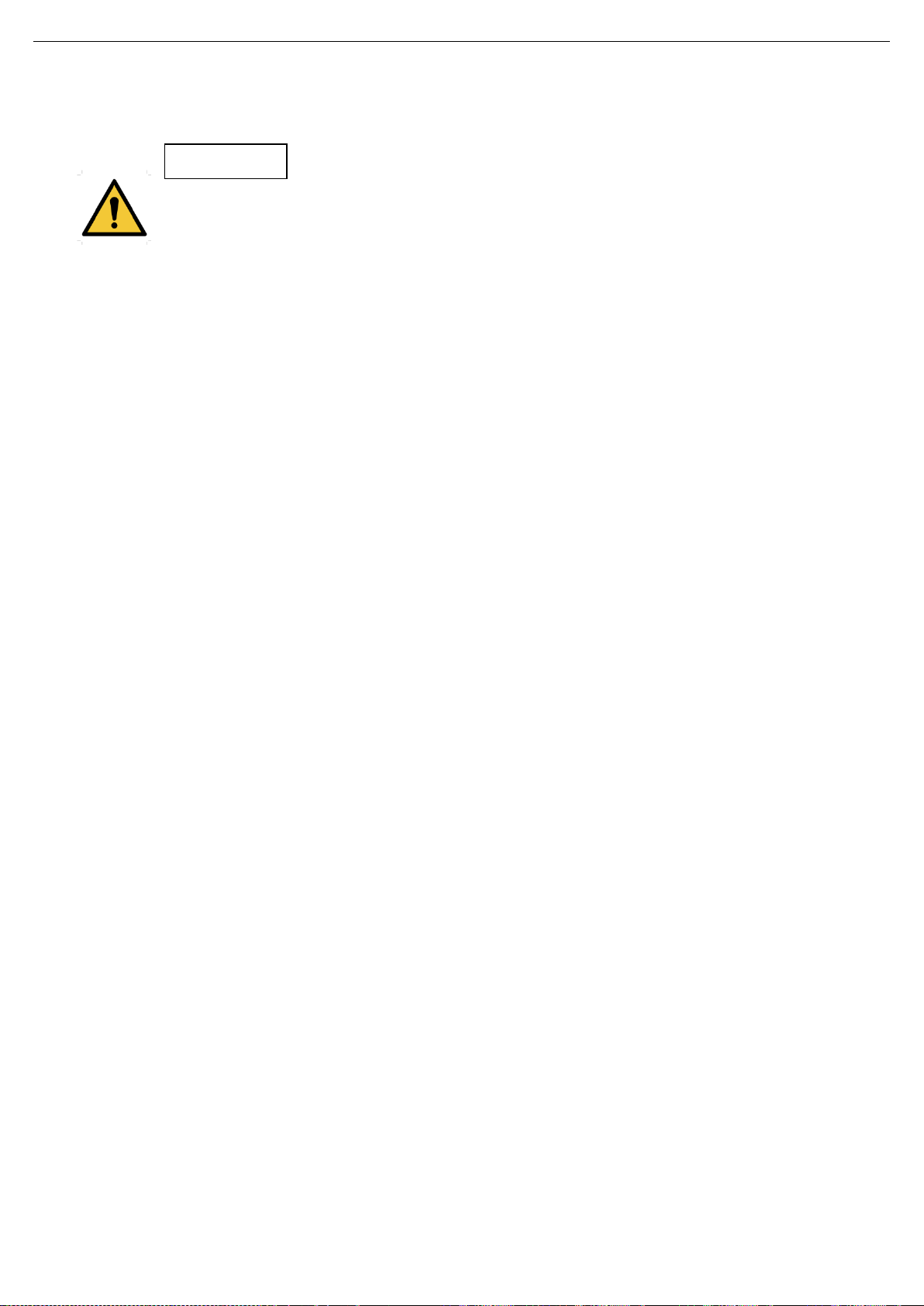

Check that the direction of rotation of the propellers is correct (it must rotate clockwise when see form the

drive side).

Follow the direction of rotation of the agitation components as indicated by the arrow attached to

the engine. An incorrect direction of rotations results in a loss of agitation performance.

Check the electrical consumption of the motor.

After a running-in period, check that the mechanical seal does not leak. If it does change it as shown in

the chapter 8.6. Disassembly and assembly agitator.

Do not modify the operating parameters for which the agitator was initially designed without written

authorisation from INOXPA (risk of damage and user hazard).

Follow the instructions for use and the safety requirements described in the instructions manual for

the tank in which the agitator is mounted.

Mechanical risk (e.g. drag, shear, cutting, impact, flattening and pinching). If the agitation element

is accessible from the top or the tank inspections hatch, then the user will be exposed to the

above-mentioned risks.

ATTENTION

ATTENTION

20.025.32.0004

Start-up

14 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

The tank must be fitted with protective devices and safety equipment. Consult the manufacturer’s instructions

manual.

Introducing an object or solid raw material may cause the agitation component and other

mechanical parts to break and compromise its safety or guarantee.

ATTENTION

Troubleshooting

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 15

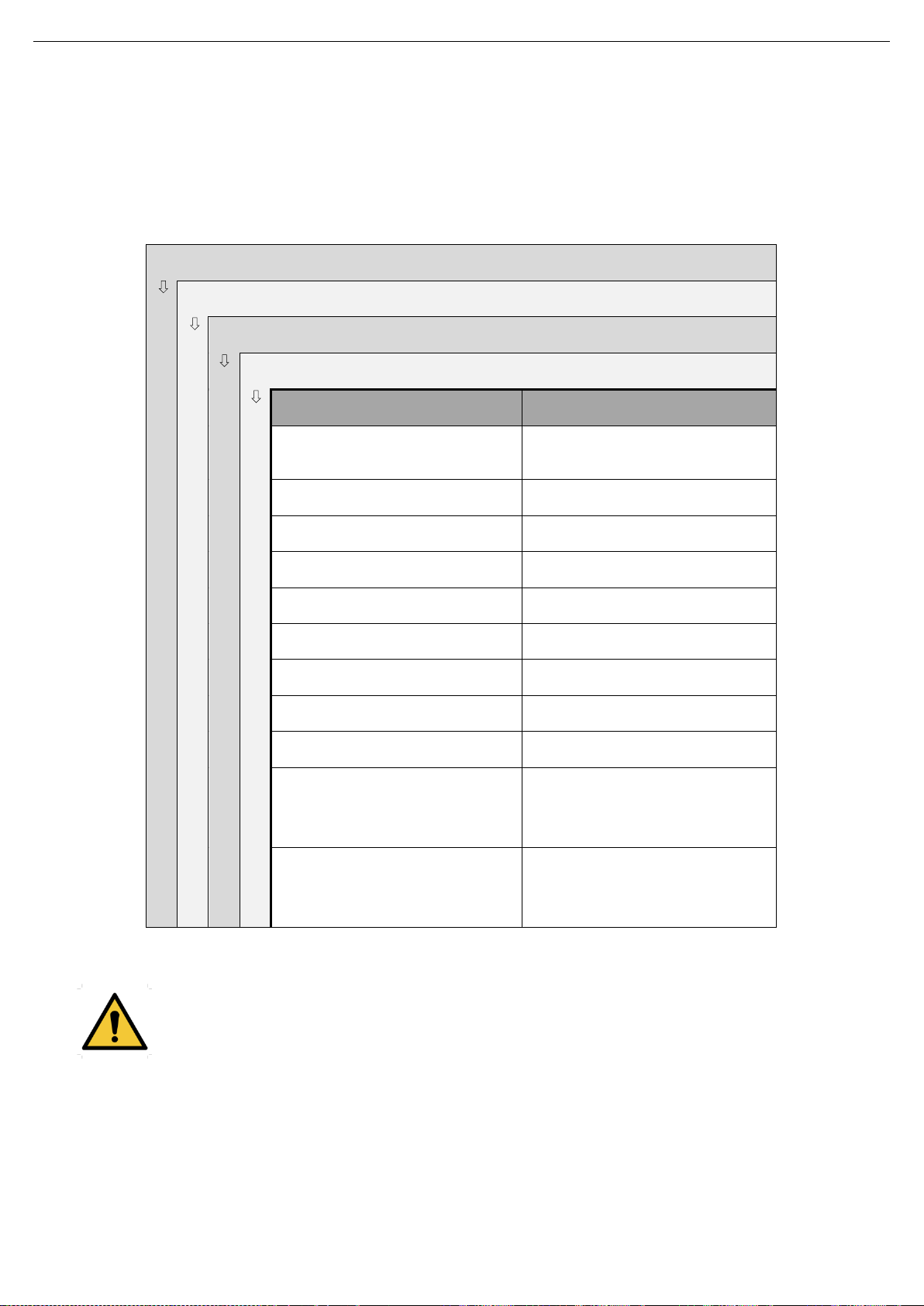

7. Troubleshooting

The attached table lists solutions to problems that may arise while operating the agitator. It is assumed that the

agitator has been properly installed and that is has been selected correctly for the specific application.

Contact INOXPA if technical assistance is required.

Motor overload

Insufficient agitation

Vibrations and noise

Leaks

PROBABLE CAUSES

SOLUTIONS

Viscosity of the liquid too high

Reduce the viscosity, e.g. by heating

the liquid

High density

Increase motor power

Tank too big for the chosen agitator

Check with the technical department

Wrong direction of rotation

Change direction of rotation

Agitator speed too low

Increase the speed

Liquid level insufficient or none

Check liquid level in the tank

Shaft bended

Replace the shaft

Critical speed

Check with the technical department

Worn bearings

Replace the bearings agitator

Lip seal worn or damaged

If the lip seal is worn, replace it.

If the lip seal is damaged, consult the

technical department.

O-rings not the right ones for the

liquid

Fit the proper O-rings, check with the

supplier

If the problems persist stop using the agitator immediately. Contact the agitator manufacturer or the

representative.

Maintenance

16 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

8. Maintenance

8.1. GENERAL CONSIDERATIONS

This agitator, just like any other machine, requires maintenance. The instructions contained in this manual cover

the identification and replacement of spare parts. The instructions are aimed at maintenance personnel and

those responsible for the supply of spare parts.

Carefully read chapter 9. Technical Specifications.

Maintenance work can only be carried out by qualified personnel that are trained and equipped

with the necessary resources to carrying out this work.

Before beginning maintenance work, ensure that the electric motor is disconnected and that the

tank is empty.

All parts or Materials that are replaced must be properly disposed of/recycled in accordance with

the current directives applicable in each area.

Before beginning maintenance work, ensure that the agitator is disconnected.

8.2. MAINTENANCE

Inspect the agitator regularly.

Do not fail to keep the agitator clean.

Check the state of the motor or the gear motor.

Check the state of the bearings.

Check the sealing: seal and/or V-ring.

Motor or gear motor maintenance shall be carried out in accordance with the manufacturer’s instructions, see

the instructions manual.

8.3. LUBRICATION

The LR/LM side-entry agitators are supported on permanently lubricated bearings, which means maintenance is

not required. The bearings can be re-greased disassembling the support, cleaning the previous grease off the

bearings or by replacing them. The bearing houses are also cleaned and finally re-greased with a 50%-80%

grease.

When re-greasing, use only special grease for ball bearings with the following properties:

Lithium-based or made up of high quality lithium,

Viscosity 100-140 cSt at 40ºC,

Consistency NLGI grade 2 or 3,

Continuous work temperature -30ºC to 120ºC.

The lubrication of the bearings of the motor or the gear motor will be carried out according to the manufacturer’s

instructions.

8.4. SPARE PARTS

To order spare parts it is necessary to indicate the type and serial number included on the agitator’s

characteristics plate, as well as the position and description of the part as found in chapter 9. Technical

Specifications.

8.5. CONSERVATION

If the agitator is out of service for a considerable period of time, clean and treat the parts with VG46 mineral oil.

The shaft must be stored in the horizontal position and on wooden supports or on supports of a similar material.

Maintenance

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 17

8.6. DISASSEMBLY AND ASSEMBLY OF THE AGITATOR

The disassembly and assembly of the agitators should only be carried out by qualified personnel

using only appropriate tools. Ensure that staff read these instructions manual attentively,

particularly the instructions that relate to their work.

Stop the motor from starting up when carrying out assembly and disassembly work on the agitator.

Place the agitator switch in the “off” position.

Lock out the electrical switchboard or place a warning sign.

Remove the fuses and take them to the workplace.

8.6.1. Disassembly of the agitator

Once the motor is disconnected, disassembly work may begin:

Empty the tank.

Remove the propeller (02) that is screwed to the agitator shaft (05) knocking a blade lightly with a plastic

hammer in counter-clockwise direction as seen from the front of the propeller. Take care to retain the O-

ring (80) in the agitator shaft (05).

Remove carefully the two parts of the mechanical seal (08), loosening the allen studs that hold them.

Remove shaft guards (47) together with its hexagonal screws (52B) and flats washers (53B).

Remove the hexagonal screws (52C) from the motor or gear motor and loosen the allen studs (55A) from

the bearing support (70).

Move the motor or gear motor and the agitator shaft (05) backwards, taking care not to hit or strain the

agitator shaft.

Remove the allen studs (55) that fix the shaft to the motor and separate the motor or gear motor (93) of

the agitator shaft (05).

Finally, remove the hexagonal screws (52, 52A), flat washers (53, 53A) that separate the flange (23)

from the lantern (04) and the latter from the bearing support (70).

8.6.2. Assembly of the agitator

Assemble the agitator shaft (05) onto the motor or gear motor (93). Locate the threaded holes above the

keyway. Introduce the allen studs into these holes and tighten until they lock on the keyway. The allen

studs must not protrude from the external diameter of the shaft.

Assemble the bearing support (70) in the lantern by means of the hexagonal screws (52A) and flat

washers (53A), without tightening them.

Introduce the agitator shaft and the motor through the bearing support (70) until the flange of the lantern,

and firmly tighten the hexagonal screws (52C).

Tighten the hexagonal screws (52A) of the bearing support (70).

Next, place the flange (23) on the lantern centering (04) fixing through the hexagonal screws (52) and flat

washers (53).

Check that the surfaces of the agitator shaft (05) and the flange (23) are in good condition (perfectly

polished finish).

When fitting the new seals, be sure to wet the O-rings with soapy water so that the fixed parts slide easily

into their locations and the rotating parts onto the shaft.

Place the stationary part of the mechanical seal (08) on its location on the flange (23).

Place the rotating part of the mechanical seal (08) and fix it to the agitator shaft through its fixing studs as

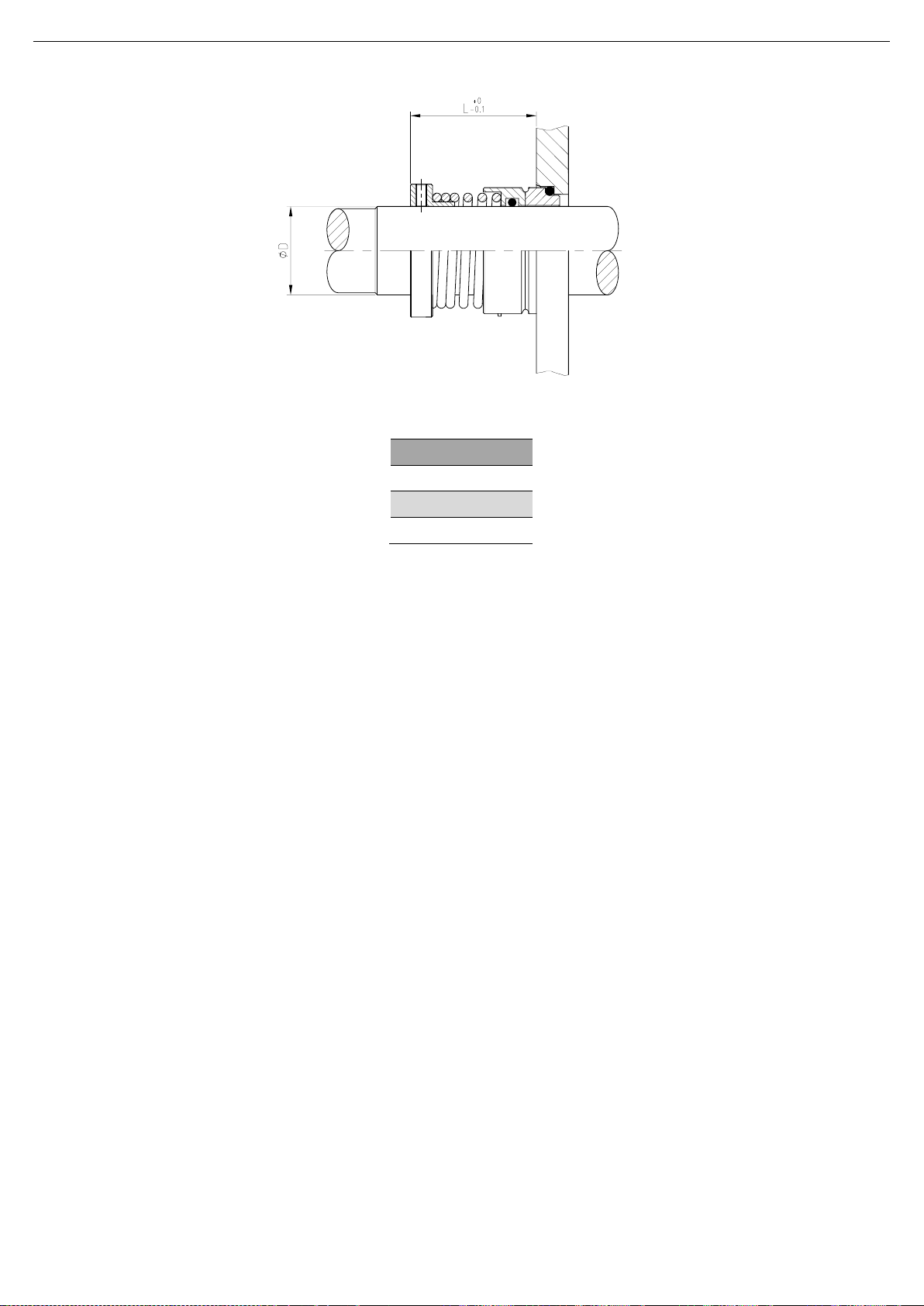

shown in the assembly instructions, figure 8.1.

Locate the shaft guards (47) with the hexagonal screw (52B) and flat washers (53B) to the lantern (04).

Place the O-ring (80) on the agitator shaft (05).

Install the agitator in the flange of the tank.

Finally, mount the propeller (02) firmly on the agitator shaft (05), checking that it will not become loose.

Maintenance

18 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

ØD

L

40

47

50

51,5

60

61,5

20.025.32.0005

Technical Specifications

INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04 19

9. Technical Specifications

9.1. MATERIALS

Parts in contact with the product AISI 316L

Other steel parts GG15

V-ring and retainer C/SiC/EPDM

Bearing support EPDM

Surface finish Ra ≤ 0,8 μm

9.2. OTHER FEATURES

Motor 4 poles, 3 ph, 230/400 V, 50 Hz

Speed (rpm) 1.500

Maximum motor power (kW) LR: 4 kW; LM: 11 kW

Maximum shaft length (mm) LR: 500; LM: 600

Maximum shaft diameter (mm) 60

Maximum propeller diameter (mm) LM: 350; LR: 650

Propeller Marine propeller (type 10)

9.3. WEIGHTS

Type agitator

Weigh (kg)

LR 1.10-20005-1-325

54

LR 1.10-20007-1-400

57

LR 1.10-20015-1-500

64

LR 1.10-20030-1-600

77

LR 1.10-20040-1-650

135

Type agitator

Weigh (kg)

LM 1.10-4015-1-175

46

LM 1.10-4030-1-200

56

LM 1.10-4055-1-225

66

LM 1.10-4075-1-250

75

LM 1.10-4110-1-275

145

LM 1.10-6011-1-200

48

LM 1.10-6022-1-225

62

LM 1.10-6030-1-250

66

LM 1.10-6055-1-275

75

LM 1.10-6075-1-300

150

LM 1.10-6110-1-350

182

Technical Specifications

20 INOXPA S.A.U. 20.025.30.01EN · (0) 2019/04

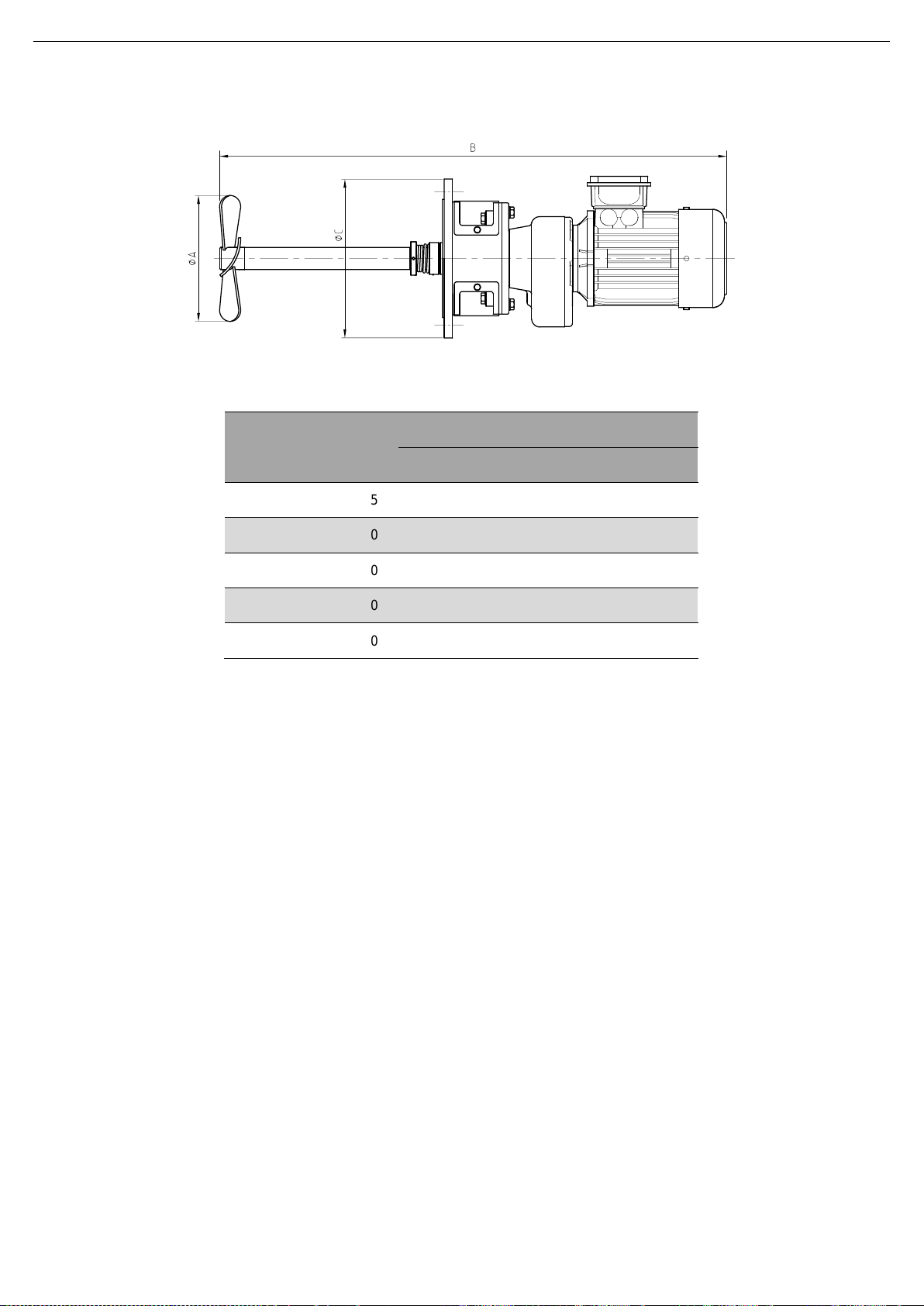

9.4. DIMENSIONS OF LR SIDE-ENTRY AGITATOR

Type agitator

Dimensions (mm)

A

B

C

LR 1.10-20005-1-325

325

910

285

LR 1.10-20007-1-400

400

910

285

LR 1.10-20015-1-500

500

950

285

LR 1.10-20030-1-600

600

1.165

340

LR 1.10-20040-1-650

650

1.205

395

20.025.32.0011

This manual suits for next models

17

Table of contents

Other INOXPA Mixer manuals