InPOWER ABS3-200A User manual

Page

1 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

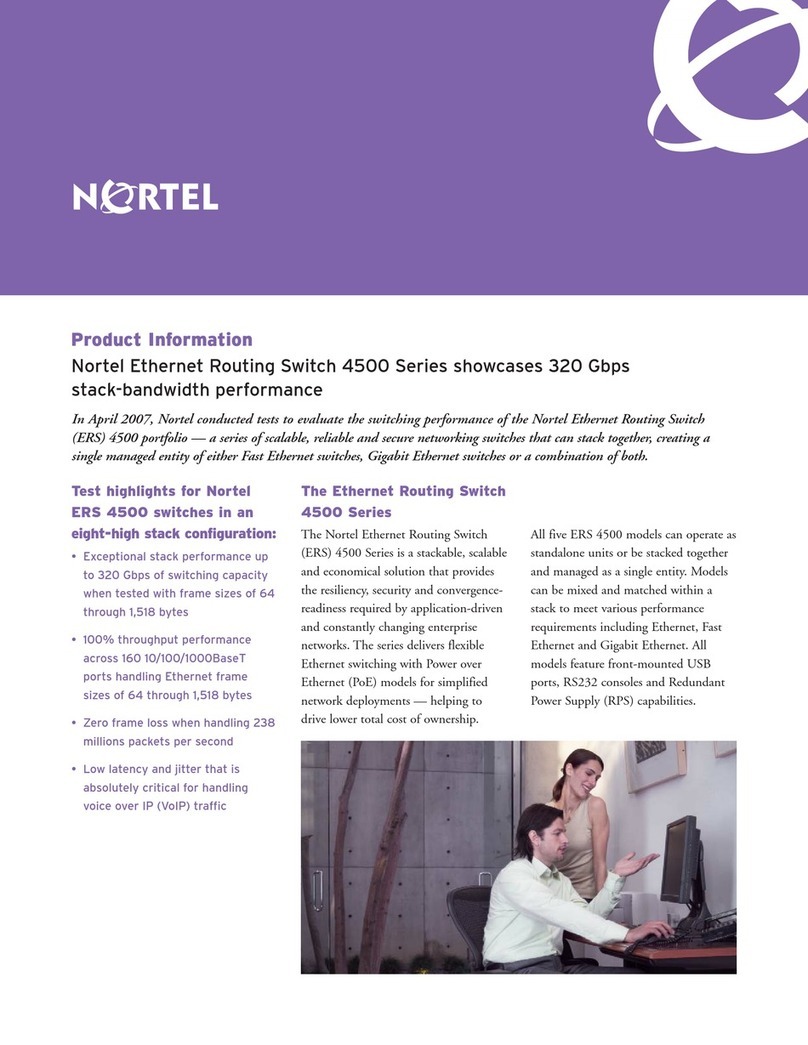

Chassis Battery

Loads

Chassis Battery

Alternator

Auxiliary Battery

Auxiliary Battery

Loads

InPower ABS3-200A

Auxiliary Battery Switch

1.0 Introduction

InPower’s ABS3 Series Auxiliary Battery Switch is next generation technology for ideal charging and

isolating an auxiliary battery from a vehicle’s chassis battery and alternator. This provides automatic

charging in either direction and also insures that the chassis battery will always be available for starting

the Vehicle. In addition there is a Manual mode where the chassis and auxiliary batteries are tied togeth-

er to provide additional starting power.

The ABS3 auxiliary battery switch uses InPower’s proven Patented solid-state contactor technology,

incorporating sophisticated microprocessor algorithms that include over-current, over-temperature, and

over and under-voltage sensing. The ABS3 will automatically reconnect if the faults are no longer pres-

ent. The ABS3 is available in 12V 200 Amp, 2 lug and 4 lug versions (ABS3-200A and ABS-200B) and a

12V, 300 Amp 4 lug version (ABS3-300).

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

LED

GND

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

Patented

www.InPowerLLC.com/Patents

INPUT

BAT 1 BAT 2

LED

GND

12V 200 AMP Auxiliary Battery Switch

ABS3-200B

InPOWER

the systems people

Patented

www.InPowerLLC.com/Patents

www.InPowerLLC.com Lot Code

Electronic

Switch

INPUT

8.0-18Vdc

INPUT

BAT 1 BAT 2

LED

GND

12V 300 AMP Auxiliary Battery Switch

ABS3-300

InPOWER

the systems people

Patented

www.InPowerLLC.com/Patents

www.InPowerLLC.com Lot Code

Electronic

Switch

INPUT

8.0-18Vdc

7.0-18Vdc 7.0-18Vdc

ABS3 12V 200 Amp 2 Lug

ABS3 12V 200 Amp 4 Lug ABS3 12V 300 Amp 4 Lug

Electronic

Switch

OWNERS MANUAL

Solid State Auxiliary Battery Switch

ABS3-200A 12V 200 Amp, 2 Lug

ABS3-200B 12V 200 Amp, 4 Lug

ABS3-300 12V 300 Amp, 4 Lug

Page

2 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

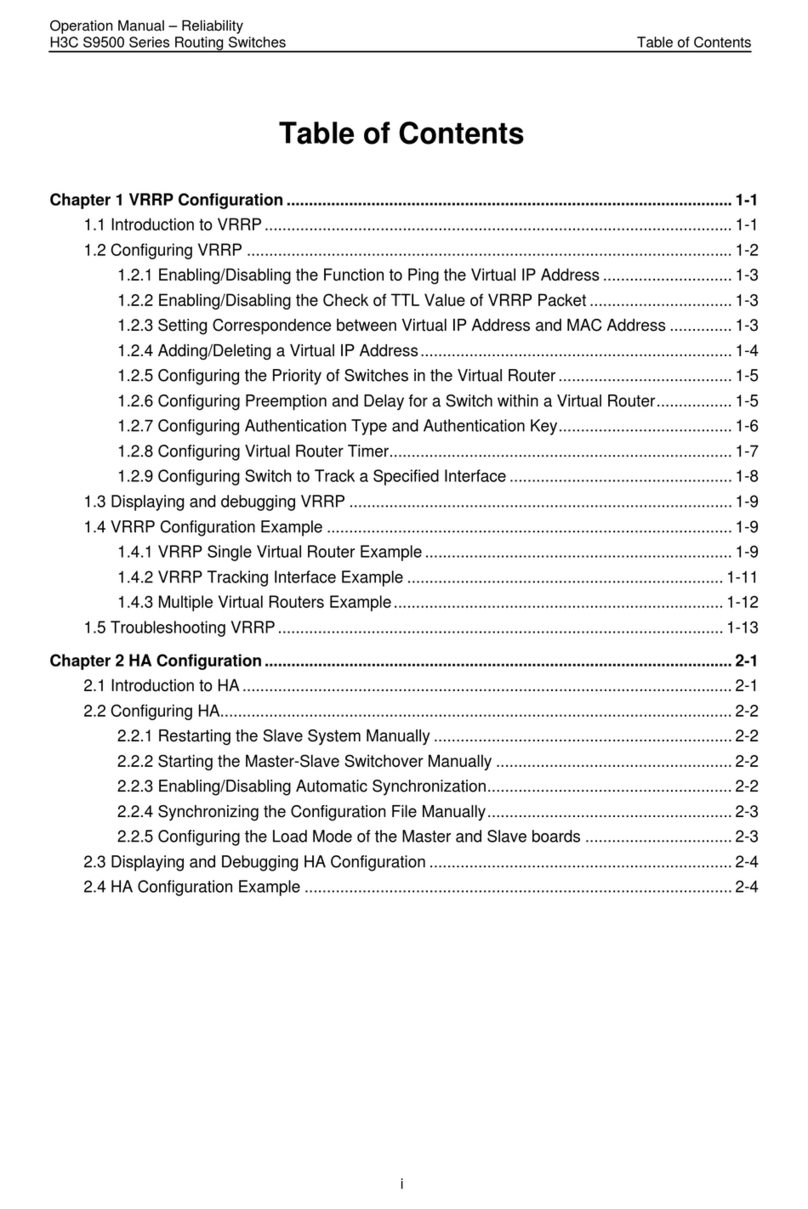

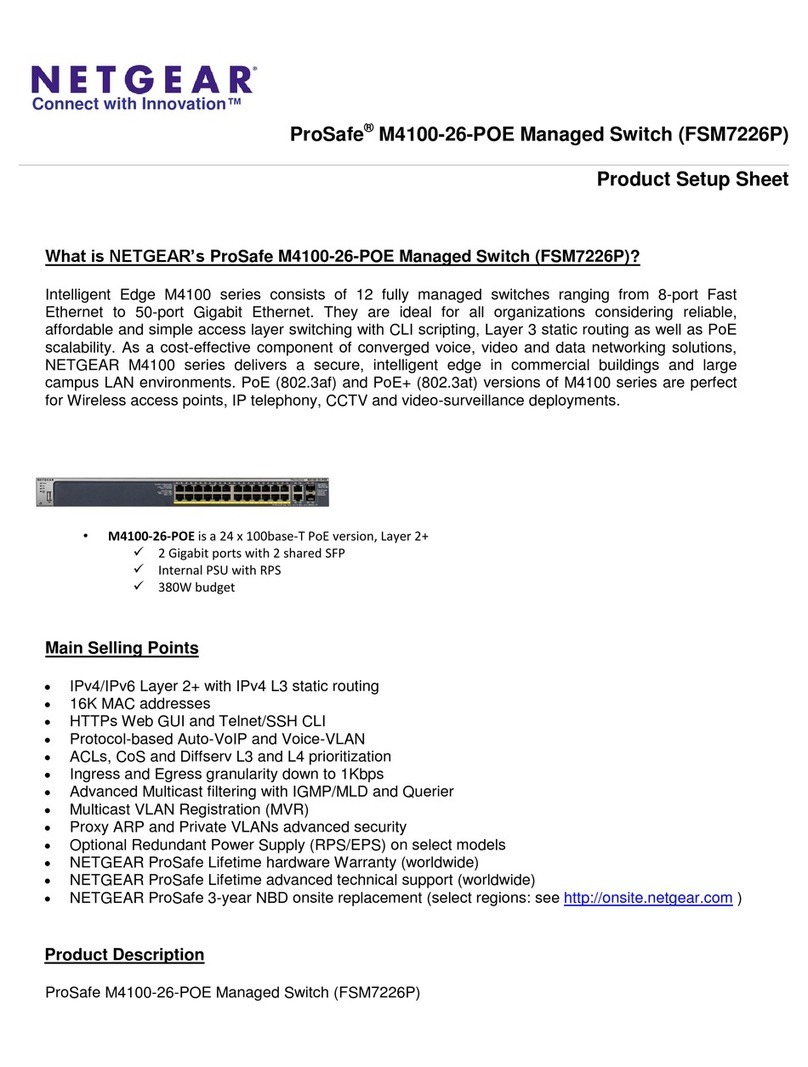

2.0 Operation

In a system with the ABS3, the auxiliary battery is charged from the chassis battery and alternator, while the

chassis battery is protected from a total discharge, and therefore is available for starting the vehicle. As the

ABS3 is bidirectional, a charging device (such as a battery charger or gen-set connected to the auxiliary

battery) can also supply charging current to the chassis battery through the ABS3 while maintaining total

discharge isolation.

The ABS3 switch accomplishes it’s tasks through the constant monitoring of voltage and current by it’s

microprocessor controller. The proper time to transfer power in either direction between the chassis battery

and the auxiliary battery is based on a proprietary algorithm that utilizes both battery voltage and current

measurements. A “boost start” feature is provided that will allow the auxiliary battery to supply current to the

chassis battery to aid engine starting.

Since this is an intelligent switch monitoring voltage, current, and temperature, it is possible to accommodate

a wide variety of customer needs for operation, with programmable times, voltage and current settings. For

custom requirements, please contact InPower LLC directly for your needs.

LED shows whether the ABS3 is ON (LED ON) or OFF (LED OFF).

2.1 Normal Operation

Chassis

Battery

Alternator

Engine Compartment

InPower LLC

ABS3 Electronic

Auxiliary Battery Switch

Fuse *

Chassis

Loads

* SAE required wiring safety fuse. Not

supplied with ABS switch. SAE requires

within 18 inches of Battery.

Auxiliary

Loads

Aux

Battery

On

System Diagram with Charger

Boost Mode

12V

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

LED

GND

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

Patented

www.InPowerLLC.com/Patents

Battery

Charger

13.2V

14.2A

Fuse *

Bi-Directional Mode

Conventional Current

Flow Depicted

Electronic

Switch

For normal operation, it is assumed that the engine is running and the alternator is supplying power to the

charge the chassis battery. When the chassis battery voltage (BAT 1) rises above 13.5 volts for 10 seconds,

the ABS3 closes and passes current to the BAT 2 side. This connects the two batteries to now charge the

auxiliary battery and power auxiliary loads.

Bidirectional Note: In the gure above, either the Alternator or the Battery Charger can charge the batteries

based on the charge requirement of either of the two batteries in the system. For the Battery Charger source,

the Auxiliary Battery becomes the Primary and the Chassis Battery becomes the Secondary Battery which the

ABS3 turns on to charge.

Over-current fault handling: If the ABS3 rated current is exceeded, the ABS3 will turn off after 1 second. If

no faults exist, the ABS3 will turn back on after 30 seconds

Automatic Operation:

• Module will automatically turn ON when battery voltage on either BAT 1 or BAT 2 is greater than

13.5Vdc for greater than 10 seconds.

• Module will automatically turn OFF when the battery voltages on BAT 1 and BAT 2 are less than

12.80Vdc for greater than 10 seconds.

Page

3 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

Manual Operation:

• Momentarily applying +12Vdc to INPUT terminal will cause the Module to turn ON if either BAT 1 and BAT

2 Voltage are at least 7.0Vdc as long as the voltage is present.

Voltage Requirements: The ABS3 switch requires one battery to be above 7.0 volts (in this case the chassis

battery) before it can close.

2.1.1 Charging Chassis and Aux from Alternator (Normal Operation)

Charge Mode

Chassis

Battery

Alternator

Engine Compartment

Fuse *

Chassis

Loads

* SAE required wiring safety fuse. Not

supplied with ABS switch. SAE requires

within 18 inches of Battery.

Aux

Loads

Aux

Battery

Fuse *

13.5 V

12.8 V

13.5 V

12.8 V

InPower LLC

ABS3 Electronic

Auxiliary Battery Switch

On

Boost Mode

12V

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

LED

GND

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

Patented

www.InPowerLLC.com/Patents

Electronic

Switch

Conventional Current

Flow Depicted

When the engine is running and the alternator starts supplying current to the chassis battery and the chassis

battery voltage rises above 13.5 volts for 10 seconds, the InPower ABS3 switch will close connecting the two

batteries. The auxiliary battery will now recharge.

Note that the ABS switch requires one battery to be above 7.5 volts before it will close. If the ABS rated

current is exceeded (100% to 110%) for 1 second the ABS switch will turn off. It will automatically reset after

30 seconds if no faults are present.

2.1.2 Discharging (Normal Operation)

Discharge Mode

Chassis

Battery

Alternator

Engine Compartment

Fuse *

Chassis

Loads

* SAE required wiring safety fuse. Not

supplied with ABS switch. SAE requires

within 18 inches of Battery.

Aux

Loads

Aux

Battery

O

Fuse *

13.5 V

12.8 V

13.5 V

12.8 V

Conventional Current

Flow Depicted

InPower LLC

ABS3 Electronic

Auxiliary Battery Switch

Boost Mode

12V

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

LED

GND

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

Patented

www.InPowerLLC.com/Patents

Electronic

Switch

If the engine is stopped, no alternator current is produced and the batteries begin to discharge. When the

voltage of the combined batteries drops below 12.8 volts for 10 seconds, the ABS3 switch will open, isolating

the auxiliary battery from the chassis battery to reserve engine starting capacity from the chassis battery.

Page

4 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

2.1.3 Boost Mode (Manual Control)

Chassis

Battery

Alternator

Engine Compartment

InPower LLC

ABS3 Electronic

Auxiliary Battery Switch

Fuse *

Chassis

Loads

* SAE required wiring safety fuse. Not

supplied with ABS switch. SAE requires

within 18 inches of Battery.

Aux

Loads

Aux

Battery

Boost Mode

(When 12V)

12V

Fuse *

13.5 V

12.8 V

13.5 V

12.8 V

Aux Boost Mode

Conventional Current

Flow Depicted

On

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

LED

GND

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

Patented

www.InPowerLLC.com/Patents

In the event the chassis battery is discharged, the auxiliary battery may be used to supply current to the

chassis battery to aid engine starting. In this case, the Chassis Battery is in a discharged state, and the

Boost Start control input to the ABS3 is activated from a remote momentary switch. The ABS3 connects the

auxiliary battery to the chassis battery for the duration that the boost start switch is applied. Alternatively,

the “boost start” can be made automatic by connecting the input to the engine start signal.

3.0 Specications

3.1 Electrical Specications

Current Rating: 200 Amps (ABS3-200A/B) 300 Amps (ABS3-300)

Standby Current: 3.8 milliamps

Over-current Protection Trip: 205 Amps (+/- 2 Amps) for 1 sec (ABS3-200A/B)

305 Amps (+/- 2 Amps) for 1 sec (ABS3-300)

Operational Temperature Range: -40oto +185oF (-40oto +85oC)

Over-temperature Shutdown: > 185oF (> 85oC)

Operational Voltage Range: +7.0 to +18.0 Volts

Automatic Trip Voltages: ON if BAT1 or BAT2 > 13.5 for >10Sec

OFF if BAT1 or BAT2 < 12.8 for >10Sec

Manual Operation: ON if +12V to INPUT Terminal

(if BAT1 or BAT2 Volts > 7.0V)

Automatic Fault Reset: ABS3 will automatically restart in 30 sec (if no faults exist)

LED Indicator: Switch ON/OFF

INPUT Signal Voltage Range: +8.0 to 18.0 Volts (True)

Standby Current: <3.8mA

Environmental: Designed to IP67

Power Terminal Torque: Brass Bolts and Copper Washers supplied with ABS3 - 10 to 15 ft-lb

Input and Gnd Terminal Torque: 8/32 Screw Terminal with Brass Nuts (4 to 5 Inch Lbs)

Page

5 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

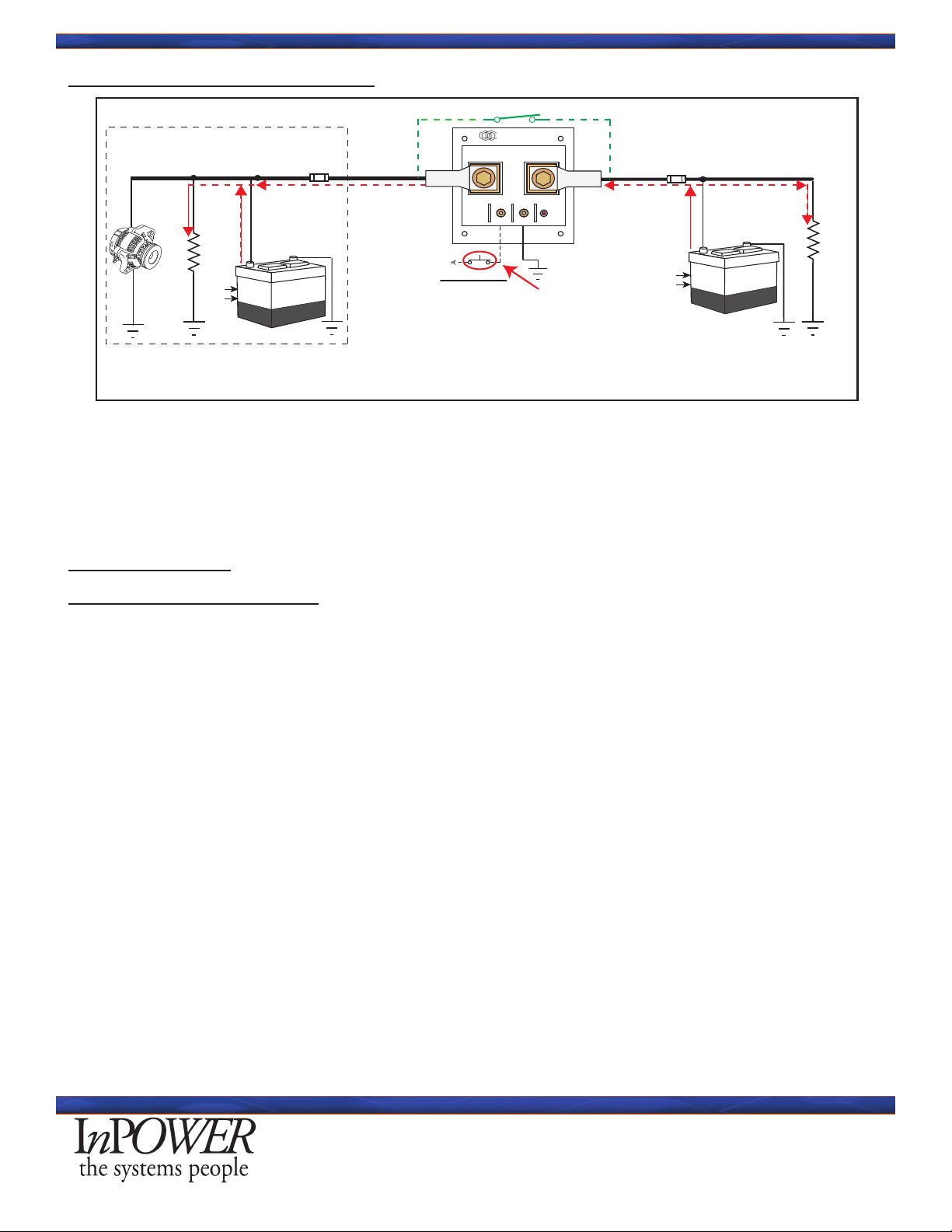

3.2 Mechanical Specications:

0.20

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

4.125

0.375

LED

GND

2.375

4.125

3.40

2.50

1.688

1.125

3.125

3.775 0.75

0.875

Double Crimp Lugs

Customer Supplied

0.813

1.4375

3.775

3.40

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

0.625

Patented

www.InPowerLLC.com/Patents

Electronic

Switch

0.20

INPUT

BAT 1 BAT 2

5.125

0.375

GND

4.125

3.775

2.50

1.688

1.125

3.125

4.775

3.40

3.375

2.375

InPOWER

the systems people

www.InPowerLLC.com Lot Code

200 AMP Auxiliary Battery Switch

ABS3-200B

7.0-18Vdc

INPUT

8.0-18Vdc

LED

Double Crimp Lugs

Customer Supplied

Double Crimp Lugs

Bronze Bolt and Copper Washer

Torque 10 to 15 Ft Lbs.

Ground Wire

To a good quality ground

(Optional User supplied) Small amount of Silicon Thermal Compound

METAL MOUNTING SURFACE

Mounting Bolt

Torque 8-32 mount-

ing bolts to 4-5 Inch

Pounds

4-5 Inch Pounds

Do Not Stack Lugs!

If Multiple Terminations are necessary,

please refer to the ABS3-200B

Dimensions are in Inches

Optional Input

Control Wire

(Boost)

(Also ABS3-300 Dimensions)

Electronic

Switch

4.0 Integration Considerations

4.1 Wire Gauge

The rst consideration is that of wire size for conduction of DC currents. Make certain to follow SAE

recommendations, and make certain to size the wiring accordingly for surge, voltage loss across the length of

wire, thermal load, thermal rating, and exibility to facilitate easy installation for both +12V and return wires.

It actually can be less expensive and easier to install multiple, smaller wires than larger ones. This is due to

both wire and lugs being less expensive as you purchase smaller gauges.

4.2 Grounding

In modern vehicles this is a major issue to remember that the ground path to the battery charging system

must be of adequate size also. Conventional grounding to the frame may not be enough with some newer

methods of connecting chassis components (using bolts and/or adhesives). Latest manufacturer’s directives

state that the only guaranteed ground is the Engine Block.

Make certain that you have a continuous path back to the batteries and charging system capable of handling

the peak amperage.

4.3 Connector Lugs

In addition to wiring considerations, to minimize losses in the system, double crimping lugs, or crimping

technology for a 360 degree crimp is important to minimize resistance (electrical and thermal) for the wire to

connector transition. In other words, maximize the good contact surface area.

4.4 Battery Cable Fusing for Wiring Protection

A fuse must be installed in each cable connecting the ABS3 to the chassis and auxiliary batteries. Each fuse

must be located within 18 inches of the respective battery. For 200 Amp service it is suggested that 225

Amp fuses minimum are used to accommodate surges (the ABS3-200A is protected).

Page

6 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

Fuse Locations

<18”

<18”

Chassis

Battery

Alternator

Engine Compartment

InPower LLC

ABS3 Electronic

Auxiliary Battery Switch

Fuse *

Chassis

Loads

* SAE required wiring safety fuse. Not

supplied with ABS switch. SAE requires

within 18 inches of Battery.

Auxiliary

Loads

Aux

Battery

Boost Mode

12V

Battery

Charger

13.2V

14.2A

Fuse *

INPUT

BAT 1 BAT 2

12V 200 AMP Auxiliary Battery Switch

LED

GND

www.InPowerLLC.com Lot Code

InPOWER

the systems people

ABS3-200A

7.0-18Vdc

INPUT

8.0-18Vdc

Patented

www.InPowerLLC.com/Patents

Fuse should sized appropriately for wire gage and rating.

For ABS3-200, 225 Amps minimum size required.

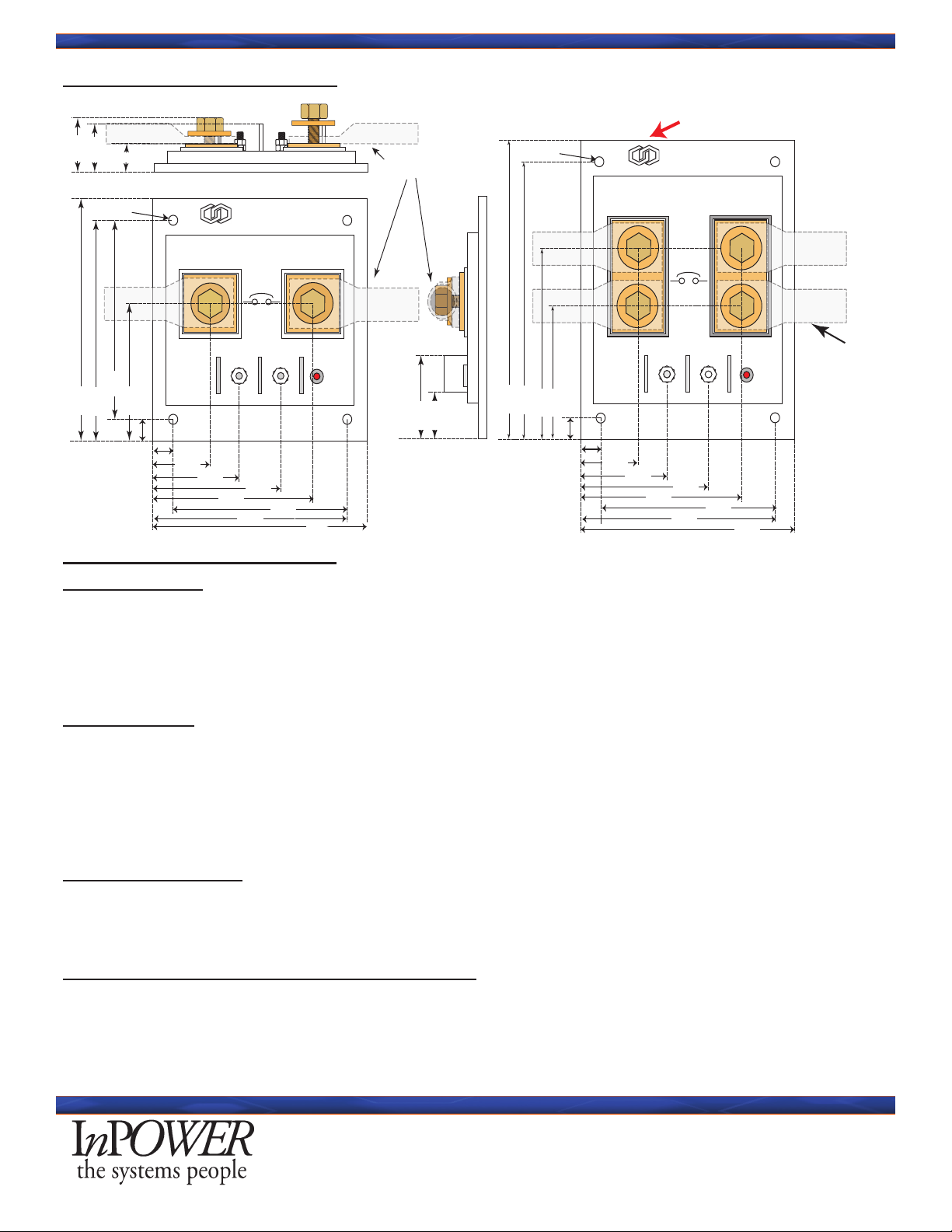

5. Installation Procedure

! !

WARNING!

5.1 Safety and Warranty Precautions

This electronic Auxiliary Battery Switch has been designed and manufactured to meet the intended

application requirements and specications. Any modications to the product or to the installation

procedure can be dangerous and will void InPower’s warranty.

This product requires the installer to be trained for installation and work on vehicle electrical systems. We

recommend that all wiring meet the SAE and applicable vehicle manufacturer’s wiring specications. In-

spect the product and all other components for damage before starting the installation. Do not perform the

installation if any problems exist.

• Read and understand the instructions in this manual and other manuals before starting the

installation.

• Make sure that the vehicle battery power is disconnected during the installation of the ABS3.

• Wear appropriate safety equipment, such as protective eyeglasses, face shield and clothing when

installing equipment and handling the battery.

• Be careful when working near a battery. Make sure that the area is well ventilated and that there are

no ames near the battery. Never lay objects on the battery that can short the terminals together. If

battery acid gets in your eyes, immediately seek rst aid. If acid gets on your skin, immediately wash

it off with soap and water.

• Take great care when making modications (welding) to the frame or body, making certain all

Batteries are disconnected. Welding can not only damage or destroy the ABS3, but will also cause

damage to the vehicle electrical systems and will void the warranty of the ABS and the vehicle itself.

• Do Not Stack Lugs on the ABS3-200A terminals - use an appropriate termination block for attaching

multiple wires. Refer also to the ABS3-200B which can accommodate a second set of lugs or a

single double holed lug.

Page

7 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

• For maximum thermal efciency, the mounting surface should be a thick metal surface such as an

aluminum plate 1/8 x 12 x 12 inches or larger.

• The ABS3, although sealed, must be mounted in a protected and dry area.

• The ABS3 is not designed for exposure to saltwater spray, environmental debris or power washing.

• It must be mounted to a at metal surface that maintains ambient temperature to dissipate excess heat.

• The module must not be mounted in the engine compartment or any location near a source of

extreme heat.

• Take into consideration the routing of the two battery cables as well as the grounding cables.

• Connect only battery cables to the ABS3 power terminals.

• If desired, to aid in the heat transfer, spread an appropriate amount of Optional User-Supplied heat

sink compound material.

• Spread the heat transfer compound evenly over the heat sink plate on the bottom of the ABS3.

Apply from the tube thinly and the goal is to cover the baseplate with 1/32 of an inch. Use a at

edge to insure that the material between the module and the mounting surface is even with no

pockets or gaps in coverage.

• Secure the module to the at metal surface using four #6 or #8 screws and tighten to a torque setting

of 5 inch pounds. Do not drill out the four mounting pad holes to use a larger size.

5.2 Required Installation Hardware

#6 or #8 Mounting hardware (bolts and nuts)

5.3 Mounting Diagram

No Stacking of Lugs!

If multiple terminations are needed, please refer

to the ABS3-200B or the ABS3-300

Double Crimp Lugs

(Customer Supplied)

Bronze Bolt and Copper Washer

Torque 10 to 15 Ft Lbs.

Ground Wire

To a good quality ground

(Optional User supplied) Small amount of Silicon Thermal Compound

METAL MOUNTING SURFACE

Optional Input

Control Wire (Boost)

Mounting Bolt

3/8 - 16 stainless steel threaded stud

Cable & Lug

Nut

Terminal boot (Not supplied with ABS2.)

Mounting screws (4 Required,

8-32 or 10-32) - (Not supplied

with ABS2.)

Thermal transfer pad

(supplied with ABS2)

IMPORTANT!

Torque mounting screws:

Minimum: 4 Inch Pounds

Maximum: 5 Inch Pounds

IMPORTANT!

Torque cable lug nuts to:

Minimum: 10 Foot pounds

Maximum: 15 Foot pounds

ABS2 Module

METAL MOUNTING SURFACE

NOTE - If the mounting screws cannot

provide a good quality ground you must

install a ground lug terminal and ground

wire.

IMPORTANT!

The mounting surface provides a means to remove heat that is generated by the ABS2

Auxiliary Battery Switch. If this surface is a poor conductor of heat, the unit will have a

lower currrent rating than if the surface is a good conductor of heat with a sufficiently

large area.

Boost Control and GND wire

and 8-32 Ring Terminal

Minimum: 4 Inch Pounds

Maximum: 5 Inch Pounds

Torque 8-32 mounting bolts

to 4-5 Inch Pounds

4-5 Inch Pounds

Page

8 of 8

ABS3 Owner’s Manual

Document: OM-215 Version Code: B

Date: Jan 28, 2021 Date: Aug 9, 2021

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

© Copyright 2021 InPower LLC

5.4 Making the Final Connections

Do not drill out the contactor’s four mounting pad holes to use a larger bolt size. Drilling the

mounting holes out will void the warranty.

Grounding

Proper operation of the ABS3 is dependent on a good quality ground system with appropriate sized wires

for the load if the chassis is not a dependable source for a ground. Both the chassis battery and the auxil-

iary battery must be connected to a solid common ground. Be wary of attaching to the frame since many

manufacturers only recommend grounding directly to the Engine Block as a guaranteed ground. Con-

sult the recommended grounding documentation for your vehicle. The ABS3 must be connected to this

common ground. Install a #16 AWG ground wire with a ring terminal under one of the four ABS mounting

screws and connect it to the common battery ground. It is generally considered that the highest quality

ground is at the chassis battery’s negative terminal (although it is best to consult your chassis manufac-

turer’s documentation).

Connect the Power Cables and Boost Input Prepare the cables to the batteries using a suitable size cable

for the current required. Install a double crimped (or 360 degree crimped) lug terminal on the ends. Termi-

nal BAT1 is connected to the positive terminal of the chassis battery and terminal BAT2 is connected to the

positive terminal of the auxiliary battery.

For the Optional Boost Input Control, install a #16 AWG ground wire with a ring terminal and connect that

to a 12V control voltage. This can be a switch or voltage source of your choice. Refer to the Input voltage

specications for this interface.

Torque the 8/32 Screw Terminal with Brass Nuts to 4 to 5 Inch Lbs).

6.0 Testing Procedure

Make the following resistance measurements with a digital multimeter with all wires removed from the

ABS3-200.

1. Measure the resistance between the two power terminals (BAT 1 to BAT 2). The resistance

should be 210-220 KOhms.

2. Measure the resistance from the control INPUT terminal to the GND terminal. The resistance

should be 130 KOhms.

3. Measure the resistance of each power terminal to a GND terminal with the + probe on the power

terminal.

4. The resistance should be 105-110KOhms (BAT 1) and 105-110KOhms (BAT 2).

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035

740-548-0965

www.InPowerLLC.com

This manual suits for next models

2

Table of contents

Other InPOWER Switch manuals