2

Contents

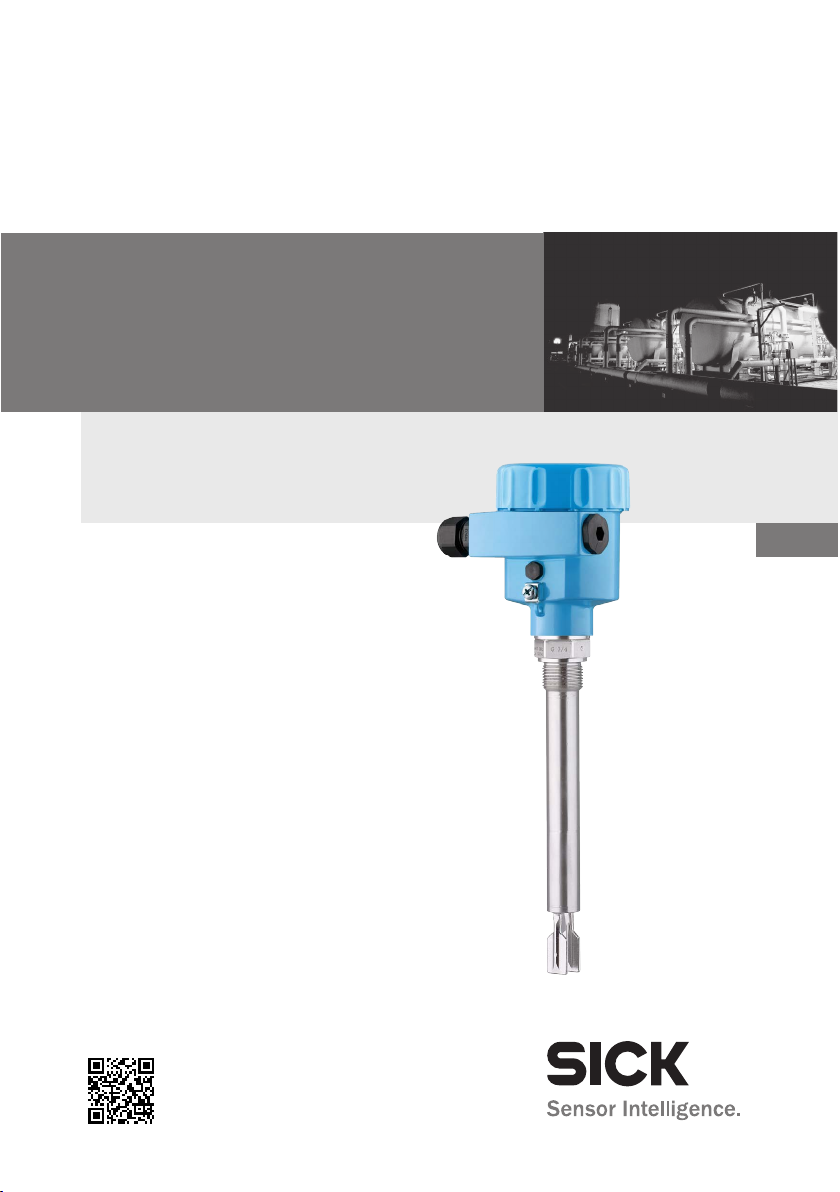

LFV 330 • NAMUR

8014386 / 1M2Z

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Conformity........................................................................................................................ 5

2.6 NAMUR recommendations .............................................................................................. 6

2.7 Installation and operation in the USA and Canada ........................................................... 6

2.8 Safety instructions for Ex areas ........................................................................................ 6

3 Product description ................................................................................................................. 7

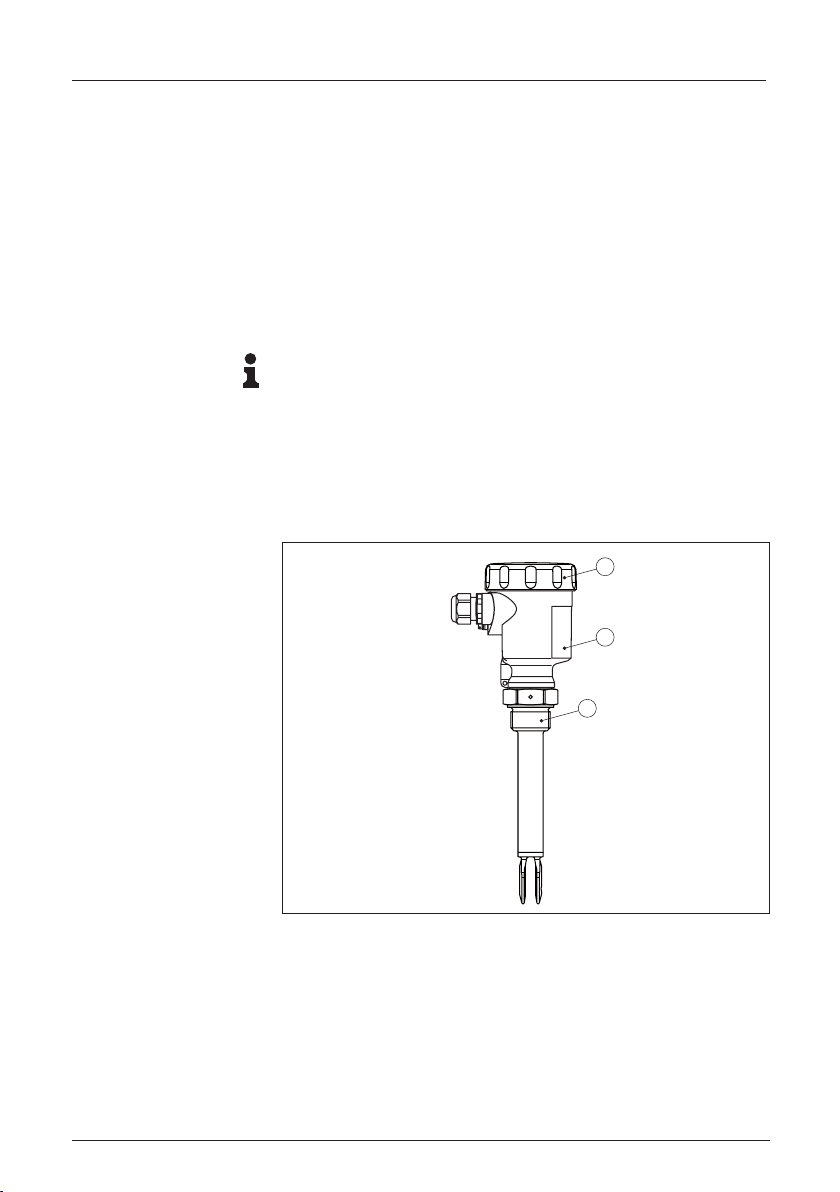

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Adjustment ....................................................................................................................... 8

3.4 Packaging, transport and storage..................................................................................... 9

3.5 Accessories...................................................................................................................... 9

4 Mounting................................................................................................................................. 11

4.1 General instructions ....................................................................................................... 11

4.2 Mounting instructions ..................................................................................................... 14

5 Connecting to power supply................................................................................................. 17

5.1 Preparing the connection ............................................................................................... 17

5.2 Connection procedure.................................................................................................... 17

5.3 Wiring plan, single chamber housing.............................................................................. 18

6 Setup ....................................................................................................................................... 20

6.1 General information........................................................................................................ 20

6.2 Adjustment elements...................................................................................................... 20

6.3 Function table................................................................................................................. 21

7 Maintenanceandfaultrectication...................................................................................... 23

7.1 Maintenance .................................................................................................................. 23

7.2 Rectify faults................................................................................................................... 23

7.3 Exchanging the electronics ............................................................................................ 24

7.4 How to proceed if a repair is necessary.......................................................................... 25

8 Dismount................................................................................................................................. 26

8.1 Dismounting steps.......................................................................................................... 26

8.2 Disposal ......................................................................................................................... 26

9 Supplement ............................................................................................................................ 27

9.1 Technical data ................................................................................................................ 27

9.2 Dimensions .................................................................................................................... 33

9.3 Trademark ...................................................................................................................... 36