INSBUD IB-Tron 3100FAN-230V User manual

Electronic controller

IB–Tron 3100FAN-230V

for Air Handling Units (AHU)

THIS PRODUCT HAS THE MARK

AND HAS BEEN MANUFACTURED IN ACCORDANCE WITH ISO 9001 STANDARD

INSBUD ul. Niepodległości 16a

32-300 Olkusz

Polska

+48 503 166 906

e-mail: [email protected]

The manufacturer promotes development policy. The right to make changes and improvements to products

and instructions without prior notice is reserved!

The contents of this manual - texts and graphics are the property of the manufacturer or its subcontractors

and are protected by law.

manual version: 2.13.0

rmware version: 07

IB–Tron 3100FAN-230V

1 General information ............................................ 4

2 Properties ................................................... 4

3 Compatibility ................................................. 4

4 Technical data ................................................ 5

5 General thoughts .............................................. 5

6 Scope of delivery ............................................... 5

7 Principle of operation ........................................... 5

8 Controller design .............................................. 5

9 Dimensions .................................................. 6

10 Control panel of the controller ...................................... 6

11 LCD display ................................................. 7

12 Mounting ................................................... 8

13 Connection module ............................................. 9

14 FAN digital input .............................................. 10

15 Connection example ............................................ 10

16 Connection - Zehnder Basic, AERIS 350 i 450 STANDARD, ITHO Daalderop Aure Vent

D250 ...................................................... 11

17 Connection - replacement of LEGRAND ............................... 11

18 Connection - single phase fan with autotransformer ........................ 11

19 Connection - low voltage cable ...................................... 13

20 Installation notes .............................................. 14

21 Turning the controller on ......................................... 14

3

22 Conguration menu ............................................. 14

23 Conguration of outputs .......................................... 14

24 FAN input operation ............................................ 16

25 Temporary ventilation level ........................................ 16

26 Ventilation time ............................................... 17

27 Calibration .................................................. 17

28 Idle time .................................................... 17

29 Backlight time ................................................ 17

30 Backlight intensity ............................................. 17

31 Temperature unit .............................................. 18

32 Time format ................................................. 18

33 Filter change reminder ........................................... 18

34 Alarm states ................................................. 18

35 Firmware version .............................................. 18

36 Time and day of the week ......................................... 19

37 Factory settings ............................................... 19

38 Keypad lock .................................................. 19

39 Operating schedule - AUTO mode ................................... 19

40 Manual mode ................................................. 20

41 Semi-automatic mode ........................................... 21

42 Errors ..................................................... 21

43 Operation instructions ........................................... 21

44 Warranty terms and conditions ..................................... 21

WWW.INSBUD.NET

1General information

The IB–Tron 3100FAN-230V controller is an in-

dependent microprocessor regulator equipped with

a large liquid crystal LCD display, dedicated to ope-

rating air handling units (AHUs). The controller al-

lows to control 3 ventilation levels, for which the si-

gnal of switching on is a short circuit of the corre-

sponding lines to the common screw terminal.

The IB–Tron 3100FAN-230V controller allows to

regulate the ventilation level in the building based

on the programmed operating schedule or in manual

mode.

The IB–Tron 3100FAN-230V controllers save

energy costs by adjusting the ventilation level ac-

cording to needs. They thus contribute to environ-

mental protection and nancial savings. Can be wi-

dely used in hotels, oces, supermarkets, factories,

hospitals, residential homes and other buildings.

2Properties

Large backlit liquid crystal display showing

current ventilation level, temperature, set-

tings, day of the week and other information.

3 ventilation level to choose from.

Possibility of dening the time after which the

control panel switches to the lter change re-

minder mode (FILTER sign and acoustic si-

gnal).

Aesthetic and modern design.

Blue backlighting of the screen (backlighting

is activated when any button is pressed and

deactivated after some time of inactivity).

Easy, intuitive operation and programming.

Operating schedule of the process in a weekly

cycle with the accuracy of 1 minute and the

possibility of programming 4 time periods each

day.

Manual or automatic operating mode.

Temperature displayed with 0,1◦Cresolution.

Support for an additional digital input (three

operating modes to choose from).

Input for connecting a dirty lter signal from

AHU. When this input is shorted to the neu-

tral wire, the AHU will be turned o as a prio-

rity and an audible signal will sound.

Power supply from 230V mains with battery

backup of settings memory.

3Compatibility

The controller can be installed in place of manual

ventilation capacity switches, e.g:

Legrand SISTENA LIFE switch for ventila-

tion control 4 positions (0-1-2-3) 20A 250V

cat. 775958.

Zehnder ventilation switch SA 1-3V 4 positions

(0-1-2-3) 20A 250V cat. 775958.

The controller is compatible with the following

AHUs, among others:

Zehnder ComfoAir 300, 350, 450, 550 Basic

Tywent B3B, ZWC-B

StorkAir

NED AIR WTA HR 300, 400

Aeris 350 Standard VV

Mistral 300, 400, 250 ECONO

Mistral Mini 250 (AC 230 )

Vasco D300EII, D400II, D400EPII, D500II,

D500EII, DX4 E, DX5 E, DX6 E, X350, X425,

X500, D275EP III

Harmann Requra 20, 30, 40, 50

ITHO ECO4, HRU-3 BVH-004, Daalderop

Aure Vent D250

Mitsubishi LGH Lossnay

Dospel Luna

Orcon HRC EcoMax, MaxComfort 300, 400,

500

CLIMA Xtract ECO Plus Flat

Connection to sample AHUs later in this manual.

The controller can also be connected directly to the

fans:

single phase fans with „taps” controlling the

fan speed. Such a fan can be recognized by the

fact that it has PE, N wires and a few wires for

supplying the control phase, e.g. L1, L2, L3.

If the fan has only three wires, PE, N and L,

it means that the fan is not factory set for

speed change. In order to control such a fan,

additional electrical components are required,

e.g. inverter or autotransformer. An example

of connection with such a fan using an auto-

transformer is given later in this manual.

three-phase fans - the appropriate connection

should be designed depending on the fan used.

5

WWW.INSBUD.NET

4Technical data

Power supply: 230 V AC

Max. contact load:

3A/240V≈700 W

Ventilation level signal: short circuit with

COM1

Filter signal: short circuit with C2

Digital input: short circuit with C2

Number of ventilation levels: 3

Housing: ABS

Display: LCD (3,2”)

Control: Electronic

Ingress Protection Code: IP30

Settings memory: 36 months

Dimensions

(height ×width ×depth):

Control panel: 86 ×86 ×15 mm

Connection module: 62 ×45 ×27 mm

Energy consumption: <2W

Storage temp.: −5÷50◦C

Display temp.: −20 ÷140◦C

5General thoughts

The power supply should be turned o when

installing the controller. It is recommended to

entrust the installation of the controller to spe-

cialized personnel.

The controller is designed to work with devices

for which the active signal of switching on ven-

tilation levels is shorting the appropriate lines

to the common screw terminal (COM1).

The common screw terminal (COM1) and the

screw terminal of the individual ventilation le-

vels are isolated from the power supply - the-

se are the so called potential-free outputs (dry

contact).

6Scope of delivery

1x Controller

1x User Manual

7Principle of operation

When operating in automatic (operating schedule)

mode, at the beginning of each time periods the con-

troller switches on the ventilation level programmed

for that time period. It is possible to program 4 time

periods per day and to assign one of the available

ventilation level to each of them.

In manual mode, the user sets the ventilation level of

the air handling unit (AHU) by himself. The air han-

dling unit (AHU) works in this mode all the time,

until another ventilation level is set or the controller

is switched o.

All ventilation level outputs are disconnected from

the common screw terminal when the controller is

o.

8Controller design

The IB–Tron 3100FAN-230V controller consists

of two parts: main panel with LCD display with key-

pad and connection module with screw terminal for

connection of air handling unit, additional button,

lter signal and power supply.

Both modules are connected with each other by a at

cable, several centimeters long.

6

WWW.INSBUD.NET

11 LCD display

1- day of the week.

2- current ventilation level or information.

3- visible symbol means keypad lock.

4- temperature or setting value.

5- visible symbol means active ventilation mo-

de.

6- graphic representation of the current ven-

tilation level.

7- visible symbol means manual mode.

8- time.

9- time period.

10 - visible symbol means active semi-

automatic mode.

11 - graphic representation of the current ven-

tilation level. The animated fan rotates with

dierent speed or is not visible.

8

WWW.INSBUD.NET

12 Mounting

Separate the two parts of the main panel housing of

the controller. To do this, insert a at screwdriver

into the two slots visible in the bottom part of the

panel and lever the plastic catches.

After levering the catches, carefully separate the two

halves of the main panel. To avoid damaging the ca-

se, start from the lower part of the panel (from the

catches side).

After separating both parts, disconnect the at ca-

ble connecting the main panel with the connection

module by pulling the plug from the socket in the

front part of the panel.

The controller wiring, led to the electrical installa-

tion box, should be connected to appropriate termi-

nals of the controller, according to the manual.

Make the connections with power o.

Carefully lay down excess wires in the cable instal-

lation box, avoiding stresses that could break wires

from their terminals.

Place the connection module in the electrical instal-

lation box and screw the back part of the main panel

casing with two screws.

9

WWW.INSBUD.NET

Connect the at cable to the socket in the front part

of the main panel.

Connect the two parts of the controller, starting with

the catches at the top of the controller and ending

with the catches at the bottom.

For mounting, a rectangular mounting box of

80x80x50mm is recommended.

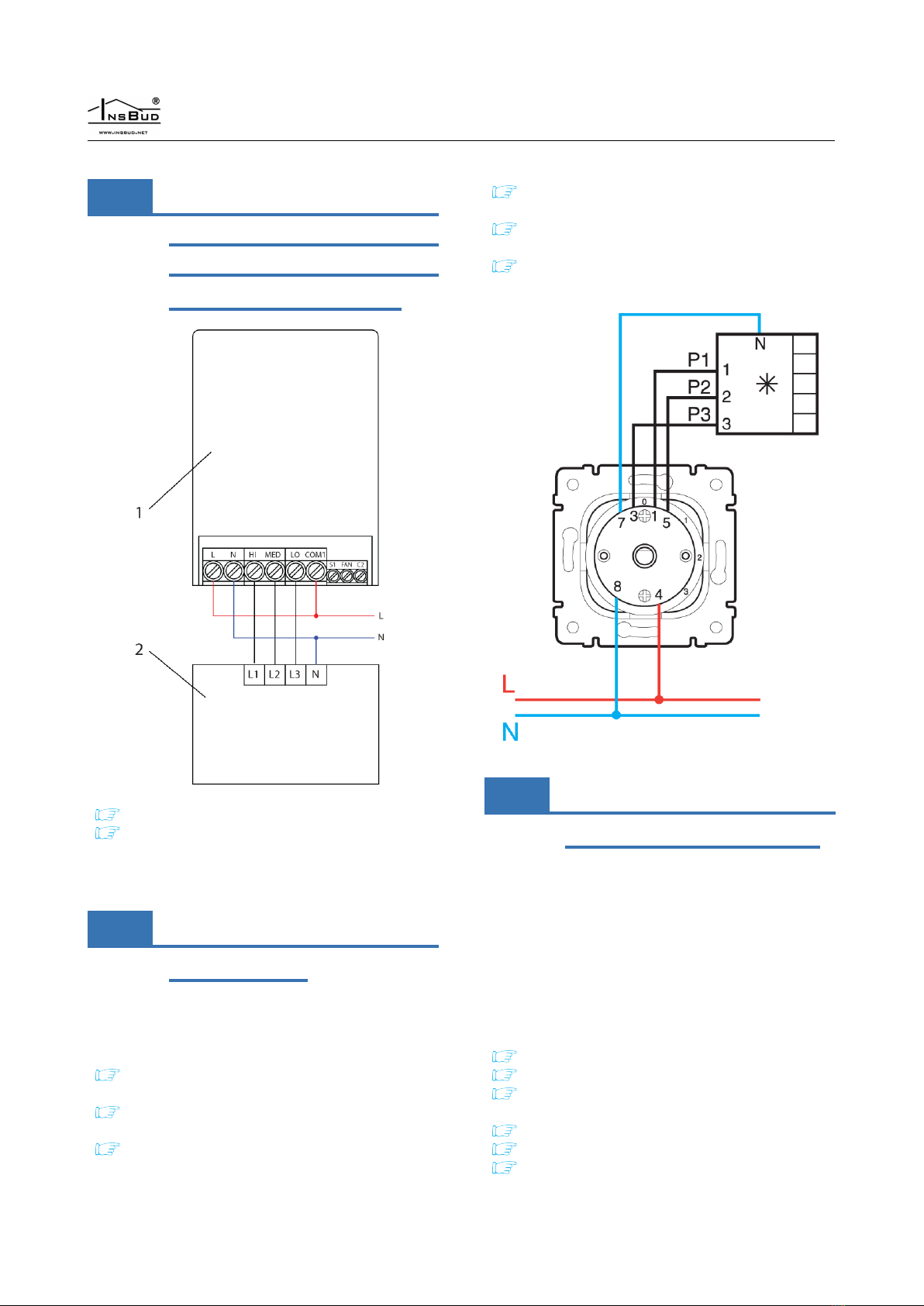

13 Connection module

L- 230 V AC power supply phase.

N- neutral wire 230 V AC.

HI - high, third ventilation level output. This

output is shorted to the common output when

the controller wants to turn on the 3rd venti-

lation level of the panel.

MED - medium, second ventilation level. This

output is shorted to the common output when

the controller wants to turn on the 2nd venti-

lation level of the panel.

LO - low, rst ventilation level. This output is

shorted to the common output when the con-

troller wants to turn on the 1st ventilation level

of the panel.

COM1 - common output of ventilation level..

SI - clogged lter signal input. When this in-

put is shorted to C2, the alarm is activated.

FAN - digital input. Shorting this input to C2

activates the input.

C2 - common input to SI and FAN.

The described situation of shorting HI, MED,

LO to COM1 refers to the situation when the

setting parameter CFG=4. A detailed descrip-

tion of other relay states for other CFG value

settings is described in the further part of the

manual.

10

WWW.INSBUD.NET

14 FAN digital input

The controller is equipped with an additional digi-

tal input FAN there can be connected e.g. a carbon

monoxide, carbon dioxide, gas or air quality sensor

(must have NO output). The active signal for this

input is shorting the FAN output with C2. Typi-

cally a monostable button is connected to this input

(so-called „bell” switch), is short-circuited when the

button is pressed and returns to the open position

when the button is released (used, for example, on

doorbells). Alternatively, one of the modes of ope-

ration of the FAN input provides for connection of

a bistable switch (standard, „on/o” type, e.g. for

lighting). Depending on the selected function (de-

scription later in this manual), the controller chan-

ges the ventilation level accordingly after shorting

the digital input (pressing the button).

15 Connection example

1- main panel

2- connection module

3- monostable buttons

4- clogged lter sensor; dierential pressure

switch, etc.

11

WWW.INSBUD.NET

16 Connection - Zehnder Ba-

sic, AERIS 350 i 450

STANDARD, ITHO Daal-

derop Aure Vent D250

1- the IB–Tron 3100FAN-230V controller

2- AHU

In the conguration menu, set the parameter

CFG=6.

17 Connection - replacement

of LEGRAND

To replace the Legrand SISTENA LIFE switch for

ventilation control 4 positions 0-1-2-3 (part number

775958) switch:

3 from Legrand switch - to HI screw terminal

in controller

5 from Legrand switch - to MED screw termi-

nal in controller

1 from Legrand switch - to LO screw terminal

in controller

4 from Legrand switch - to L screw terminal

in controller

8 from Legrand switch - to N screw terminal

in controller

7 from Legrand switch (if connected) - to N

screw terminal in controller

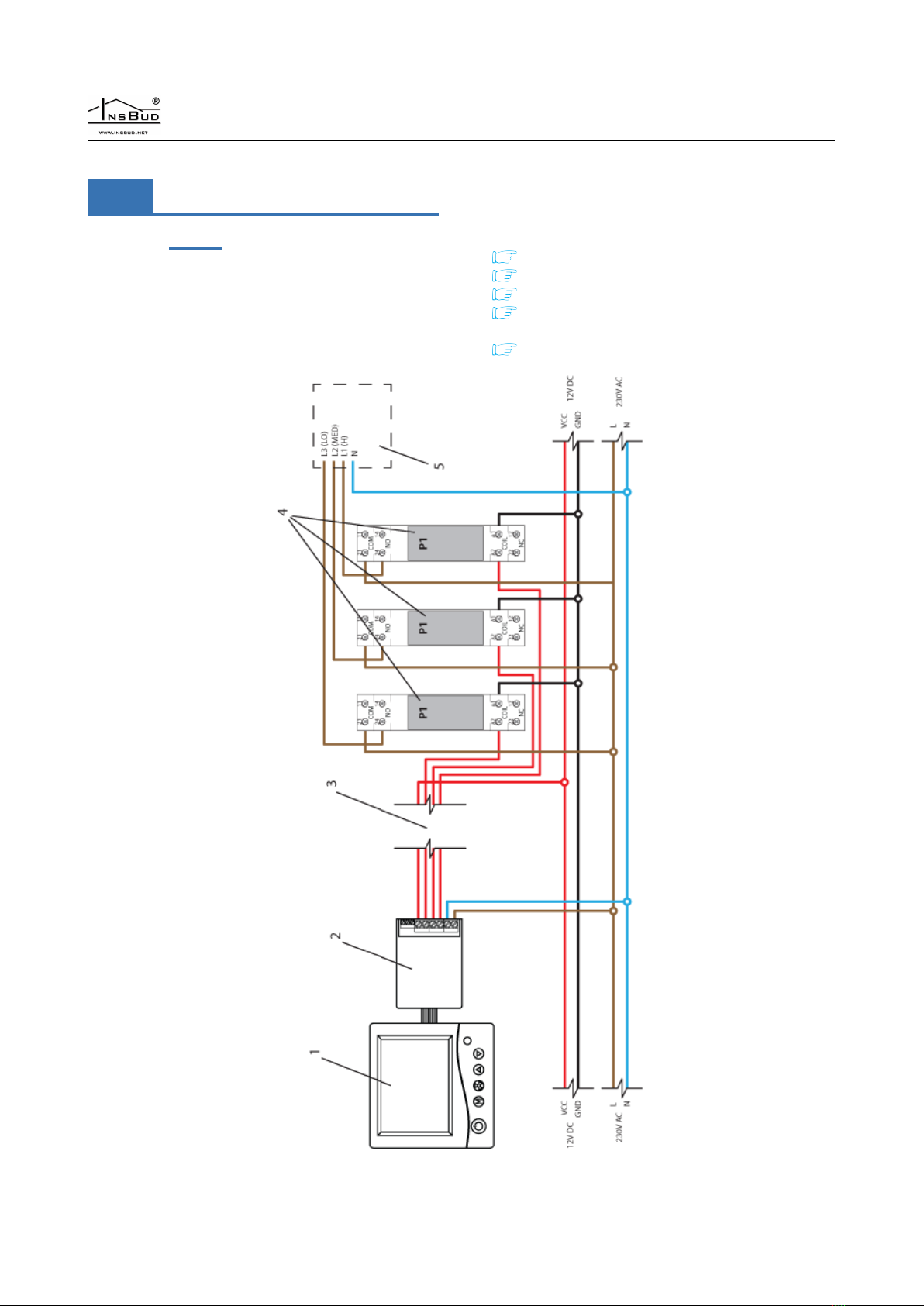

18 Connection - single phase

fan with autotransformer

Below is an example of how to connect a IB–Tron

3100FAN-230V controller with a single-phase fan

using an autotransformer. The example shows the

connection of two fans connected on separate auto-

transformers with full isolation. In addition, there is

a solution that turns o the autotransformer when

the fans are about to be turned o, so that the auto-

transformer does not consume electricity during „idle

state”.

1- main panel

2- connection module

3- 230V AC relay with a TH35 rail mounting

base

4- autotransformer

5- supply fan

6- exhaust fan

12

WWW.INSBUD.NET

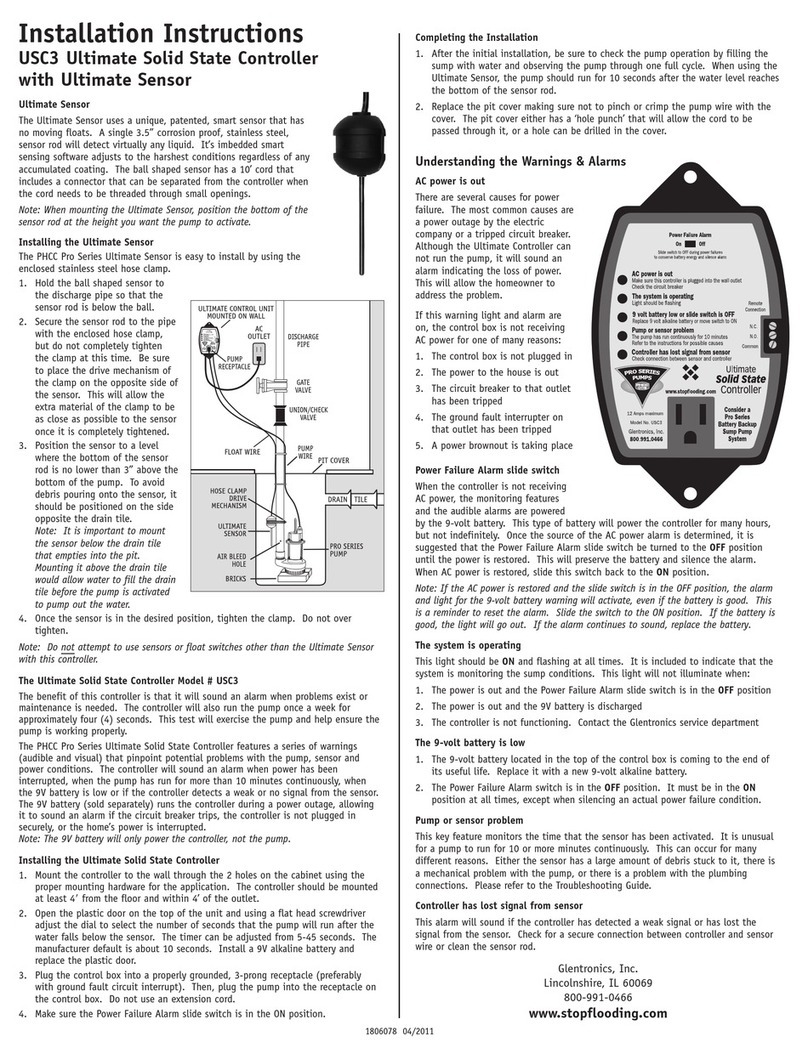

19 Connection - low voltage

cable

If there is a low voltage cable between the AHU and

the controller, e.g. if the control signal is a UTP ca-

ble and the control signal is a 230V phase, additional

relays and a 12V power supply have to be used. The

controller still requires a 230V power supply. If 230V

power supply is not available, use a low voltage con-

troller. Below is an example of connection.

1- main panel

2- connection module

3- low voltage cable, e.g. UTP cable

4- 12V DC relay with TH35 rail mounting

base

5- AHU

14

WWW.INSBUD.NET

20 Installation notes

The main panel together with the connection modu-

le is usually installed in a generally accessible room,

e.g. in the living room. The controller is connected

to the AHU with a multi-wire cable.

In addition, one to several push buttons/switches

can be connected in parallel to the connection mo-

dule for remote ventilation level control.

Such buttons will be usually installed in rooms,

which require temporary increase of ventilation le-

vel from time to time, e.g. in a toilet or a kitchen

Additional push buttons should be connected with

a two-wire cable. Ideally, it should also be a twisted

pair of wires, but this is not an absolute requirement.

You can use a telephone cable or a two-wire cable of

the „link” type.

The installation of additional buttons is optional. If

buttons are not to be mounted, leave the button in-

put terminal unconnected.

21 Turning the controller on

To turn the controller on or o, press the P

button.

When the controller is o, the display shows only

the current temperature. All ventilation level out-

puts are deactivated (open circuit). When the con-

troller is o, the clogged lter detection function is

still active.

22 Conguration menu

The conguration menu is used to set the operating

parameters of the controller. To enter the congura-

tion menu:

If the controller is on, turn it o by pressing

the Pbutton.

With the controller o, press and hold the M

button for about 3seconds.

The controller is in the conguration mode. Menu,

setting number, setting label, setting value and unit

are displayed.

To change the value of the setting shown, press

the DOWN or UP button.

To move to the next setting, press the Mbut-

ton. When the last setting is reached, pressing

the Mbutton again returns to the rst setting.

The controller exits the conguration menu after the

set time of inactivity has elapsed or after pressing

either of the buttons: Por FAN. Pressing the FAN

button or the inactivity time expires saves the chan-

ges and exits the conguration menu. Pressing the

Pbutton cancels the changes and exits the congu-

ration menu.

23 Conguration of outputs

For dierent air handling units available on the mar-

ket, particular ventilation levels may be switched on

according to dierent standards. For example, for

many air handling units lack of any signal from the

controller means that the unit is switched on in the

rst ventilation level. For another type, to switch

on the rst ventilation level, it is necessary to give

a signal to the appropriate input. Also, some AHUs

allow the ventilation to be switched o by means of

an attached controller, while others do not.

The IB–Tron 3100FAN-230V controller can con-

trol dierent types of air handling units. The user

has a possibility to choose the proper signal stan-

dard for the air handling unit. This is done by the

CFG parameter in the conguration menu.

6 types of AHUs have been dened, for which the

LO, MED and HI outputs are switched on for par-

ticular ventilation levels as shown in the table:

15

WWW.INSBUD.NET

CFG = 1

O Ventilation level 1 Ventilation level 2 Ventilation level 3

Possible to set from the controller No Yes Yes Yes

Relay output states

LO

N/A

On O O

MED O On O

HI O O On

The above settings means:

it is not possible to switch the AHU o from the controller (it is not possible to set „o” value in the

operating schedule or in the manual mode). Other ventilation levels are available for setting.

if the controller wants to switch on the rst ventilation level of the air handling unit then relays will be

set as follows: LO = On (short circuit to COM1); MED = O (open circuit with COM1); HI = O (open

circuit with COM1).

if the controller wants to switch on the second ventilation level of the air handling unit then relays will

be set as follows: LO = O (open circuit to COM1); MED = On (short circuit with COM1); HI = O

(open circuit with COM1).

if the controller wants to switch on the third ventilation level of the air handling unit then relays will be

set as follows: LO = O (open circuit to COM1); MED = O (open circuit with COM1); HI = On (short

circuit with COM1).

CFG = 2

O Ventilation level 1 Ventilation level 2 Ventilation level 3

Possible to set from the controller No Yes Yes Yes

Relay output states

LO

N/A

O O O

MED O On O

HI O O On

CFG = 3

O Ventilation level 1 Ventilation level 2 Ventilation level 3

Possible to set from the controller Yes Yes Yes Yes

Relay output states

LO On O O O

MED O O On O

HI O O O On

CFG = 4

O Ventilation level 1 Ventilation level 2 Ventilation level 3

Possible to set from the controller Yes Yes Yes Yes

Relay output states

LO O On O O

MED O O On O

HI O O O On

CFG = 5

O Ventilation level 1 Ventilation level 2 Ventilation level 3

Possible to set from the controller Yes Yes Yes Yes

Relay output states

LO O On On On

MED O O On O

HI O O O On

16

WWW.INSBUD.NET

CFG = 6

O Ventilation level 1 Ventilation level 2 Ventilation level 3

Possible to set from the controller Yes Yes Yes Yes

Relay output states

LO O O O On

MED O O On O

HI O On On On

To set the appropriate output signal standard:

Enter the conguration menu. Press the M

button until the setting number 01, labeled

CFG, appears on the display.

Set the value. Exit the conguration menu or

move to another setting.

24 FAN input operation

The user can choose one of the three modes of ope-

rating the additional digital input FAN.Mode 1 and

2 enables the use of a monostable button, mode 3 -

a bistable switch.

1. Ventilation. After short pressing of the additio-

nal button, connected to the FAN input, tem-

porary change of the ventilation level takes place

(temporary ventilation). The user decides which

ventilation level should be switched on at that

moment, as well as the time how long this venti-

lation level is switched on. For example, if the but-

ton is placed in the kitchen, the user can tempo-

rarily set the highest ventilation level by pressing

the button. Another example would be a button

in the bathroom, which allows to temporarily stop

ventilation while taking a bath to raise the tem-

perature in the bathroom. After the ventilation

time has elapsed, the controller will switch back

to the mode the AHU was in before the button

was pressed. To exit the ventilation mode before

the expiry of the set ventilation time, press and

hold the additional button for about 3seconds.

When the ventilation mode is active, the ventila-

tion icon is shown on the control panel.

2. Increasing ventilation level. Each short press

of the button increases the ventilation level. If

the AHU is in the highest ventilation level, pres-

sing the button switches on the lowest ventila-

tion level (for AHU without the possibility to

switch o) or switches o (for AHU with the

possibility to switch o). The sequence is repe-

ated. If the controller operates in manual mode

(MANUAL), pressing an additional button cau-

ses permanent change of ventilation level.If the

controller operates in automatic mode (AUTO),

pressing the additional button causes switching to

semi-automatic mode (OVERRIDE), i.e. venti-

lation level change until the end of the current

time period. To return to automatic mode, press

and hold the additional button for about 3se-

conds.

3. Ventilation level override. This mode allows

connecting a bistable switch to the digital input

FAN. The switch can be placed e.g. near a kit-

chen hood. When this switch is activated (short-

circuited), the programmed ventilation level is

started and it lasts as long as the switch is ac-

tivated. After deactivation of the switch (open-

circuited), ventilation level returns to the mode,

in which it was before the switch was activated.

In this mode when digital input is short-circuited

the ventilation icon is displayed on the screen.

To set FAN input operation:

Enter the conguration menu. Press the M

button until the setting number 02, labeled

INMOD, appears on the display.

Set value 1 to set the ventilation function. Set

value 2 to set increasing ventilation level func-

tion. Set value 3 to set the ventilation level

override. Exit the conguration menu or move

to another setting.

25 Temporary ventilation

level

When an additional digital input FAN has been as-

signed a ventilate function (parameter INMOD =

1) or a ventilation level override function (parameter

INMOD = 3), the user should dene which ventila-

tion level will be activated when the additional but-

17

WWW.INSBUD.NET

ton is pressed in ventilate mode or when the switch

is shorted in ventilation level override mode. To set

the temporary ventilation level:

Enter the conguration menu.Press the M

button until the setting number 03, labeled

b_SPd, appears on the display.

Set the ventilation level that will be started

when the external button is pressed. Exit the

conguration menu or move to another setting.

26 Ventilation time

When an additional digital input FAN has been assi-

gned with ventilation function (parameter INMOD

= 1), the user should dene how long after pressing

additional button ventilation should last. To set the

ventilation time:

Enter the conguration menu. Press the M

button until the setting number 04, labeled

bTIME, appears on the display.

Set the ventilation time in minutes (from 1 to

30). Exit the conguration menu or move to

another setting.

27 Calibration

If the temperature indicated by the controller diers

from the actual temperature, the temperature sensor

should be calibrated. To set the calibration:

Enter the conguration menu. Press the M

button until the setting number 05, labeled

CALIB, appears on the display.

Set the value by which the current tempera-

ture indication should be changed in order to

obtain the correct indication. For example, if

20◦C is displayed and the actual temperatu-

re is 18◦C, set −2◦C. Exit the conguration

menu or move to another setting.

28 Idle time

Idle time is the time after which the controller exits

parameter setting mode to default operating mode,

calculated from the last time any of the buttons were

pressed. A larger value gives the user more time to

enter settings.

To set the idle time:

Enter the conguration menu. Press the M

button until the setting number 06, labeled

PTD, appears on the display.

Set the appropriate value. It can be selected

from the range of 5÷30 s, with a step of 5s.

Exit the conguration menu or move to ano-

ther setting.

29 Backlight time

Backlight time is the time after which the LCD bac-

klight tuns o, calculated from the last time any of

the buttons were pressed. To set the backlight time:

Enter the conguration menu. Press the M

button until the setting number 07, labeled

LIGHT, appears on the display.

Set the appropriate value. It can be selected

from the range of 10 ÷60 s, with a step of 10s.

It can also be set to OFF - backlight always

o or On - backlight always on Exit the con-

guration menu or move to another setting.

30 Backlight intensity

The IB–Tron 3100FAN-230V controller is pro-

grammed to automatically turn o the screen bac-

klight when the backlight time expires. By default,

the backlight is then turned o completely. However

user can set the controller not to turn o the bac-

klight completely, but only to decrease its intensity.

User can also set the backlight intensity when the

controller is active.

To set the intensity of the backlight when the con-

troller is active:

Enter the conguration menu. Press the M

button until the setting number 08, labeled

LT_oN, appears on the display.

Set the intensity of the backlight (in percent)

that will be maintained when the controller is

active. Exit the conguration menu or move to

another setting.

18

WWW.INSBUD.NET

To set the intensity of the backlight when the con-

troller is inactive:

Enter the conguration menu. Press the M

button until the setting number 09, labeled

LT_oFF, appears on the display.

Set the backlight intensity (in percent) that

will be maintained after the backlight timeout

(instead of turning it o completely). Exit the

conguration menu or move to another setting.

31 Temperature unit

The user can choose whether to display the tempe-

rature in degrees Celsius ◦C or Fahrenheit ◦F.

To set the temperature unit:

Enter the conguration menu. Press the M

button until the setting number 10, labeled

UNIT, appears on the display.

Set the temperature unit. Exit the congura-

tion menu or move to another setting.

32 Time format

The user can choose whether to display the time in

12 or 24 hour format. To set the time format:

Enter the conguration menu. Press the M

button until the setting number 11, labeled

CLOCK, appears on the display.

Set 12 or 24 hour format. Exit the congura-

tion menu or move to another setting.

33 Filter change reminder

The user can set a reminder to change the lter. User

need to specify the time after which the control pa-

nel enters the reminder mode. To set the lter change

reminder:

Enter the conguration menu. Press the M

button until the setting number 12, labeled

FILTR, appears on the display.

Set the number of days after which the lter

change reminder is activated or set „OFF” to

disable the reminder. Exit the conguration

menu or move to another setting.

When the time limit expires, repeat the step of

setting the number of days, otherwise the alarm

is still active.

34 Alarm states

The controller can report alarms (e.g. lter change)

both when it is on and when it is o. To set whether

the alarm information is to be displayed also when

the controller is switched o:

Enter the conguration menu. Press the M

button until the setting number 13, labeled

ALoFF, appears on the display.

Set the appropriate setting:

YES - alarms are always reported.

NO - no alarms are reported when the con-

troller is in the o mode.

Exit the conguration menu or move to another set-

ting.

35 Firmware version

To check the rmware version:

Enter the conguration menu. Press the M

button until the setting number 14, labeled

VER, appears on the display.

The manufacturer promotes a policy of development

and therefore reserves the right to make changes to

the controllers and manuals without prior notice.

The manufacturer is open to all kinds of suggestions

that will improve our controllers. If you have an idea

for adding a new feature or need an unusual solution,

please contact us.

This manual is valid for IB–Tron 3100FAN-230V

controller with rmware version 07.

19

WWW.INSBUD.NET

36 Time and day of the week

To set the current time and day of the week:

Turn on the controller.

Press and hold the FAN button for about 3

seconds. The displayed time starts ashing.

Set the current time.

Press the FAN button again. The day of the

week will start ashing.

Set the day of the week:

Mon - Monday.

Tue - Tuesday.

Wed - Wednesday.

Thu - Thursday.

Fri - Friday.

Sat - Saturday.

Sun - Sunday.

Conrm the settings.

37 Factory settings

To reset the controller and return to the factory set-

tings:

Turn o the controller.

Press and hold for about 3 seconds both but-

tons: Mand FAN simultaneously.

The display will show RESET for about 5 se-

conds.

38 Keypad lock

To protect the controller from unwanted changes to

settings, user can lock the keypad.

When the keypad lock is active, the display shows

a padlock symbol and the keypad does not respond

to the pressed keys.

To enable/disable the keypad lock:

Press and hold for about 3 seconds both keys:

DOWN and UP simultaneously.

39 Operating schedule

- AUTO mode

In automatic mode, user can set an operating sche-

dule. It means that the programmed ventilation level

of the AHU is automatically set at certain time.

Thanks to the operating schedule it is possible to set

ventilation level lower in the periods when, for exam-

ple, the building is not used or during the night, and

higher when the building is used.

Four time periods can be programmed for each day

of the week, which are symbolically represented on

the display:

Time period no. 1.

e.g. 7:00 - wake-up call

Time period no. 2.

e.g. 9:00 - leaving home

Time period no. 3.

e.g. 15:00 - returning home

Time period no. 4.

e.g. 21:00 - sleep

To set the operating schedule:

Turn on the controller. Make sure that the

controller is set to automatic mode (time pe-

riods and AUTO symbols are visible on the

display).

If the hand symbol (manual mode) appears on

the display instead of the time periods sym-

bol, press the Mbutton. Pressing this button

when the controller is turned on switches be-

tween manual and automatic mode.

20

Table of contents

Popular Controllers manuals by other brands

Glentronics

Glentronics USC3 installation instructions

YASKAWA

YASKAWA JOHB-GA50 installation manual

Syntec

Syntec S08-SMD-33B Series installation instructions

Johnson Controls

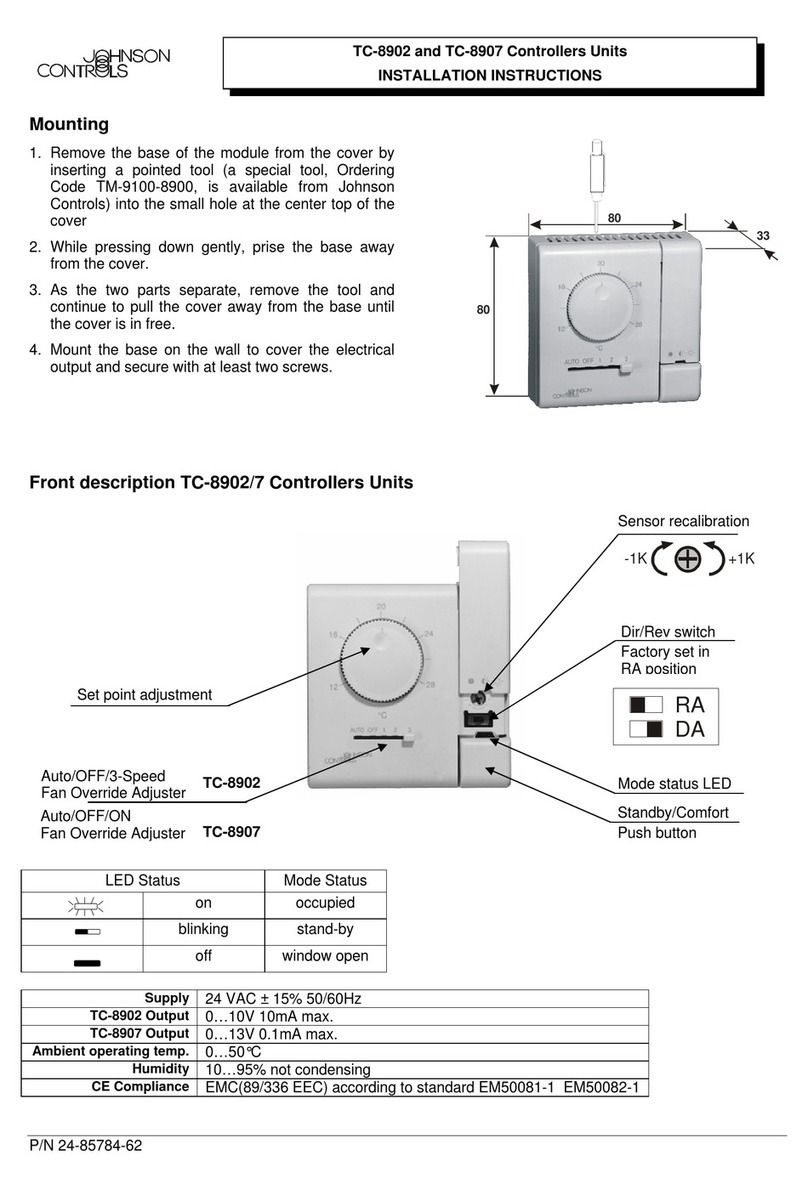

Johnson Controls TC-8902 installation instructions

Vacon

Vacon 100X series Installation and maintenance manual

Skov

Skov DOL 834 Technical manual