Inscape Height Adjustable Table User manual

OCTOBER 2019

Height

Adjustable Table

User Guide

Glossary

Components:

Desk leg (DL) The lifting columns, typically with powder coated steel proles, responsible for lifting the working load of the application.

Control box (CBD6S) Both the computer and power supply of the system.

Desk panel (DP) The user interface. Depending on the model, it is used to activate the application, set memory positions,

display the height, display error codes, connect to mobile apps, and give reminders to the user.

Motor cable Transmits low voltage power (18-39 VDC) from the control box to the desk legs,

and also transmits Piezo signals when available from the desk leg.

Mains cable Transmits high voltage power (120 VAC in US and Canada) to the control box.

Other:

Initialize Procedure to reset all desk legs to the fully retracted position so that the control box knows where they are.

Reference Any group of desk legs that run in parallel when an Up or Down command is sent to the control

box. It is possible to have a custom control box conguration that allows for more than one

Reference. [Example: Two (2) desk legs on Reference #1 (Channels #1 and #2) to lift a work

surface, and one (1) LA31 on Reference #2 (Channel 3) to adjust a monitor array.]

Height Adjustable Table – User Guide | October 2019 3

Introduction

There are four available options for control switches:

1. Basic Control Switch (DPF1K)

2. Programmable Control Switch with Display (DPF1C)

3. Basic Paddle Control Switch (DPG1K)

4. Programmable Paddle Control Switch (DPG1C)

Only DPF control switches must be mounted with a 45˚ mounting bracket and placed at the edge of the tabletop.

See illustration below:

Control switch mounted with a 45˚ mounting

bracket on the edge of a tabletop.

Height Adjustable Table – User Guide | October 2019 4

Basic Control Switch (DPF1K)

This controller provides basic up and down functions.

Height Adjustable Table – User Guide | October 2019 5

Programmable Control Switch with Display (DPF1C)

The programmable control switch with display shows you the height in either centimeters or inches. It also

features an automatic shut-off for when the unit is not in use thereby saving power in standby mode. As

an extra feature, the panel can be used for diagnostics as error codes can be displayed.

How to use the controls

Up and down (arrows):

Activate either the up or down button for parallel drive. The system will drive until the button is released again or the system reaches end position.

Memory:

The four small buttons are used for memory drive or storing memory.

Store Memory:

• Press the “S” button – display will ash for 2seconds

• Within these two seconds press one of the small buttons with dots and the position will be stored at this button

• The panel will acknowledge by showing “1”, “2” or “3” in the display depending on chosen position

Memory drive (small buttons with dots):

Press one of the memory buttons and the system will start driving to the pre-programmed memory position.

Keep the button pressed until the desired position has been reached.

Display function:

Display shows the actual height in either centimeters or inches.

Display will show error codes if error in table occurs.

= Parallel up

= Parallel down

S = Store memory

• = Memory 1

•• = Memory 2

••• = Memory 3

Height Adjustable Table – User Guide | October 2019 6

Basic Paddle Control Switch (DPG1K)

This controller provides basic up and down functions.

Height Adjustable Table – User Guide | October 2019 7

Programmable Paddle Control Switch (DPG1C)

The programmable paddle control switch with display shows you the height in either centimeters or inches.

As an extra feature, the panel can be used for diagnostics as error codes can be displayed.

Height Adjustable Table – User Guide | October 2019 8

How to use the controls

Up and down (arrows):

Activate either the up or down button for parallel drive. The system will drive until the

button is released again or the system reaches end position.

Memory:

This switch has a "store memory" button that supplies four memory positions.

Display function:

Display shows the actual height in either centimeters or inches.

Display will show error codes if error in table occurs.

Bluetooth:

Once the Desk Control™ App is downloaded onto your device, the paddle switch can be connected

via Bluetooth. This App can drive controls and create pre-sets for your desk.

• App comes in 8 languages (English, German, French, Spanish, Italian, Korean, Chinese and Japanese

Light strip reminder:

A thin line of LED lighting is used to remind the user to adjust the height of the desk based on the intervals chosen.

• Three intervals for reminders (55 minutes, 50 minutes or 45 minutes)

• Intervals can be customized through the Desk Control™ App

Programmable Paddle Control Switch (DPG1C)

Height Adjustable Table – User Guide | October 2019 9

Basic Troubleshooting Guide

Two ways to Troubleshoot:

1. Controller with display only shows error codes. To order parts, refer to order entry codes in chart at the end of the document

2. Swap controllers if you have multiple to see if it is only the controller that is having errors

Standard Troubleshooting Procedures:

P1 - Initialize the control box (“reset”)

Note: This is commonly the solution when a complaint is that a desk will move down but not up. When

a control box requires initialization, this is how the system is programmed to behave.

1. Hold Down button on desk panel to ensure the desk is retracted to its lower limit (whether

it’s the fully retracted hard stop, or a congured lower limit).

2. Briey release Down

3. Press and hold Down for 5 seconds, wait until all desk movement has stopped, then release

a. If initialization is successful, you should see a slight up/down “handshake” movement of the desk legs

b. If you have a desk panel with display, you should also see E01 during this part of the procedure.

P2 - Check all cable connections

1. Mains cable, connected to both the control box and power outlet.

2. All motor cables, connected to both the control box and desk leg.

3. Assuming a standard control box conguration, these must be connected in channels 1 and 2, or channels 1, 2 and 3 for a 3-leg table.

They can’t be connected in channels 1 and 3 or 2 and 3 unless there is a conguration on the control box specifying this arrangement.

4. Desk panel cable, connected to the control box in either port A1 or A2 (doesn’t matter which)

P3 - Check for obstructions

1. Check under, above and on the sides of the desk for any obstructions that could prevent movement in either direction.

Note: Ideally, for each of the following two troubleshooting procedures (P4 and P5), one would have an extra,

known good version of the components listed in the Components Glossary at the beginning of this document. It’s

not necessary to have the exact same item numbers as those that are being evaluated, unless one is replacing a

single desk leg. However, it’s possible to do some troubleshooting with a different type of desk leg.

P4 - Check for faulty component(s) WITH error codes (digital display on Desk Panel, or on app via Bluetooth)

Note: Check the error code list in the appendix of this troubleshooting guide for assistance. The code should

read E##. Some error codes are channel-specic which can help pinpoint the problem.

Height Adjustable Table – User Guide | October 2019 10

SYMPTOM PROCEDURE

System will move down but not up 1. Initialize (P1)

System unresponsive (no power to display

with any button is pressed). If any of these

steps activates the digital display, initialize

the system (P1).

1. Check mains cable connection

2. Test power outlet using another device (lamp, phone charger, etc.)

3. Plug in a new switch and test

4. Connect all existing cables to a new control box and test

SYMPTOM 1. PROCEDURE

System is powered, but will not initialize 1. Try pressing and releasing the down button a few times

before pressing and holding for 5 seconds.

2. Also, be aware if the control box has a special conguration: If the desk

is programmed with a lower stroke limit, so as to avoid a collision with

something like a le cabinet, it is possible that it also has a custom, longer

Forced Initialization Time. This is the time required to hold Down before

initialization begins. Sometimes this is 10 seconds or longer.

3. If you have a standard control box without a special conguration (i.e. “Plug

& Play”), try to initialize each leg in Channel 1 by itself, with nothing else

plugged into the motor channels on the control box. Also, swap the motor

cables so that a different motor cable is used to initialize Channel 1 by

itself. The problem could be a faulty desk leg or a faulty motor cable.

Channel-specic error (Ex: E41 – Channel

1 overload) – Everything except Piezo

errors (E59-E63)

1. Swap the motor cable connections at the control box (Motor cable #1 from

channel 1 to 2, motor cable #2 from channel 2 to 1). If It remains E41, there

could be a problem with the application (load or obstruction on one side)

or a bad control box. If the error changes to E42, go to step P4-3-b.

2. Swap the motor cable connections at the desk legs, so that the leg that was

originally connected to Channel 1 is back in Channel 1, but with the motor

cable that was originally connected to Channel 2. If it remains E42, it is

most likely a bad motor cable, now connected to Channel 2. If it goes back

to E41, it is most likely a bad desk leg, now connected to Channel 1.

Desk is uneven 1. Initialize the desk. If both legs begin to run down, complete the

initialization. If only one leg moves, stop and move to Step 2.

2. Check motor cable connections. Check to ensure motor cables are not pulled during

movement. With a standard, Plug & Play control box, it’s possible that only one leg is

connected, and connected to Channel 1. In this case, it will initialize and run Channel

1 only. If there is only one leg but it’s connected to Channel 2, it will not initialize.

3. If a motor cable was disconnected, try initializing again.

4. If unsuccessful, connect the desk leg from Channel 2 into Channel

1, with nothing in Channel 2, and initialize.

5. Try initializing the same leg that’s in Channel 1, but with a different

motor cable. If it still won’t initialize, replace the desk leg.

Basic Troubleshooting Guide

Height Adjustable Table – User Guide | October 2019 11

System will not initialize.

OR

System won’t complete the full range of

motion.

– After each of these steps, attempt to

initialize (P1).

1. Check mains cable connection. Test power outlet using

another device (lamp, phone charger, etc.)

2. Plug in a new switch.

3. Connect all existing cables to a new control box.

4. Try pressing and releasing the down button a few times

before pressing and holding for 5 seconds.

5. Also, be aware if the control box has a special conguration: If the desk is programmed

with a lower stroke limit, so as to avoid a collision with something like a le cabinet, it

is possible that it also has a custom, longer Forced Initialization Time. This is the time

required to hold Down before initialization begins. Sometimes this is 10 seconds or longer.

6. If you have a standard control box without a special conguration (i.e. “Plug

& Play”), try to initialize each leg in Channel 1 by itself, with nothing else

plugged into the motor channels on the control box. Also, swap the motor

cables so that a different motor cable is used to initialize Channel 1 by

itself. The problem could be a faulty desk leg or a faulty motor cable.

Desk is uneven 1. Initialize the desk. If both legs begin to run down, complete the

initialization. If only one leg moves, stop and move to Step 2.

2. Check motor cable connections. Check to ensure motor cables are not pulled during

movement. With a standard, Plug & Play control box, it’s possible that only one leg is

connected, and connected to Channel 1. In this case, it will initialize and run Channel

1 only. If there is only one leg but it’s connected to Channel 2, it will not initialize.

3. If a motor cable was disconnected, try initializing again.

4. If unsuccessful, connect the desk leg from Channel 2 into

Channel 1, with nothing in Channel 2, and initialize.

5. Try initializing the same leg that’s in Channel 1, but with a different

motor cable. If it still won’t initialize, replace the desk leg.

P5 – Check for faulty component WITHOUT error codes (no digital display on Desk Panel, no Bluetooth)

SYMPTOM PROCEDURE

System will move down but not up 1. Initialize (P1)

SYMPTOM PROCEDURE

Basic Troubleshooting Guide

Height Adjustable Table – User Guide | October 2019 12

Error Codes

Please contact your SRT representative and provide them with the error code (EXX) for further assistance.

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E01 Position Lost

The desk has an

unknown position and

needs to be initialized

• Position error

• New Desk Leg added • Initialize the system

E02 General

Overload Up

Overload in upward

direction has occurred - -

E03 General

Overload Down

Overload in downward

direction has occurred - -

E08 Watchdog Indicate that software

failed to kick watchdog • Program fault

• Unplug mains cable for 15 sec

• Initialize the system

• Replace Control Box

E09 LIN collision Collisions detected

on the LIN bus

• Key pressed on two or

more connected handset

simultaneously

• Multiple LINBUS devices

activated simultaneously

• Check if another desk panel is

connected and being activated

• Unplug all but one desk

panel and test system

E10 Power fail

Power fail happened,

or power regulator

adjusted below 10%

• Mains cable pulled during driving

• Internal fault

• Only 1 battery for a 3- or

4-channel system

• "E10 is a power fail, voltage on

power supply drops below a

certain limit, power removed"

• Check mains cable is not caught,

and is allowed to freely travel

• Use strain-relief loop

built into control box

• Use a 2nd battery; charge batteries

E11 Channel

mismatch

Change in number

of actuators since

initialization

• Disconnection

• Desk Leg added

• Check Motor cable

connections and Integrity

• Change Motor cable or Desk Leg

• Initialize the system

E12 Position error

One channel have

position different

than others

• Too much back drive occurred

• Move table to fully

retracted position

• Initialize system

E13 Short circuit Short circuit detected

during operation

• Squeezed Motor Cable

• Short in motor

• Check motor cable connections

• Isolate and replace Motor Cable

• Isolate and replace Desk Leg

Height Adjustable Table – User Guide | October 2019 13

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E15 Power limit System has reached

its power limitation

• Mains cable pulled during driving

• Internal fault

• Many times will see

this alongside E10

• "E15 is when power regulator

has adjusted speed down on

actuators without any signicant

current draw, usually caused

by power supply dropping."

• Check mains cable is not caught,

and is allowed to freely travel

• Use strain-relief loop

built into control box

E16 Key Error

Illegal keys pressed

(handled internally

in DP1C).

• Hitting multiple buttons

simultaneously • Check switch

E17 Safety missing LIN bus unit does not

support safety feature

• * DP1C/DPF1C does not

have up-to-date software

• >Try DP with more recent software

version (version printed on label)

E18 Missing

Initialization plug

A special service tool

is required to change

number of channels

to the system

• [BASELIFT Only]

• Service tool missing

from BASELIFT system

when initializing

• Add service tool

E23 Ch1 missing Channel 1 is

detected missing

• Disconnection

• Faulty motor cable

• Faulty motor in leg

• Check Motor cable

connections and Integrity

• Change Motor cable or Desk Leg

• Initialize the system

E24 Ch2 missing Channel 2 is

detected missing

• Disconnection

• Faulty motor cable

• Faulty motor in leg

• Check Motor cable

connections and Integrity

• Change Motor cable or Desk Leg

• Initialize the system

E25 Ch3 missing Channel 3 is

detected missing

• Disconnection

• Faulty motor cable

• Faulty motor in leg

• Check Motor cable

connections and Integrity

• Change Motor cable or Desk Leg

• Initialize the system

E26 Ch4 missing Channel 4 is

detected missing

• Disconnection

• Faulty motor cable

• Faulty motor in leg

• Check Motor cable

connections and Integrity

• Change Motor cable or Desk Leg

• Initialize the system

E29 Ch1 type Channel 1 is not same

type as when initialized

• Change in Desk Leg type

• Loose wire inside motor

• Check Desk Leg type

• Change Desk Leg

• Initialize the system

Error Codes

Height Adjustable Table – User Guide | October 2019 14

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E30 Ch2 type

Channel 2 is not

same type as when

initialized or not same

type as channel 1

• Change in Desk Leg type

• Loose wire inside motor

• Check Desk Leg type

• Change Desk Leg

• Initialize the system

E31 Ch3 type

Channel 3 is not

same type as when

initialized or not same

type as channel 1

• Change in Desk Leg type

• Loose wire inside motor

• Check Desk Leg type

• Change Desk Leg

• Initialize the system

E32 Ch4 type

Channel 4 is not

same type as when

initialized or not same

type as channel 1

• Change in Desk Leg type

• Loose wire inside motor

• Check Desk Leg type

• Change Desk Leg

• Initialize the system

E35 Ch1 pulse fail Channel 1 had to

many pulse errors

• Loose/faulty cable

• Hall sensor PCB

• Check motor cable

connections and integrity

• Initialize the system

• Change Desk Leg

E36 Ch2 pulse fail Channel 2 had to

many pulse errors

• Loose/faulty cable

• Hall sensor PCB

• Check motor cable

connections and integrity

• Initialize the system

• Change Desk Leg

E37 Ch3 pulse fail Channel 3 had to

many pulse errors

• Loose/faulty cable

• Hall sensor PCB

• Check motor cable

connections and integrity

• Initialize the system

• Change Desk Leg

E38 Ch4 pulse fail Channel 4 had too

many pulse errors

• Loose/faulty cable

• Hall sensor PCB

• Check motor cable

connections and integrity

• Initialize the system

• Change Desk Leg

E41 Ch1 overload up Overload up occurred

on channel 1

• Leg is overloaded

• Hit obstruction

• Reached end stop (before

initialization at upper

end-stop occurs)

• Remove obstruction

• Remove load

• Initialize if necessary

E42 Ch2 overload up Overload up occurred

on channel 2

• Leg is overloaded

• Hit obstruction

• Reached end stop (before

initialization at upper

end-stop occurs)

• Remove obstruction

• Remove load

• Initialize if necessary

Error Codes

Height Adjustable Table – User Guide | October 2019 15

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E43 Ch3 overload up Overload up occurred

on channel 3

• Leg is overloaded

• Hit obstruction

• Reached end stop (before

initialization at upper

end-stop occurs)

• Remove obstruction

• Remove load

• Initialize if necessary

E44 Ch4 overload up Overload up occurred

on channel 4

• Leg is overloaded

• Hit obstruction

• Reached end stop (before

initialization at upper

end-stop occurs)

• Remove obstruction

• Remove load

• Initialize if necessary

E47 Ch1 overload

down

Overload down

occurred on channel 1 • Hit obstruction • Remove obstruction

• Initialize if necessary

E48 Ch2 overload

down

Overload down

occurred on channel 2 • Hit obstruction • Remove obstruction

• Initialize if necessary

E49 Ch3 overload

down

Overload down

occurred on channel 3 • Hit obstruction • Remove obstruction

• Initialize if necessary

E50 Ch4 overload

down

Overload down

occurred on channel 4 • Hit obstruction • Remove obstruction

• Initialize if necessary

E53 Ch1 anti-col Anti-collision triggered

on channel 1 • Hit obstruction • Remove obstruction

• Initialize if necessary

E54 Ch2 anti-col Anti-collision triggered

on channel 2 • Hit obstruction • Remove obstruction

• Initialize if necessary

E55 Ch3 anti-col Anti-collision triggered

on channel 3 • Hit obstruction • Remove obstruction

• Initialize if necessary

E56 Ch4 anti-col Anti-collision triggered

on channel 4 • Hit obstruction • Remove obstruction

• Initialize if necessary

E59 Ch1 SLS/PIEZO Safety limit switch

activated on channel 1 • Hit obstruction • Remove obstruction

• Initialize if necessary

E60 Ch2 SLS/PIEZO Safety limit switch

activated on channel 2 • Hit obstruction • Remove obstruction

• Initialize if necessary

Error Codes

Height Adjustable Table – User Guide | October 2019 16

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E61 Ch3 SLS/PIEZO Safety limit switch

activated on channel 3 • Hit obstruction • Remove obstruction

• Initialize if necessary

E62 Ch4 SLS/PIEZO Safety limit switch

activated on channel 4 • Hit obstruction • Remove obstruction

• Initialize if necessary

E65 Ch1 pulse dir Pulses counted wrong

direction in channel 1

• Motor poles are crossed

• Hall sensor Cables are crossed

• Check motor cable

connections and integrity

• Initialize the system

• Exchange Desk Leg

E66 Ch2 pulse dir Pulses counted wrong

direction in channel 2

• Motor poles are crossed

• Hall sensor Cables are crossed

• Check motor cable

connections and integrity

• Initialize the system

• Exchange Desk Leg

E67 Ch3 pulse dir Pulses counted wrong

direction in channel 3

• Motor poles are crossed

• Hall sensor Cables are crossed

• Check motor cable

connections and integrity

• Initialize the system

• Exchange Desk Leg

E68 Ch4 pulse dir Pulses counted wrong

direction in channel 4

• Motor poles are crossed

• Hall sensor Cables are crossed

• Check motor cable

connections and integrity

• Initialize the system

• Exchange Desk Leg

E71 Ch1A short

Short circuit on channel 1

[If T-splitter is used,

short circuit on 1A]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E72 Ch1B short

Short circuit on channel 1

[If T-splitter is used,

short circuit on 1B]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E73 Ch2A short

Short circuit on channel 2

[If T-splitter is used,

short circuit on 2A]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

Error Codes

Height Adjustable Table – User Guide | October 2019 17

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E74 Ch2B short

Short circuit on channel 2

[If T-splitter is used,

short circuit on 2B]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E75 Ch3A short

Short circuit on channel 3

[If T-splitter is used,

short circuit on 3A]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E76 Ch3B short

Short circuit on channel 3

[If T-splitter is used,

short circuit on 3B]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E77 Ch4A short

Short circuit on channel 4

[If T-splitter is used,

short circuit on 4A]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E78 Ch4B short

Short circuit on channel 4

[If T-splitter is used,

short circuit on 4B]

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E84 DC-out DC unit has been

disconnected or failed

• [Reserved for future

development] • [Reserved for future development]

E86 Master

Connection to master lost

OR following messages

are from master

• [Only used in multiparallel

system]

• Poor cable connection

to master box

• If followed by another error

code, then codes being

communicated from master box

• Check connection to master

box, check cable integrity

• If communicating other

error codes, see above

E87 Slave 1

Connection to

1st slave lost OR

following messages

are from 1st slave

• [Only used in multiparallel

system]

• Poor cable connection

to slave box

• If followed by another error

code, then codes being

communicated from slave box

• Check connection to master

box, check cable integrity

• If communicating other

error codes, see above

Error Codes

Height Adjustable Table – User Guide | October 2019 18

DIAGNOSTIC CODES FOR CBD6S

CODES NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

E88 Slave 2

Connection to

2nd slave lost OR

following messages

are from 2nd slave

• [Only used in multiparallel

system]

• Poor cable connection

to slave box

• If followed by another error

code, then codes being

communicated from slave box

• Check connection to master

box, check cable integrity

• If communicating other

error codes, see above

E89 Slave 3

Connection to

3rd slave lost OR

following messages

are from 3rd slave

• Damage to motor cable

• Damage to cable exiting

leg (if applicable)

• Inspect motor cable for

damage, replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

100

Forced

initialization

Reference 1

Forced initialization was

initiated on this reference.

Note: This code is

not transmitted in

LINBUS, therefore it is

not displayed on the

desk panel. It is only

viewable in the CBD6S

congurator list of most

recent 10 error codes.

- -

101

Forced

initialization

Reference 2

- -

102

Forced

initialization

Reference 3

- -

103

Forced

initialization

Reference 4

- -

Error Codes

Height Adjustable Table – User Guide | October 2019 19

Replacement Parts

OE CODES FOR REPLACEMENT PARTS

OE CODES DESCRIPTION COLOUR IMAGES

INLK1DL5BLK DL5 2 Stage Leg Black

INLK1DL5GRY DL5 2 Stage Leg Grey

INLK1DL5WHT DL5 2 Stage Leg White

INLK1DL6BLK DL6 3 Stage Leg Black

Height Adjustable Table – User Guide | October 2019 20

Table of contents

Other Inscape Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

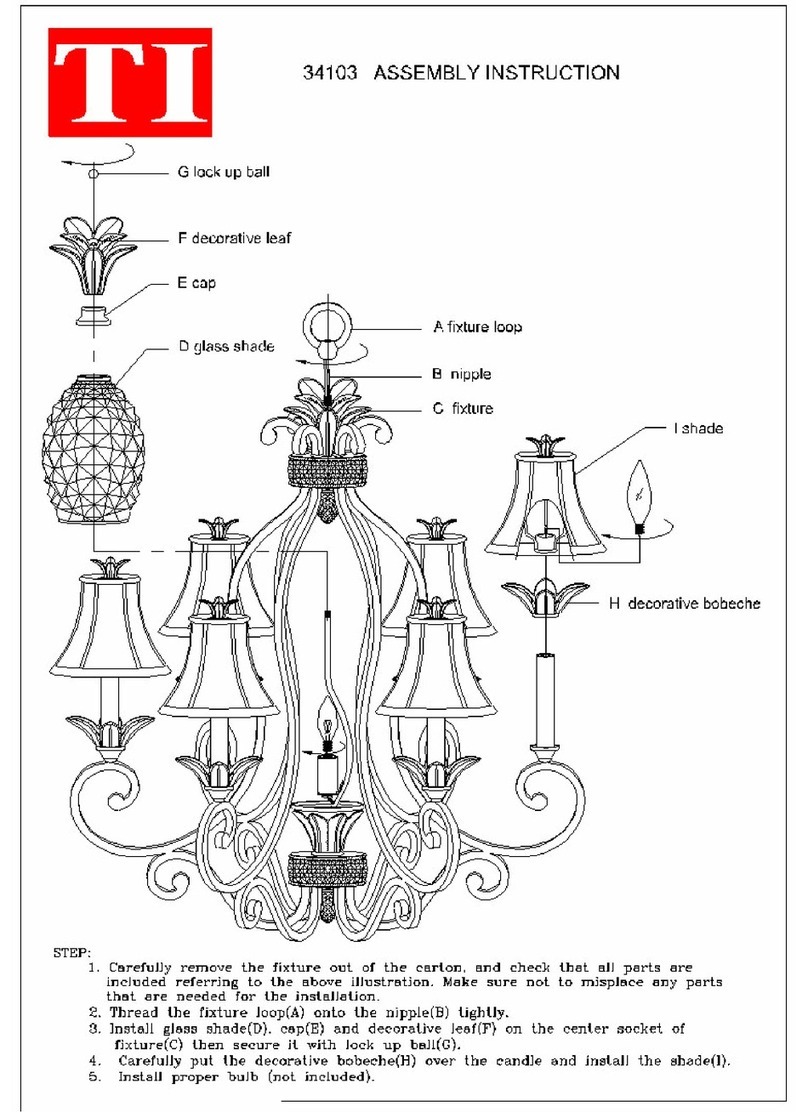

Triarch

Triarch 34103 Assembly instructions

Coaster

Coaster 603502 Assembly instructions

IKEA

IKEA ANDY DRAWER UNIT W/CASTERS 15X23" instructions

Munchkin

Munchkin brica Night Light Baby In-Sight owner's manual

Meble Furniture

Meble Furniture PARIS Assembly instructions

Coaster

Coaster 190621GLD Assembly instructions