insize IST-SD Series User manual

MN IST- -SD SERIES-E

V0

DIGITAL TORQUE SCREWDRIVER

IST-SD SERIES

www.insize.com

OPERATION MANUAL

1 2

Peak hold and Track mode selectable

Digital torque value readout

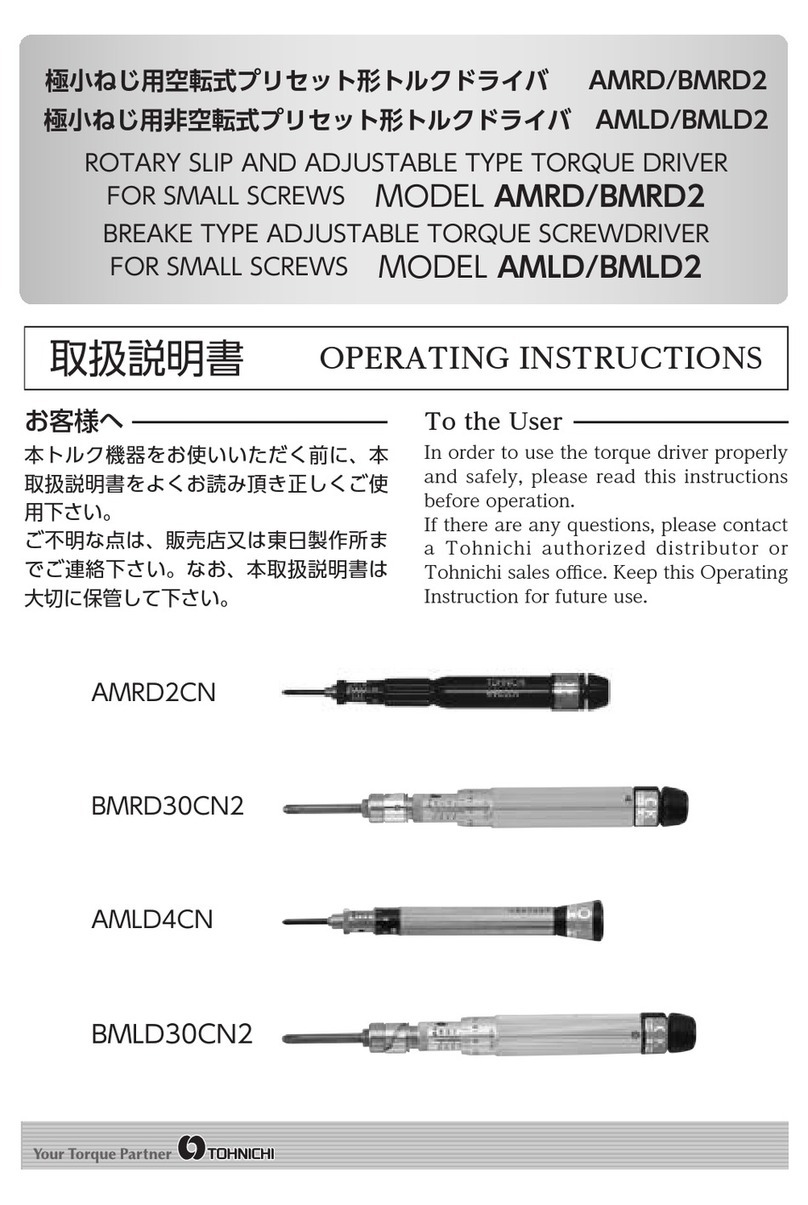

Structure:

CW and CCW operation

+/-2.5% or +/-3% accuracy

1

2

Working Condition:

Operation temperature: -10℃~60℃

Store temperature: -20℃~70℃

Humidity: Can reach 90% if no condensation

Parameter

Recharge batteries are compatible

Buzzer and LED indicator for the pre-settable target torque

Auto power off after about 5 minutes idle

Engineer units(cN-m, in-lb, kg-cm) selectable

1 Auto Bit Holder

2 Communication Port 3 LCD Readout 4 LED Indicator

5 Anti-slip Handle 6 Battery Cover 7 Buzzer 8 Calibration mark

9 Buttons 10 Torque Value 11 Units 12 Peak/Track Mode

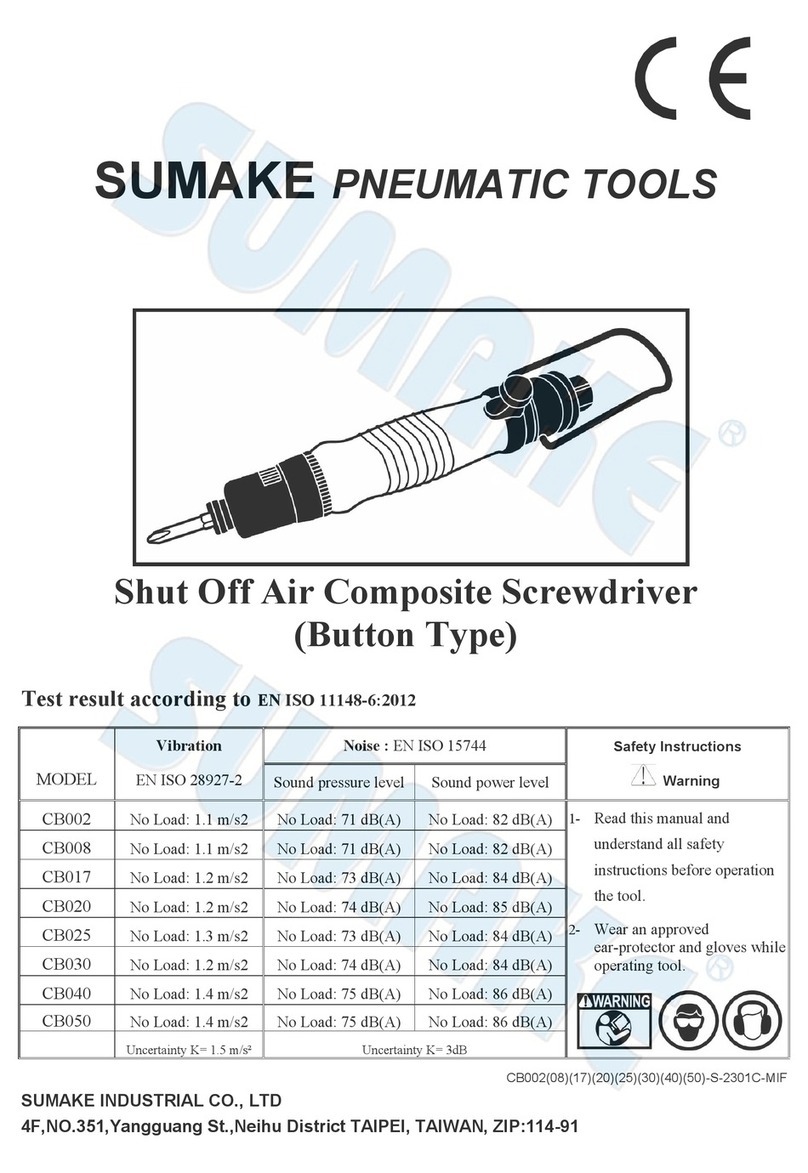

Range

Accuracy

Resolution

±2.5%

±3.5%

0.1cN.m

Code

80-400cN.m

IST-SD50 IST-SD200 IST-SD400

CW

1xAAA battery

Length

1/4"

203mm

Size of shank(L)

Power supply

Weight 200g

±2.5%

±3.5%

0.1cN.m

40-200cN.m

1/4"

203mm

200g

±3%

±4%

0.1cN.m

10-50cN.m

1/4"

193mm

190g

Note:

1.The accuracy of readout is guaranteed from 20%-100% of

maximum range +/-1 increment. The torque accuracy is a

typical value. Calibration point is on the rubber grip. For

keeping the accuracy, calibrate the screwdriver for a constant

period time(1 year).

2. One cycle means twist the screwdriver from 0 cN.m to

maximun range and back to 0 cN.m.

3. Horizontal and vertical test.

4. Environmental test: a. Dry heat b. Cold c. Damp heat d.

Change of temperature e. Impact(Shock) f. Vibration g. Drop

5. Electromagnetic compatibility test:

a. Electrostatic discharge immunity (ESD)

b. Radiated susceptibility (RS)

c. Radiated emission (RE)

Main Function

Description

Specification

CCW

Battery installation:

Remove the battery cap.

Insert one AAA battery matching the -/+ polarities of the battery to

the battery compartment.

Before using the screwdriver

3 4

Attention: If an external force is applied to the screwdriver during

power-on period, an initial torque offset will be recorded in the

memory.

Press to power on the digital screwdriver.

Power on and resetting the screwdriver

Usually press to reset the digital screw before using it.

1Step 1: Unit selection

2Step 2: SET Target Torque

The screwdriver will auto power off after about 5 minutes idle for

power saving. Press to power on the screwdriver again.

Auto power off:

Cautions: During communication period( Send appears), the auto

power off function is disabled.

If the screwdriver does not function normally, loosen the battery

cap then tighten it to re-start.

Resetting the screwdriver:

Setup:

Power On/Clear

Unit Selection/Setting

Adjust Torque Value Up

Adjust Torque Value Down

Put on the battery cap and fasten it tightly according to the

following figures.

Pre-setting unit: cN.m

Unit Selection: in.lb

Unit Selection: kg.cm

Press

Press

Pre-setting target torque

Increase torque value

Decrease torque value

Press

Press

Note:

The “Unit Selection” is cyclic.

5 6

1

3Step 3: Peak hold/Track mode selection

Track mode

Set Peak/Track mode

按 键选择

(Exit)

Track Mode Operation

Start

Setting target torque

Apply torque

Buzzer Green LED

Reach 90% of target torque

Red LED

Reach target torque

Note: 1. If is appeared, that means this

screwdriver has ever been applied more than 110%

of torque of the spec.

2. When reaching the setting target torque, the green

and red LED will be on at the same time.

Set Peak/Track mode

Communication

Peak hold Mode

Communication

Long press

Press

Press

Press for selection

Note:

Communication is for calibration of

screwdriver. Please contact your local

dealer for information.

Current torque value

Reach 90% of target torque

Reach 90% of target torque

Reach target torque

Buzzer

(system initial)

7 8

Peak Hold Mode Operation:

Start

Setting target torque

Apply torque

Current Max. Value

(Peak hold)

Reach 90% of target torque

Apply torque

Released

Flashing

Buzzer Green LED

Reach 90% of target torque

Red LED

Reach target torque

Reach target torque

Buzzer

Note: 1. If is appeared, that means this

screwdriver has ever been applied more than 110%

of torque of the spec.

2. When reaching the setting target torque, the green

and red LED will be on at the same time.

1Over-torque (110% of Max. torque range) could

cause breakage or lose accuracy.

2Do not shake violently or drop screwdriver.

3Do not use this screwdriver as a hammer.

4Do not leave this screwdriver in any place exposed to excessive

heat, humidity, or direct sunlight.

Attention:

One year periodic recalibration is necessary to

maintain accuracy.

Please contact your local dealer for calibrations.

5Do not use this apparatus in water.(not waterproof)

6If the screwdriver gets wet, wipe it with a dry towel as soon as

possible. The salt in seawater can be especially damaging.

7Do not use organic solvents, such as alcohol or paint thinner

when cleaning the screwdriver.

8Keep this screwdriver away from magnets.

9Do not expose this screwdriver to dust or sand as this could cause

serious damage.

10 Do not apply excessive force to the LCD panel.

11 Apply torque slowly and graspe the center of the handle. Do not

applu load to the end of the handle.

12 When checking the accuracy or calibration, please use the bit

head packed inside the below mold case.

1When the screwdriver is not used for an extended period of time,

remove the battery.

2Keep a spare battery on hand when in long trip or cold areas.

3Sweat, oil and water can prevent a battery’s terminal from making

electrical contact. To avoid this, wipe both terminals before

loading a battery.

4Dispose of batteries in a designated disposal area. Do not throw

batteries into a fire.

Maintenance

Battery Maintenance

(system initial)

This manual suits for next models

3

Table of contents

Popular Power Screwdriver manuals by other brands

F.F. Group

F.F. Group CSC 3.6V EASY Original instructions

Skil

Skil 2236 instructions

Bosch

Bosch GSR Professional 9 Original instructions

Hercules

Hercules HD94B Owner's manual & safety instructions

Kilews

Kilews SKD-BE830L Operation and maintenance manual

Everwin

Everwin EWS-202 Operation and maintenance manual