Everwin EWS-202 User manual

EWS-202 / EWS-89-7500

Air Impact Screwdriver

OPERATIONS and MAINTENANCE MANUAL

CE DECLARATION OF CONFORMITY

19’/08/08

Everwin Pneumatic Corp.

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD READ AND STUDY

THIS MANUAL TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND

INSTRUCTIONS. KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE

REFERENCE.

2

CE DECLARATION OF CONFORMITY

CE Declaration of conformity ENGLISH

EVERWIN PNEUMATIC CORP. declares that the product as described in attached documentation is in conformity

with the Machinery Directive 2006/42/EC and the European standard EN ISO 12100/EN ISO 11148-6.

CE Dichiarazione di conformità ITALIANO

EVERWIN PNEUMATIC CORP. dichiara, assumendo la piena responsabilità, che questa fissatrice e conforme alla

Direttive Europee 2006/42/EC e alla norma armonizzata EN ISO 12100/EN ISO 11148-6.

CE Konformitätserklärung DEUTSCH

EVERWIN PNEUMATIC CORP. erklärt hiermit in alleiniger Verantwortung das dieses Gerät ubereinstimmt mit den

Europäischen Richtlinien 2006/42/EC und den Europäischen Norm EN ISO 12100/EN ISO 11148-6.

CE Déclaration de conformité FRANCAIS

EVERWIN PNEUMATIC CORP. déclare et prend sur soi toute la responsabilité de cette déclaration, que le produit est

en conformité avec les Directives Européennes 2006/42/EC et avec la norme harmonisée EN ISO 12100/EN ISO

11148-6.

CE konformiteitsverklaring NEDERLANDS

EVERWIN PNEUMATIC CORP. verklaart hierbij onder eigen verant woordelijkheid dat deze machine in

overeenstemming is met de Europese Richtlijnen 2006/42/EC en de Europese norm EN ISO 12100/EN ISO 11148-6.

CE Declaracion de conformidad ESPAGNOL

EVERWIN PNEUMATIC CORP. declaramos bajo nuestra sola responsabilidad que este producto esta en

conformidad con las Directivas Europeas 2006/42/EC y con la normativa EN ISO 12100/EN ISO 11148-6.

Overensstemmelseserklæring / CE Deklaration

DANSK

EVERWIN PNEUMATIC CORP. erklærer herved, at produktet er i overenstemmelse med nedenstående normer eller

normative dokumenter 2006/42/EC i henhold til bestemmelserne i EU’s direktiv EN ISO 12100/EN ISO 11148-6.

Överstämmelseförklaring / CE Deklaration SVENSK

EVERWIN PNEUMATIC CORP. förklarar härmed att produkten överensstämmer med följande normer och direktiv

2006/42/EC och SS-EN ISO 12100/SS-EN ISO 11148-6.

SAMSVARSERKLÆRING / CE Deklaration NORSK

EVERWIN PNEUMATIC CORP. erklærer herved att produktet er i samsvar med følgende normer og direktiv 2006/42

EC og NS-EN ISO 12100/NS-EN ISO 11148-6.

Todistus CE standardinmukaisuudesta FINSK

EVERWIN PNEUMATIC CORP. vakuuttaa täten tuotteen vastaavan seuraavla standardeja ja direktiivejä: 2006/42/EC

ja EN ISO 12100/EN ISO 11148-6.

Deklaracja zgodności CE POLSKIE

EVERWIN PNEUMATIC CORP. oświadcza, że produkty opisane w załączonej dokumentacji spełniają wymogi

Dyrektywy Maszynowej 2006/42/EC oraz Europejskiej normy EN ISO 12100/EN ISO 11148-6.

Machine Type: EWS-202, EWS-89-7500

Machine Name: Industrial Air Impact Screwdriver

Place of Issue: No. 7, Wugong 7th Rd., Wufeng Dist., Taichung City 41353, Taiwan.

Date of Issue: Aug. 08, 2019

Signature of Issuer: _____________________

Hung-Ming Chuang

General Manager

3

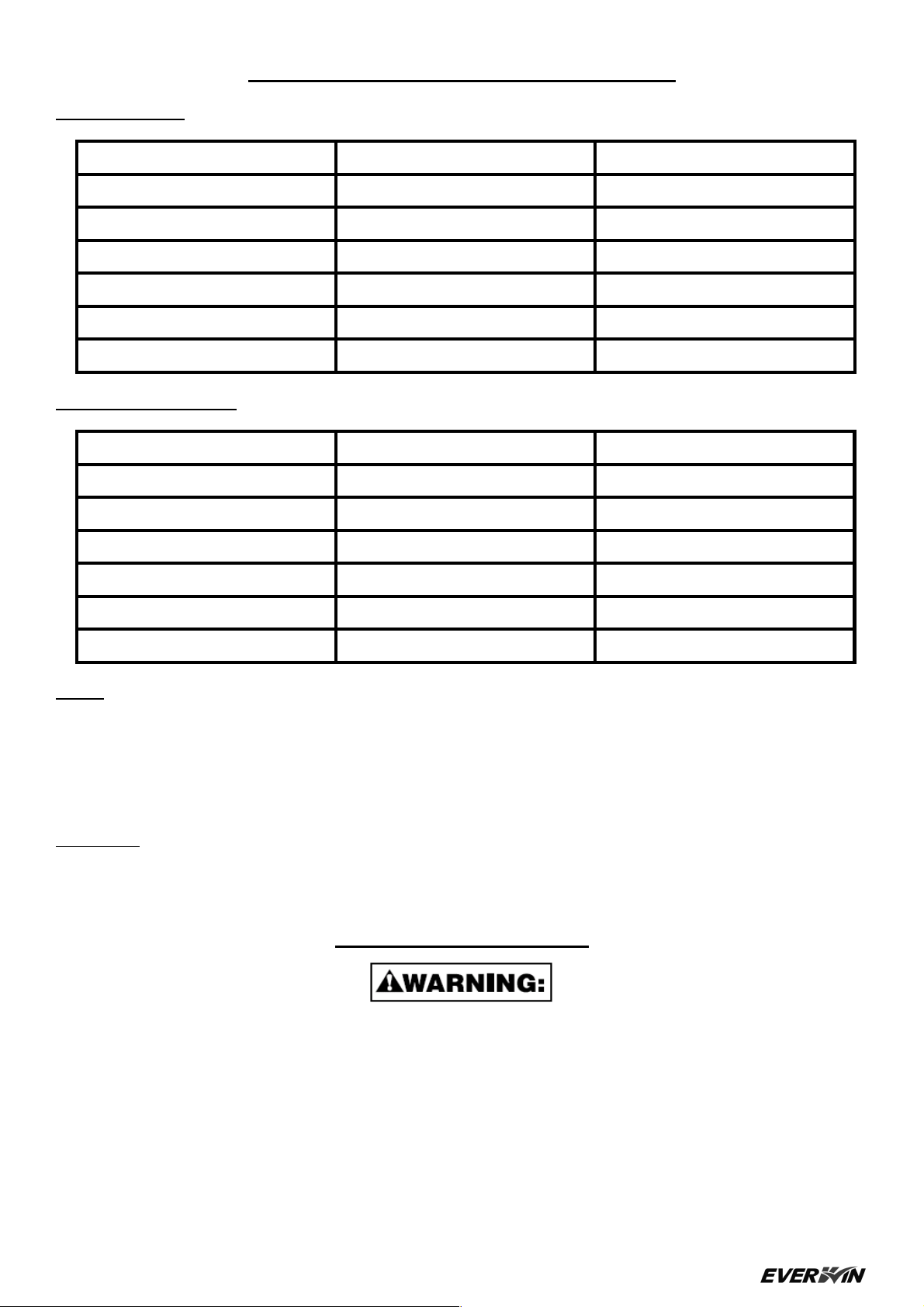

SPECIFICATIONS AND TECHNICAL DATA

SPECIFICATIONS

MODEL

EWS-202

EWS-89-7500

HEIGHT

6.1" (156mm)

6.1" (156mm)

WIDTH

1.7" (43mm)

1.7" (43mm)

LENGTH

7.1” (181mm)

7.9” (200mm)

WEIGHT

2.2lbs. (1.0kg)

2.4lbs. (1.1kg)

OPERATING PRESSURE

90 psi (6.2 Bar)

90 psi (6.2 Bar)

ACTUATION MODE

TRIGGER ACTUATED

TRIGGER ACTUATED

DRIVE SPECIFICATIONS

MODEL

EWS-202

EWS-89-7500

FREE SPEED

12,000 rpm

800 rpm

MAX TORQUE

900 in-lbs. (102 Nm)

WORKING TORQUE

300~480 in-lbs. (34~54 Nm)

130 in-lbs. (15 Nm)

ENERGY

0.5 HP

0.5 HP

AIR INLET

1/4” PT-19 or NPT-18

1/4” PT-19 or NPT-18

AVG. AIR CONSUMPTION

4 CFM (113 L/min)

4 CFM (113 L/min)

NOISE

A-weighted single-event sound power level LWA, 1s:

EWS-202: 100 dBA, EWS-89-7500: 100 dBA

A-weighted single-event emission sound pressure level at work station LpA 1s,d:

EWS-202: 89 dBA, EWS-89-7500: 89 dBA

These values are determined and documented in accordance to EN ISO 15744.

VIBRATION

EWS-202: 3.07 m/s

2

, EWS-89-7500: 1.29 m/s

2

These values are determined and documented in accordance to EN ISO 28927-2.

SAFETY INSTRUCTIONS

1. Keep work area clean and well-lit.

2. Do not operate power tools in explosive atmospheres, such as in the presence of combustible liquid, gases or dust.

Power tool create sparks which may kindle the dust or fumes.

3. Disconnect tool before when not in use.

4. High sound levels can cause permanent hearing loss. Use hearing protection during operation.

5. Maintain a balanced body position and secure footing during operation.

6. Slip/Trip/Fall is a major cause of serious injury or death. Be aware of excess hose left on the walking or work ground.

7. Repetitive work motions, awkward positions and exposure to vibration can be harmful to hands and arms. If

numbness, tingling, pain or whitening of the skin occurs, stop using the tool and consult a physician.

8. Always wear impact-resistant eye and face protection when operating the tool or near the operation, repairing,

maintaining the tool or changing accessories on the tool.

4

TOOL USE AND CARE:

1. Use support handle or other practical ways to secure and support the work piece to a stable platform.

2. Do not force the tool. Use the correct tool for your application. The correct tool can do the job better and more secure

at the rate of tool designed.

3. Disconnect the air supply before making any adjustments, changing accessories, or storing the tool. Always

disconnect the air supply before performing any inspection, maintenance, or cleaning the tool.

4. Use only accessories recommended by the manufacturer for your model.

5. Use the lever underneath the trigger to select forward (clockwise) or reverse (anti-clockwise) rotation.

6. Do not leave the tool unattended when it is connected to an air supply.

7. Use compressed air only.

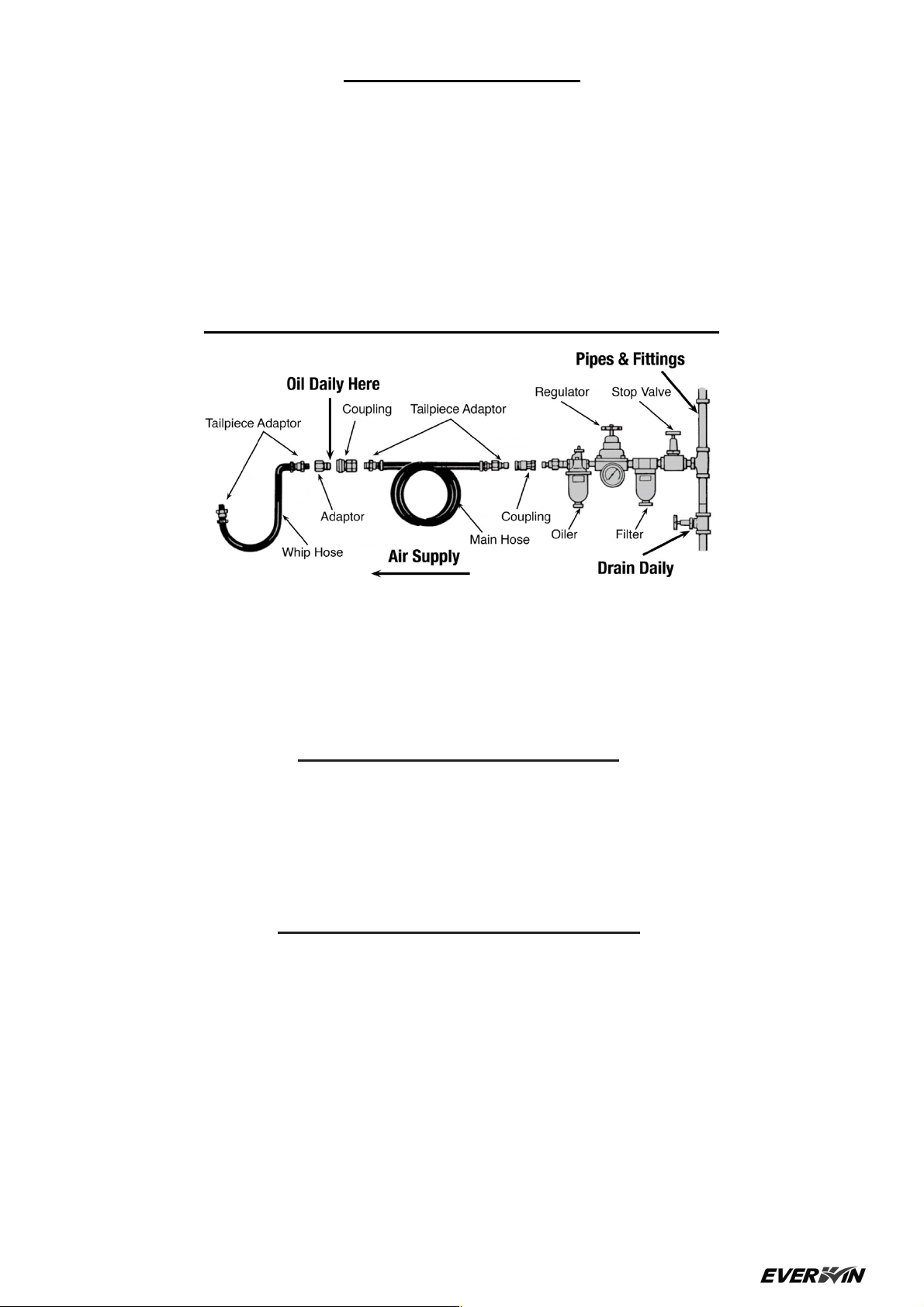

AIR SUPPLY SETUP AND CONNECTING HAZARD:

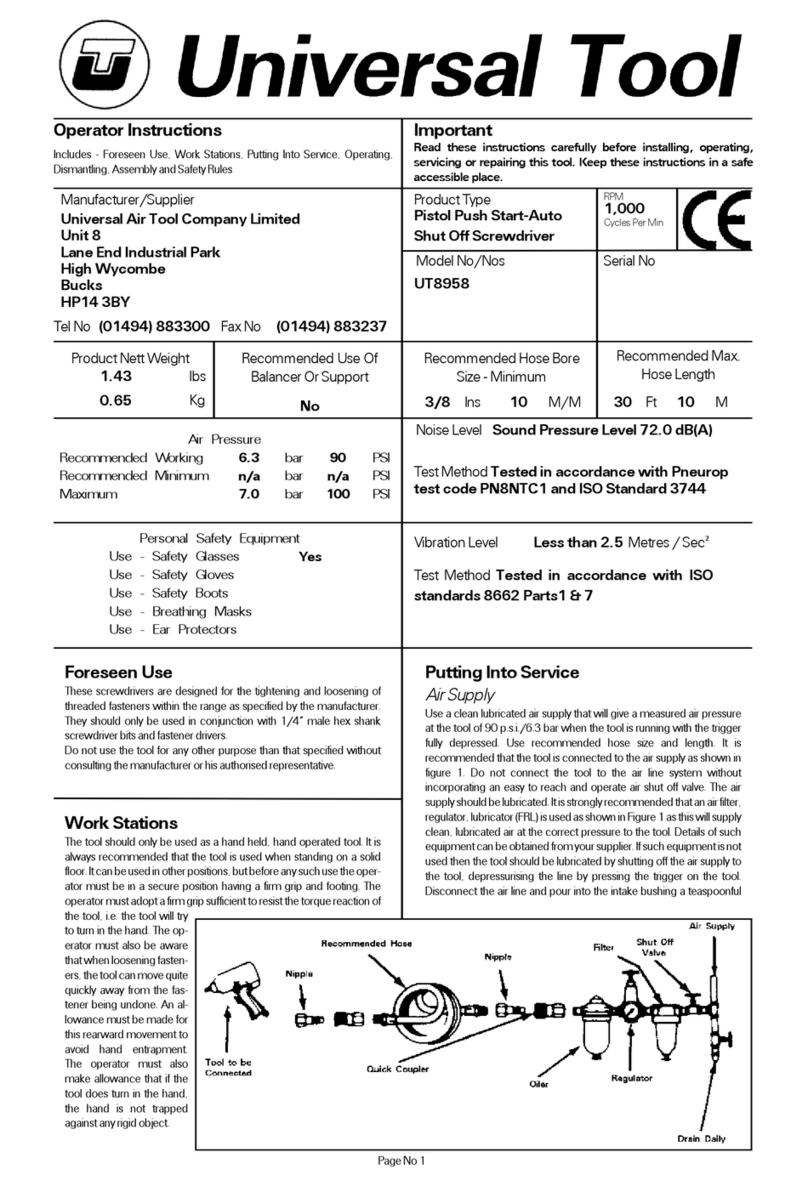

Recommended Air Line Components

1. For best service, incorporate a regulator, oiler and an inline filter.

2. If not using an automatic lubricating system, before operating the tool, add a few drops of pneumatic tool oil to the

airline connection. Add more after each hour of constant using.

3. Do not exceed maximum air pressure of 90 PSI/ 6.2 bar or as stated on tool nameplate.

OPERATING INSTRUCTIONS:

1. Disconnect the air supply before handling the screwdriver bit or socket, adjusting the clutch or dismantling the tool.

2. Hold the tool correctly, be ready to counteract normal or sudden movements – have both hands available.

3. Immediately after adjusting the clutch, check for correct operation.

4. Do not use with reduced air pressure or in a worn condition: the clutch may not operate, resulting in sudden rotation

of the tool handle.

LUBRICATION & MAINTENANCE:

Lubricate the tool daily with a good grade of air tool oil. If no air line oiler is used, run a teaspoon of oil through the tool.

The oil can be squirted into the tool air inlet, or into the hose at the nearest connection to the air supply, then run the

tool. The rust inhibitive oil is acceptable for air tools.

This manual suits for next models

1

Popular Power Screwdriver manuals by other brands

Berner

Berner BACIS-1 18V Original instructions

Makita

Makita 6823 instruction manual

Panasonic

Panasonic EY7420 operating instructions

Parkside

Parkside PAS 7.2 A1 Operation and safety notes

EINHELL

EINHELL TC-SD 3,6 Li Original operating instructions

Universal Tool

Universal Tool UT8958 Operator instructions