Instanta 3001F Guide

This manual suits for next models

4

Other Instanta Boiler manuals

Instanta

Instanta SureFlow Touch WMS6PB Guide

Instanta

Instanta CTS11F Guide

Instanta

Instanta Titan Pro Bulk User manual

Instanta

Instanta CH1000 Guide

Instanta

Instanta Barista Pro WB-2 Guide

Instanta

Instanta SureFlow Plus Series Guide

Instanta

Instanta WM3 Guide

Instanta

Instanta InstaTap UCB Series Service manual

Instanta

Instanta CPF2100 Guide

Instanta

Instanta 1000-C Guide

Instanta

Instanta Barista Pro SW Series User manual

Instanta

Instanta SureFlow Compact Series Guide

Instanta

Instanta DB500 Guide

Instanta

Instanta 1500 Operator's manual

Instanta

Instanta 1501F Guide

Instanta

Instanta CTSP15PB Guide

Instanta

Instanta WA2N Guide

Instanta

Instanta 1000-C Guide

Instanta

Instanta DB2000 Guide

Instanta

Instanta SureFlow CTS13SL User manual

Popular Boiler manuals by other brands

HKS lazar

HKS lazar Holz Master Operation and installation manual

Radiant

Radiant R1K 75 user manual

Biasi

Biasi ADVANCE 25C User manual and installation instructions

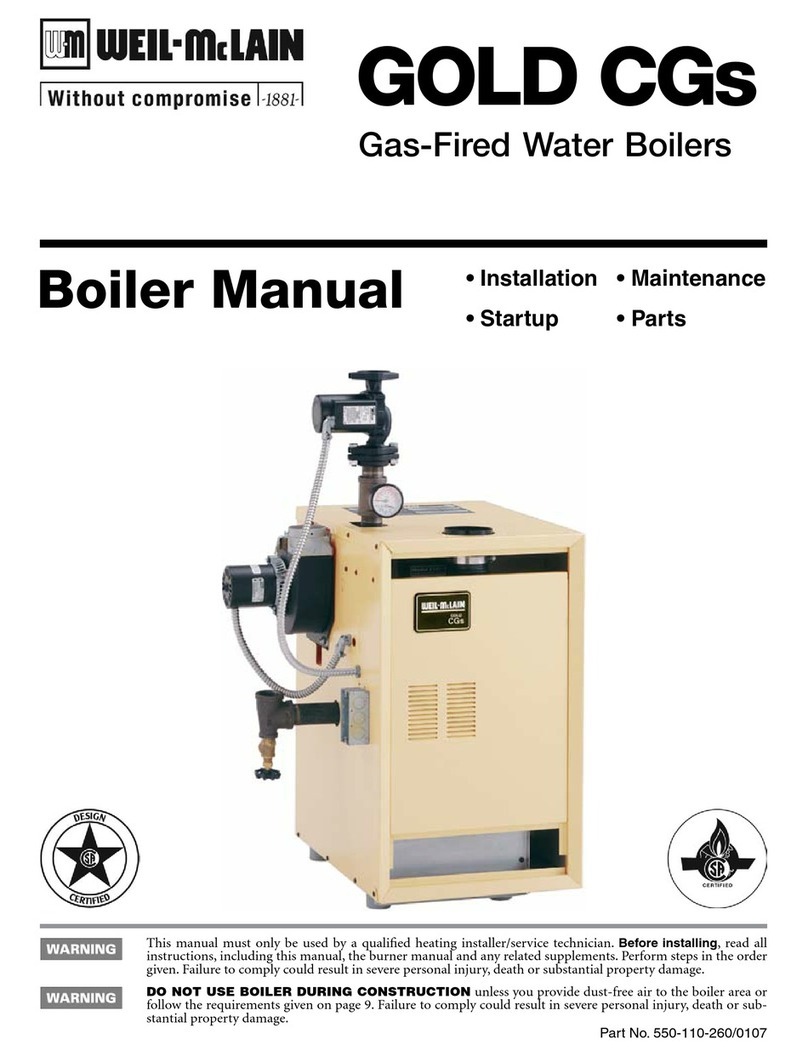

Weil-McLain

Weil-McLain GOLD CGS 550-110-260/0107 manual

IDEAL

IDEAL LOGIC Combi E 35 user guide

Munchkin

Munchkin VWH High Efficiency Hot Water Supply Boiler Installation & operating instructions

Bosch

Bosch Worcester 28CDi User instructions

Ariston

Ariston microGENUS HE 24 MFFI user manual

klover

klover DIVA SLIM Series Installation, use and maintenance, useful tips

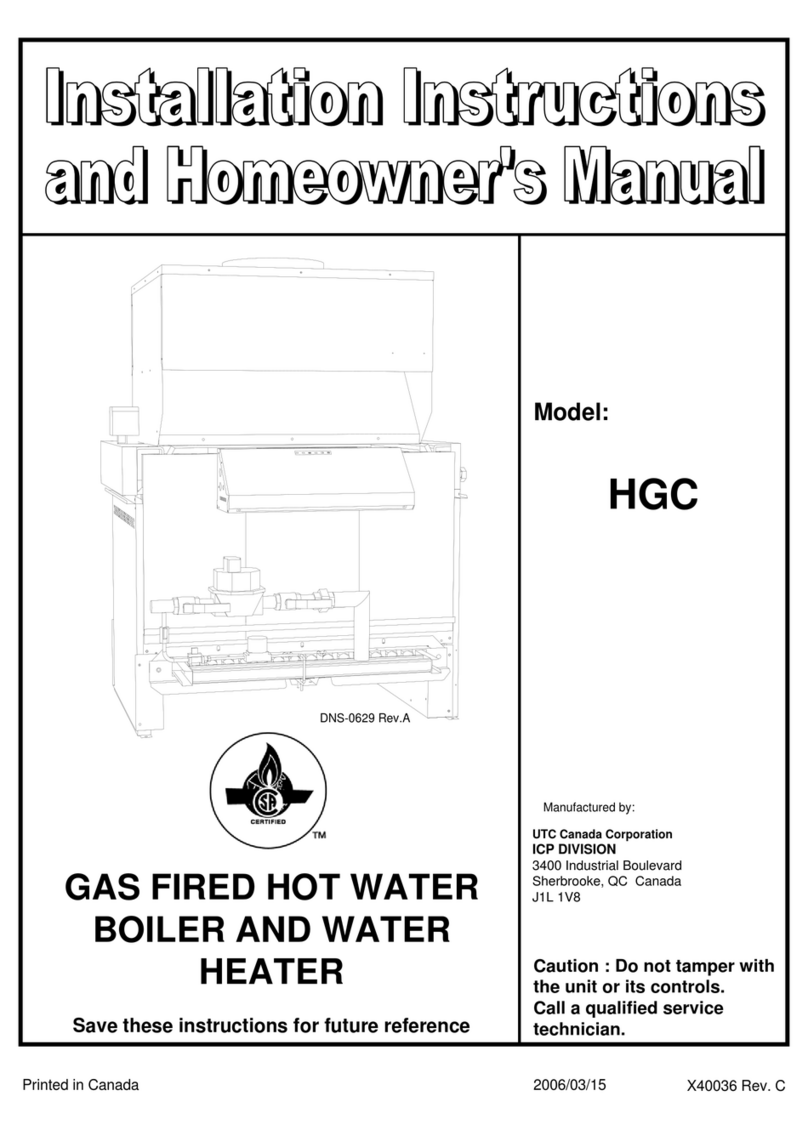

Dettson

Dettson HGC Installation instructions and homeowner's manual

Lennox

Lennox GSB8-E installation instructions

Viessmann

Viessmann Vitoladens 300-C Service instructions

Viessmann

Viessmann Vitodens 100-W B1HF Series Installation and service instructions

geminox

geminox FCX 22 C Technical instructions

Bosch

Bosch Worcester Greenstar CDi Conventional Series instruction manual

DeDietrich

DeDietrich NeOvo EcoNox EFU 36 user manual

Viessmann

Viessmann Vitocrossal 100 Installation instructions for contractors

Viessmann

Viessmann Vitocrossal 300 CU3A Application guide