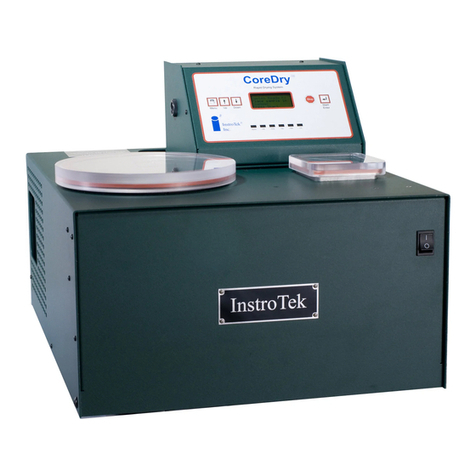

InstroTek CORELOK User manual

innovators in instrumentation technology

OPERATING MANUAL

Asphalt Density Measurement System

www.InstroTek.com

CORE

LOK

®

© 2018 InstroTek, Inc.

CoreLok®Software Operation

Manual Revision 24

InstroTek

1

1. Table of Contents

****************************************

1. INTRODUCTION 2

2. STANDARD AND OPTIONAL ACCESSORIES 8

3. CONTROL PANEL 9

4. INSTALLATION OF THE GRAVITYSUITE™ SOFTWARE 10

5. GETTING STARTED 11

6. BULK SPECIFIC GRAVITY (Gmb) OF COMPACTED ASPHALT 13

SPECIMENS (ASTM D6752 & AASHTO T 131)

7. MAXIMUM SPECIFIC GRAVITY (Gmm) OF LOOSE ASPHALT 18

MIXTURES (ASTM D6857)

8. APPARENT SPECIFIC GRAVITY OF FINE AND COARSE AGGREGATES 22

(ASTM D7370)

9. DETERMINATION OF SAMPLE POROSITY/PERMEABILITY USING THE 26

CORELOK MACHINE (ASTM D7063)

10. APPARENT GRAVITY OF PLASTIC BAGS 30

11. ROUTINE MAINTENANCE AND TROUBLESHOOTING 34

12. CONVERSION TABLE 44

13. INDEX 45

14. WARRANTY 47

InstroTek

2

1. Introduction

Increasing use of coarse and open graded mixes has created a need for more

reliable and accurate method of measuring the bulk specific gravity of

laboratory and field specimens. Open graded mixes readily absorb water and

drain quickly when removed from the water tank. The lack of control over the

penetration and drainage of water in and out of asphalt samples creates a

fundamental problem with the water displacement measurement method using

the current procedure (ASTM D2726 or AASHTO T 166) for determination of

specific gravity.

The most efficient and accurate method of correcting for this problem is to seal

the samples prior to testing in water. The current sealing methods, namely,

Paraffin and Parafilm are optimized for 100-mm diameter samples. They are

difficult to impossible to use effectively for 150-mm samples and cause large

measurement variability. The new system explained in this manual provides an

advanced and automatic solution to sealing asphalt samples.

The CoreLok system is a vacuum chamber that is used with specially designed

polymer bags to completely seal field and laboratory asphalt samples from

water during the bulk specific gravity measurements.

The CoreLok is a versatile density system with many different applications. This

device can be used for determination of bulk gravity of compacted asphalt

samples (ASTM D6752 & AASHTO T331), maximum gravity of loose asphalt

samples (ASTM D6857), porosity or permeability of compacted field or laboratory

samples (ASTM D7063), and gravity and absorption of fine and coarse

aggregates (ASTM D7370).

InstroTek

3

System Overview

The CoreLok uses a 1.25 hp vacuum pump in conjunction with control

electronics and a vacuum tight chamber to seal samples. The system is

completely integrated and operates on 120 or 220-volt (optional) power. The

sample is placed inside a specially designed plastic polymer bag, inserted in the

chamber and the door is closed. A switch recognizes the door closure and

activates the vacuum pump. The vacuum pump operates until the vacuum

gauge indicates 99% of full vacuum. An integrated pressure gauge monitors the

vacuum level and displays the vacuum within the chamber. The pump is

capable of producing 29.7 inches (754 mm) of Hg vacuum. At this point the

chamber and the bag are close to absolute vacuum. An automatic sealing

strip heat-seals the bag at the open end and air is allowed to enter the

chamber in a controlled manner. Since the bag is sealed and is under vacuum,

the increased pressure in the chamber forces the plastic bag around the

sample creating a tightly vacuum-sealed sample. Once the chamber reaches

atmospheric pressure, the chamber door automatically opens. The sample can

be removed and tested. The bag density is known and accounted for in the

calculation of the bulk specific gravity.

Critical Measurement Parameters

The following three aspects are important and should be recognized when using

the CoreLok system:

1. Vacuum pressure

2. Testing time after sealing

3. Sample temperature prior to sealing

1. Vacuum Pressure. The pump should be able to create a vacuum of 29.7 in.

(754 mm) Hg inside the chamber. The residual volume after sealing the

sample should be less than 2% by volume of the specimen, the limit required

by the current ASTM D1188 for sealing asphalt specimens. The calculation

based on an asphalt sample 5” in height and 6” in diameter with a volume of

141.4 in3and 1% residual volume yields a pressure of 0.3 in. Hg using Boyle’s

InstroTek

4

Law, which would indicate a vacuum pump requirement capable of 29.7 in.

Hg (30-0.3 in. Hg) of vacuum.

P1V1= P2V2

Where, P2is the pressure on the bag during the sealing process, V2is the void

volume not occupied by the plastic bag after sealing and V1is the total air

volume of the bag not occupied by the core.

The vacuum performance of the unit should be checked on a yearly basis, or

as needed, by using an absolute vacuum gauge that can be placed directly

inside the chamber. This will ensure the integrity of the pump, vacuum hoses

and the seals.

2. Testing time after sealing. The CoreLok plastic bags are designed with multi-

composition layers of plastic. The requirement for the plastic is to be flexible

to conform to the sample and to provide enough strength to resist punctures

from asphalt samples. To accomplish this specification the molecular

structure of the bag is designed to hold vacuum levels produced by the

CoreLok for approximately one hour. The water displacement test should be

conducted within 2 minutes after the sealing process. Samples can be

tested after this time but two items have to be looked at prior to testing. First,

a major leak can occur in the bag by mishandling of the bag before or after

the sealing process. This could easily be seen within a few seconds of

sealing. With careful handling, most of these leaks can be avoided. Second,

due to excessive stretching of the plastic around sharp points, “micro” leaks

can occur. This can be defined as thinning of the plastic, which will allow air

into the bag over a very long time (hours). This does not affect the results if

the sample is tested within the first 30 minutes of the sealing process. The

surface tension on the bag is sufficient to keep water out of the bag.

For best results, the bag should be checked prior to testing to ensure tight fit

around the sample. Presence of a major leak is obvious in this process with

immediate loosening of the bag.

3. Sample temperature prior to sealing. Introduction of air into the chamber

after heat- sealing the bag is done in a controlled manner to avoid artificial

compaction of the sample in the chamber. The bag conforms to the sample

in a slow and methodical way. Tests with the CoreLok indicate that

InstroTek

5

temperatures below 120º F will not affect the sample density. It is

recommended that samples be cooled to this temperature prior to sealing.

Table 1, shows data on nine different asphalt samples tested at room

temperature, 120F, 150F and 200F. The density errors as seen from this test

range from 0 to 0.019 g/cm3. The maximum error occurred at 150F on a

coarse graded mix. To ensure accurate density measurements by the

CoreLok test, we recommend temperatures of less than 120F.

Table 1: Density (g/cm3) of Samples Tested in the CoreLok at Different

Temperatures

Sample

Density @

Room

Temp

g/cm3

Density @

120F

Density @

150F

Density @

200F

Difference

g/cm3

1. Fine

2.310

2.303

0.007

2. Fine

2.273

2.265

0.008

3. Coarse

2.214

2.233

0.019

4. Coarse

2.097

2.105

0.008

5. Fine

2.302

2.304

0.002

6. Fine

2.282

2.282

0.000

7. Fine

2.308

2.300

0.008

8. Coarse

2.210

2.219

0.009

CoreLok Applications

In addition to measuring bulk specific gravity of compacted specimens, the

CoreLok can also be used for the following applications:

1. Maximum specific gravity (Gmm) or “Rice” specific gravity of loose

asphalt mixtures. Special channel bags are required for this test.

2. Apparent specific gravity of fine and coarse aggregates.

3. Bulk specific gravity and absorption of fine and coarse aggregates.

4. Porosity or permeability of field and laboratory samples.

5. Indirect determination of percent asphalt content

InstroTek

6

Safety Precautions

Always follow these basic safety precautions when using electrical or pump

appliances:

Read all instructions carefully.

Take notice of all warning labels located on the CoreLok.

Do not tip the CoreLok on its side.

Do not use on wet surfaces.

Do not immerse any part of the CoreLok, the CoreLok cord or plug into

water or other liquids.

To disconnect, grip plus and pull from wall outlet. Do not disconnect by

pulling on the cord.

Do not allow cord to dangle over or touch hot surfaces.

Do not operate the CoreLok if the cord is damaged in any way.

Do not place on or near a heat source.

Use of accessory attachments not recommended or sold by InstroTek may

be dangerous and my void your warranty.

Do not operate the CoreLok with the housing removed.

Do not operate if the chamber lid appears to be damaged or cracked.

Do not lay hand on the intake to check pump suction. Exposure of any

part of the body to the vacuum can result in personal injury to the

exposed part.

Never operate the pump with an open, accessible inlet. Vacuum

connections, oil filling opening or oil draining opening must not be

opened during operation of the pump.

Beware of hot surfaces that can cause burns. The operating pump can

have surfaces that reach temperatures higher than 80 C (175F).The bag

sealing edge will still be hot immediately after operation, so avoid

contact.

Only allow authorized personnel with proper machinery operating

knowledge to transport, install, operate, perform maintenance (servicing)

or dispose of hazardous wastes.

Do not use for other than intended use.

InstroTek

7

Product Specifications

Overall Size

19” X 19” X 25” (483 X 483 X 635 mm) (W X H X Depth)

Chamber Size

16.75” X 7.25” X 19.6” (425 X 184 X 497 mm) (W X H X

Depth)

Seal Bar

16.0” (406 mm)

Pump

Busch 1.25 h.p.

Vacuum Level

29.95 inches (760.7 mm)” Hg, 1 TORR, 1.33 mbars

Mode of

Operation

Automatic and controlled by a gauge to 99% of full

vacuum

Electrical

Specification

120 VAC, 60 Hz, 13 amps or optional 220 VAC, 50 Hz, 6.5

amps

Filler Plate

3-3/4” (19mm)

Footprint

3.25 sq. ft.

Net Weight

120 lbs. (53 kg)

InstroTek

8

2. Standard and Optional Accessories

1. Water Tank (24” x 18” x 18”)

2. Over Flow Container

3. Hanging Basket

4. Core Edge Breaker

5. Operation Manual (USB Drive)

6. Scissors

7. Sliding Plate

8. Small Sample Bags (10” x 14”)

9. Channel Bags for Gmm Testing

10. Large Sample Bags (15” x 18”)

11. Hanging Rod

12. Filler Plates

Not Shown –Protective Cover

Optional Accessories

1

2

3

12

4

5

6

7

8

9

10

11

Tank Stand

Scales

AggPlus

Please call InstroTek if you need to purchase any optional accessories.

InstroTek

9

3. Control Panel

Factory Settings

Control

Program #1

Program #2

Description

Power

Switch

On

On

Operation begins when lid is closed.

Vacuum

Control

99%

99%

Vacuum within chamber is 99% of absolute

vacuum.

Dwell

15

300

Ensures that a vacuum of 99% is achieved.

Seal

1.0

1.0

Time setting of seal bar.

Seal Bar

InstroTek

10

4. Installation of the GravitySuiteSoftware

GravitySuitefrom InstroTek is provided with each CoreLok. This software is also

available on our web site at www.instrotek.com/downloads. This package will

allow you to enter information necessary to automatically calculate bulk

specific gravity with the CoreGravitysoftware, maximum (apparent) specific

gravity with MaxGravitysoftware, Aggregate bulk gravity, absorption and

apparent gravity with AggSpecand Porosity or Permeability with Porosity

program.

To install the GravitySuite package on Windows 95 or a higher windows

version:

1. Double click GravitySuite.exe on the USB drive or location of the

downloaded file.

2. Follow the prompts.

3. The program will install on your computer and will automatically place an

icon on your desktop.

4. Optional: You might need to use the rubber sheets for maximum specific

gravity tests. Please review the maximum gravity procedures and if

rubber sheets are required for your test, contact InstroTek. When you

receive the rubber sheets, note that a density value is written on the

corner of each sheet. Write this value in your manual for future reference.

You will enter this value into the program by first opening MaxGravity.

Weigh the rubber sheets and enter the weight in MaxGravity software.

The program will ask for the density of the rubber sheets. Enter the

password - DENSITY. Once the password is entered, enter the density

value written on the rubber sheets. If the rubber sheets are replaced, a

new density must be entered. The software will now automatically correct

for the rubber sheets.

InstroTek

11

5. Getting Started with the CoreLok

Note: Comply with all the items in this section prior to operation.

CoreLok

Bags.

Use only bags that are provided by InstroTek,

Inc. Polymer bags should be handled with

care. Small holes can develop in bags that are

mistreated and render them useless for

effective sealing. During transportation, store

the bags in a safe, protected place. Bag sizes

are critical for optimum vacuum operation.

Two different size puncture-resistant bags are

provided for use with both small and large

cores.

For all 4” cores and for 6” cores up to 2”

thick, use the small bags (10” X 14”).

For all other large sizes, use the large

bags (15” X 18”).

For special sample types and shapes,

contact InstroTek, Inc.

Bag color may vary depending on the date of

manufacture.

SEAL

The SEAL time is set at the factory for 1.0

seconds, however, this may be adjusted by

the user if there is evidence that bags are not

sealing completely or the bags are melting

beyond the needed SEAL time. To change this

setting press the MENU button until “SEAL 1.0” is

displayed on the screen, use the UP or DOWN

arrow buttons to extend or shorten the SEAL

time, finally press the MENU button to return to

the PROGRAM# screen

Stop

Before operating, check proper oil level. See

Illustration on page 39. Oil level should register

between ½ and ¾ level on the pump sight

glass visible by removing the stainless steel

housing. Operation of the pump, even for a

few seconds, without oil can cause extensive

wear and damage. If oil needs to be added,

refer to the Maintenance section of the

Operator’s Guide.

InstroTek

12

Caution

Pumps that have been filled with oil must only

be moved in the upright position (horizontally).

The angle of slope may not be over 10°

maximum. Otherwise, oil may escape. Avoid

any other orientations while moving the pump.

Never tip the CoreLok on its side!

Warning

Make sure that the unit rests on a sturdy, flat

surface. If you intend to place the unit on a

mobile cart, make sure that the cart is able to

support the weight and that the cart is large

enough to allow the unit to rest on its feet as

designed. Units should never be placed so

that they are resting off the edge of a counter

or cart.

Warning

Plug the unit into a properly installed, rated

and grounded receptacle. Never remove the

grounding pin. Do not plug the unit to an

extension cord.

Warning

Check the pump for the presence of any oil

leaks, because there is the danger that

someone may slip on oil that may have leaked

from the pump.

Caution

The pump’s ambient operating temperature

should be between 0° C

(32° F) and 40° C (104° F).

InstroTek

13

6. Bulk Specific Gravity (Gmb) of Compacted Asphalt

Specimens ASTM D6752 & AASHTO T 331

The following procedure can be used as an alternative to ASTM D2726 &

AASHTO T 166 for determination of bulk specific gravity of compacted asphalt

specimens. This procedure requires that a dry compacted asphalt specimen be

placed inside a bag and vacuum-sealed with the CoreLok. The bag is then

placed underwater and a submerged weight is determined. The weight in air

and the submerged weight can be used to calculate the bulk specific gravity of

the asphalt specimen.

Note: The latest version of the GravitySuite

software can be downloaded from

our web site at www.instrotek.com/downloads.

Important: To avoid errors in submerged weight of the sample, use a large water

tank. The minimum recommended dimensions for the tank are 610(L) X460(W)

X460(D) mm (24X18X18 in). See “CoreLok Bags” on page 11 for correct bag size

usage.

Note: Make certain the sample is at room temperature and loose debris and

sharp edges are removed—use the CoreEdge Breaker to knock down the rough

specimen edges—before beginning the test.

Procedure

1. Select Program #1. In Program #1, the Dwell time is set at the factory, thus

making sure that all trapped air is removed from the bags.

2. Place enough filler plates inside the CoreLok to ensure the specimen will

not impede the machine lid from closing. You will need the sliding plate

for this test so this height will also need to be taken into account.

3. Select an appropriate size bag (see above for core size information).

Inspect the bag for holes or stress points. Do not use the bag if you find

holes or stress points.

4. Weigh the bag, record the total weight in column A of the Bulk Specific

Gravity Data Collection Table (pg. 17).

5. Weigh the dry sample and record the sample weight in column B.

6. Place the empty bag inside the CoreLok chamber.

7. Gently place the core inside the bag ensuring the core is resting on top of

the sliding plate while taking care to not puncture the bag.

8. Place the bag opening over the seal bar with approximately 1” overlap

and close the chamber door. After the vacuum and sealing operation,

the chamber door will open. See “SEAL” on page 11 for additional

information.

InstroTek

14

9. Gently remove the sealed sample from the chamber and immediately

transfer the sample to a large water bath equipped with scales and a

cushioned weighing basket. Completely submerge the bag in water.

Caution: Make certain the bag is not touching the sides or bottom of the

water tank.

10. Allow the scales to stabilize and record the weight in column C.

11. Remove the sealed core from the water. Cut open the bag and remove

the core. Weigh the core and record the weight in column D.

12. Hand-calculate the results or launch the GravitySuite package to

automatically calculate the results using the CoreGravity option.

InstroTek

15

Sample Preparation

CAUTION

Do Not Test Samples with a Jagged Bottom Surface

CUT THE BOTTOM SURFACE BEFORE TESTING WITH THE CORELOK

InstroTek

16

Sample Sealing Process

1. Place appropriate number of filler plates into the vacuum chamber.

One plate is sufficient for 150 mm gyratory specimens.

2. Place sliding plate towards the backside of the chamber on top of the

filler plate. Make sure the rubber strips are facing up and the smooth

side is resting on the filler plate.

3. Select a bag and inspect the bag for holes or stress points. Weigh the

inspected “good” bag.

4. Weigh the dry sample (review Sample preparation step in procedure).

5. Place the bag in the CoreLok and on the sliding plate.

NOTE: The clear bag is shown for illustration only.

6. Place a sample in the bag.

7. Place the bag over the seal bar. Make certain the open end of the

bag is approximately 1” over the seal bar.

8. Close the door with both hands and hold down firmly for 2-3 seconds.

9. Allow the CoreLok to perform the vacuum and sealing operation.

10. Carefully remove the sealed sample taking care to not puncture the

bag. Submerge the sample using the provided cushion basket.

InstroTek

17

CoreLok™ Bulk Specific Gravity Data Collection Table

Sample

ID

A

Bag

Weight

(g)

B

Dry

Sample

Weight

before

Sealing

(g)

C

Sealed

Sample

Weight

in

Water

(g)

D

Dry

Sample

Weight

After

Water

Submer

sion

E

Ratio

B/A

F

Bag

Appare

nt

Gravity

From

Table

G

Total

Volume

(A+D) -

C

H

(Volume

of Bag)

A/F

I

(Volume

of

Sample)

G - H

J

Bulk

Specific

Gravity

B/I

Important

Check bags for holes and stress points prior

to use. Do not use damaged bags

Hang the provided cushioned weighing

basket in the water tank from the scale (a

hooked rod is provided)

Use the sliding plate (rubber strips up) in the

CoreLok chamber to reduce friction to the

bags

Wipe away loose debris and break sharp

points on the sample

After you load the sample in the bag, do not

touch the bag. Adjust the bag position in the

chamber by moving the sliding plate

Never place the sealed sample on a hard

surface

Test the sample immediately or a maximum

of 2 minutes after sealing the sample

Gently shake the sample in the water tank

prior to placing in the weighing basket to

remove air bubbles

Place the sample gently in the basket in the

water tank.

Do not drop the sample on the basket or in

the water tank

If weight in column D is greater than 5 grams

of weight in column B dry the sample and

repeat the test

Use the provided GravitySuite software to

calculate your bulk specific gravity

Use the double bag procedure for very

heavy samples that cause repetitive

punctures

Table of contents

Other InstroTek Laboratory Equipment manuals