InstroTek CoreDry User manual

www.InstroTek.com

OPERATING MANUAL

innovators in instrumentation technology

Rapid Asphalt Drying System

CORE

DRY

®

© 2018 InstroTek, Inc.

CoreDry

Operation Manual Version 8

Important

CoreDry units are shipped within the Continental

United States with oil in the pump –the additional oil

shipped with the unit is for your next oil change.

CoreDry units shipped outside the Continental United

States are WITHOUT oil in the pump. An extra bottle is

shipped with the unit for filling before use.

************************************************************

PRECAUTIONS WHEN USING THE COREDRY

1. There is an air heater located inside the

CoreDry to maintain the sample at room

temperature. The heat is on during flow cycle.

THE BOTTOM OF THE DRYING CHAMBER MAY BE

VERY HOT DURING AND AFTER COMPLETION OF

THE TEST.

2. Be aware that the vapor trap reaches

temperatures below freezing.

3. Voltage of 120V is present inside the CoreDry

cabinet. DO NOT PROBE INTO THE MAIN

CABINET WITH CONDUCTIVE MATERIALS, TOOLS,

FINGERS OR HANDS. IF COVER MUST BE

REMOVED CONTACT INSTROTEK FIRST.

4. Do not attempt to repair this unit. Maintenance

on this unit must be done by trained

technicians.

5. Change your vacuum pump oil after 80 hours

of use (the indicator in the software will prompt

you to do this). Only use recommended

vacuum oil (InstroTek part number 419.0005).

6. Change your Tank Filters every 1 to 2 months

depending on usage (InstroTek part number

977.1004 package of 12 filters).

7. Change your exhaust filter on the vacuum

pump once a year (InstroTek part number

977.1002, 977.1005, or 977.1006 depending on

pump model).

8. Call InstroTek at (919) 875-8371 if you have any

questions.

InstroTek

1

1. Table of Contents

****************************************

1. INTRODUCTION 2

2. GETTING STARTED 5

3. MENU FUNCTIONS 10

4. AGGREGATE TESTING 12

5. EMULSION TESTING 15

6. MAINTENANCE 20

7. TROUBLESHOOTING 26

8. INDEX 28

9. WARRANTY 30

InstroTek

2

1. Introduction

Congratulations on the purchase of your CoreDry Unit. The

CoreDry is a new, innovative device used for rapid vacuum

drying of samples, while maintaining the sample at room

temperature. Keeping the sample cool during drying process

ensures that the characteristics of the sample have not

changed.

This product is the result of industry demand for rapid testing

results in the road paving industry in which previous drying

methods took many hours. Although the results are the same,

drying with rapid vacuum technology provides the user with

samples that can be tested in a few minutes. Now you can

use the dry weight from the CoreDry to measure your core

density in minutes or get a quick measure of your stockpile

aggregate moisture content.

The CoreDry uses high vacuum in conjunction with a

thermoelectric cold trap to first draw the water out from every

pore of a sample, quickly evaporate the drawn out water by

lowering the vapor pressure and then trap and condense the

vapor in a separate chamber. The vapor trap serves two

purposes in the system: first it prevents much of the vapor from

entering the pump which keeps the pump efficiency high and

secondly it improves the efficiency of the drying process by

increasing the vacuum of the system by causing condensation

to occur.

InstroTek

3

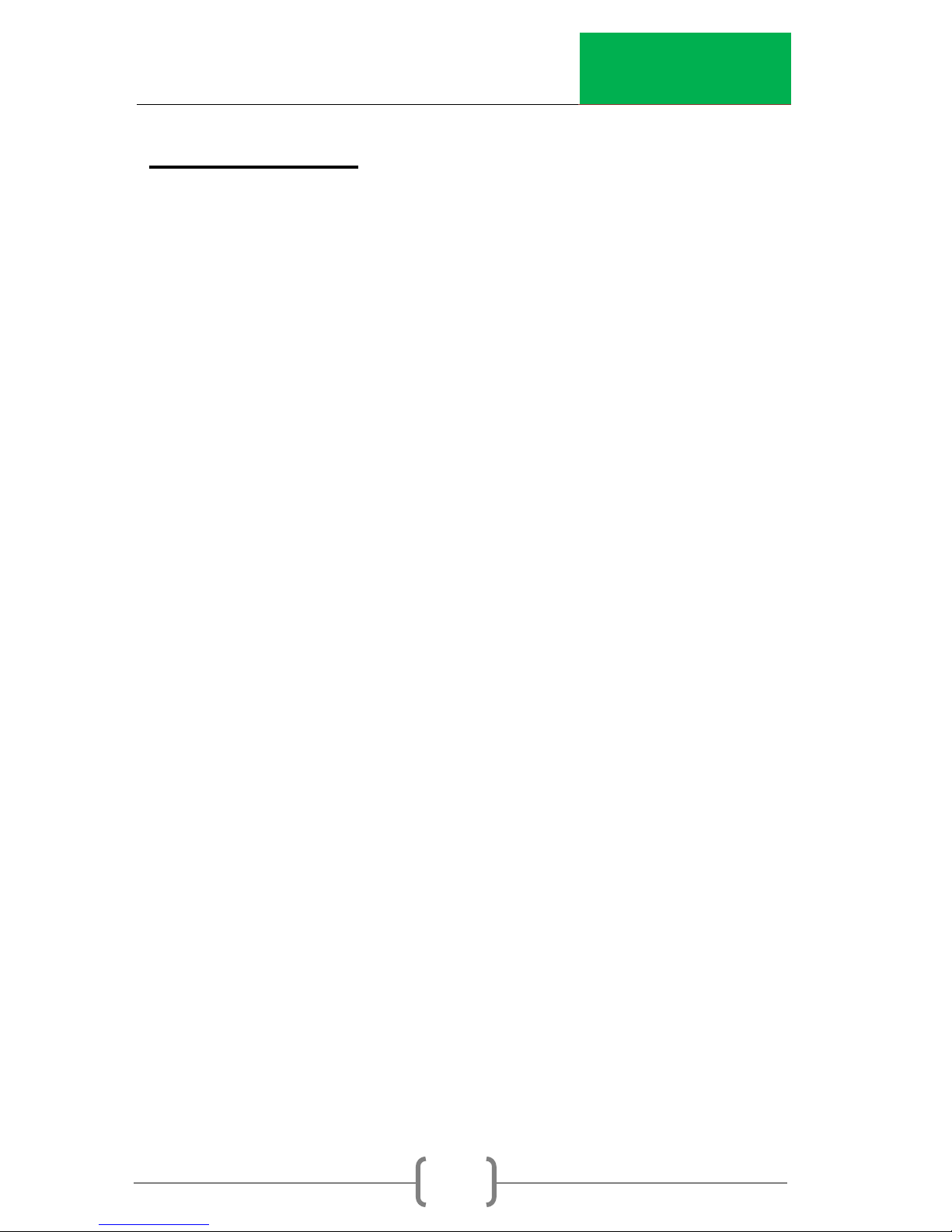

CoreDry Components

CoreDry Front View

CoreDry Back View

Cold Trap

with Lid

Sample

Chamber with

Lid

On/Off

Switch

Oil Fill Plug

Oil Level

Site Glass

Glass

Drain Valve

Power Modules

Serial Number

Plate

Power

Cable

InstroTek

4

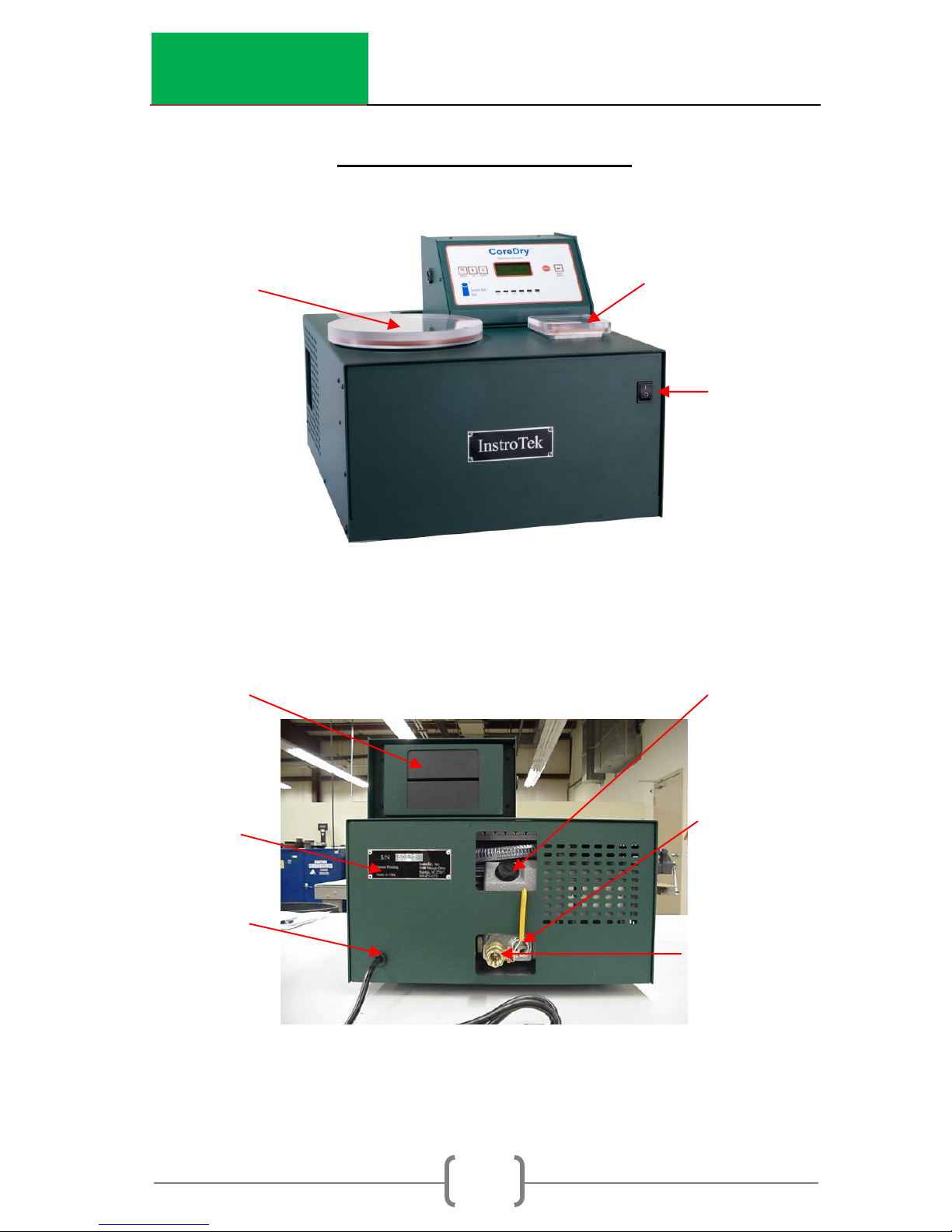

Flow Plate &

Wire Mesh

Sample

Flow Plate

and Sample

Holder

Installed in

Sample

chamber

Tank Filters

InstroTek

5

2. Getting Started

Setup and Quick Start

1. Remove from shipping box: Remove foam protection from

box and remove CoreDry unit, covers and accessories. Place

CoreDry close to 120V outlet on a flat bench surface. Leave

at least 6” of space on both sides of the CoreDry for air

circulation. DO NOT PLACE NEXT TO ANY HEAT GERNERATING

DEVICES.

2. Pump oil: In continental United States, the pump oil bottle

sent with the unit inside the drying chamber is for a future oil

change after approx. 80 hours of use. IMPORTANT –For

international units, use the oil to fill the vacuum pump, before

the first use. Please refer to maintenance section of this

manual for filling and replacing the vacuum pump oil.

3. Lids and Flow Plate: Remove the Sample Chamber lid, which

is located next to the CoreDry unit inside the box. The Flow

Plate/Mesh holder is in the bottom of the large tank along

with extra tank filters, the Cold Trap lid, a bottle of oil, and

the CoreDry CD. Remove all packing material from the large

tank. Place the wire mesh sample support in the bottom of

the large sample tank on top of the flow plate. Place the lids

on the large and small tanks.

4. Turn on CoreDry: Plug the unit in a wall outlet and flip on the

on/off switch to the ON position. The display will indicate the

software version once turned on. Next it will pressurize the

system. Then the display will prompt for the user to dry the

cold trap. After the Cold Trap is dry the CoreDry will cool the

Cold Trap. Once all the initial steps have been completed

the system is ready to for use.

Note: Always plug the CoreDry directly into the wall socket. Do

not use extension cords or power strips.

InstroTek

6

Turn Unit On: Initialization and prep flow chart.

Place the sample in the chamber, place the lid firmly on the

chamber and the unit starts cycling (after pushing the start key):

CoreDry

Version X.X.X

CoreDry

Version X.X.X

System

Pressurizing XX

CoreDry

Version X.X.X

Dry Cold Trap

T= XX

CoreDry

Version X.X.X

Cold Trap

Cooling = XX

System Ready

P1

Start to Begin

Auto Mode

Program #X

Cycle = XX T = XX

Pressure = XXX mmHg

Auto Mode

Program #X

Flow Cycle

Cycle= XX T=XX

Auto Mode

Auto Mode

Program #X

Flow Cycle

Cycle= XX T=XX

Auto Mode

Program #X

Flow Cycle

Cycle= XX T=XX

Auto Mode

Program #X

Flow Cycle

Cycle=XX T=XX

Unit cuts off when sample is dry or a message will prompt the

user to rotate the sample, when sample is not completely dry.

InstroTek

7

5. Daily Test:

a) Every day before starting operation, dry the cold trap

and the sample chamber using a lint free cloth. Do not

use paper towel as pieces of paper can get left in the

system and subsequently be pulled into the vacuum

pump.

b) Place the appropriate lids on the sample chamber and

the cold trap. Press start to begin a test without any

samples. The vacuum reading on the display should be

6 mmHg or less when complete. If the vacuum without

a sample is higher than 6 mmHg, refer to the trouble

shooting section or call InstroTek for service information.

Note: When you receive the CoreDry or after transport to

other locations, you might have to run the CoreDry several

cycles to achieve 6 mmHg. Moisture from humidity might

build up within the vacuum lines. By running the unit several

times, the CoreDry eliminates the moisture in the pipes and

reduces the pressure within the chamber to 6 mmHg.

Sample is Dry

Dry Trap Press Enter

when Done.

mmHg XX

Cycles XX

Sample is Not Dry

Rotate Sample!

Dry Cold Trap!

Press Start

Note: This indicates sample is

dry. Do not press enter until you

are ready for another sample.

Note: This indicates the number

of cycles and the vacuum of

the last cycle.

Note: This screen indicates

sample is not dry. Rotate the

sample 180°, dry cold trap and

press enter to continue drying.

InstroTek

8

6. Drying Samples:

Note: To speed up the drying process for multiple samples,

dry one sample in the CoreDry and place all other samples

in front of a fan.

a) Make sure the sample is at room temperature or higher.

Higher sample temperatures will speed up the drying

time and is preferable (temperature not to exceed

110F). Conversely, cooler than room sample

temperatures will significantly lengthen the drying time.

b) Towel dry the surface of your wet asphalt sample to

remove as much of the free water as possible. Place

the sample on its side, then on the wire mesh sample

support (as shown below), place the lid on sample

chamber and press start. When sample is dry, unit will

automatically stop and pressurize so that lids can be

freely removed.

Important note for drying extremely wet samples- If the

sample is not dry after 45 cycles, remove the sample and

place at room temperature for 15 minutes. After 15 minutes it

is ok to put the sample back in the sample chamber and

complete the drying with the CoreDry.

Note: STOP button can be pressed at any time to stop the

operation and release pressure in the chambers.

InstroTek

9

7. Cold Trap: Liquid and/or ice will accumulate in the cold trap

as samples are drying. Between samples, during rotations,

and for faster drying, it is best to remove the cold trap lid and

the divider plate and wipe out the moisture. Be sure to

always replace the divider before drying the next sample.

Caution: Use a lint free cloth to remove moisture from the

cold trap and the sample chamber. Do not use paper towel

as pieces of paper will be left in the system and

subsequently be pulled into the vacuum pump.

For best

results,

place the

sample on

its side.

InstroTek

10

3. Menu Functions

To access the Menu press the ‘Menu’ Button on the CoreDry

Keypad. To cycle through the different menu settings press the

Up or Down key to change the menu options. To view or

change a menu press ‘Enter’ when a particular menu option is

displayed. To exit out of the Menu press ‘Stop’ or press the

‘Down’ key until the main display is reached.

1. Program #: This menu function allows you to program up

to 5 different settings for drying cores or other samples.

Press the ‘UP’ and ‘DOWN’ keys to cycle between

Programs 1 through 5. Once the desired program is

selected press ‘Enter’ to Store.

2. Oil Change: Displays the amount of time until your next

oil change is required. Time is displayed in hours.

3. Run Hours: Displays the amount of time the CoreDry unit

has operated. Time is displayed in hours.

4. Max Cycles: This menu function shows the maximum

number of cycles the CoreDry will run until the sample

needs to be rotated. Default setting is 10.

5. Check Cal: This will display the current status of the

Calibration. It will show either “Calibrated” or “Not

Calibrated.”

6. Cool Time: Displays the amount of time that the Cold

Trap will cool at initialization and in between samples.

Default setting is 60.

7. Self-Test: Before using Self-Test place both lids on sample

tank and Cold Trap. The Self-Test switches between the

individual parts of the CoreDry to isolate and determine

the operational status of each part. The Self-Test will

switch between the valves, relay, pump, +Line, and

Power Supplies. Once the Self-Test is completed the

CoreDry will display the results of the Self-Test as well as

InstroTek

11

all of the current settings. The screen will scroll every 5

seconds or the Up and Down arrows can be used to

navigate through the results. NOTE: Units with serial

numbers 499 and below that have been upgraded do

not include a Self-Test feature. Menu item “7. Sys

Settings” will display the current system settings.

8. Oil Reset: Resets the timer in between oil changes back

to 80 hours. After each oil change it is important to go

into this menu function and reset the timer.

9. Tank Filter: Resets the timer for the tank filters. After the

tank filters have been changed it is important to go into

this menu function and reset the timer.

10. Exh Filter: Resets the timer for the Pump Exhaust filter.

After the Pump Exhaust filter has been changed it is

important to go into this menu function and reset the

timer.

11. Beeper Vol.: Adjusts the volume of the beeper between

four settings Off, Low, Med, or High. Default setting is

Med.

InstroTek

12

4. Aggregate Testing Using the InstroTek

CoreDry™

The CoreDry can be used for determination of aggregate

moisture content. Use the following procedure to dry

aggregates and to determine moisture content:

1. Set the CoreDry to program 2 (PR2) by pressing the

Menu key. Change the program number to program 2.

2. Remove the wire mesh sample holder and the flow

plate from the sample chamber.

3. Place the bottom portion of the aggregate fixture on a

scale capable of reading to 0.1 gram and tare the

scale.

4. Place approximately 100-500 grams of aggregates in

the aggregate fixture. Please refer to the following

table for aggregate quantities to use in the fixture.

Record weight.

5. When you determine the sample weight, re-tare the

scale.

6. Replace the lid and tighten the fasteners on the

aggregate fixture.

7. Weight the entire fixture with the aggregate on the

scale. Record this as weight A. This is the weight of the

entire fixture with wet aggregates.

8. Place the aggregate fixture in the chamber. The fixture

will be in direct contact with the bottom of the sample

chamber.

9. Place the chamber lid on top of the sample chamber

and press Enter.

10. The unit will start the drying operations.

11. When the unit stops, remove the aggregate fixture and

place on the scale. Record this weight as weight B. This

is the weight of the fixture and the dry aggregate.

Caution: The aggregate fixture might be hot to the

touch, when it’s removed from the sample chamber.

InstroTek

13

Note: If the maximum number of cycles (20) is reached

and the aggregate is still not dry, the unit will display a

message prompting the user to turn the sample and

restart the drying operations. At this point remove the

fixture from the chamber, shake the fixture to re-orient

the aggregates and replace inside the sample

chamber. Close the lid and press Enter. The unit will

continue until the sample is completely dry.

12. Determine the moisture content by the following

equation

Moisture Content= Weight A –Weight B

Aggregate Type

Sample Weight

Crushed fine aggregates

and sand

100-150 grams

Rounded fine aggregates

300-400 grams

Coarse aggregates

400-500 grams

Note: The above estimates on sample weights are based

on saturated aggregate samples.

If the aggregate is not saturated, higher sample

weights can be used.

InstroTek

14

Aggregate

Sample Fixture

Aggregate

Fixture with one

fastener and lid

removed

InstroTek

15

5. Emulsion Testing

Introduction

The eDryTM is an accessory kit designed to be a simple and

effective way of drying asphalt emulsions in less than 30 minutes

using the CoreDryTM. It enables laboratories to recover the

residual asphalt of emulsion to determine the percent residual

asphalt without changing the binder properties. The residual

binder can be tested using test standard methods, such as the

shear strength using DSR and the flexibility using BBR.

Equipment

Thin film

applicator

Metal Pan

Silicone Sheet

Rack

Rack

Thin Film

Applicator

InstroTek

16

The eDry kit includes the following:

1 thin film spreader

1 rack with 5 shelves

10 metal pans and silicone liners (5 for testing and 5 for

preparing the next sample)

CoreDry control board (necessary for older models)

Preparing a Sample

1. Prepare a space with a protective sheet to capture any

spills of the emulsion.

2. Weigh a clean silicone sheet and metal pan to the

nearest 0.01 g.

3. Remove the silicone sheet from the metal pan. Pour

emulsion on the silicone sheets to form a circle

approximately the size of a quarter toward one edge of

the sheet.

Table of contents

Other InstroTek Laboratory Equipment manuals