Optional accessories inclu e On/Off AC Line Switch, FWD-BRK-REV Switch, Run-Stop-Jog

Switch, Signal Isolator, an Anti-Plug Reversing Mo ule. Quick-connect terminals are pro-

vi e for easy installation of all optional accessories. The control is available in black finish

(P/N 8401) an FDA approve white finish (P/N 8402).

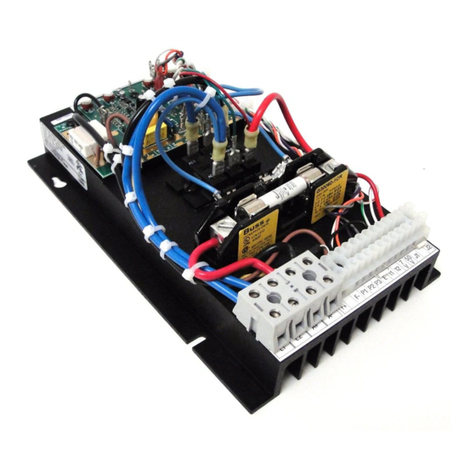

STANDARD FEATURES

•Short Circuit Protection – Protects control from a short circuit at motor connections.

•Electronic Motor Burnout Protection – Shuts own the control if a prolonge overloa con-

ition exists.

•Active Bridge – Limits the AC line inrush current when power is turne on an also prevents

high spee runaway if the power transistor shorts.

•Heat Spreader – Allows power transistor to operate safely uring momentary overloa con-

itions.

•Auto AC Line Select – Control automatically a justs for 115 or 208/230 Volt AC line input.

•Start/Stop Switch – Provi es electronic start an stop functions.

•Diagnostic LEDs – For power on (ON), stop (STOP) an motor overloa (OL).

•Trimpots – Provi e a justment for acceleration (ACCEL), eceleration (DECEL), maximum

spee (MAX), minimum spee (MIN), jog spee (JOG), current limit (CL), time current limit

(TCL), an IR compensation (IR).

•Selectable Jumpers – Provi e settings for armature voltage or tach-generator fee back

(J1), motor current (J2), time or non-time current limit (J3), tach-generator voltage (J4), an

run relay output (J5).

•Barrier Terminal Blocks – Facilitate wiring of AC line, motor armature an fiel , tach-gen-

erator, an run relay output.

•Quick-Connect Terminals – Facilitate connecting Start/Stop switch, Run-Stop-Jog switch,

FWD-BRK-REV switch, an Inhibit switch.

II. SIMPLIFIED OPERATING INSTRUCTIONS

A. Power Connection – Connect the AC line to L1 an L2 terminals of TB1 an the groun

wire (Earth) to the green groun screw as shown in Figure 3, on page 6 an as escribe

in Section IIIA, on page 6 an Section IIIB, on page 6.

B. Permanent Magnet (PM) Motor Connection (Two-Wire T pe) – Connect the motor

armature to A1 (+) an A2 (-) terminals of TB1 as shown in Figure 3, on page 6 an as

escribe in Section IIIC, on page 6. Be sure that jumper J3 is set to the correspon ing

motor voltage position as escribe in Section IVA, on page 9. Do not use F1 and F2

terminals of TB2 for an purpose other than to power the field of a shunt wound

motor. Do not use F1 and F2 terminals for PM motors.

Note: Motor performance an efficiency, inclu ing brush life, may be a versely affecte

when operating the control in step own mo e (208/230 Volt AC line with 90/130 Volt DC

motors).

C. Shunt Wound Motors (Four-Wire T pe) – Connect the motor armature as escribe in

Section IIIC, on page 6. Connect full voltage fiel wires (90 Volt DC motors with 100 Volt

DC fiel an 180 Volt DC motors with 200 Volt DC fiel ) to F1 (+) an F2 (-) terminals of

TB2 as escribe in Section IIID, on page 7. Connect half voltage fiel wires (90 Volt DC

motors with 50 Volt DC fiel an 180 Volt DC motors with 100 Volt DC fiel ) to F1 (+) ter-

minal of TB2 an L1 (-) terminal of TB1 as escribe in Section IIIE, on page 7.

Note: Do not connect motor armature lea s to F1 an F2 terminals.

2

IMPORTANT – You must rea these simplifie operating instructions before procee ing.

These instructions are to be use as a reference only an are not inten e to replace the

etaile instructions provi e herein. You must rea the Safety Warning, on page 1,

before procee ing.