Intab PC-Logger 2100 User manual

PC-Logger 2100

user’s manual

© INTAB Interface-Teknik AB

September 2004

CONTENTS

1 OVERVIEW...............................................................................................1

1.1 On-line and Off-line recordings..........................................................2

1.2 Memory Capacity during On-line and Off-line recordings.................2

1.3 Functional Block Diagram..................................................................3

1.4 Display and Keys ................................................................................4

1.5 Power Requirements...........................................................................5

2 ANALOGUE INPUTS / RANGES...........................................................6

2.1 Ranges.................................................................................................6

2.2 Temperature measurements - T/C's.....................................................7

2.2.1 Ranges and linearization.........................................................7

2.2.2 Cold Junction Compensation..................................................8

2.3 Temperature measurements - Pt100 sensors.......................................8

3 CONNECTIONS........................................................................................9

3.1 Power Supply......................................................................................9

3.2 Computer.............................................................................................9

3.3 Connecting Sensors and Transducers................................................10

3.3.1 Differential Inputs.................................................................11

3.3.2 Common Mode.....................................................................12

3.4 Examples...........................................................................................13

3.4.1 Thermocouples T/C ..............................................................13

3.4.2 20mA Current Loops ............................................................14

3.4.3 Voltage output transducers : .................................................16

3.4.4. RTD (Pt100) sensors.............................................................17

3.5 Common errors when connecting transducers..................................18

4 DIGITAL PORTS - COUNTERS.........................................................19

4.1 Counters............................................................................................19

4.1.1 Reset mode............................................................................19

4.1.2 Accumulating mode..............................................................19

4.2 Digital Inputs.....................................................................................20

4.3 Digital Output ...................................................................................20

5 CONNECT DIGITAL PORTS...............................................................21

5.1 Switch / Relay on Digital Input.........................................................22

5.2 TTL/CMOS signal on digital input...................................................22

5.3 External relay on digital output.........................................................23

5.4 Status Led on digital output ..............................................................23

6 MISCELLANEOUS ................................................................................23

6.1 Reset of the PC-logger 2100.............................................................23

6.2 Controller Program ...........................................................................23

6.3 50/60Hz Adaption.............................................................................23

7 TECHNICAL DATA / SPECIFICATIONS..........................................23

7.1 ANALOGUE DATA ........................................................................23

7.1.1 Method of measurement .......................................................23

7.1.2 Measurement interval ...........................................................23

7.1.3 Inputs ....................................................................................23

7.1.4 Ranges...................................................................................23

7.1.5 Divisions/Dynamic ranges....................................................23

7.1.6 Resolution .............................................................................23

7.1.7 Accuracy................................................................................23

7.1.8 Temperature Coefficient .......................................................23

7.1.9 Noise .....................................................................................23

7.1.10 Common mode......................................................................23

7.1.11 Constant Current Output .......................................................23

7.2 DIGITAL PORTS - COUNTERS .....................................................23

7.2.1 Digital Output........................................................................23

7.2.2 Pulse Inputs and Digital Inputs (at 25°C +/-10°C)...............23

7.2.3 Auxiliary voltage output : V-Out ..........................................23

7.3 INTERNAL DATA STORAGE CAPACITY...................................23

7.4 COMPUTER INTERFACE ..............................................................23

7.5 POWER REQUIREMENTS .............................................................23

7.5.1 Built-In NiCd-accumulators..................................................23

7.5.2 Mains Adapter.......................................................................23

7.6 MECHANICAL.................................................................................23

8 Questions and Answers............................................................................23

INDEX...................................................................................................................23

Page 1

1 OVERVIEW

1 OVERVIEW

A "PC-logger 2100" together with our software and a personal computer running

Windows

, constitutes a versatile and powerful data acquisition/recording

system.

PC-logger 2100 is a complete logger useful for many purposes. It will, for

example, easily replace/outdate any strip chart recorder.

The logger measures the full range of industrial analogue signals: +/-10V, +/-1V

and +/-20mA. It is also possible to directly connect thermocouples for

temperature measurements. Cold Junction compensation and linearization are

internally handled by the logger. It is also possible to measure temperature by

means of RTD's (e.g. Pt100 sensors).

In addition to the analogue inputs the logger is equipped with 3 counter inputs.

These can be used for event (pulse) counting, e.g. flow, rpm, etc.

Recordings can be made directly to the storage media on the host computer

(On-line recordings) or temporarily to the internal memory in the logger.

(Off-line recordings) During Off-line recordings there is no need for the host

computer to be connected to the logger. This way the computer can be used for

other purposes during off-line recordings.

Main features

-8 analogue inputs.

-Range and measurement type are user configurable through software.

(10V, 1V, 100mV, 50mV, 20mA, Thermocouple type: J, K, R, S, T, E,...)

-16 bit resolution AD converter.

-3 counter inputs. (plus 3 digital inputs and one Alarm Output.)

-Constant current source suitable for Pt100 measurements.

-On-line recording directly to computer.

-Off-line recordings using internal memory of 224KB.

-Voltage output for transducers etc.

-Display and keys for easy handling.

-Fully compatible with Intab's "EasyView Pro"

-Small dimensions: 250 x 110 x 40mm.

To fully understand the potential of the PC-logger 2100 we strongly recommend

the studying of this entire manual with emphasis on chapter 3 which describes

how to connect sensors and transducers.

How the PC-logger is handled using our software and a PC is explained in the

program manual and by the program itself through its user-friendly and self-

explanatory menus.

Those users who intend to write their own software to collect data are

recommended to obtain the "Command Manual" that describes available

commands and their syntax.

Page 2 INTAB Interface-Teknik AB, Sweden

1.1 On-line and Off-line recordings

PC-logger 2100 can make recordings in two different ways: On-line and

Off-line.

An On-line measurement is performed with the computer connected to the

logger during the entire recording. Measured data are continuously transferred

from the logger to the computer and stored on disk.

During the recording it is also possible to analyse/evaluate the measurements in

real-time on the computer screen. You can also analyse previously acquired

recordings while the current recording is taken care of in the background.

An Off-line recording should be initiated by transferring measurement

parameters from the computer to the logger. These parameters tell the logger

how to perform its recording and contain information about: interval, active

channels, channel configuration, etc. (See also software manual.) All parameters

are valid until a new set is transferred.

The PC-logger can then, after the parameters have been transferred, be

disconnected from the computer. The recording is started using the keys on the

logger itself. During the recording, the data is stored in the logger's internal

memory which has a capacity of appr. 110.000 values.

When the recording is completed the logger is again connected to the computer

for transferral of collected data to disk.

1.2 Memory Capacity during On-line and Off-line recordings

Every stored sample occupies 2 bytes of memory.

When making On-line measurements, it is the amount of free space on the

computer's disk (floppy disk or hard disk) that limits the length of the recording.

For an Off-line recording the limiting factor is the internal memory capacity of

the logger. This memory of 224k Bytes can hold 112 000 values.

The parameters that affect the maximum recording length (or duration) are:

Sampling Interval, Reduction Factor (Averaged Value), Number of channels

used and of course if it is an On-line or Off-line recording.

When using Intab's software, the user is always informed of how long the

recording can last while entering the various parameters.

Example: Off-line-recording.

The PC-logger can sample on 8 channels, 10 times each hour during 2 months.

(0,1 x 224.000) / (2 x 8) = 1400 hours! (58 days)

Please note that the PC-logger only can handle one recording at a time. If an

Off-line recording is started before the previous Off-line recording was

transferred to disk, the first one will be lost!

Page 3

1 OVERVIEW

1.3 Functional Block Diagram

The illustration above shows a simplified diagram of the building blocks of the

2100-logger. In addition to what is shown, there is separate power input and an

auxiliary voltage output for supplying sensors.

Note that the control program of the 2100 resides in RAM. This makes it a

simple operation to modify or update the logger by simply downloading a new

program from the computer: BOOT. (See also chapter 6)

Page 4 INTAB Interface-Teknik AB, Sweden

1.4 Display and Keys

An LCD and adjacent keys are incorporated to make it possible to handle the

unit when disconnected from computer.

They are used to start and stop recordings and to check sensor signals and

wiring.

Select one of three main functions using up/down arrows.

"MULTIMETER" is used to check correctness of sensor signals. Scroll

between channels with up and down arrows. The upper line of the display shows

sensor output voltage or current. The bottom line shows the (linearly)

transformed value with the engineering unit you have assigned to it. (See also "x-

form" in the software manual.)

"RECORD" should be selected to stop or start recordings. Remember that a start

erases the previous recording, so don't forget to transfer it first.

The display has a built in lamp. Turn it on and off with the lamp key. To

conserve power it will automatically be turned off after about 15 seconds.

Note that "RECORD" will also contain the information "Recording on" if a

recording is in progress.

Page 5

1 OVERVIEW

1.5 Power Requirements

The "2100 PC-logger" is normally powered by the supplied mains adapter. It

supplies 12V at a max of 500mA.

The 2100 is fitted with internal rechargeable batteries. They will give the user at

least 8 hours of continuous operation without mains supply when fully charged.

These batteries are trickle-charged by the mains adapter.

There is no danger of overcharging the batteries. They should be left on

charge even if the "2100" isn't to be used for a long time. This will prolong

battery life and ensure fully charged batteries at all times.

Batteries should be replaced at least once every four years.

Some applications require the PC-logger to be powered by other sources. Use a

cable fitted with a "TA3F" (Switchcraft) connector to connect to, for example, a

car battery.

The logger will "fall asleep" about 2 minutes after the last command or key-

stroke has been entered. This property saves the power in the rechargeable

batteries for when it is needed.

Incoming serial (RS-232) commands or pressing the "C"-key will wake the

"2100".

The built in real time clock will wake the logger in time for every sample if a

recording is in progress.

EasyView Pro automatically supplies the right time to the logger. Make sure that

your computer has the correct time.

Page 6 INTAB Interface-Teknik AB, Sweden

2 ANALOGUE INPUTS / RANGES

All analogue channels are DIFFERENTIAL. They measure the voltage between -

and GND and the voltage between + and GND. The subtraction is then

performed internally.

Standard inputs are balanced. This makes them very insensitive to noise if the

signal source is correctly connected. A signal cable consisting of a twisted pair

can be very long if the lowest potential of the source is connected to ground via a

separate cable.

Each channel is individually programmable. It can via the software be set to

measure voltage, current or temperature (thermo emf). The range (=sensitivity)

for each unit (voltage, current, temperature) is also programmable.

This versatile property can be compared to the rotary switch on an ordinary

multimeter with the difference that the user has to press a few keys on the

computer instead (see software manual).

Several types of T/C´s can be employed in the same recording and still be

correctly linearized.

2.1 Ranges

There are approx. 25000 divisions of each range. To put it in other words: each

range has a resolution of FS/25000.

Here is a table of main ranges and their resolutions:

RANGE RESOLUTION

+/- 10V 400 µV

+/- 1V 40 µV

+/- 100mV 4 µV

+/- 50mV 2 µV

+/- 20mA 0.8µA

Each channel has an internal shunt (51ohms) that is used to measure current. It

must be connected manually via an external jumper in the screw terminal (see

Section 3.4.2.)

NOTE that the shunt will overheat if subjected to more than 80mA.

Page 7

2 ANALOGUE INPUTS / RANGES

2.2 Temperature measurements - T/C's

The "2100" is specially adapted for temperature measuring using thermocouples.

The high resolution of the A/D converter makes it possible to record

temperatures in excess of 1000°C with a resolution of 0.1°C using

thermocouples of type "K".

Thermocouples are active sensors that don't require powering to supply a signal.

They are highly non-linear but are linearized by the "2100".

A thermocouple is, in its simplest form, a pair of wires of dissimilar metals that

are soldered together at one end. The other end is connected to the two screw

terminals of a channel. The difference in temperature between the soldered end

and the screw terminals gives rise to a voltage that can be measured.

This voltage is different for different thermocouple materials. Simply "tell" the

software which type(s) you are using by specifying J, K, T; S, R or ...etc. for

each channel before starting a recording.

2.2.1 Ranges and linearization

Different types of thermocouples have differing levels of output. They therefore

have differing fields of application most often depending on the temperature

range to be measured.

What two materials make up the couple may also be of a certain importance. We

will however have to assume that this is known to the user.

Below is a short summary of the properties of the most common types of

thermocouples. It is included to help in selecting type and range for your

application. "K" is the most common type.

"Cold Junction" = 0°C

TYPE mV at

200°C mV at

600°C mV at

1200°C

MAX temp °C

K 8.137 24.902 48,828 1370

J 10.777 33.096 ---------- 760

T 9.286 --------- ---------- 400

S 1.440 5.237 11.947 1760

R 1.468 5.582 13.224 1760

Thermocouples are highly un-linear. This is corrected by the internal program of

the "2100".

Thermoelectric voltage is measured (in mV) and then adjusted for the cold

junction temperature according to the type specified. This adjusted voltage is

then used as input variable to a linearizing table. The table (one for each

thermocouple type) is constructed so that its contribution to the measurement

error is negligible.

(+/-0.05°C for T<250°C; +/-0.15°C for T>250°C and "K"-type)

Page 8 INTAB Interface-Teknik AB, Sweden

2.2.2 Cold Junction Compensation

When using thermocouples to measure temperature it is almost always necessary

to know the temperature of the "cold junction". Thermoelectric voltage has to be

"adjusted" with respect to this temperature.

Thermoelectric voltage is the result of the temperature difference between the

"cold junction" and the "hot junction".

A solid state temperature sensor has been placed centrally in the screw terminal

area of the analogue board. Its temperature is automatically sampled every time a

temperature measurement is taken. All temperature measurements are thus

compensated for the actual temperature of the terminals themselves.

Some precautions have to be taken if the "2100" is exposed to rapid temperature

gradients. Since temperature is measured in one point only, a gradient from one

side of the unit to the other may cause misreadings.

By giving the unit time to reach a stable temperature before recordings are

started and by protecting it from sudden changes of ambient temperature a very

high degree of accuracy can be achieved.

2.3 Temperature measurements - Pt100 sensors

The "2100" can also take temperature readings from a Pt-100 sensor. This is

achieved by conventional four wire resistance measurement technique.

A constant current is passed through the sensor via one pair of wires. The

voltage developed across the resistor ( a Pt-100 is a temperature dependent

resistor ) is measured by a channel via the second pair of wires.

The constant current is available at terminal "I-out" on the left-hand side of

channel 1. Several Pt-100´s can be connected in series to the same current

source. ( See next chapter ).

Page 9

3 CONNECTIONS

3 CONNECTIONS

3.1 Power Supply

Power is applied through a TA3F (Switchcraft) female cable connector

connected as follows: .

socket no. 1: + 12-15VDC at max 150mA

socket no. 2: 0V

socket no. 3: + 10-15VDC at max 80mA

Connecting power through pin 3 is an alternative to pin one. It saves power by

not charging the internal accumulators.

Power can also be connected via screw terminals Vin and Gnd. They are

paralleled by pins 3 and 2 respectively.

3.2 Computer

The PC-logger 2100 connects to a serial port of a computer via supplied spiral

cable.

The 15 pin D-sub connectors has the following pins and signal names:

pin no. 2 : Tx

pin no. 3 : Rx

pin no. 5 : CTS

pin no. 6 : DTR

pin no. 7 : Signal return (Gnd)

Leave all other pins unconnected.!

Typical computer-to-PC-logger cables:

Page 10 INTAB Interface-Teknik AB, Sweden

3.3 Connecting Sensors and Transducers

Several years of experience has shown us that 95% of all problems are the result

of erroneous connection of sensors. To avoid measurement errors, noise pickup

and other strange phenomena, it is of paramount importance that all sensors and

signal sources be correctly connected. Chapters 3.3, 3.4 and 3.5 of this manual

must be considered a “compulsory curriculum” to achieve this.

Sensors, transducers and process signals connect to the screw terminal along the

side of the "2100". All screw terminals are detachable. Terminal assignment and

polarity are also printed along the side, see illustration below.

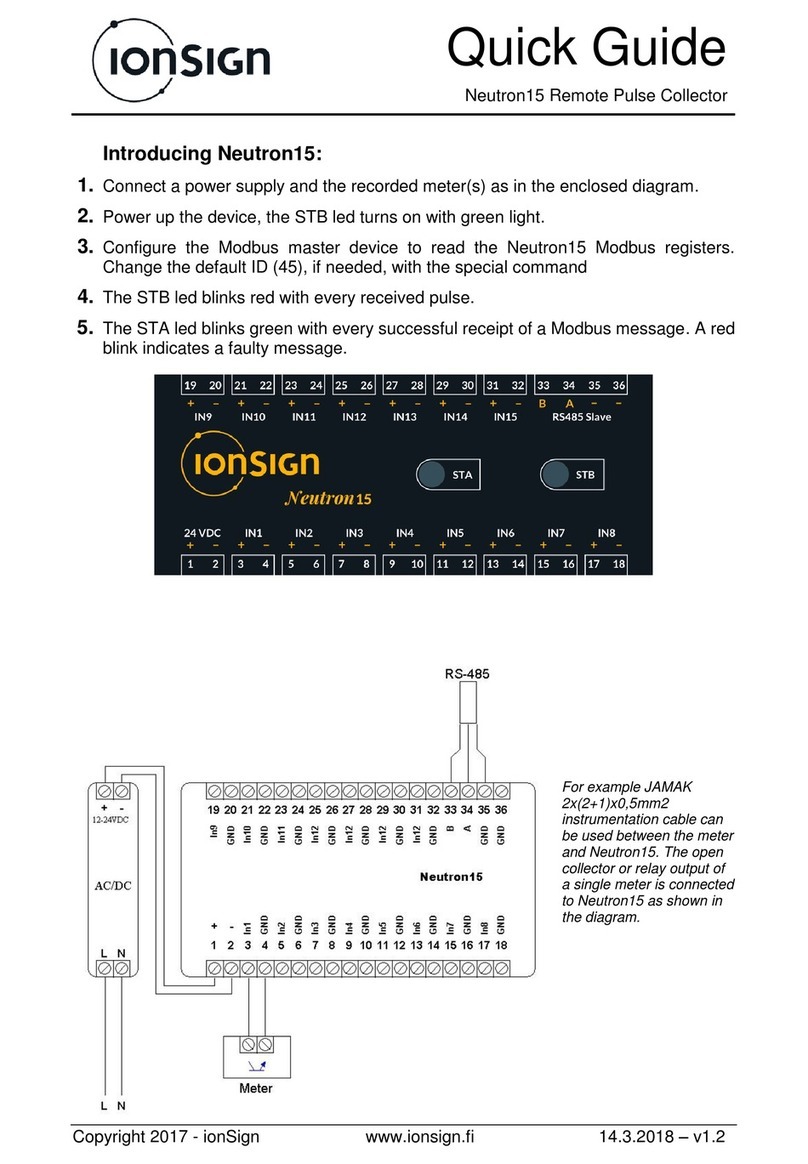

P1, P2 and P3 are digital and

counter inputs.

V-In is auxiliary PSU input

V-Out is an auxiliary voltage

supply for transducers.

I-Out is a constant current

source (0.500mA) for four-

wire resistance

measurements (f.ex. Pt100)

To measure 20mA process

signals you must connect a

jumper between "I" and "+"

on respective channel.

For differential

measurements you connect

the two signals between

ground and "+", and ground

and "-".

For single ended signals you

connect a jumper between

"-" and "Gnd" of respective

channel.

Page 11

3 CONNECTIONS

3.3.1 Differential Inputs

OBSERVE !!!

When connecting signals from sensors and/or transducers some simple rules

about referencing them to logger signal ground must be followed.

All analogue channels are differential with a very high impedance to signal

ground. Their inputs have no internal connection to signal ground.

Differential channels measure (as the name implies) the difference in voltage

between the + and the - in relation to signal ground.

Another way of saying this is that each channel really measures two voltages:

-the minus input measures the voltage between signal ground and "-";

-the plus input measures the voltage between signal ground and "+";

-the difference between these two voltages is then calculated internally and

finally presented as the channel value.

A third way is to say that signals must never be allowed to float electrically with

respect to signal ground of the "2100". They must in some way be connected!

The figure above shows one input channel. Note that the ground sign point is

common to all circuitry and channels.

Page 12 INTAB Interface-Teknik AB, Sweden

3.3.2 Common Mode

To maintain accuracy in your measurements you have to make sure that no signal

is outside the common mode range. The difference signal that is to be measured

may not have a common voltage with respect to signal ground that exceeds 10V

(see figure below)

A sensor that is left "floating" with respect to signal ground may easily drift

outside this range because of leakage voltages or static electricity.

This will result in, to say the least, unpredictable measurements, but will not

damage the inputs as long as they are within 30 Volts from signal ground. (see

also technical data: Max overvoltage).

(The shield of shielded cables may be connected to signal gnd at one end only!)

Those users who always have "floating" signals should "ground" all negative

inputs by connecting a short jumper between "-" and "Gnd" of the terminals of

each channel.

It should also be pointed out that water must, almost invariably, be considered to

be a conductor.

Page 13

3 CONNECTIONS

3.4 Examples

Below follow a few examples of how to connect different sensors and signals to

the "2100".

It is always a good idea, not to say good practise and a sign of competence, to

first draw a schematic diagram of how sensors are to be connected to the PC-

logger and how they may be interconnected. This will save a lot of time by

avoiding common pitfalls like reversed or mixed-up leads, ground loops and

floating signals.

3.4.1 Thermocouples T/C

There are two ways of connecting thermocouples. See examples below. They

differ in the way the signals are referenced to signal gnd.

The two methods can of course be combined.

1) Thermocouple hot junction in contact with conducting object :

Connect object to be

measured to PC-Logger

signal ground via a

separate lead. One lead

is enough for all

channels monitoring the

same object: Gnd is

common to all channels.

(Remember?)

Examples: Water

temperature at several

places in a large vessel ;

several thermocouples

along a metal pipe.

2) Thermocouple hot junction in contact with non-conducting object :

To prevent the measured

signal from "floating

away", each sensor "-"

must be jumpered to

signal "Gnd".

Examples: Measuring air

temperature or plastic

container surface

temperature.

Page 14 INTAB Interface-Teknik AB, Sweden

3.4.2 20mA Current Loops

Current loops can be connected in a number of ways. They are basically the same

but appear to be different because they are powered and/or referenced to gnd

differently. Below are a few examples with illustrations.

NOTE : The shunt resistor must for current measuring be manually connected

via a small jumper (=short wire) between "I" and "+". See schematic diagram of

inputs in section 3.3.1.

1) Connecting current loops with common ground points:

Avoid ground

loops by only

connecting the

gnd of one

channel to system

ground.

NOTE! Ground loops can give rise to considerable measurement errors !

Try to keep other instruments in the source path of the transmitter. This will

make it impossible to exceed the common mode range. You can of course also

connect them in the return path ( ground side ) if you make absolutely sure that

the common mode range (10V) isn't exceeded.

Add resistances of inserted instruments to make sure. The sum may not exceed

10V/20mA=500Ω!

2) Connecting ungrounded (floating) current loops:

Give all floating

current sources a

ground reference by

shorting the

negative inputs to

"2100" signal

ground with the help

of a short piece of

hook-up wire.

Again it must be stressed that "floating" is meant in respect to "2100" signal

ground, not any other ground that may be lying around (like safety earth/ground)!

This, of course, also does not necessarily mean that it is floating with respect to

other grounds! Confused? - Get an electronics engineer to help you!

Table of contents

Other Intab Data Logger manuals