Intab PC-logger 3150 Operating instructions

How to use

PC-logger 3150

Hardware

with

accessories

Interface-Teknik AB

Gjutarevägen 1

SE-443 61 STENKULLEN

Tel. +46(0)302-246 00

www.intab.se, [email protected]

Rev. E, January 2003

ii

MANUALS

of the

PC-Logger 3150 System:

-"How to Use PC-Logger 3150 " How to connect sensors and transducers

correctly

-"EasyView - manual" A tutorial guide to a user-friendly expert

data analysis program

-"Command Manual" Describes the ASCII strings (used by

software) that make the PC-Logger 3150

tick

iii

CONTENTS

MAIN UNIT......................................................................1

1 AN OVERVIEW ..............................................................................................................................1

1.1 G

ENERAL

I

NFORMATION

................................................................................................................1

1.2 O

N

-

LINE

R

ECORDINGS

....................................................................................................................2

1.3 O

FF

-

LINE

R

ECORDINGS

..................................................................................................................2

1.4 S

TORAGE

C

APACITY

.......................................................................................................................2

1.4.1 Storage capacity in Computer .............................................................................................3

1.4.2 Storage Capacity in the PC-Logger 3150............................................................................3

1.5 B

LOCK

D

IAGRAM

...........................................................................................................................4

1.6 D

ISPLAY AND

K

EYS

(

OPTION

).........................................................................................................5

1.6 P

OWER SUPPLY

...............................................................................................................................6

2 INPUTS/RANGES ...........................................................................................................................7

2.1 R

ANGES

:

V

OLTAGE AND

C

URRENT

.................................................................................................8

3 CONNECTIONS..............................................................................................................................9

3.1 P

OWER

...........................................................................................................................................9

3.2 C

OMPUTER

.....................................................................................................................................9

3.3 I

NPUTS

.........................................................................................................................................10

3.3.1 Differential Inputs..............................................................................................................11

3.3.2 Common Mode...................................................................................................................12

3.4 S

ENSOR

C

ONNECTION

E

XAMPLES

................................................................................................13

3.4.1 Connecting 20mA current loops ........................................................................................13

3.4.2 Connecting Voltage Signals...............................................................................................15

3.5 C

OMMON CONNECTION ERRORS

...................................................................................................16

4 STARTING RECORDINGS.........................................................................................................19

4.1 S

TART

T

RIG

..................................................................................................................................19

4.1.1 Start on key-stroke .............................................................................................................19

4.1.2 Start on digital input..........................................................................................................20

4.1.3 Start on Analog Level ........................................................................................................20

4.1.4 Digital and Level Start combined......................................................................................20

4.2 S

TOP

T

RIG

....................................................................................................................................20

4.2.1 Stop on key-stroke..............................................................................................................20

4.2.2 Stop on Digital Signal........................................................................................................21

4.2.3 Stop on Analog Level.........................................................................................................21

4.2.4 Stop when Memory Full.....................................................................................................21

4.3 T

RIG

W

INDOW

-

P

RE

/P

OST

T

RIG

R

ECORDING

...............................................................................22

4.4 Illustration: Start, Stop and Trig Sequences...........................................................................23

4.5 T

RIG

O

UTPUT

...............................................................................................................................24

5 MISCELLANEOUS.......................................................................................................................25

5.1 M

ASTER

R

ESET

............................................................................................................................25

5.2 C

ONTROL

P

ROGRAM

....................................................................................................................25

6 TECHNICAL SPECIFICATIONS...............................................................................................26

6.1 ANALOG

CIRCUITS.................................................................................................................26

6.2 A

UXILIARY VOLTAGE SOURCE

......................................................................................................27

6.3 T

RIGGER INPUT

/

OUTPUT

...............................................................................................................27

6.4 S

TORAGE MEMORY

(

OPTIONAL

)....................................................................................................28

6.5 C

OMPUTER COMMUNICATION

.......................................................................................................28

6.6 C

OMMANDS

..................................................................................................................................28

iv CONTENTS

6.7 P

OWER

.........................................................................................................................................29

6.8 M

ECHANICAL SPECIFICATIONS

.....................................................................................................29

OPTION: Digital I/O and Pulse Counters......................31

1 OVERVIEW...................................................................................................................................31

1.1 D

IGITAL

O

UTPUTS

........................................................................................................................31

1.2 D

IGITAL

I

NPUTS

...........................................................................................................................32

1.2.1 Opto isolated inputs........................................................................................................32

1.2.2 TTL-compatible inputs.................................................................................................... 32

2 COUNTERS ...................................................................................................................................33

2.1 R

ESET MODE

................................................................................................................................33

2.2 N

ORMAL MODE

............................................................................................................................33

3 CONNECTIONS............................................................................................................................34

3.1 D

IGITAL OUTPUTS

........................................................................................................................35

3.2 D

IGITAL INPUTS

...........................................................................................................................35

3.2.1 Opto Isolated ................................................................................................................... 36

3.2.2 TTL Compatible...............................................................................................................36

4 TECHNICAL DATA.....................................................................................................................37

4.1 D

IGITAL

O

UTPUTS

........................................................................................................................37

4.2 D

IGITAL

I

NPUTS

(@

25C

+/-10C) ................................................................................................37

4.2.1 Opto Isolated Inputs........................................................................................................37

4.2.2 TTL-compatible inputs....................................................................................................37

4.3 A

UXILIARY

P

OWER

......................................................................................................................38

4.3.1 for Opto-Couplers ...........................................................................................................38

4.3.2 for TTL-Inputs.................................................................................................................. 38

INDEX........................................................................................39

1

MAIN UNIT

1 AN OVERVIEW

MAIN UNIT

1 AN OVERVIEW

1.1 General Information

The PC-Logger 3150 is a very versatile addition to our line of Analog to

ASCII Converters. It will cover the medium measuring rate range: up to a 1000

times per second.

Input ranges are +/-10V; +/-1000mV; +/-100mV; +/-50mV; 20mA.

Pulse counters are available as an optional add-on.

An PC-Logger 3150 together with software and a personal computer

constitutes a powerful data acquisition system.

The main use is off-line when an internal memory (optional) of the PC-Logger

3150 stores data for later transferral to computer.

On-line use is also possible but is limited by the performance of connected

computer. Max speed has to be determined by experiment.

Main features are :

•8 analog inputs

•Programmable ranges on all inputs

•12 bit ADC

•Off-line memory data storage (optional)

•Trigger input and output

•Auxiliary voltage output

•Programmable sampling interval: 1ms to 1000ms

•Fully compatible with all INTAB logger software

The scope of this manual is to enable the user to correctly connect sensors and

transducers and use the PC-Logger 3150 off-line.

How the PC-Logger 3150 is handled using our software and a PC is explained

in the program manual and by the program itself by its user-friendly and self-

explanatory menus.

For best use and best results it is ABSOLUTELY essential that this

manual is studied in its entirety. Special emphasis should be put on

studying chapter 3 which describes how to connect transducers and other

signal sources.

2 INTAB Interface-Teknik AB

1.2 On-line Recordings

On-line measurements are performed with the PC-Logger 3150 connected to

the computer's RS-232 port. Measurements can in this mode be monitored in

real-timeon the computer's display. The user must however be aware of the

speed-limitations set by the computer: don't expect it to handle more than eight

channels five times a second. If you are the fortunate owner of a faster

computer with a fast disk-drive you can probably go faster.

The user him/herself has to determine the maximum speed on his/her particular

computer.

1.3 Off-line Recordings

Off-line recordings are possible with loggers equipped with (optional) data

memory.

Off-line measurements should be preceded by the transferral of measurement

parameters from the computer to the PC-Logger 3150.

These parameters contain, among others (see program manual), information

about measurement interval and what channels that are to be active. They are

effective until a new set of parameters are downloaded. The PC-Logger 3150

can, after downloading of the parameters, be disconnected from the computer

and started with the help of the keys next to the LCD (see section 1.5). After

all measurements are completed (see stop : section 4.2) the PC-Logger 3150 is

again connected to a computer for transferral of collected data (X-fer).

1.4 Storage Capacity

The number of measurements that can be stored by the PC-Logger 3150 and/or

computer is dependent on the size and type of memory used.

The longest possible duration of a recording is a function of the number of

channels that are active, sampling rate and the size of the storage medium.

A discussion of how the maximum length of a recording can be calculated

from known parameters follows below.

It is assumed that recordings are made using software supplied by INTAB.

3

MAIN UNIT

1 AN OVERVIEW

1.4.1 Storage capacity in Computer

Storage capacity in your computer can readily be calculated. The amount of

free space on the disk that will store your measurement data is the limiting

factor.

A 3½" disk will store more than 1,400,000 bytes. This is sufficient to store a

total of 700 000 values.

If we now consider a case where you sample and store 5 channels per second

the following formula applies:

Measuring time = 700 000/5 = 140 000 seconds or almost 40 hours. This time

is naturally multiplied by five if you only use one channel.

Another example: this storage space can be two measurement rounds, each of

two channels every other millisecond for a total duration of 700 seconds (or

nearly twelve minutes).

The formula you use is: interval*storage capacity divided by 2 and the number

of active channels : I*S/(2*C).

Apply this to a hard disk, and you will find that storage space will last a very

long time.

Remember that total storage time in a disk is the sum of all recordings. You

just have to allow for a header space of 16k bytes.

1.4.2 Storage Capacity in the PC-Logger 3150

Storage capacity in the PC-Logger 3150 itself is calculated almost in the same

way as it is calculated in the on-line case.

Three sizes of memory can be supplied: 64k, 64k+512k or 64k+1M.

Every value stored uses two bytes, so the formula in the previous section can

be used here too.

An example: having 64k memory, you want to measure four channels 10

times every second. The interval is 0.1 seconds.

The formula will then be: 0.1*64,000/(2*4)=800 seconds.

Note:

The internal memory of the PC-Logger 3150 will only store one recording at a

time. Starting a new recording will erase the previous one.

Recordings have to be transferred to your computer before loading new

parameters or starting new measurements.

4 INTAB Interface-Teknik AB

There is no limit to the number of times the same recording can be transferred

to the computer.

Measurement data will also not be lost if the internal batteries run down. A

back-up lithium battery will retain data for more than 10 years.

1.5 Block Diagram

This illustration shows a simplified block diagram of the PC-Logger 3150.

The expert notes that all amplification takes place before the multiplexer.

5

MAIN UNIT

1 AN OVERVIEW

1.6 Display and Keys (option)

The LCD (Liquid Crystal Display) with adjacent keys are supplied with all

PC-Logger 3150:s that are equipped with internal measurement data memory.

This display and key combination is indispensable when making off-line

recordings.

You indicate which function you want using the up/down arrows and then

confirm your choice with the OK-key.

The Multimeter is used to check transducer connections and function before

recording is started. You scroll up and down among the channels using the

up/down keys. Automatic scrolling is started with the key "hidden" under the

logo. A new channel is then shown every three seconds (try this feature by

pressing "PC-Logger 3100").

Record is selected when you intend to collect data. Verify your choice with

"OK". See illustration below and section 4 of this manual.

Starting a new recording will delete the previous one.

Don't forget to transfer data to the computer between recordings.

(*) See section 4 : TRIGGER.... for further information on starting and

stopping a recordings

6 INTAB Interface-Teknik AB

1.6 Power supply

The PC-Logger 3150 is normally powered by the supplied mains adaptor. It

has an output of 13.5V at a max of 500mA.

The PC-Logger 3150 is also fitted with internal rechargeable batteries. They

will give the user at least one hour of recording time without mains supply.

The batteries are trickle charged when the mains adaptor is connected. There is

no danger of overcharging the batteries, they should be left on charge to

prolong their life and keep them ready to use at all times.

Some applications require the PC-Logger 3150 to be powered by other

sources.

Use a cable fitted with a TA3F (Switchcraft) connector to connect to, for

example, a car battery.

Don't use sources supplying more than 16V as this is the maximum allowed.

The PC-Logger 3150 will "fall asleep", if it isn't powered by an outside source,

about two minutes after the last command or key-stroke has been entered. This

feature saves your rechargeable batteries for when they are needed.

Incoming serial (RS-232) commands or pressing the C-key will wake the PC-

Logger 3150.

7

MAIN UNIT

2 INPUTS/RANGES

2 INPUTS/RANGES

NOTE !

To get good results it is of utmost importance that all signals to be

measured are connected correctly.

Experience tells us that 95% of all problems (like noise, electrical

interference, measurement errors etc.) are the result of incorrect

connections and wiring.

A careful study of sections 2 and 3 is therefore highly recommended.

All analog inputs are differential and have no internal connection to signal

ground. The impedance between the positive and negative inputs to ground is

of the order of several megohms. They must therefore never be allowed to float

outside the specified common mode range, but must be referenced to ground in

some way.

The inputs are also balanced making them very unsusceptible to electrical

noise. Sensor wiring can be very long if a pair of twisted wires is used and the

ground reference is connected to the lowest potential of the signal source via a

separate wire.

8 INTAB Interface-Teknik AB

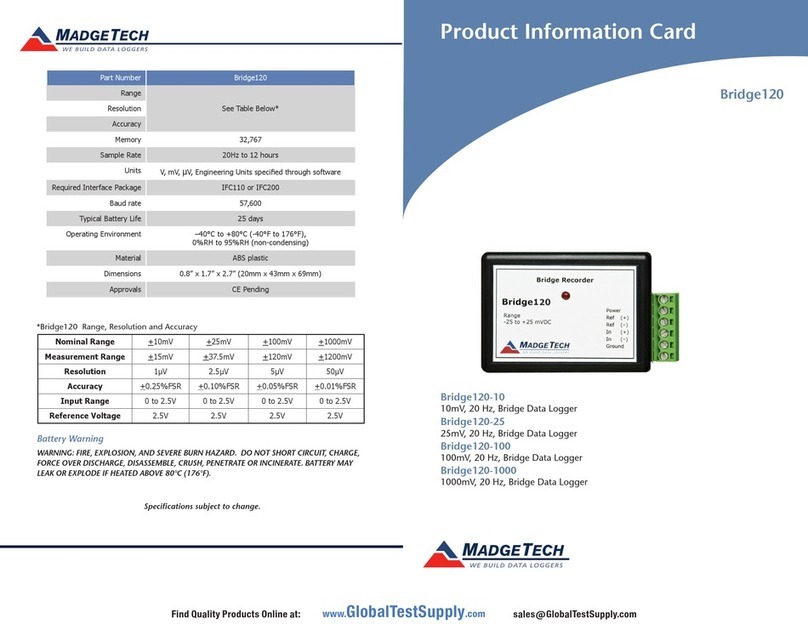

2.1 Ranges: Voltage and Current

Each programmable (option) range or preset range has a resolution of at least

+/-1800 divisions.

Translated into measured units this can be illustrated like this:

RANGE RESOLUTION ACCURACY

+/-10V

+/-1000mV

+/-100mV

+/-50mV

+/-20mA

5.5mV

0.55mV

0.055mV

30µV

11µA

0.12% of FSR

0.12% of FSR

0.12% of FSR

0.12% of FSR

0.12% of FSR

Each channel has an internal 51Ωshunt that is used to measure current. It is

connected into the input circuitry by putting the small DIP-switch in position

"current".

9

MAIN UNIT

3 CONNECTIONS

3 CONNECTIONS

3.1 Power

Power is applied through a TA3F (Switchcraft) female connector connected as

follows :

Pin 1 :

Pin 2 :

Pin 3 :

13 - 16VDC

0V

18 - 24VDC

N.B. Connecting power through pin 3 is an alternative to pin 1 !

3.2 Computer

PC-Logger 3150 connects to a serial port of the computer using the supplied

spiral cable.

The 15 pin D-Sub connector has the following pinouts:

pin 2: Tx

pin 3: Rx

pin 5: CTS

pin 6: DTR

pin 7: GND

Leave the rest of the pins unconnected!

Typical PC-Logger 3150 to computer cables:

10 INTAB Interface-Teknik AB

3.3 Inputs

Transducers and sensors connect to the detachable screw terminals.

Here is an illustration of how the screw terminals are placed.

These are analog channel inputs.

Behind each channel input terminal there is a pair of Dip-

switches.

One (Volt/Current) connects the shunt resistor into the

input circuitry for current measurements (0 - 20mA).

The other (Diff/ Gnd) shorts the negative input to signal

(or reference) ground for single ended measurements.

This terminal (Gnd) is logger signal ground. All signals

must in some way be referenced to this point.

"+5V" is an auxiliary voltage for the Trig input (T-in).

"T-in" is a trigger input to start or stop recordings.

"G" is the signal return (ground) for trig-signals.

"T-out" is an output reflecting trig status.

"V-Out" is an auxiliary voltage for sensors or x-ducers.

Its voltage is adjustable between 2V and 10V by a

potentiometer.

These terminals are found under the lid of the logger. They are detachable.

Use the 16-hole bracket as strain-relief for transducer cables. You can use a

tie-wrap or simply thread the wire trough two holes.

NOTE!

These terminals are accessible also in those loggers that are equipped with an

optional jack panel. The jack panel must be regarded as just an extension box

and does NOT make familiarisation with the terminal area unnecessary.

The user still has to determine how the dip-switches are to be programmed.

11

MAIN UNIT

3 CONNECTIONS

3.3.1 Differential Inputs

There are a two basic requisites that have to be fulfilled when connecting

signals and/or sensors and transducers :

1 - No signal must be left floating with respect to logger signal ground.

2 - System grounds must be connected so that no ground loops are created.

Use a one-point grounding scheme!

The following sections will help in understanding how this can be achieved.

Let us first take a look at a block diagram of the inputs.

Differential channels (inputs) can be considered to be two different inputs:

•the - input measures the voltage between the GND and

-

•the + input measures the voltage between the GND and +

The difference between these two voltages is then "calculated" internally.

From the above it must be obvious that just applying a voltage between - and +

cannot possibly work! The amplifier must see signals referenced to GND.

(GND, by the way, is an internal "signal ground" or reference that has nothing

in common with mains protective ground or any other ground that may be

lying around.)

If you have problems in understanding this, it is a good idea to tie the

-

input to

GND by putting the "Diff/Gnd" switch in position "Gnd". The result will be

that the channel will measure the voltage at the + input and then subtract the

voltage at the - input (which is zero volts) and present the correct value.

Just be sure that all your minuses have the same potential so that no

smoke signals are generated.

12 INTAB Interface-Teknik AB

N.B.

In all work connecting signals to the logger you have to take the following

points into account :

•Analog ground is common to all channels.

•Analog ground is internally connected to RS-232 signal return (D-sub

pin 7).

•Analog ground is internally connected to power input return ( pin 2).

•Analog ground is internally connected to trig input and output signal

return ("G")

•Analog ground is internally connected to negative V-out.

3.3.2 Common Mode

To maintain accuracy in your measurements you have to take the common

mode range into account. The common mode range is 10V.

This is another way of looking at or taking advantage of the "differentiality" of

the inputs.

The impedances between "Gnd" and positive and "Gnd" and negative inputs

are very high. This means that unless they in some way are connected, the

inputs may float electrically, way beyond the allowed limit.

The inputs will not be damaged by voltages above this as long as they are

within 30V off signal ground.

The following sections of this manual will provide some examples of how

transducers can be connected.

13

MAIN UNIT

3 CONNECTIONS

3.4 Sensor Connection Examples

Transducers can supply signals of differing types. They are usually "single

ended" or "differential" (ratiometric). Below are some examples of how they

can be connected. Note that combinations are always possible.

It is also always good practise to plan connections and to make a schematic

diagram before actually doing them.

3.4.1 Connecting 20mA current loops

Currents are usually process type signals: 0-20mA or 4-20mA.

These loops can be connected in more ways than one.

It cannot be stressed enough that it is necessary to have a diagram of the

system from which these signals emanate in order to connect multiple

signals correctly.

Remember that the 51Ωshunt resistor has to be connected to the input

circuitry by putting the Dip-switch in position "current". See illustrations

below.

1) Connecting current loops with common grounding :

One connection to

the common ground

potential is enough.

Two would have

created a ground

loop that may cause

problems in the

form of electrical

interference.

"Other instruments" may also be connected in the current return path if it is

absolutely certain that the total voltage drop across them is well within max

common mode range.

14 INTAB Interface-Teknik AB

2) Connecting floating (ungrounded) current loops

All signals have to

be referenced to

"Gnd".

They may otherwise

drift outside the

common mode

range.

3) Connecting two-wire mA transmitters using power from V-out.

The auxiliary Voltage output

(V-out) can power 20mA

transmitters.

Make sure that the voltage is

sufficient for your x-mitter.

4) Connecting two-wire mA transmitters powered by external source.

Transmitters that require

higher voltages have to be

powered by an external

source.

Don't forget to put the dip-

switch in position "Gnd"

unless this source has some

other connection to logger

ground.

15

MAIN UNIT

3 CONNECTIONS

3.4.2 Connecting Voltage Signals

Voltage signals can be connected in two basic ways. Which one to use depends

on whether the signal is "floating" or not.

Combinations of the two methods are of course possible!

Differential or ratiometric transducers may also be directly connected.

1) Connecting signals with common grounding

Note that only one of the

Diff/Gnd switches is in

position "Gnd".

This will establish a

good reference potential

for both channels.

2) Connecting isolated or "floating" signals.

Each floating signal has

to be individually

grounded to logger

"Gnd".

3) Differential or Ratiometric transducers

This illustration shows

how a bridge type

transducer (load cells,

pressure sensors etc.)

should be connected.

The "V-out" is used as

excitation voltage.

16 INTAB Interface-Teknik AB

3.5 Common connection errors

1) Ground loops:

Instrument with two Single Ended Outputs

Two apparently separate outputs from an instrument are each connected to a

channel. Both channels have the negative input shorted to ground via the

"Diff/Gnd"-switches.

Measured values may be either unstable or inaccurate.

Solution: break the ground loop by putting one of the switches in the "Diff"

position.

2) Floating signal : no connection to system ground

A signal equivalent to a common flashlight battery is connected to + and - of

one of the channels. Readings are unstable.

Solution: give this signal a proper ground reference by shorting the negative

input to logger ground by placing the Dip-switch in the "Gnd" position.

Table of contents

Other Intab Data Logger manuals